You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foundation

- Thread starter lenweiler

- Start date

-

Looking good

Can I ask what is that between the two freeze pluges?

Can I ask what is that between the two freeze pluges?

memike said:Looking good

Can I ask what is that between the two freeze pluges?

It's a billet aluminum bung with a 1/2'' thread (one per side). The exterior water lines from the water pump, enter the block at these points. We chose this method of cooling in lieu of the OEM (through the front of the block). The 'half moon' water holes at the front will be filled.

AdamR

Big Member

What are you going to do for an oil filter ? AN lines to a remote mount filter ?

AdamR said:What are you going to do for an oil filter ? AN lines to a remote mount filter ?

Bingo. The original feed had to be welded shut on account of a hole.

flyboy01

Its almost done!

I don't think it will work out for you, you should let me have it.

ValiantMike

Well-Known Member

Niiice

flyboy01 said:I don't think it will work out for you, you should let me have it.

LOL. Only if it dosen't live up to expectations.

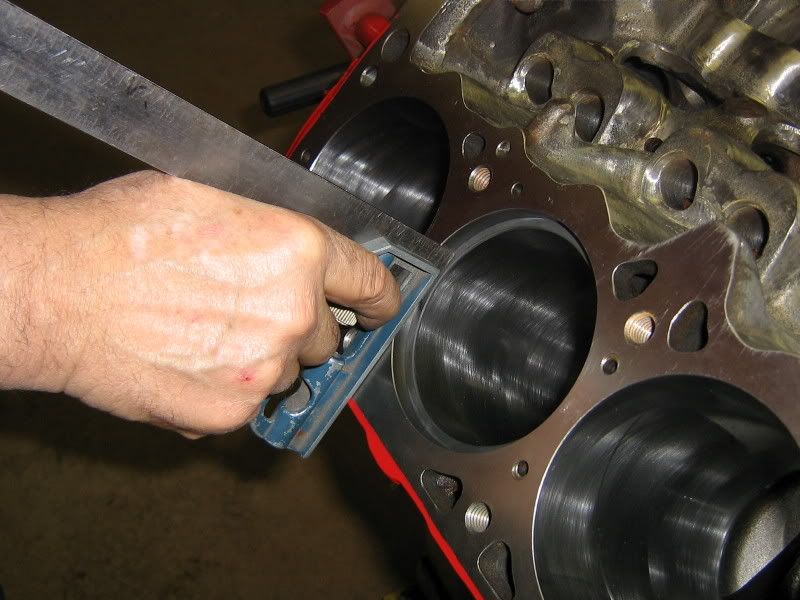

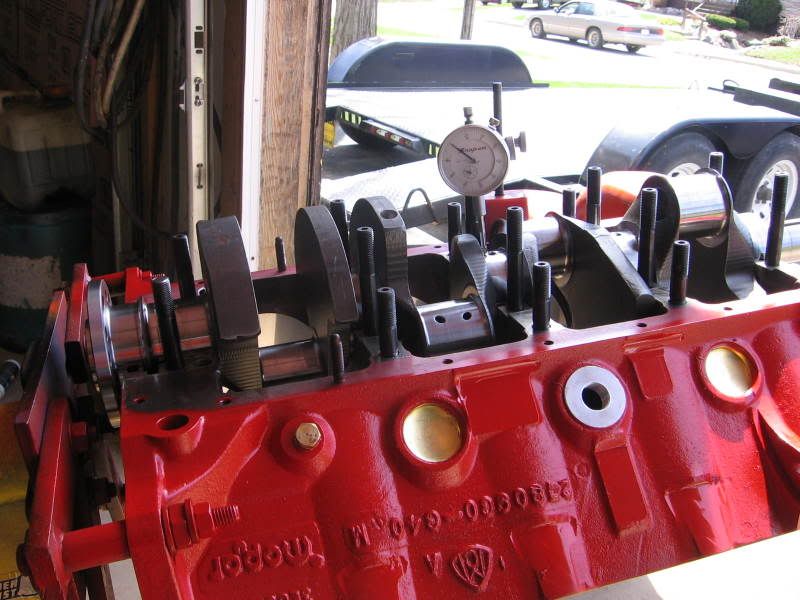

We made a start today on the shortblock. Just easing into it.

