4.185" BORE AND 3.79" STROKESorry again did I miss bore and stroke here somewhere?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Desk Top Dyno

- Thread starter tvt59

- Start date

-

PRH

Well-Known Member

4.185 x 3.79 x 8 = 417ci

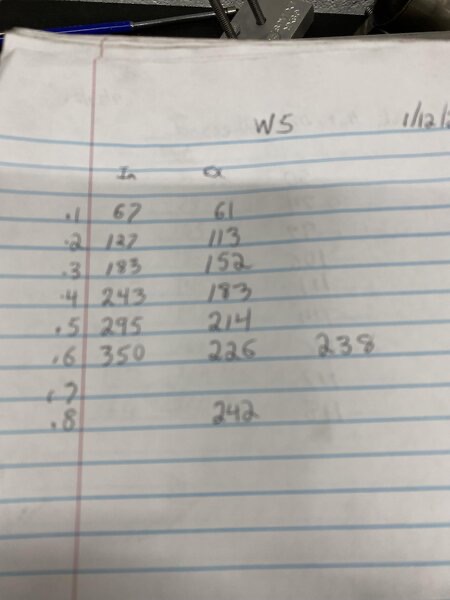

I think you’d find that if you had those heads flowed somewhere else, the 55cfm jump in flow from .500-.600 wouldn’t be easily reproduced on a different bench.

I think you’d find that if you had those heads flowed somewhere else, the 55cfm jump in flow from .500-.600 wouldn’t be easily reproduced on a different bench.

Last edited:

4.185 x 3.79 x 8 = 417ci

I think you’d find that if you had those heads flowed somewhere else, the 55cfm jump in flow from .500-.600 wouldn’t be easily reproduced on a different bench.

View attachment 1716204224

I’ve seen this before and it was right before the port went turbulent. I don’t like those numbers from .300 on up.

DionR

Well-Known Member

Is it a disc or some type of software? Do you know if it's still available?

I got it on a disk back when Windows 95 was a thing.

There was one update to it at some point that I downloaded and have never had a problem with it running since them.

No idea if you can still get it. Sounds like someone found it someplace, but I haven’t looked for it myself.

What I have won’t drill down as far as things like header tube length and collector size, nor will it do things like ported intakes. Just basic inputs like dual plane, single plane, EFI, small tube headers with open exhaust, things like that. So for some stuff like an AirGap that can kind of work like a dual plane down low and a single plane up high the program is just a guess.

All I’ve ever done with it is play. I looked at different possibilities and help people before with it, stuff like “stroker vs. ported heads” but nothing all that scientific.

I also bought the Desktop Drag program, but that’s even more of a guessing game. Fun to play with and see how much I might be helping or hurting myself with a car setup depending on rear gears and such. But I hold no illusions that anything I do on it is anything but a guess at the possibilities.

B3422w5

Well-Known Member

4.185 x 3.79 x 8 = 417ci

I think you’d find that if you had those heads flowed somewhere else, the 55cfm jump in flow from .500-.600 wouldn’t be easily reproduced on a different bench.

View attachment 1716204224

Yea, that number jump looked….wierd.

PRH

Well-Known Member

I’ve seen this before and it was right before the port went turbulent. I don’t like those numbers from .300 on up.

Never say never……… but let’s just say I’m skeptical the numbers would show a 20% increase from .500-.600 on my bench.

I also don’t think the “big number” would get too close to 350……… not that my bench is the last word in flow data.

In other words, do I think that head would equal the flow I saw from a cnc ported Victor head with a 2.15” valve @.600 lift(348cfm) on my bench?

No.

Last edited:

Never say never……… but let’s just say I’m skeptical the numbers would show a 20% increase from .500-.600 on my bench.

I also don’t think the “big number” would get too close to 350……… not that my bench is the last word in flow data.

In other words, do I think that head would equal the flow I saw from a cnc ported Victor head with a 2.15” valve @.600 lift(348cfm) on my bench?

No.

A lot of times it’s not the flowbench but the person reading the flowbench. With a digital bench I can see turbulence building a lot faster than I could on my old fluid manometer bench. So let’s say a guy wants to brag up a bad port. In a case like the “Airwolf” heads my flow numbers had crazy bounce like let’s say from 310-327 cfm. A salesman could say that head flows 327 right. Why not right because there’s probably no one looking over his back. Instead of a suck-azz port job guys will say wholly crap those heads flow GREAT.

PRH

Well-Known Member

I had some SB heads here that had been ported, and the supplied flow numbers showed a 30cfm gain from .500-.600.

I told the owner I didn’t think those heads were capable of the numbers he had gotten.

The heads were coming to me for finishing and assembly anyway, so I tested them.

I checked one cylinder on each head.

From .500-.600, one port gained 7cfm…… the other 5cfm.

And on my bench the better of the two ports was down 38cfm from the numbers he got from the porter.

I told the owner I didn’t think those heads were capable of the numbers he had gotten.

The heads were coming to me for finishing and assembly anyway, so I tested them.

I checked one cylinder on each head.

From .500-.600, one port gained 7cfm…… the other 5cfm.

