Oops only 75.5

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E58 400 plus HP Dart sport build

- Thread starter 4.7Light

- Start date

-

.What's the difference between std and E58 ?

About 20 horsepower. The E58 had the 68 340 cam in it. It was a four-barrel motor with the bigger 850 CFM carburetor.

It was the motor that replaced the 340 in the Darts and Dusters and the Roadrunners too. An it was used in cop cars too.

The EH1 360 in the Little Red was a factory modified E58.

Little stuck on piston choice I dont want a hyperkinetic piston now. Builders really hate on them for breaking and I'm concerned as they were pretty vocal and it was multiple folks. I know a lot here use them but I'm going to error on caution regarding my kb107 and not buy. I need a stock weight piston forged if possible flattop valve relief. The ones I have seen look like I will have to rebalance and do a new converter and such for the combo. It's also about the fact it's my motor and I want to do it my way my choices if that makes any sense. Any suggestions on the piston choice still waiting to hear back on overbore and how much I may have to go.

good luck with the pistons I had to go with speed crow crap heavy forged pisstons could not find the Mahle pistons I used on previous builds . What is with the hate on hyper pistons seems many here use them with no trouble

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,244

- Reaction score

- 12,239

If your engine builder has problems with KB hyper pistons breaking, you need a different engine builder.

He was either way he just warned me about tuning and getting it correct or you can create your own issues. Some refused to build at all with them. My big issue is don't want to have to rebalance everything and have a crank that I could never use again. Read a few here and horror stories on confusion what harmonic balancer do I use now torque converter and plate and such. Just trying to take all the information in and weed out the BS and the real facts. HP is great but not at the sake of reliability is also the goal here.If your engine builder has problems with KB hyper pistons breaking, you need a different engine builder.

Ok did more reading and watched several videos on manufacturing processes. I will go look up what I found that matches weight closer to stock and roll the dice. I see no reason based on how I intend to drive car and only occasionally track no forged is needed. Cost is not the issue KB is very inexpensive and this looks like a good alternative. DODGE Speed Pro H116CP 30 Speed-Pro Hypereutectic Pistons | Summit Racing Yes it's the new casting and see why they would fail it's the builder not the piston. Piston slap makes perfect sense and I had heard that was an issue more wear at start-up. I drive 5 miles to work it would not heat up for a while and wear out quickly.

piston slap , it's not 1960 , my mahle forged pistons never made noise , not like the old heavy forged pistons from the 60's they made noise until warm , still put over 700,000 miles on a 440 over 13 years problem free

Right and they have some silicon in them I'm sure makes perfect sense. Just not what I need for my application right. I get the part of why I don't need to spend on forged for something I really don't need. I have a buddy has forged like yours he makes way more horsepower but he does not track the car and just drives it 15 years since the build 351 CJ as a 390 stroker around 550 HP. For sure reliable but for my application not something I really need.piston slap , it's not 1960 , my mahle forged pistons never made noise , not like the old heavy forged pistons from the 60's they made noise until warm , still put over 700,000 miles on a 440 over 13 years problem free

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,244

- Reaction score

- 12,239

Definitely understand, and your doing the right thing by asking questions. But the ballancing concern is something you need to address regardless. The factory ballance job from Chrysler wasn't very good to begin with. There is really no drop in piston that will ballance your factory assembly properly.He was either way he just warned me about tuning and getting it correct or you can create your own issues. Some refused to build at all with them. My big issue is don't want to have to rebalance everything and have a crank that I could never use again. Read a few here and horror stories on confusion what harmonic balancer do I use now torque converter and plate and such. Just trying to take all the information in and weed out the BS and the real facts. HP is great but not at the sake of reliability is also the goal here.

Yeah I'm trying to keep things as simple as possible. I do have a budget I go over it all stops and will sit unfinished for long time. I plan to keep balanced as externally balanced. If I start jerking with that many things have to be changed out and not in the budget to go crazy with that. I'm sure I'm ok so far with what I got basically a stock bottom end more compression. Once I know for sure hopefully the pistons fit the bill if not builder can help guide me right direction.Definitely understand, and your doing the right thing by asking questions. But the ballancing concern is something you need to address regardless. The factory ballance job from Chrysler wasn't very good to begin with. There is really no drop in piston that will ballance your factory assembly properly.

