I should say that the blower hasn't worked since I rebuilt the engine. I gutted the dash and haven't put stuff back together. That's not to say the blower doesn't have energy, but it definitely ain't blowing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine stays running without key in ignition (and more!)

- Thread starter Righty Tighty

- Start date

-

I should say that the blower hasn't worked since I rebuilt the engine. I gutted the dash and haven't put stuff back together. That's not to say the blower doesn't have energy, but it definitely ain't blowing.

Then the mystery continues. lol

Yeah but a blower is not going to run long nor is it going to generate long.........maybe a couple seconds. An electrical draw as large as the ignition on the blower is not going anywhere

Okay sports fans, I think the problem is solved!

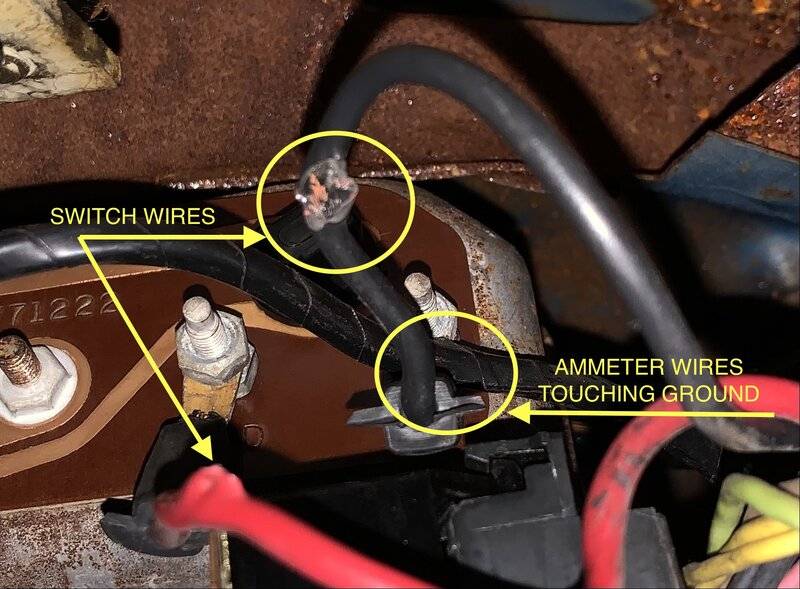

I replaced the damaged battery cable to eliminate that problem, then started at the light switch. The reason I started there, was because the other day I noticed the switch itself was very hot to the touch after leaving the battery connected for about 30 minutes or so. I looked under the dash and behind the cluster, and found the two light switch wires melted together. Apologies if it's out of focus, I was in a yoga position that doesn't have a name yet.

So I separated the two and connected the battery, still had the problem with the dash lights. Went back underneath, and noticed the ammeter wiring was wedged between the light switch ground post and one of the ammeter posts. I relocated the ammeter wiring away from the switch ground, and now the dash lights work properly again.

Someone tell me if this makes sense: when the positive battery cable melted and grounded against the header, it shorted and caused the ammeter to spike, the ammeter wires got hot and melted against the light switch ground, shorted the switch, which caused the switch wires to melt together and kept the dash lights on whenever connected to power.

I think when I repositioned the positive battery cable away from the header the first time, it may have still been making contact somewhere, causing the car to stay running. I went back and made sure it wasn't touching anywhere, and miraculously the car would shut off when it was supposed to.

Edit: I’m looking again at the pictures, and I think the red and black wires may be the ammeter wires? I’ll get back under and check. I was bent into a pretzel at the time.

I replaced the damaged battery cable to eliminate that problem, then started at the light switch. The reason I started there, was because the other day I noticed the switch itself was very hot to the touch after leaving the battery connected for about 30 minutes or so. I looked under the dash and behind the cluster, and found the two light switch wires melted together. Apologies if it's out of focus, I was in a yoga position that doesn't have a name yet.

So I separated the two and connected the battery, still had the problem with the dash lights. Went back underneath, and noticed the ammeter wiring was wedged between the light switch ground post and one of the ammeter posts. I relocated the ammeter wiring away from the switch ground, and now the dash lights work properly again.

