Bugman

Well-Known Member

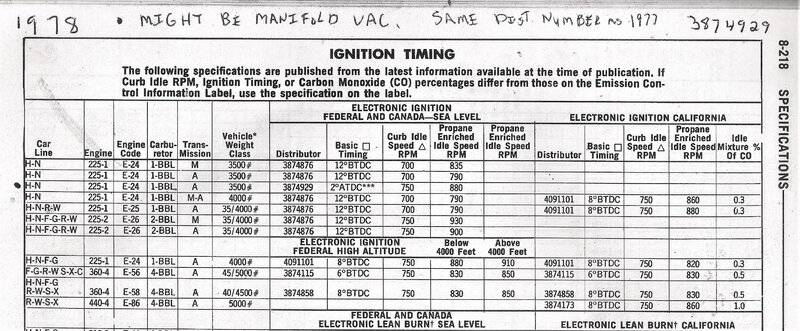

That 79 dist was maybe this one was used in 78 and 80

You do not want to reduce the pipe size at the muffler to 2 inch, that would restrict flow - bad dawg!The reason I'm fudging with the distributor is I already have "a lot of detonation and lousy fuel economy" (15 mpg in town). My goal with the distributor is to reduce the mechanical advance to eliminate the ping.

I have stock 2" exhaust all the way back. I think the Super Six cars came with a 2.25" pipe. I asked the muffler shop to give me a 2.25" pipe with a 2" muffler, but the guy convinced me it wouldn't make a difference. I think he was wrong and I am considering telling him to do it anyway. This is what I am looking at:

and maybe this:

- Walker 21489 Quiet-Flow Stainless Steel Muffler

- Flowmaster 12018409 Super Hp-2 Muffler 2.00"In/Out 18" 409S

and maybe even this:

I don't want excess noise, but I do want the engine to run well.

I agree.Here's what I measured with the 1979 springs and governor plate in the 1974 distributor (vacuum line to distributor was disconnected and plugged). Initial timing was 10.5 degrees BTC. I only get 7.7 degrees of mechanical advance, which is all in by 1750 RPM. This doesn't seem right.

That seems to be working ok and pretty close to specs in the books.And here's the vacuum advance chart for the 11.0R vacuum pod. There's no advance until vacuum is about 8 inches, and it maxes out at about 19 degrees advance (above initial) by 14 inches.

We had a Dave White Racing here. But that's a common last name. A Friend of a Friend. RIPDunno who Joe White is no idea.

On a related note I have a couple of distributor questions to add in here after work.

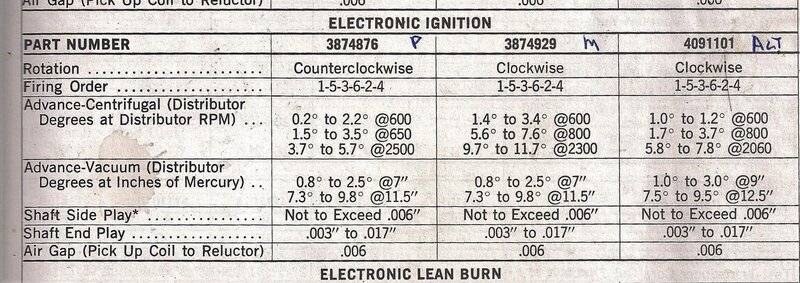

The tag number on the donor distributor is 3874876 and it was on a 2bbbl auto car. If I'm reading the chart right, it is only supposed to provide a maximum of about 7 degrees of mechanical advance at the crank (~4.7 at 2200 rpm compared to ~1.2 at 600 rpm, so 3.5 degrees difference at the distributor, times 2). I was seeing 7.7, consistent with the chart. Combined with the 12 degree initial setting, the total advance would be about 19 on the Super Six car from the factory. Does that seem right? I know my engine likes up to 20 degrees at idle, so I would have no problem bumping the total to about 28 with the distributor as is.

When using engine as distributor test machine, it is helpfull to reset timing to 0 degrees and use lowest possible idle speed. Turn on heater fan and head lights,this uses Alternator to place load on engine,helps steady idle speed.

Your measure ments are close enough.Not much advance past 20 degrees,yes thats about right. Short answer use distributer as is except change vaccum advance to the 8.5 one 17 degrees instead of 22.