NC Engine Builder

Grumpy Old Man

- Joined

- Oct 10, 2008

- Messages

- 7,244

- Reaction score

- 12,239

No problem keeping it external, I'm just saying you definitely should re-ballance it after you decide on pistonsYeah I'm trying to keep things as simple as possible. I do have a budget I go over it all stops and will sit unfinished for long time. I plan to keep balanced as externally balanced. If I start jerking with that many things have to be changed out and not in the budget to go crazy with that. I'm sure I'm ok so far with what I got basically a stock bottom end more compression. Once I know for sure hopefully the pistons fit the bill if not builder can help guide me right direction.

If your engine builder has problems with KB hyper pistons breaking, you need a different engine builder.

This...

They don't have a clue regarding machining tolerance and/or most important ring gaps. They are likely gapping rings using the .004/inch of bore. If you do that with a hyper, it will break the tops off from rings butting. I've had hypers running a 200 shot and never had a issue.

If they are just pulling rings out of the box and installing them, RUN. TELL them that you want the top ring gapped at .0065/inch. so if you have a .030 360 with a 4.030 bore it's going to gap at .026 and if running a small nitrous unit .030

Bad tune ups kill pistons as well. Detonation is the enemy of all pistons.

Thanks for the information that's a big help this is the part that's new to me. But I'm really enjoying it and learning is great.This...

They don't have a clue regarding machining tolerance and/or most important ring gaps. They are likely gapping rings using the .004/inch of bore. If you do that with a hyper, it will break the tops off from rings butting. I've had hypers running a 200 shot and never had a issue.

If they are just pulling rings out of the box and installing them, RUN. TELL them that you want the top ring gapped at .0065/inch. so if you have a .030 360 with a 4.030 bore it's going to gap at .026 and if running a small nitrous unit .030

Bad tune ups kill pistons as well. Detonation is the enemy of all pistons.

Got these little pieces in place progress soon I hope. My new energy suspension trans mount in and got the Orange ECU 6800 rpm installed. Just sticking with factory style but upgraded. I'm sure things will change as I drive the car.

All Carter carbs are mechanical secondary carbs. Wire tie the linkage for consistency on the secondary opening.6253s 850 thermoquad. Carb looks great just wanted something with mechanical secondary.

What is with the hate on hyper pistons seems many here use them with no trouble

All I can say is a few machinists said they did t like KB themselves but the piston was fine. When I hear people breaking a hyper piston, it’s ether they added to much N02, boost and never adjusted there timing requirements. And/or there dumb as a box of rocks (sorry rocks) and they shouldn’t be allowed near cars.

It is a well know and established fact that the hyper slug can not take a detonation. They make for a absolutely fine replacement or street strip piston. There should be zero issues with them.

greymouser7

Vagrant Vagabond “Veni Vidi Vici”

- Joined

- Apr 17, 2010

- Messages

- 3,748

- Reaction score

- 1,478

If your engine builder has problems with KB hyper pistons breaking, you need a different engine builder.

I wonder about this concept. Dan Dvorak swore against Hypereutectic Pistons and he was an accomplished engine builder. I remember RRR saying "You have to read the instructions and gap the rings correctly." Maybe these pistons are fragile without extra caution and precaution. Once properly installed (not including nitrous use, or maybe forced induction) perhaps these pistons perform perfectly fine within >>?what?, designed<< parameters.?.

replicaracer43, do you think it is possible that intelligent, competent, engine builders could run into problems between heavy foot customers, liability, and the thinner KB-107's Hypereutectic pistons and operation outside designed parameters?

Though in your favor (replicaracer43), the common denominator IS the KB-107's, among engine builders and drivers.

I can not speak for ANYONE else, but, I have built and raced small Mopar engines with Hyper whatever pistons. NOT. ONE. PROBLEM!!!!!

All I can say is read the flippin instructions!!!!

All I can say is read the flippin instructions!!!!

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

This is so easy to fix;Advance springs sure are easy to change compared to taking the OE distributor apart!

The problem is that stinking wire clip. All I did was drill and tap the end of the driveshaft for a small Allen-head screw and fabricate a lil spacer to keep the Allen-screw from binding it all up. Now I can swap distributor cams in a heartbeat. Yeah I still have to remove the base-plate, but hey the distributor was only 30years old when I installed it in 1999, and was free.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

I am NOT a builder; but I think I designed at least one pretty good engine.