Someone tell me if this makes sense: when the positive battery cable melted and grounded against the header, it shorted and caused the ammeter to spike, the ammeter wires got hot and melted against the light switch ground, shorted the switch, which caused the switch wires to melt together and kept the dash lights on whenever connected to power.

I think when I repositioned the positive battery cable away from the header the first time, it may have still been making contact somewhere, causing the car to stay running. I went back and made sure it wasn't touching anywhere, and miraculously the car would shut off when it was supposed to.

Edit: I’m looking again at the pictures, and I think the red and black wires may be the ammeter wires? I’ll get back under and check. I was bent into a pretzel at the time.

Last edited:

Mattax

Just the facts, ma'am

Went back underneath, and noticed the ammeter wiring was wedged between the light switch ground post and one of the ammeter posts. I relocated the ammeter wiring away from the switch ground, and now the dash lights work properly again.

Yes.Someone tell me if this makes sense: when the positive battery cable melted and grounded against the header, it shorted and caused the ammeter to spike

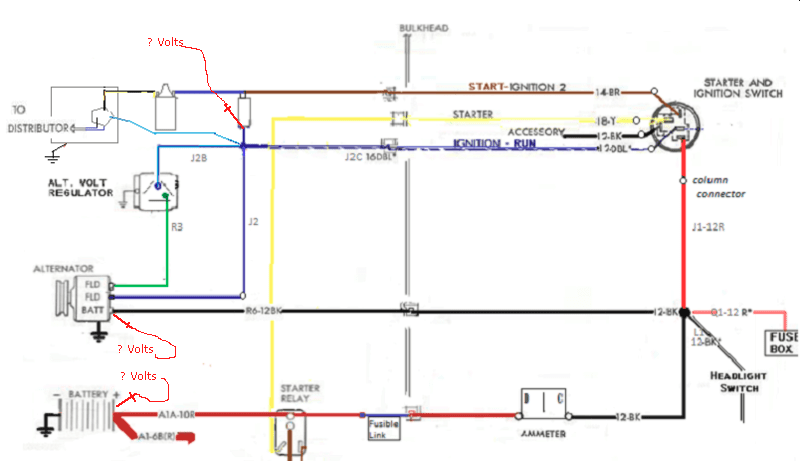

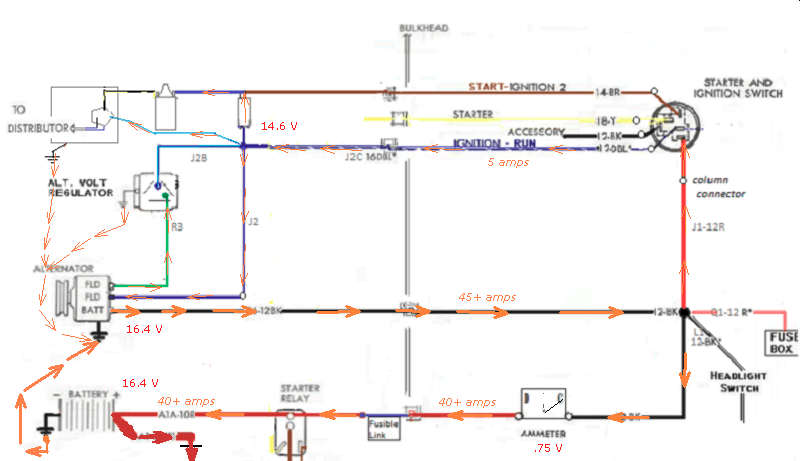

Starter cable grounding to header caused the alternator to supply as much power as it could. The ammeter maxes out at 40 amps. Orange arrows show the path of current flow.

Reasonable theory.the ammeter wires got hot and melted against the light switch ground,

It's likely that wiring was eventually going to be a doomed situation regardless. here's why I suspect that. As far as I know, the factory light switches did not have a ground tab. Only thing that needs a ground in the headlight switch is the dome light control. Usually grounding for that was just the attachment to the dash. I think the headlight switch was replaced and at that time the wires got pinched. The factory routing in general was pretty good in providing support for the electrical cables. Mechanics (like us) often find wire routing in the way and/or a pain to undo and put back so we don't bother. Works when you only keep the car for 5 more years. Not so with 15 or 25 more years!

