Tomorrow I'll report back with the resultmagnet on a stick

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Green Bearings - 8.75 rear end

- Thread starter 318willrun

- Start date

-

abodyjoe

Well-Known Member

Installed Green bearings from Dr Diff. He said to take out the thrust button.

He told me I didn't have to remove it with the axles and green bearings I bought from him.

In the past I've always delt with Moser and never had to pull it out.

Anybody have any photos? The button on my 66 was about as big as a dime with a tit that went into the centering hole in the axle. One axle pushes against the other with the button in between. Some photos I see on the net look like a metal disc that gets stays in the carrier when the axles are pulled.

I wonder if his axles are a tad shorter.....He told me I didn't have to remove it with the axles and green bearings I bought from him.

In the past I've always delt with Moser and never had to pull it out.

jimjimjimmy

lobsterman

I wonder if his axles are a tad shorter.....

no the difference is in the bearings old style vs new style

If it is a clutch type you might be able to rig up a small center punch to a long piece of pipe and drive the button off the roll pin. Then retrieve the buttons one in each axle tube with a magnet. If it is a cone type, forget it, the third member has to come out and the SG taken apart to remove the thrust unit.

but there is a chance I have the new style?? Is there a positive visual difference that I can look tomorrow?no the difference is in the bearings old style vs new style

It's not a sure grip. It's a open unit. 2.76 741 castingIf it is a clutch type you might be able to rig up a small center punch to a long piece of pipe and drive the button off the roll pin. Then retrieve the buttons one in each axle tube with a magnet. If it is a cone type, forget it, the third member has to come out and the SG taken apart to remove the thrust unit.

Then you have two options. 1) remove the third member, remove the cross shaft and take the thrust block out. or 2) short one or both axles a little.

I thought about pulling both axles and putting a film of red paint on the end and see by flashlight if they touch the button.Then you have two options. 1) remove the third member, remove the cross shaft and take the thrust block out. or 2) short one or both axles a little.

Just install one axle all the way in without nuts, slide the other one in and see if it pushes the first one out.

When I installed them, both axles went flush to the backing plate. I can test it the way you mentioned, that's a good way. I can have somebody hold one axle in by hand firmly against the backing plate, then I can push the other in and see if it reflects on the other.Just install one axle all the way in without nuts, slide the other one in and see if it pushes the first one out.

abodyjoe

Well-Known Member

I wonder if his axles are a tad shorter.....

not sure but when ever i got moser axles it was the same. never removed it.

jimjimjimmy

lobsterman

but there is a chance I have the new style?? Is there a positive visual difference that I can look tomorrow?

the old style has a crimped on 5 hole flange .

mderoy340

Well-Known Member

Agree, old style crimped.the old style has a crimped on 5 hole flange .

New style has snap ring.

green bearing install

abodyjoe

Well-Known Member

from @DoctorDiff 's web site... Why Green Bearings? - Quality Body Shop Drivetrain

The need for non-adjustable wheel bearings

Most of these problems can be avoided by installing non-adjustable sealed ball “Green” wheel bearings. The name comes from the Green Bearing Company which first produced them. The company has since been purchased by Bearing Technologies.

Unfortunately, the original Mopar Green wheel bearing design has 2 problems.

First generation (RP-400) Green bearings, still sold by Mopar Performance and others, are problematic because the crimped-on flange will not allow the bearing to wiggle around inside a housing that is not perfectly straight (none are).

In addition, the design causes the axle to be inserted DEEPER into the housing than necessary. This results in pre-loading against the differential thrust block and early bearing failure.

Second generation (MO-400) snap-ring style Green bearings are forgiving because they can move around inside the housing and they do not preload the differential thrust block in a stock application.

Most guys who have problems with Green bearings are running the RP-400 first generation version or incorrectly made aftermarket axles or housings or poorly designed rear disc brake kits, all of which cause pre-loading and premature bearing failure.