My Eddy-headed 367 has been running KB107s since 1999, and currently has over 100,000 miles on it.

In the beginning, this engine had a lotta trouble with running hot, that I could not solve. This engine was not assembled by me, on this first iteration.

Finally, I tore the engine down and sent the block out for honing a lil more skirt clearance ( the bore is reported to be 4.045 now) and got me some Plasma-Moly file-fit rings. I opened up the top gap to .032, and Second was .026 IIRC.

BAM ! instant heat relief.

I now run a minimum coolant temp of 207*F, on purpose, and she is impossible to overheat, running the same parts as when it ran hot.

On Day-1, my KB107s fell in .012 below deck.

I tried to run an .028 gasket for .040 Quench; but at the first scheduled tear-down, I found that the Fire-ring was migrating towards the valley and was only a short time from letting go. Good catch.

So I sent the block out to zero-deck it, to use the famed FelPro 1008s. The new Q was thus .039.

A couple of years later my cam spit off lobes, so on the Fourth inspection, I decked the block again, to get the pistons to pop up a lil to maintain the cylinder pressure with the new bigger cam. The new Q is about .032 with the .039 FelPros.

Cylinder Pressure on all three iterations was thus maintained at or nears 180psi. And all three iterations ran on 87E10 without detonation.

My car is a manual-trans car, so I do not have the option of a Hi-stall, so it has to perform right down to idle-speed. And with the high cylinder-pressure, it does. So much so that I have to retard the ignition below 700rpm to operate down there, without the power overwhelming the driveshaft.

If your pistons also drop in at .012 below-deck, and

if you also use the .039 gaskets with those closed chamber heads;

then your Q will be about .051..

They tell me that is about the maximum for Q to be, to still be considered a Quench-engine. And they say, usually talking about iron heads, that Q of this magnitude, occasionally elicits detonation on anything but best pump-gas. But I think with alloy heads, you should be fine.

As to balance; just get it done.

The KB107-Hypers are so light (502grams), that the Engine wants to rev like lightning. With decent springs, mine revs to a self-imposed red-line of 7200, and in the first two gears at WOT (with 3.55s), I can't hardly shift fast enough to not bang off the rev-limiter. Your engine will thank you for it.

With the Late-Closing Intake event of that Mutha cam, your cylinder pressure will not be very high even tho your compression ratio might be. That translates to a modest amount of sub 3000rpm Power. So try not to stall it too low.

The Desk-Top Dyno was Waaaaaaaaay off on my build, the car just barely got into the 12s (12.9@106mph). Which at 3650 race-weight, I think translated to 335 hp. That was with the Hughes HE2430AL cam;

270/276/110; 223/230@.050; and lifts of .538/.549@1.6arms. Great street cam, BTW! This combo ran a short time at 11.3Scr at 192psi. yes still on 87E10

I also run extra oil to the top end in an effort to cool the valve springs, and to help the aluminum roller-tipped 1.6 arms to survive. Since those rockers currently have over 100,000 miles on them, I think it must be working.

And I drilled the tops of my rods to try and grab some lube. And I slightly enlarged the spray-holes in the rods, that spray onto the cylinder walls.

Don't forget about the other Oiling Mods, and I highly recommend an extra capacity oil-pan to help cool the oil that is getting beat up pretty bad by all these mods. To support all that, I run a hi-volume oilpump, for which I had to modify the filter baseplate so it wouldn't blow the filter off. lol.

Good luck on your combo; It's getting to look a lot like mine except not the cam. I think you wouldda liked the 268 better...... but what do I know.

Happy HotRodding

EDIT;