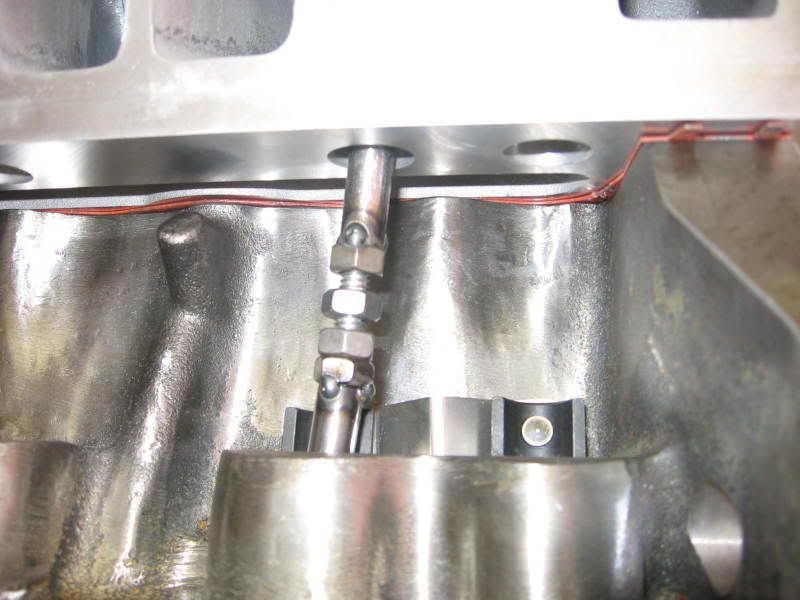

Here we've milled the #5 main cap on one side to facilitate oil pump clearance. We also used a 12 point nut. Lots of clearance now.

Oil feed was chamferred and radiused for flow.

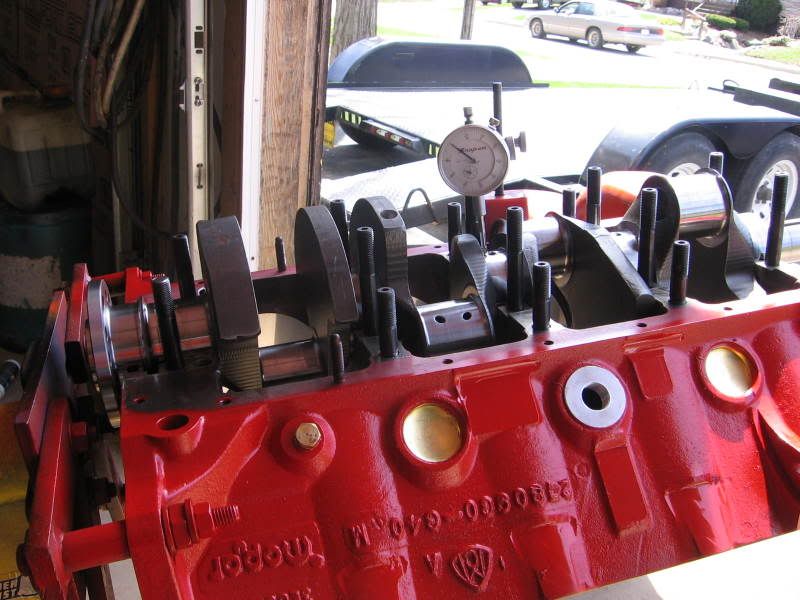

Finally we checked crank run-out. There was NO appreciable measurement. That would be under .oo1". This is typical Callies work. And my machinist had the hoan bang on.

Here we've milled the #5 main cap on one side to facilitate oil pump clearance. We also used a 12 point nut. Lots of clearance now.

Oil feed was chamferred and radiused for flow.

Finally we checked crank run-out. There was NO appreciable measurement. That would be under .oo1". This is typical Callies work. And my machinist had the hoan bang on.

daves66valiant

68 Dart 340/727:66 Signet Vert 340/5spd: 68 D100

very niiiice. wanna maka sexy time with number # mopar engine in all canadakstan.