I have several customers running MO-400 snap-ring Green bearings in daily drivers. The design is no different than what came stock in millions of other vehicles, including ’60s era Mopar 7.25″ and Ford 9″ rears. (For example, see here) I do not stock, nor do I recommend the first generation RP-400 Green bearing with the crimped-on 5 hole retainer. I only carry the “loose fit, snap ring style” second generation MO-400 design.

mycuda

Well-Known Member

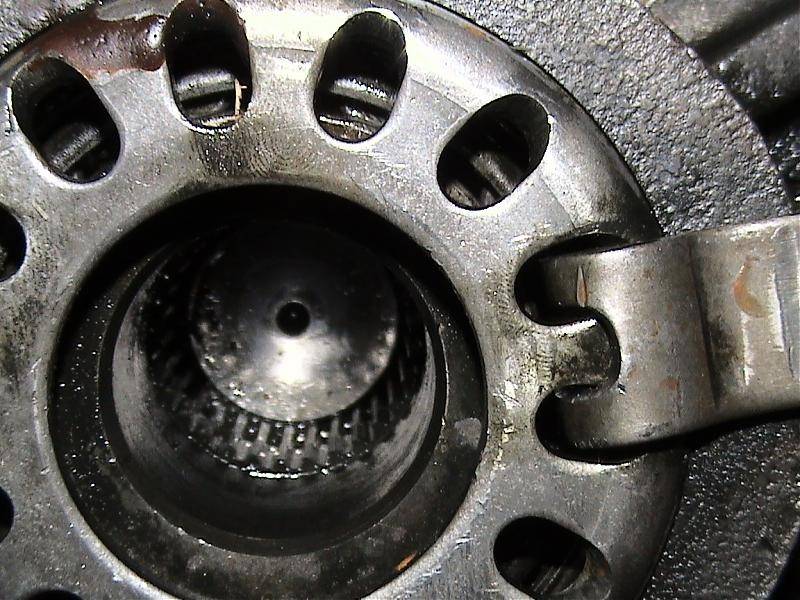

Pull axles look down housing with flashlight. You see 3/8" hole in center of carrier, good no button.

If you see carriage bolt looking or giant rivethead rounded buttonhead. Use extension magnet and remove both.

If you see carriage bolt looking or giant rivethead rounded buttonhead. Use extension magnet and remove both.

Yes, open diff and cone type sure grip has a slot through the the thrust block that the cross pin passes through. Hoping your axles aren't butting up against it and you don't have to pull the center section.

Pulled a axle back out, here are some pictures of my bearings. I see "O" rings, but no snap rings.

ok, did these 4 things.

- I removed all axle bolts and pulled the one out. I had my wife hold some pressure against the axle still in the housing and I put the other in and hit it with the palms of my hands and she said her side didn't move at all nor did she even feel the "hitting" on her axle.

- Next, I put orange paint on the end of my axle and installed it, tightened down 2 nuts and then removed it. There was no paint on the thrust button nor was the paint on the end of my axle disturbed.

- I measured from the button to where the retainer plate bolts flush against, then I measured from the retainer plate to the end of the axle and the axle length looked to be least a 1/16 shorter.

- Just for peace of mind, I ground about .015 off the end of one axle and assembled. I'm confident that these axles are not butting up to the button.

You have the old style green bearings.

I don't remember the open carrier having anything but a pin for the small carrier gears. No block or button like a sure grip has. Imbwbidi

I don't remember the open carrier having anything but a pin for the small carrier gears. No block or button like a sure grip has. Imbwbidi

yeah, I think the bearings should be ok, axles are not touching the thrust button. there the "button", looks like a sure grip one.You have the old style green bearings.

I don't remember the open carrier having anything but a pin for the small carrier gears. No block or button like a sure grip has. Imbwbidi

I have to ask, is there a block or a button. Is there a difference between years or carriers? My 66 had a button that fit in the center drill hole in the end of the axle. I retrieved it with a magnet taped to a piece of redi rod and I put it back in with a dab of grease to hold it. You guys are talking about a block that you have to pull the pin to remove. The first 2 picks are the button and the second 2 are the block from what I can tell.

I believe this.....

-

Similar threads

- Replies

- 29

- Views

- 2K

- Replies

- 1

- Views

- 448