Bulldozer

free ice cream sandwiches

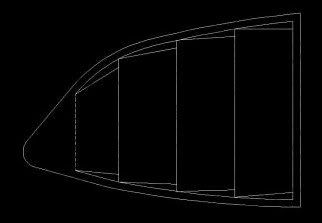

if there was even a basic shape out there that fits the windows and has the slats with the openings , i would spend a couple days sanding and fitting, and even spraying them myself

agreed- the way they stop short just screams "not made for this car" to me.

Anybody know if metal shops give free estimates? I can draw the things up in cad if someone's willing to work with me and give me the dimensions of some prototypes they work up. I know alot of shops, that's all they need.

Although I think they look horrendous ... there's no way in hell I'd be caught dead with it on my car.... lol..

all in good fun. I'll help if I can.

I think they are totally do able out of steel and $1100 or what that other guy was selling them for seems way high to me....

Just thinking..... I still hate these things... a lot.... but I think the horizontal louvers look less horrific IMO.