Something like that. As far as you can tell the switch is fine. So seems more like the insualtion between the instrument light wire and one of the power supply wires got chaffed/cut/pinched and melted together.shorted the switch, which caused the switch wires to melt together and kept the dash lights on whenever connected to power.

Neither of the wires circled appear to be the power feeds to the light switch.

If either wire connecting to the ammeter grounded, the fusible link would have melted.

The feed to the light switch B1 terminal from the main splice probably is black with a white tracer.

There is also a second feed to the light switch coming from the fusebox hot side connecting at the B2 terminal.

Colors and routing here are for '67 but concept is the same

B1 powers only the headlights. Internally there is a 15 amp circuit breaker.

B2 powers the parking lights, and alos goes to the rheostat for the instrument lights.

Wire for the Instrument lights then goes back to a 2 or 3 amp fuse then to the instrument lamps.

Last edited:

Awesome, thanks bunch for all that info. Believe it or not, I'm glad this happened, because it's helped me learn and understand a little more about my car's electrical system.

I'm going to have a look under the dash tomorrow so I can put a visual to the diagrams you've shared.

I'm going to have a look under the dash tomorrow so I can put a visual to the diagrams you've shared.

Tell you what, and this is long overdue. You should drop the column and yank the cluster out of there. That is the ONLY way you have any chance of digging around under there and getting it all "found." You need to be unwrapping the harness and inspecting it for other "meltage" under the wrap. I did not realize it had this kind of damage.

Thanks, I’ll do that. The good news is that I’ve pulled the cluster several times, so I’ve got that process down pretty good.

It also helps to be a contortionist as well. Ugh.Thanks, I’ll do that. The good news is that I’ve pulled the cluster several times, so I’ve got that process down pretty good.

Luckily I’m 5’10”, so it’s not too terrible. I feel bad for those 6ft+ fellas out there…

Yeah, I'm 6'1" and not 25 anymore!Luckily I’m 5’10”, so it’s not too terrible. I feel bad for those 6ft+ fellas out there…

Hey folks, back from fighting fire in Oregon and I'm eager to get back under the hood! I'm going to pull the cluster so I can inspect the wires and connections, and replace the damaged gauge wires. I have two questions:

1) I read somewhere that it is wise to use wire that is specific to automotive applications, as it is made to withstand vibrations, etc. Is that true?

2) Second question is more of an update. I've started the car a couple times to move it in and out of the driveway since finding the melted wires, and while the dash light and ignition issues seem to be gone, now the ammeter moves with changing RPM. More specifically, the needle moves to the charge side (right) with increased RPM. I saw another thread here where the member was experiencing a similar issue, but I can't seem to find it. I'm still going to be checking connections, but I'm starting to suspect the alternator. Thoughts?

1) I read somewhere that it is wise to use wire that is specific to automotive applications, as it is made to withstand vibrations, etc. Is that true?

2) Second question is more of an update. I've started the car a couple times to move it in and out of the driveway since finding the melted wires, and while the dash light and ignition issues seem to be gone, now the ammeter moves with changing RPM. More specifically, the needle moves to the charge side (right) with increased RPM. I saw another thread here where the member was experiencing a similar issue, but I can't seem to find it. I'm still going to be checking connections, but I'm starting to suspect the alternator. Thoughts?

Mattax

Just the facts, ma'am

Hey folks, back from fighting fire in Oregon

Assess that one you can take a better look. From the photo above only looks like damager to a portion of the insulation. IF SO, I'd fix that and not replace. Second option would be to splice in a short length. The reason is those factory ring terminals are generally very well fitted and insulated for that job. If they're damaged, then that's another story. If you do add wire, keep the length clsoe to original making allowance for the loss of flexibility at the splices.replace the damaged gauge wires

Inline wiring splice clips........from the Dodge RAM service manual

Compared with house wire? Yes sure. Automotive wire is always stranded.1) I read somewhere that it is wise to use wire that is specific to automotive applications, as it is made to withstand vibrations, etc. Is that true?