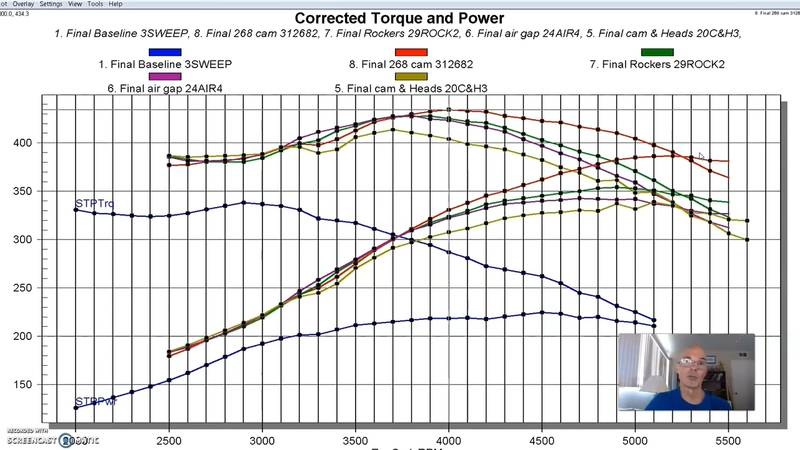

BTW, take a good look at this graph, notice that, not including the baseline; below 3200rpm, nothing much changed. And that nothing really gets going until about 3800/4000. It's a good thing you'll be buying a TC.

My Eddy-headed 367 has been running KB107s since 1999, and currently has over 100,000 miles on it.

In the beginning, this engine had a lotta trouble with running hot, that I could not solve. This engine was not assembled by me, on this first iteration.

Finally, I tore the engine down and sent the block out for honing a lil more skirt clearance ( the bore is reported to be 4.045 now) and got me some Plasma-Moly file-fit rings. I opened up the top gap to .032, and Second was .026 IIRC.

BAM ! instant heat relief.

I now run a minimum coolant temp of 207*F, on purpose, and she is impossible to overheat, running the same parts as when it ran hot.

On Day-1, my KB107s fell in .012 below deck.

I tried to run an .028 gasket for .040 Quench; but at the first scheduled tear-down, I found that the Fire-ring was migrating towards the valley and was only a short time from letting go. Good catch.

So I sent the block out to zero-deck it, to use the famed FelPro 1008s. The new Q was thus .039.

A couple of years later my cam spit off lobes, so on the Fourth inspection, I decked the block again, to get the pistons to pop up a lil to maintain the cylinder pressure with the new bigger cam. The new Q is about .032 with the .039 FelPros.

Cylinder Pressure on all three iterations was thus maintained at or nears 180psi. And all three iterations ran on 87E10 without detonation.

My car is a manual-trans car, so I do not have the option of a Hi-stall, so it has to perform right down to idle-speed. And with the high cylinder-pressure, it does. So much so that I have to retard the ignition below 700rpm to operate down there, without the power overwhelming the driveshaft.

If your pistons also drop in at .012 below-deck, and

if you also use the .039 gaskets with those closed chamber heads;

then your Q will be about .051..

They tell me that is about the maximum for Q to be, to still be considered a Quench-engine. And they say, usually talking about iron heads, that Q of this magnitude, occasionally elicits detonation on anything but best pump-gas. But I think with alloy heads, you should be fine.

As to balance; just get it done.

The KB107-Hypers are so light (502grams), that the Engine wants to rev like lightning. With decent springs, mine revs to a self-imposed red-line of 7200, and in the first two gears at WOT (with 3.55s), I can't hardly shift fast enough to not bang off the rev-limiter. Your engine will thank you for it.

With the Late-Closing Intake event of that Mutha cam, your cylinder pressure will not be very high even tho your compression ratio might be. That translates to a modest amount of sub 3000rpm Power. So try not to stall it too low.

The Desk-Top Dyno was Waaaaaaaaay off on my build, the car just barely got into the 12s (12.9@106mph). Which at 3650 race-weight, I think translated to 335 hp. That was with the Hughes HE2430AL cam;

270/276/110; 223/230@.050; and lifts of .538/.549@1.6arms. Great street cam, BTW! This combo ran a short time at 11.3Scr at 192psi. yes still on 87E10

I also run extra oil to the top end in an effort to cool the valve springs, and to help the aluminum roller-tipped 1.6 arms to survive. Since those rockers currently have over 100,000 miles on them, I think it must be working.

And I drilled the tops of my rods to try and grab some lube. And I slightly enlarged the spray-holes in the rods, that spray onto the cylinder walls.

Don't forget about the other Oiling Mods, and I highly recommend an extra capacity oil-pan to help cool the oil that is getting beat up pretty bad by all these mods. To support all that, I run a hi-volume oilpump, for which I had to modify the filter baseplate so it wouldn't blow the filter off. lol.

Good luck on your combo; It's getting to look a lot like mine except not the cam. I think you wouldda liked the 268 better...... but what do I know.