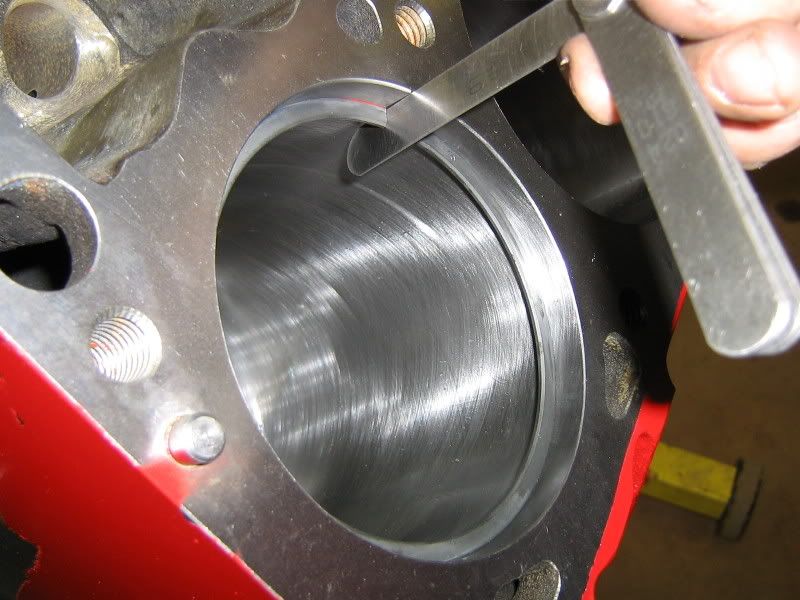

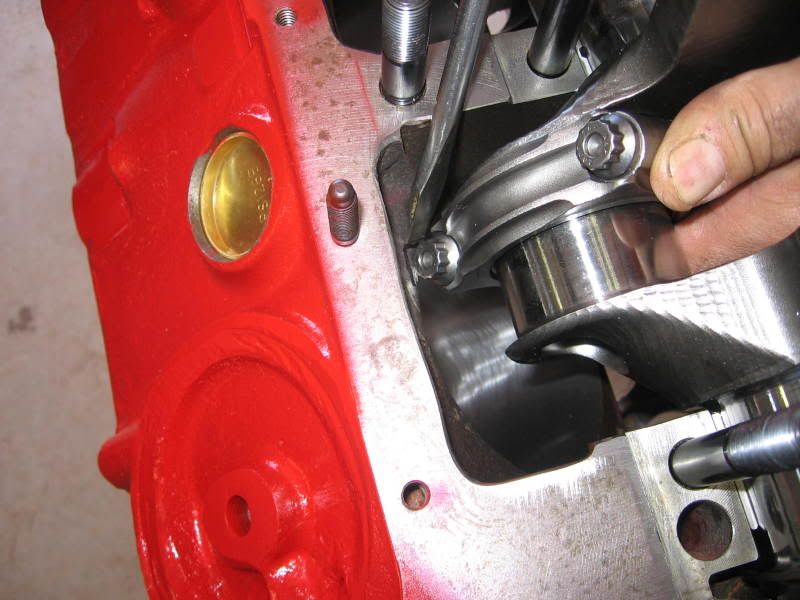

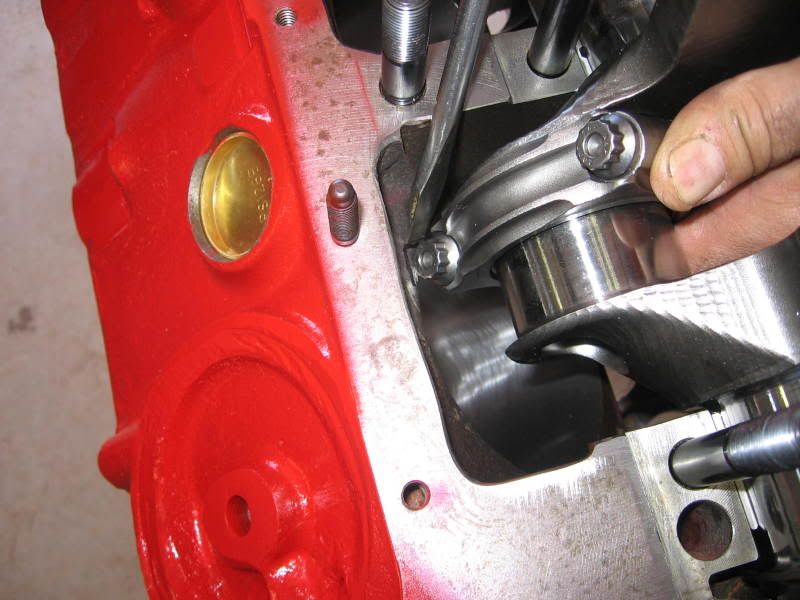

Well. Even with the stroker rods, grinding was still necessary for clearance. Likely because of the extra bottom-end iron added to this repro block.

15 minutes of grinding with a carbide cutter is all it took.

Small notch........... plenty of clearance.

Crank is now installed.

15 minutes of grinding with a carbide cutter is all it took.

Small notch........... plenty of clearance.

Crank is now installed.

63dartman

Well-Known Member

That is a beautiful piece of metal! Your thread here is really helpful also. For us guys that have never assembled a bottom end and have never seen it done. Thanks!!

AdamR

Big Member

lenweiler said:I thought it might be too much for some. Kinda waiting for the Site Admin. to cancel me out.......... But there are some, like you mentioned, that have never done it. It's not rocket science............