And on my bench the better of the two ports was down 38cfm from the numbers he got from the porter.

Really and truly the flow bench should be used to test a head porters work. CFM doesn't always equate to horse power. I've seen heads that had lots of peak flow but didn't make good horse power on the track. I guess the same can be said of dyno numbers. When I get the engine put together and in the car next year there won't be any way to hide either a good performance or a bad one.A lot of times it’s not the flowbench but the person reading the flowbench. With a digital bench I can see turbulence building a lot faster than I could on my old fluid manometer bench. So let’s say a guy wants to brag up a bad port. In a case like the “Airwolf” heads my flow numbers had crazy bounce like let’s say from 310-327 cfm. A salesman could say that head flows 327 right. Why not right because there’s probably no one looking over his back. Instead of a suck-azz port job guys will say wholly crap those heads flow GREAT.

PRH

Well-Known Member

One situation where you could see a big gain in flow as the lift starts to get past .500” is if the valve is sort of “way too big” for the chamber, and the chamber wall is quite close in proximity to the valve for a large portion of the circumference of the valve.

Then when you finally get a large enough curtain area exposed thru high lifts, the port takes off.

That being said, a 55cfm jump from .500-.600 out of a W5 head still seems like a stretch to me.

Then when you finally get a large enough curtain area exposed thru high lifts, the port takes off.

That being said, a 55cfm jump from .500-.600 out of a W5 head still seems like a stretch to me.

Last edited:

One situation where you could see a big gain in flow as the lift starts to get past .500” is if the valve is sort of “way too big” for the chamber, and the chamber wall is quite close in proximity to the valve for a large portion of the circumference of the valve.

Then when you finally get a large enough curtain area exposed thru high lifts, the port takes off.

That being said, a 55cfm jump from .500-.600 out of a W5 head still seems like a stretch to me.

That’s what I’m running into now on that set of 2.08 valve Edelbrock heads I’m doing for a buddy. If I had known he was going to limit me to a 4.080 head gasket size I wouldn’t have taken the job unless he would go with a 2.05 valve. These heads have given me nightmares.

Sorry again did I miss bore and stroke here somewhere?

I'm trying to make 740 hp with a W5 head, 3.79 stroke 4.185 bore 422", solid roller and about 14 to one

There ya go buddy! 3.79 X 4.185 = 422 cid

PRH

Well-Known Member

A v8 with a bore of 4.185” and a stroke of 3.790” ends up at 417” displacement…….. not 422”.

A v8 with a bore of 3.790” and a stroke of 4.185” ends up at 377.7” displacement.

A v8 with a bore of 3.790” and a stroke of 4.185” ends up at 377.7” displacement.

PRH

Well-Known Member

One thing to understand about the DD program is…….. it Loves big air flow numbers……… and does a poor job of predicting output on larger cube builds using small-ish heads that have modest flow.

As an example, I built 2 BB’s during the same time period several years ago…… a 446 and a 493.

The top ends were nearly identical(heads were done at the same time), same intakes(Holley SD), same carb(Holley 850), compression ratio within 1/2 point, very similar cams from the same lobe family, same dyno, same dyno operator(me).

The DD predicted the 446 would make more power than the 493.

The actual dyno showed what I expected the outcome would be……. Which was that the 493 was better than the 446 everywhere.

Peak was about 40hp better.

The only way to get the DD to show the 493 hp the same as what the actual dyno showed was to artificially inflate the head flow numbers……. By a fair amount.

I ran multiple actual builds, that had been tested on the real dyno, thru DD…….. and frankly, the predictions were often not very close to real world results.

If you plug in numbers for something like 355 SBC with a decent pair of heads and a typical bracket race cam…….. the numbers are pretty close.

BBM stroker with cleaned up RPM heads? Not close.

As an example, I built 2 BB’s during the same time period several years ago…… a 446 and a 493.

The top ends were nearly identical(heads were done at the same time), same intakes(Holley SD), same carb(Holley 850), compression ratio within 1/2 point, very similar cams from the same lobe family, same dyno, same dyno operator(me).

The DD predicted the 446 would make more power than the 493.

The actual dyno showed what I expected the outcome would be……. Which was that the 493 was better than the 446 everywhere.

Peak was about 40hp better.

The only way to get the DD to show the 493 hp the same as what the actual dyno showed was to artificially inflate the head flow numbers……. By a fair amount.

I ran multiple actual builds, that had been tested on the real dyno, thru DD…….. and frankly, the predictions were often not very close to real world results.

If you plug in numbers for something like 355 SBC with a decent pair of heads and a typical bracket race cam…….. the numbers are pretty close.

BBM stroker with cleaned up RPM heads? Not close.

Last edited:

justinp61

Well-Known Member

- Joined

- May 15, 2009

- Messages

- 3,065

- Reaction score

- 4,053

^^This^^Really and truly the flow bench should be used to test a head porters work. CFM doesn't always equate to horse power. I've seen heads that had lots of peak flow but didn't make good horse power on the track. I guess the same can be said of dyno numbers. When I get the engine put together and in the car next year there won't be any way to hide either a good performance or a bad one.

I get a kick out of guys who declare dyno numbers mean nothing but swear by flow bench numbers.