Under the dash, General Purpose automotive wire is sufficient. Sometimes its labeled primary wire.

There are other stranded wire grades that have more density, flexibility, and/or insulation that is more resistant to heat, oil and gasoline.

In the engine bay I often use marine wire or a SAE with a medium wall insulation.

Two possibilities:changing RPM. More specifically, the needle moves to the charge side (right) with increased RPM.

1. Battery is low and the alternator is maxing out at slow idle. When you raise the rpm, the alternator can produce more power and the battery is sucking up that additional power. Make sure the battery is fully charged (use a charger) and see if this goes away.

2. The regulator isn't regulating properly. Two directions to investigate here:

a. Has the brush from the rotor that normally is connected back to the regulator been grounded? If this happens the regulator can't control current through the rotor. It could be internal or more frequently, the green wire has been pinched against the body or the regualtor failed.

b. The regulator is sensing the wrong voltage. If the regulator is seeing less than 14ish volts, it will let more current through the rotor in an attempt to bring the voltage up. Check what the regulator is seeing by comparing the alternator output voltage to the voltage at a convenient location near the regulator's sense wire (Blue). Ballast resistor or the blue wire where it connects to the alternator are two locations that can be fairly easily backprobed.

Ok. Its possible that one of the diodes is out or one of the windings (there are three) is broken. This would cause lower output at all times, but most noticiable at low speed.but I'm starting to suspect the alternator. Thoughts?

Here's where I would begin.

1. Charge battery

2. Start car and this time have a handheld voltmeter to make measurements in conjunction with reading the ammeter.

If when ammeter shows increasing charge the system volts go up above 14.8 or so, then there is a lack of regulator control. If so, then measure what the regulator is seeing, and go from there.

Mattax

Just the facts, ma'am

This post shows how the isolated field alternator works with its regulator.

Identifying Chrysler Alternators (1960-1976)

Because the regulator has boot type connector, voltage it is sensing will have to be the next closest locations in the J2 circuit.

Voltage of the J2 circuit should be fairly close to the votlage measured at the alternator output and the battery at hte same time.

If there is a big difference, then that indicates resistance to current flow.

Identifying Chrysler Alternators (1960-1976)

Because the regulator has boot type connector, voltage it is sensing will have to be the next closest locations in the J2 circuit.

Voltage of the J2 circuit should be fairly close to the votlage measured at the alternator output and the battery at hte same time.

If there is a big difference, then that indicates resistance to current flow.

View attachment 1715777862 Did that once - in Idaho - I got a pretty easy assignment - structural protection. My hats off to you and anypone with a red card right now.

Assess that one you can take a better look. From the photo above only looks like damager to a portion of the insulation. IF SO, I'd fix that and not replace. Second option would be to splice in a short length. The reason is those factory ring terminals are generally very well fitted and insulated for that job. If they're damaged, then that's another story. If you do add wire, keep the length clsoe to original making allowance for the loss of flexibility at the splices.

Inline wiring splice clips........from the Dodge RAM service manual

Compared with house wire? Yes sure. Automotive wire is always stranded.

Under the dash, General Purpose automotive wire is sufficient. Sometimes its labeled primary wire.

There are other stranded wire grades that have more density, flexibility, and/or insulation that is more resistant to heat, oil and gasoline.

In the engine bay I often use marine wire or a SAE with a medium wall insulation.

Two possibilities:

1. Battery is low and the alternator is maxing out at slow idle. When you raise the rpm, the alternator can produce more power and the battery is sucking up that additional power. Make sure the battery is fully charged (use a charger) and see if this goes away.