Keep up the good work. I think theres more then a few of us that have never screw our own short blocks together.

Yo! Len. This is really good.

Thanks for the positives. Thought that there might be a few guys out there, a little leery of doing this. This is old hat to some of us, and we get by on pretty much regular tools.

That's pretty much for the shortblock. There will be more. So easy with these cameras. Next I'll be skimming over the head prep. Mostly finding installed height and such. Some parts are comming in.

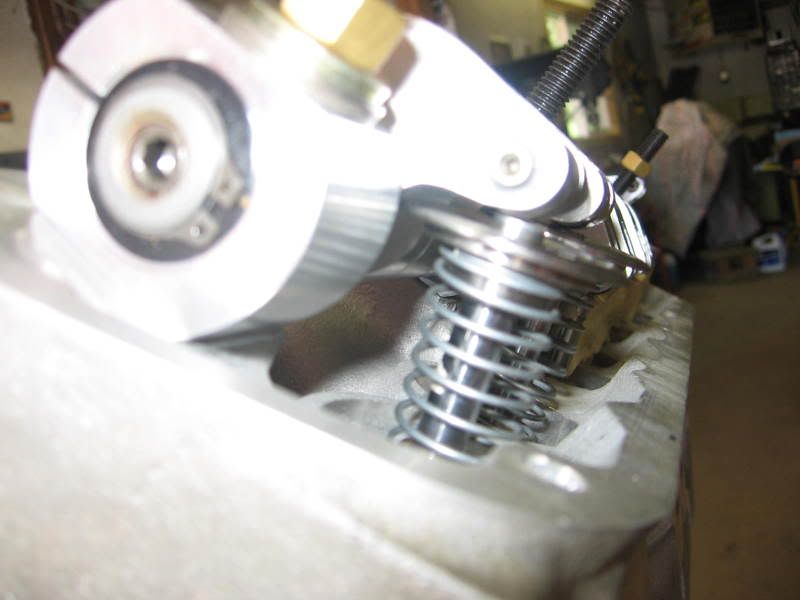

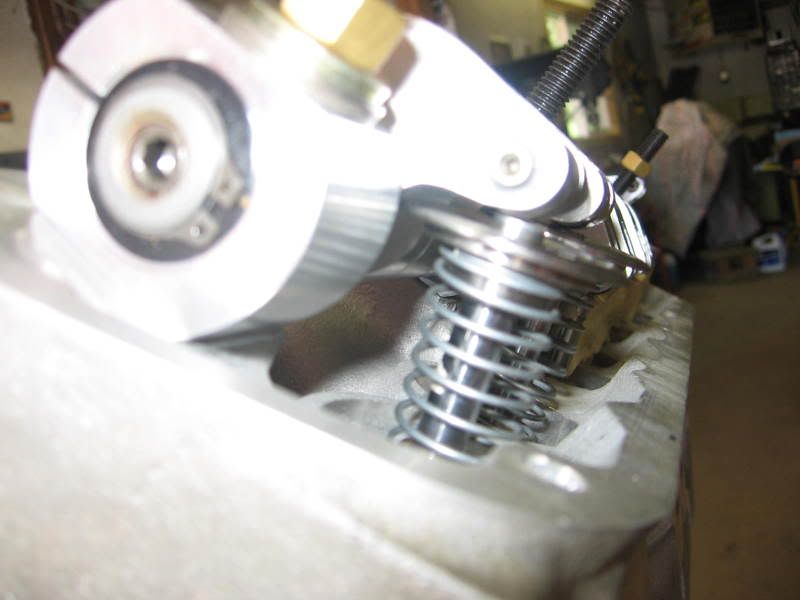

These springs were recommended by the gent that did my heads.

He felt the springs rec. by Crane for the cam, might be a tad inadequate. The valves are Ferrea, the ex. are 11/32" stems, and the int. are 5/16" stems.

We took a stab at the retainer/lock set up, ballparking the titanium retainers at +.110" installed height and the locks at 0 gain.

Unfortunately, with the addition of the spring seats we'll be below our installed height of min. at 1.95, after all the math.

So we've ordered new locks with +.050" more installed height. These springs have a seat press. at 240lb. @ 2.00" and nose press. of 600lb@ .700".

I try to follow installed heights and pressures almost religeously. Spring press. can make or break the cams performance. One of the reasons, I'm sure, that the other engine is under underperforming.

That's pretty much for the shortblock. There will be more. So easy with these cameras. Next I'll be skimming over the head prep. Mostly finding installed height and such. Some parts are comming in.

These springs were recommended by the gent that did my heads.