Please excuse my poor math.There ya go buddy! 3.79 X 4.185 = 422 cid

PRH

Well-Known Member

Apparently the flow numbers posted were from Bretts

R&D w5 head?

Do I have that right?

Does TVT have any flow numbers for the heads he’s planning on using for his build?

R&D w5 head?

Do I have that right?

Does TVT have any flow numbers for the heads he’s planning on using for his build?

ValiantRacing

Well-Known Member

I use the Pipe Max program, it wants a lot of details about the engine, and will tell you what size header to run.

Apparently the flow numbers posted were from Bretts

R&D w5 head?

Do I have that right?

Does TVT have any flow numbers for the heads he’s planning on using for his build?

I think his heads were the ones Brett ported. Brett posted that he needed a set to experiment with so I’m thinking those are the heads going on his engine.

I donated the head that Brett is developing. Larry smith ported the heads that I'm going to use but he passed away before he could finish them. Brett is going to finish the port job and install 5/16 stem valves in them and cut them down for the T&D rocker system. So the flow sheet that I posted should be close enough for me to get the idea of what the engine will make. Them main goal is to be able to push 3100 lbs to a 5.95 1/8 mile et. And I'm pretty sure that I can accomplish this. Didn't mean to create all of this. But thank you to DionR for helping with this guestimate . With the current cam selection it should make 720 @ 7500. going to try a different cam tonite.I think his heads were the ones Brett ported. Brett posted that he needed a set to experiment with so I’m thinking those are the heads going on his engine.

Performance Trends does not seem to like those numbers.. A ton of cranking pressure (254PSI) and can't make 400HP. I double checked the numbers and it seems like I have them correct. I will try to figure out what is going on over the next few days if I find the time.

Last edited:

PRH

Well-Known Member

Using the Wallace dynamic compression calculator…….

With 14:1 and the cam in at 106, and 0 ft elevation, it shows the cranking pressure as 216.

As for a simple SB 700+hp combo…….from about 20 years ago…….(SBC unfortunately)

Stock block 406 with an early NASCAR 18* top end off of a 9:1 358 Busch North engine.

Those engines would make a tad over 500hp with a 390cfm carb(pulling close to 8” of vacuum at 8000rpm).

Install intake, heads, rockers, etc onto a 12.5:1 406, add a 4150/4500 carb adapter, 1050 4500 carb, and increase the cam duration by about 20*…….and wa-la …….725hp.

That particular set of heads flowed in the 330’s.

With 14:1 and the cam in at 106, and 0 ft elevation, it shows the cranking pressure as 216.

As for a simple SB 700+hp combo…….from about 20 years ago…….(SBC unfortunately)

Stock block 406 with an early NASCAR 18* top end off of a 9:1 358 Busch North engine.

Those engines would make a tad over 500hp with a 390cfm carb(pulling close to 8” of vacuum at 8000rpm).

Install intake, heads, rockers, etc onto a 12.5:1 406, add a 4150/4500 carb adapter, 1050 4500 carb, and increase the cam duration by about 20*…….and wa-la …….725hp.

That particular set of heads flowed in the 330’s.

Last edited:

I donated the head that Brett is developing. Larry smith ported the heads that I'm going to use but he passed away before he could finish them. Brett is going to finish the port job and install 5/16 stem valves in them and cut them down for the T&D rocker system. So the flow sheet that I posted should be close enough for me to get the idea of what the engine will make. Them main goal is to be able to push 3100 lbs to a 5.95 1/8 mile et. And I'm pretty sure that I can accomplish this. Didn't mean to create all of this. But thank you to DionR for helping with this guestimate . With the current cam selection it should make 720 @ 7500. going to try a different cam tonite.

So what valve size are you using in yours since Brett thought that valve in the test head was to big.

Power output depends on the cylinder heads and there is rarely enough information for any computer program to get close. We use PipeMax and it can get close, but only if you know the VE. And nobody really knows the VE until after the engine is run on the dyno so that kind of makes the program useless for predicting power.Does any of my buddies on the have a desk top dyno ? I used to have the app years ago. You could plug in perimeters for and engine and it'd give you an approximate hp and torque figures. If someone does have this software I'd pay you for plugging the specs of an engine I'm going to build for my new braket car.

When you're dealing with something "weird" like W5 heads the best place to get a power estimate is from a W5 expert. And they most likely would want to know details on the heads before they gave you a number.

I can usually predict power within a few % just by looking at the parts a guy brings in to the dyno. But that trick only works for OOTB cylinder heads. Once someone starts whittling on the heads all bets are off. Power might go up but sometimes it goes down. Same thing with home ported manifold, home re-worked carbs, etc.

Good w5 heads with the right cam should be able to make 740 on that short block, but I'm not really familiar enough with W5 heads to predict a number. We just ran a 429 inch SB Chevy that made 780 hp on the dyno. So the question is if W5 heads are as good as a 15 degree SBC head. The 429 SBC had a much bigger cam than what you posted. I think the SBC was 280/290.

dave ellis

Well-Known Member

From where?I Googled it last night. It's available on a disk and direct download.

-