magnumdust

Well-Known Member

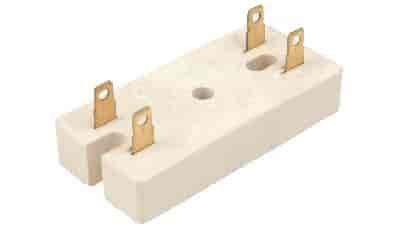

Just finished wiring my 4pin hei and now I can't get the car to start most of the time.

I think I have the wiring right. I run a wire from the neg post to the correct pin(b I think) then I have the switched wire/ pos wire from coil connected together on one side of a wire connector and the other side goes to it's correct pin.

Then the other side of the hei box goes to the dist per instructions.

The module is mounted where my old mopar box was with a piece of scrap metal i found in my garage. I "think" it's either a polished alum or stainless steel.

Car gas started twice, once while checking spark with the #1 wire and a screwdriver across the valvecover. And a second time after trying to reseat the pin Connectors.

Any ideas?

I think I have the wiring right. I run a wire from the neg post to the correct pin(b I think) then I have the switched wire/ pos wire from coil connected together on one side of a wire connector and the other side goes to it's correct pin.

Then the other side of the hei box goes to the dist per instructions.

The module is mounted where my old mopar box was with a piece of scrap metal i found in my garage. I "think" it's either a polished alum or stainless steel.

Car gas started twice, once while checking spark with the #1 wire and a screwdriver across the valvecover. And a second time after trying to reseat the pin Connectors.

Any ideas?