He felt the springs rec. by Crane for the cam, might be a tad inadequate. The valves are Ferrea, the ex. are 11/32" stems, and the int. are 5/16" stems.

We took a stab at the retainer/lock set up, ballparking the titanium retainers at +.110" installed height and the locks at 0 gain.

Unfortunately, with the addition of the spring seats we'll be below our installed height of min. at 1.95, after all the math.

So we've ordered new locks with +.050" more installed height. These springs have a seat press. at 240lb. @ 2.00" and nose press. of 600lb@ .700".

I try to follow installed heights and pressures almost religeously. Spring press. can make or break the cams performance. One of the reasons, I'm sure, that the other engine is under underperforming.

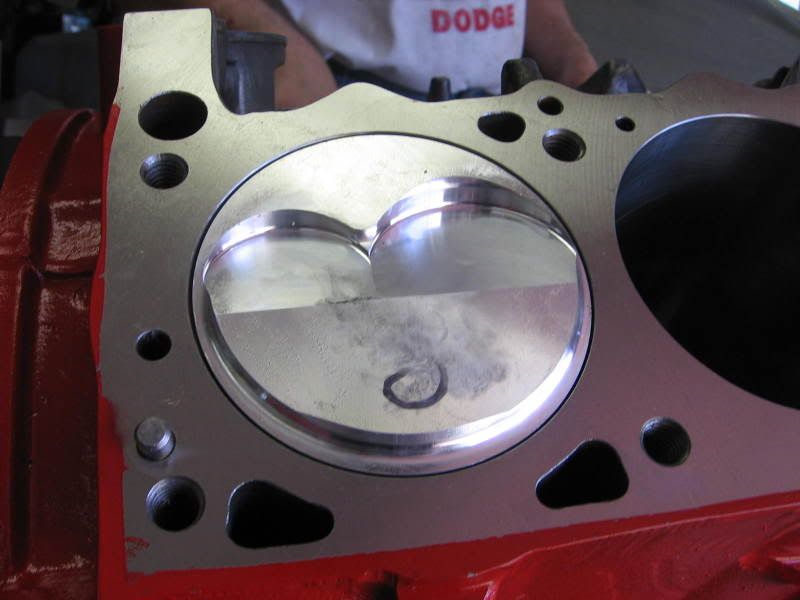

Man that is going to be a great motor! The deck height sure is awesome!

Can't wait to see the heads going on top of all of that piston.

Can't wait to see the heads going on top of all of that piston.

Pistons, and rods are now installed. Took a bit......... and we covered it up toot sweet......

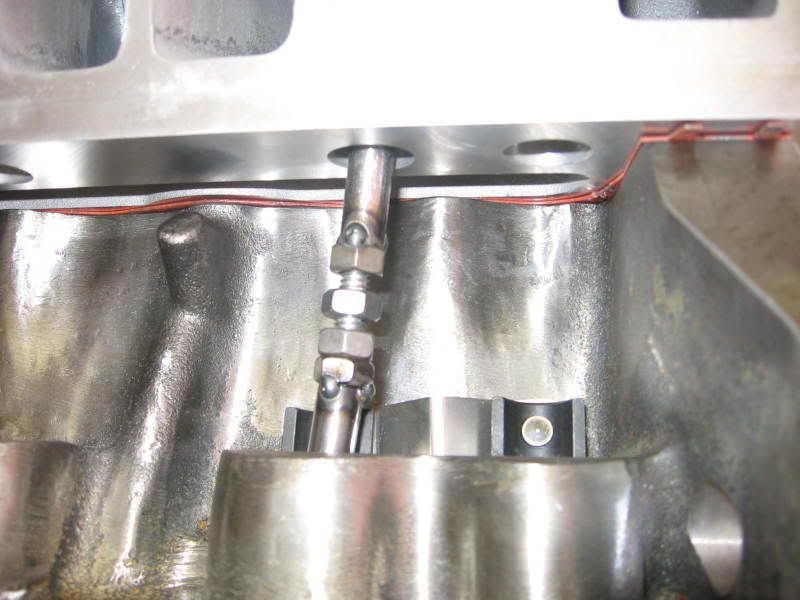

We have moved on to the rocker/valve system and checked all the tolerances we could think of,........... and maybe a few of our own.

We made our own pushrod tool so we can find optimum lengths....

We have moved on to the rocker/valve system and checked all the tolerances we could think of,........... and maybe a few of our own.

We made our own pushrod tool so we can find optimum lengths....

-

Similar threads

- Replies

- 5

- Views

- 173

- Replies

- 22

- Views

- 1K

- Replies

- 178

- Views

- 4K