2. The regulator isn't regulating properly. Two directions to investigate here:

a. Has the brush from the rotor that normally is connected back to the regulator been grounded? If this happens the regulator can't control current through the rotor. It could be internal or more frequently, the green wire has been pinched against the body or the regualtor failed.

b. The regulator is sensing the wrong voltage. If the regulator is seeing less than 14ish volts, it will let more current through the rotor in an attempt to bring the voltage up. Check what the regulator is seeing by comparing the alternator output voltage to the voltage at a convenient location near the regulator's sense wire (Blue). Ballast resistor or the blue wire where it connects to the alternator are two locations that can be fairly easily backprobed.

Ok. Its possible that one of the diodes is out or one of the windings (there are three) is broken. This would cause lower output at all times, but most noticiable at low speed.

Here's where I would begin.

1. Charge battery

2. Start car and this time have a handheld voltmeter to make measurements in conjunction with reading the ammeter.

If when ammeter shows increasing charge the system volts go up above 14.8 or so, then there is a lack of regulator control. If so, then measure what the regulator is seeing, and go from there.

Thanks! We were a type 6 strike team assigned initial attack at first and supporting hand crews, then reassigned to mop up. Fun and rewarding work.

I'm glad you recommend just repairing the wire instead of replacing, because I wasn't looking forward to replacing them. The repair will be easy.

I'll get the battery on the charger now. I checked the regulator before I left town, however I checked its resistance, not the voltage it was seeing. I re-check and look for voltage this time.

Dartswinger70

Well-Known Member

Kinda reminds me of when i was a kid and installed a Grant steering wheel, i made a right turn and the horn went on and wouldnt stop LOL! I had a friend in the car he was looking at me like WTF? I seem to recall pulling over yanking the battery cable then ripping the horn button off and disconnecting the wiresLOL!

Kinda reminds me of when i was a kid and installed a Grant steering wheel, i made a right turn and the horn went on and wouldnt stop LOL! I had a friend in the car he was looking at me like WTF? I seem to recall pulling over yanking the battery cable then ripping the horn button off and disconnecting the wiresLOL!

Haha! I've heard of friends connecting their buddy's horn to the brake switch...I'd love to do that someday.

Dartswinger70

Well-Known Member

There ia one about hooking the coil wire to the metal seat frame on the drivers seat, the spark is high voltage shocks the driver tush. I have never tried it. and another about taking a mountain dew bottle full of antifreeze, sticking a vacuum line it it and resting it on the manifold of a carbed car hooked into manifold vacuum. Creates a nice plume of white smoke for the whole neighborhood to enjoy...Haha! I've heard of friends connecting their buddy's horn to the brake switch...I'd love to do that someday.

Mattax

Just the facts, ma'am

I'll get the battery on the charger now. I checked the regulator before I left town, however I checked its resistance, not the voltage it was seeing. I re-check and look for voltage this time.

Resistance check of a wire is good for checking for major failures.

Its not sensitive enough to measure the resistance that can cause voltage loss during some normal operating scenarios.

There's a little example in this post showing the effect of just .06 Ohms of resistance in a connection.

Short version is this:

V=I x R

Under normal operation, the alternator supplies maybe 5 amps to power the ignition and alternator.

V = 5 amps x .06 ohms

V = .3 Volts

Everything works like normal...

But lets say the battery is real low on charge and the resistance is in the alternator output wire.

5 amps to run the car and 20 amps to charge the battery all going through the .06 ohms resistance,

Volts reduced = 25 amps x .06 ohm

Volts reduced = 1.5 Volts

So in this scenario all circuits after that resistance location will see power at 1.5 Volts less than the alternator is producing at.

Okay, I checked the voltage at the battery, alternator, and VR while idling.

Battery ~16.4

Alternator ~16.4

VR ~14.6

I also checked the ammeter, and I got -0.75 when the needle was pegged to the right. I'll be honest, I still don't quite have a firm grasp on what I'm dealing with, but as you said

so, I thought I'd swap voltage regulators to see if there would be any change, and BOOM. Problem solved. No more erratic ammeter needle. I still wonder if there could be a problem elsewhere that hasn't made itself obvious yet, so I'm going to keep checking.

Battery ~16.4

Alternator ~16.4

VR ~14.6

I also checked the ammeter, and I got -0.75 when the needle was pegged to the right. I'll be honest, I still don't quite have a firm grasp on what I'm dealing with, but as you said

Voltage of the J2 circuit should be fairly close to the votlage measured at the alternator output and the battery at hte same time.

