Ironmike

Well-Known Member

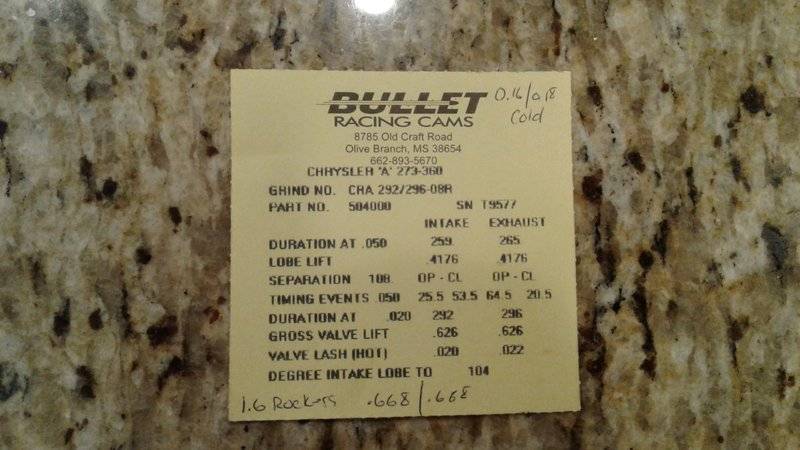

Degreed my Bullet solid roller today. Supposed to be a 108 LSA. When I set it up dot to dot it came out 109.5.

Tim wanted it installed at 104, so I advanced til I got 103.5.

Talked to them and they were very cool about it. All cores aparrantly are not perfect. I think the important thing is that I got it real close to 104.

Tried a Howards Cam billet timing set and it's really nice, but has a wee bit of slop. Not sure whether I'm gonna return it or not. Last 2 I used were Cloyes and they were both pretty tight.

How much flex do ya think is ok, if any?

Tim wanted it installed at 104, so I advanced til I got 103.5.

Talked to them and they were very cool about it. All cores aparrantly are not perfect. I think the important thing is that I got it real close to 104.

Tried a Howards Cam billet timing set and it's really nice, but has a wee bit of slop. Not sure whether I'm gonna return it or not. Last 2 I used were Cloyes and they were both pretty tight.

How much flex do ya think is ok, if any?