Happy HotRodding

EDIT;

BTW, take a good look at this graph, notice that, not including the baseline; below 3200rpm, nothing much changed. And that nothing really gets going until about 3800/4000. It's a good thing you'll be buying a TC.

Last edited:

I actually dumped the iron heads for a few reasons and picked up speed master 65cc aluminum ones. Stock 4bbl intake gone air gap style instead. With the kbs if I go that route will be at 10.7 CR to 1 about. The cam I'm running should be better than my first choice with a 1.6 rocker well into 500 duration both sides. This should easily hit my mark for horsepower. Will be a fun driver. I did actually watch these vids along with a few others Simpson speed shop read a great deal on the trickflow build he did and the iterations. They and Edelbrock are way to proud of their chunks of aluminum lol. Cost was insane for what I was planning. This is just my first resto mod and the learning curve mobile. No disrespect but A bodys are affordable and I love them. When I move up I won't jerk around on a triple the cost car. Here I can learn I screw up I can afford to go at it again.I am NOT a builder; but I think I designed at least one pretty good engine.

My Eddy-headed 367 has been running KB107s since 1999, and currently has over 100,000 miles on it.

In the beginning, this engine had a lotta trouble with running hot, that I could not solve. This engine was not assembled by me, on this first iteration.

Finally, I tore the engine down and sent the block out for honing a lil more skirt clearance ( the bore is reported to be 4.045 now) and got me some Plasma-Moly file-fit rings. I opened up the top gap to .032, and Second was .026 IIRC.

BAM ! instant heat relief.

I now run a minimum coolant temp of 207*F, on purpose, and she is impossible to overheat, running the same parts as when it ran hot.

On Day-1, my KB107s fell in .012 below deck.

I tried to run an .028 gasket for .040 Quench; but at the first scheduled tear-down, I found that the Fire-ring was migrating towards the valley and was only a short time from letting go. Good catch.

So I sent the block out to zero-deck it, to use the famed FelPro 1008s. The new Q was thus .039.

A couple of years later my cam spit off lobes, so on the Fourth inspection, I decked the block again, to get the pistons to pop up a lil to maintain the cylinder pressure with the new bigger cam. The new Q is about .032 with the .039 FelPros.

Cylinder Pressure on all three iterations was thus maintained at or nears 180psi. And all three iterations ran on 87E10 without detonation.

My car is a manual-trans car, so I do not have the option of a Hi-stall, so it has to perform right down to idle-speed. And with the high cylinder-pressure, it does. So much so that I have to retard the ignition below 700rpm to operate down there, without the power overwhelming the driveshaft.

If your pistons also drop in at .012 below-deck, and

if you also use the .039 gaskets with those closed chamber heads;

then your Q will be about .051..

They tell me that is about the maximum for Q to be, to still be considered a Quench-engine. And they say, usually talking about iron heads, that Q of this magnitude, occasionally elicits detonation on anything but best pump-gas. But I think with alloy heads, you should be fine.

As to balance; just get it done.

The KB107-Hypers are so light (502grams), that the Engine wants to rev like lightning. With decent springs, mine revs to a self-imposed red-line of 7200, and in the first two gears at WOT (with 3.55s), I can't hardly shift fast enough to not bang off the rev-limiter. Your engine will thank you for it.

With the Late-Closing Intake event of that Mutha cam, your cylinder pressure will not be very high even tho your compression ratio might be. That translates to a modest amount of sub 3000rpm Power. So try not to stall it too low.

The Desk-Top Dyno was Waaaaaaaaay off on my build, the car just barely got into the 12s (12.9@106mph). Which at 3650 race-weight, I think translated to 335 hp. That was with the Hughes HE2430AL cam;

270/276/110; 223/230@.050; and lifts of .538/.549@1.6arms. Great street cam, BTW! This combo ran a short time at 11.3Scr at 192psi. yes still on 87E10

I also run extra oil to the top end in an effort to cool the valve springs, and to help the aluminum roller-tipped 1.6 arms to survive. Since those rockers currently have over 100,000 miles on them, I think it must be working.

And I drilled the tops of my rods to try and grab some lube. And I slightly enlarged the spray-holes in the rods, that spray onto the cylinder walls.