If there is a big difference, then that indicates resistance to current flow.

so, I thought I'd swap voltage regulators to see if there would be any change, and BOOM. Problem solved. No more erratic ammeter needle. I still wonder if there could be a problem elsewhere that hasn't made itself obvious yet, so I'm going to keep checking.

Mattax

Just the facts, ma'am

That's terrible, but possible the VR was working correctly. After all, it appears it was controlling to 14.6 Volts.Okay, I checked the voltage at the battery, alternator, and VR while idling.

Battery ~16.4

Alternator ~16.4

VR ~14.6

Argh!I also checked the ammeter, and I got -0.75 when the needle was pegged to the right.

When the ammeter is pegged there's over 40 amps flowing to battery. (or out if its pegged toward discharge).

Either case way that's enough current to cause problems even through small resistance. If you see that, shut it down and find the problem.

The insulation here probably got melted off when I had to drive the car after a jump start for about 20 minutes.

It saw between 20 - 35 amps for much of that time.

The bulkhead terminal with the black wire is my Barracuda's alternator output wire. The entire dust seal is melted away.

Here's what happened to someone's ammeter wires when they let the engine run for 20 minutes with the ammeter pegged to charge.

OK. Now thats out of the way. Lets see if there is a problem at the ammeter connections.

You measure .75 Volts and the meter was indicating at least 40 amps.

V = Ix R,

.75 V = 40 amps x R

.018 ohms = R

I'd clean those connections, and very gently (with the battery disconnected) see if there is any play or looseness in the studs.

To clean, disconnect the battery, remove the nuts and gently scrub with something like De-oxit. Because they are ring terminals, if you used something slightly abrasive, that would be OK.

You may have solved it, or part of it. Its not clear if it was the regulator or a connection or both.I'll be honest, I still don't quite have a firm grasp on what I'm dealing with, but as you said

so, I thought I'd swap voltage regulators to see if there would be any change, and BOOM. Problem solved. No more erratic ammeter needle. I still wonder if there could be a problem elsewhere that hasn't made itself obvious yet, so I'm going to keep checking.

When a battery sees more than 15 Volts, even if its fully charged, it will draw power. Think of it as overcharging. The battery can't actually move any more ions from the acid to the lead plates, but the acid gets hot and starts to boil off....

Its hard to know in this casehow much of that 40 ampos was overcharging and how much was due to low battery.

I'm guessing by hte time you changed regulators the battery finally came up to full charge since you put it on the charger.

One reason for the big voltage difference was the extremely high current the battery was drawing.

Imagine water flowing through a pipe.

When there is low flow, a small or crusty pipe will not impeded the flow.

When there is high flow, a small or crusty pipe can make a big differnce. Whatever water gets through is going to be at lower pressure on the other side of the crusty connection than the well is pumping at.

So yes there still may still be poor connections in the wiring.

These can be found by purposely turning on items which draw current and then measuring for votlage differences along the current path.

Maybe current path needs better explaining.

Current is the electrons flowing from the low voltage to the high voltage. Its general practice to describe flow from the high voltage source, so just think of it that way.

If the battery is like a water tower full of water, the alternator is like a pump.

Current is like the stream of water flowing from the pump or water tower to the toilet, sink, shower, etc.

If the pump is running and capable of producing 14.5 psi and supplying 20 gallons per hour, you;ll get plenty of water for a shower at something close to 14.5 psi.

The water tower at best can supply awater at 12.5 psi, but it has hundreds of gallons. So if people are doing laundry, watering the lawn, and flushing the toilet and the pump can't supply the water for all that, pressure will drop and the water tower will supply the water.

Last edited:

Mattax

Just the facts, ma'am

Maybe my understanding of your ammeter voltage reading is not what you meant.

The voltage measurements dont add up.

If the alternator output was at 16.4 V, and there was a .75 V drop across the ammeter, then the voltage at the battery should have been around 15.7 V

But you measured 16.4 volts at both the battery and the alternator. If thats correct, then there must have been a very bad connection between the main splice and the ignition wire point where you measured 14.6 V

Hope that makes sense.

Now that's its running close to normal, you could test for voltage drops again.

The battery should recharge quickly after start. When the ammeter is showing zero, you can add known loads by turn, the heater fan, lights etc and measuring for voltage drop.

Column connectors can be a problem point, as can be the bulkhead connector.

PS. There's another example of voltage drop in this post. Maybe that one is clearer.

The voltage measurements dont add up.

If the alternator output was at 16.4 V, and there was a .75 V drop across the ammeter, then the voltage at the battery should have been around 15.7 V

But you measured 16.4 volts at both the battery and the alternator. If thats correct, then there must have been a very bad connection between the main splice and the ignition wire point where you measured 14.6 V

Hope that makes sense.

Now that's its running close to normal, you could test for voltage drops again.

The battery should recharge quickly after start. When the ammeter is showing zero, you can add known loads by turn, the heater fan, lights etc and measuring for voltage drop.

Column connectors can be a problem point, as can be the bulkhead connector.

PS. There's another example of voltage drop in this post. Maybe that one is clearer.

Last edited:

Apologies, but I thought that's what you meant with your original test. I thought I was to connect the voltmeter to the ammeter while the car was running (and showing the problem) to see what voltage the ammeter was seeing. I'll try again today, and also try turning on some accessories. Actually, all I have to turn on are the lights...no fan, radio, etc. Haha.If you see that, shut it down and find the problem.

I waited until the battery was fully charged before beginning any diagnostics. In fact, when my charger indicated the battery was fully charged/maintaining, I checked the battery with the voltmeter and it showed 16.6 volts. Could the charger have overcharged the battery? It's not exactly a high quality unit, just something I picked up from WallyWorld a few years back.I'm guessing by hte time you changed regulators the battery finally came up to full charge since you put it on the charger.

I REALLY appreciate your patience and great explanations along with the diagrams. I know this stuff is pretty basic knowledge to most people, so for you to take the time and break it down and explain it several different ways really says a lot. Thank you.

Mattax

Just the facts, ma'am

It's actually a mystery to more people than you'ld imagine. Took Nacho over in the moparts forum to explain how the system worked before I finally got on track.

I agree that doesn't seem right. Do you have some other batteries you can check the voltmeter with? Something like 9V or 3 or 4 C cells could work too if you can keep them lined up or in a holder.

@toolmanmike might have some insight both the charger and the meter, if you want to post the specific models.

My understanding of wet cells is the most they can charge up to is around 12.8 Volts. I can't imagine how there could be higher than that unless its a 16 Volt battery. Immediately after charging there a slightly higher voltage due to something called surface charge. So often it will measure 13ish volts right after shutting the car ogff. If you flip the lights on for a couple seconds, the surface charge disappears. There's really minimal stored energy in the surface charge, and it will go away pretty quickly even without turning something on.

In fact, when my charger indicated the battery was fully charged/maintaining, I checked the battery with the voltmeter and it showed 16.6 volts. Could the charger have overcharged the battery? It's not exactly a high quality unit, just something I picked up from WallyWorld a few years back.

I agree that doesn't seem right. Do you have some other batteries you can check the voltmeter with? Something like 9V or 3 or 4 C cells could work too if you can keep them lined up or in a holder.

@toolmanmike might have some insight both the charger and the meter, if you want to post the specific models.

My understanding of wet cells is the most they can charge up to is around 12.8 Volts. I can't imagine how there could be higher than that unless its a 16 Volt battery. Immediately after charging there a slightly higher voltage due to something called surface charge. So often it will measure 13ish volts right after shutting the car ogff. If you flip the lights on for a couple seconds, the surface charge disappears. There's really minimal stored energy in the surface charge, and it will go away pretty quickly even without turning something on.

Last edited:

-

Similar threads

- Replies

- 36

- Views

- 1K

- Replies

- 36

- Views

- 1K

- Replies

- 12

- Views

- 735