Don't forget about the other Oiling Mods, and I highly recommend an extra capacity oil-pan to help cool the oil that is getting beat up pretty bad by all these mods. To support all that, I run a hi-volume oilpump, for which I had to modify the filter baseplate so it wouldn't blow the filter off. lol.

Good luck on your combo; It's getting to look a lot like mine except not the cam. I think you wouldda liked the 268 better...... but what do I know.

Happy HotRodding

EDIT;

BTW, take a good look at this graph, notice that, not including the baseline; below 3200rpm, nothing much changed. And that nothing really gets going until about 3800/4000. It's a good thing you'll be buying a TC.

View attachment 1715986672

Last edited:

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,608

- Reaction score

- 13,849

Wiki says Oklahoma is around 1200ft elevation.

10.7 is a good number for alloy heads....... with the right cam, like one with an Ica of around 60 degrees. Your cylinder pressure would come at around 178psi, not optimum but pretty close.

The Mutha-Thumpr SBM is spec'd at

287/305/107(probably at .006tappet), and 235/249@.050 lifts of .530/.515 with 1.6 arms, and they want it installed at 102.

If you do that, the ICA will be about 67* according to their spec numbers. This will drop your cylinder pressure down to around 167psi. Well you could almost run that with the iron heads. So then you have given up a pretty large amount of the advantage that those alloy heads offered.

Ideally you would want to run up around 185psi and I run there on 87E10. To get close to that with an Ica of 67*, you would need to increase the SCR to 11.5 for 183psi, and now yer talking!.

The difference between 167psi and 183psi is night and day in the midrange and especially at the lower end.

What I'm suggesting, is,

that you could probably run a cam about one to almost two sizes smaller on the street, depending on your local elevation, at the higher pressure, and not lose any zero to 60mph ET; and the bonus is that you could run a more street friendly convertor. Not to mention pick up a ton of fuel-economy.

You paid a lotta money for those alloy heads, and now with the Mutha, yer giving up a considerable amount of the benefits away, to get a sound? which comes from the very early opening exhaust event, and the exhaust-dilution on the overlap cycle....... which used to be called EGR; the very thing everybody loved to hate when it first came to the Mopar-world in the early 70s.

Ok, I get that the 235*cam is gonna make a lotta power.

But it's top end power.

If you run a street friendly say 3.73s, With a powerpeak around 5300, that would come at 52/71/103mph. Shifting at 6100 will be around; 48/82/117mph. Course this assumes the tires ain't spinning all the way. ...... and that will be the best trick. If you can't hook, yer 60ft alone will be well over 2 seconds. So what good is all the power gonna be if yer already a half a second behind a guy with half the motor, who did hook.

Here's what I'm saying: by my car's trapspeed of 93mph in the Eighth, it is making over 430 hp. In second gear (Manual trans and roadgear of 6.82) She will easily break traction at 50mph with BFG 295/50-15s. If it's already spinning, then it will keep right on spinning all the way thru Second, to 7200=85mph.

Ok I get that I can back out of the throttle and let the tires catch; but that would be missing the point. If I back out, I might as well just have less power in the first place. My Hughes HE3037AL cam specs at

276/286/110(@.008tappet) , 230/237 @.050, lifts of .549/.571 @1.6arms

This is about ONE size smaller than the Mutha, but without the Exhaust hoopla.

Here are the rest of the events, first the Comp with the advertised probably at .006 tappet rise ; then my Hughes3038 at .008 tappet rise, then my previous cam (HE2430AL) which was my favorite, especially when it ran at 11.3Scr/pumping over 190psi.

287int/114.5 compression/95.5extraction/305exhaust/82*o-lap/Ica of 67*

276int/ 114 compression /105 extraction/ 286exhaust/61* o-lap/Ica of 66*

270int/ 119 compression/108 extraction/276exhaust/53* o-lap/Ica of 61*

This last one (the HE2430AL) was BB strong in the bottom end, and even up the midrange. It was so strong that I traded some pressure for extraction, by retiming the cam and bolted on a double overdrive trans, geared for 65=1640rpm, and promptly got over 30mpgUSg. Yes and it too never got anything but 87E10.

But Ok, I get that you may be hooked on the Mutha's sound, but at what sacrifice?

And OK, I get that you might not care as much about being quick in the Zero to 60 arena. But I had to give it up, or put a buncha money into the suspension. Which would have made her a point and shoot kindof car. But I came to find out that I really liked sliding around corners near full steering lock. So then, I just learned to be "pretty good at it" as one cop said, as he handed me the ticket with a big smile on his handsome face. Then added; "but you can't be doing that here...." Sir-Yes Sir!.

10.7 is a good number for alloy heads....... with the right cam, like one with an Ica of around 60 degrees. Your cylinder pressure would come at around 178psi, not optimum but pretty close.

The Mutha-Thumpr SBM is spec'd at

287/305/107(probably at .006tappet), and 235/249@.050 lifts of .530/.515 with 1.6 arms, and they want it installed at 102.

If you do that, the ICA will be about 67* according to their spec numbers. This will drop your cylinder pressure down to around 167psi. Well you could almost run that with the iron heads. So then you have given up a pretty large amount of the advantage that those alloy heads offered.

Ideally you would want to run up around 185psi and I run there on 87E10. To get close to that with an Ica of 67*, you would need to increase the SCR to 11.5 for 183psi, and now yer talking!.

The difference between 167psi and 183psi is night and day in the midrange and especially at the lower end.

What I'm suggesting, is,

that you could probably run a cam about one to almost two sizes smaller on the street, depending on your local elevation, at the higher pressure, and not lose any zero to 60mph ET; and the bonus is that you could run a more street friendly convertor. Not to mention pick up a ton of fuel-economy.

You paid a lotta money for those alloy heads, and now with the Mutha, yer giving up a considerable amount of the benefits away, to get a sound? which comes from the very early opening exhaust event, and the exhaust-dilution on the overlap cycle....... which used to be called EGR; the very thing everybody loved to hate when it first came to the Mopar-world in the early 70s.

Ok, I get that the 235*cam is gonna make a lotta power.

But it's top end power.

If you run a street friendly say 3.73s, With a powerpeak around 5300, that would come at 52/71/103mph. Shifting at 6100 will be around; 48/82/117mph. Course this assumes the tires ain't spinning all the way. ...... and that will be the best trick. If you can't hook, yer 60ft alone will be well over 2 seconds. So what good is all the power gonna be if yer already a half a second behind a guy with half the motor, who did hook.

Here's what I'm saying: by my car's trapspeed of 93mph in the Eighth, it is making over 430 hp. In second gear (Manual trans and roadgear of 6.82) She will easily break traction at 50mph with BFG 295/50-15s. If it's already spinning, then it will keep right on spinning all the way thru Second, to 7200=85mph.

Ok I get that I can back out of the throttle and let the tires catch; but that would be missing the point. If I back out, I might as well just have less power in the first place. My Hughes HE3037AL cam specs at

276/286/110(@.008tappet) , 230/237 @.050, lifts of .549/.571 @1.6arms

This is about ONE size smaller than the Mutha, but without the Exhaust hoopla.

Here are the rest of the events, first the Comp with the advertised probably at .006 tappet rise ; then my Hughes3038 at .008 tappet rise, then my previous cam (HE2430AL) which was my favorite, especially when it ran at 11.3Scr/pumping over 190psi.

287int/114.5 compression/95.5extraction/305exhaust/82*o-lap/Ica of 67*

276int/ 114 compression /105 extraction/ 286exhaust/61* o-lap/Ica of 66*

270int/ 119 compression/108 extraction/276exhaust/53* o-lap/Ica of 61*

This last one (the HE2430AL) was BB strong in the bottom end, and even up the midrange. It was so strong that I traded some pressure for extraction, by retiming the cam and bolted on a double overdrive trans, geared for 65=1640rpm, and promptly got over 30mpgUSg. Yes and it too never got anything but 87E10.

But Ok, I get that you may be hooked on the Mutha's sound, but at what sacrifice?

And OK, I get that you might not care as much about being quick in the Zero to 60 arena. But I had to give it up, or put a buncha money into the suspension. Which would have made her a point and shoot kindof car. But I came to find out that I really liked sliding around corners near full steering lock. So then, I just learned to be "pretty good at it" as one cop said, as he handed me the ticket with a big smile on his handsome face. Then added; "but you can't be doing that here...." Sir-Yes Sir!.

Last edited:

-

Similar threads

- Replies

- 3

- Views

- 777

- Replies

- 65

- Views

- 13K

- Replies

- 5

- Views

- 2K