POS Dakota

Anti-Socialist

I decided to open the box and check them out.

Man are they nice!!!! =P~ I'm impressed.

If you have a magnum headed motor and the stud rockers got you down with all the flex and guideplate doo doo, you should really check these out.

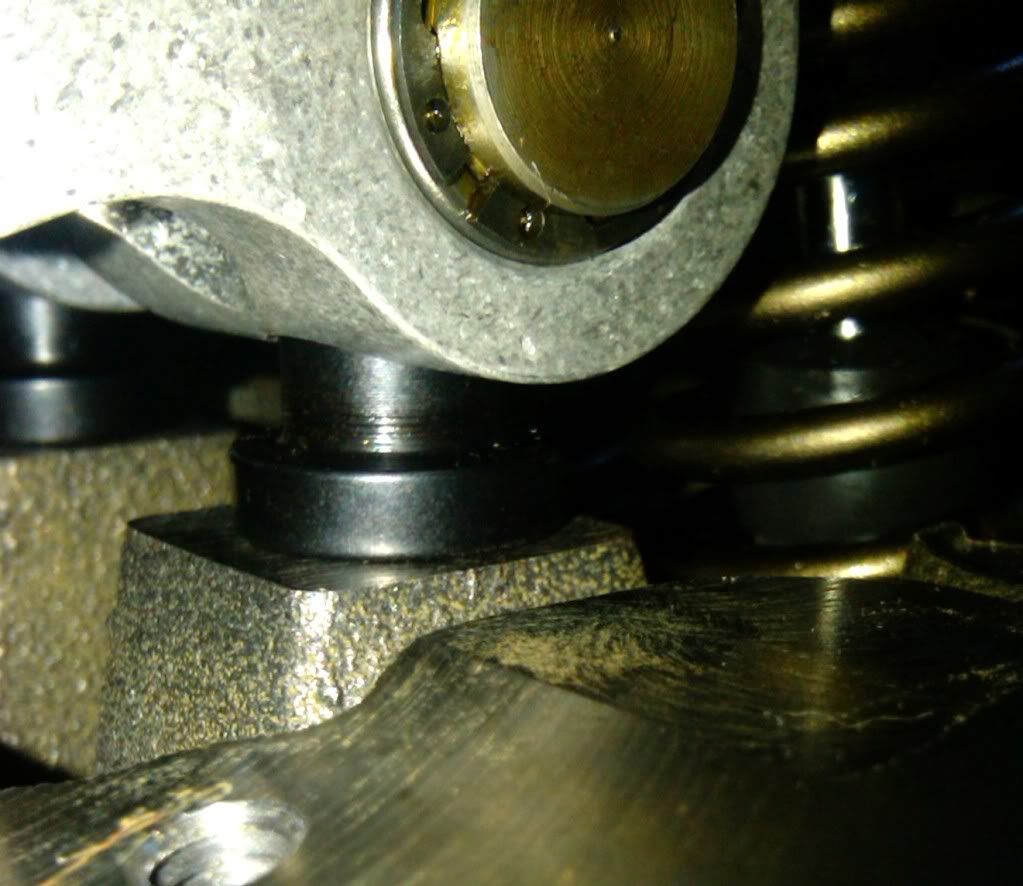

They are basically an intake and exhaust rocker joined by a common shaft that bolts to the magnum stud bosses with 2 pedestals per "unit" that has a saddle on top and a wide base at the bottom. The shaft is secured through the pedestal into the boss of the head with an allen capscrew that postitively locates everything and creates and extremely solid system.

Very high quality and very nice.

I posted this because I am assuming there aren't a lot of these out there. I havent seen any pics other than the hughes site and I am sure there are others with curiosity. I searched around and didnt see anyone having them.

Thought I would share.

I attached some pics so you could see what your 590 bucks shipped gets you. Yeah, they cost twice as much as a set of good chevy stud rockers. About the same as a set of racer browns with pushrods which are the only comparable setup I know of. But they are definitely high quality, and I have no reservations. They will withstand more punishment than a single studmount chevy rocker with greater accuracy and stability I am sure.

Anyone know who makes these rockers? They remind me of TD rockers. I posted a pic of the pushrod part# too. Anyone recognize that? They look like nice pushrods. They are ball/ball oil-through for a hyd roller setup and are 7.45 inch. Black oxide coated and no different than any comp pushrod I have seen...

If you are leary of using a magnum head because the rockers are less stable than the LA shaft system, these put things on a pretty much even playing field.

Man are they nice!!!! =P~ I'm impressed.

If you have a magnum headed motor and the stud rockers got you down with all the flex and guideplate doo doo, you should really check these out.

They are basically an intake and exhaust rocker joined by a common shaft that bolts to the magnum stud bosses with 2 pedestals per "unit" that has a saddle on top and a wide base at the bottom. The shaft is secured through the pedestal into the boss of the head with an allen capscrew that postitively locates everything and creates and extremely solid system.

Very high quality and very nice.

I posted this because I am assuming there aren't a lot of these out there. I havent seen any pics other than the hughes site and I am sure there are others with curiosity. I searched around and didnt see anyone having them.

Thought I would share.

I attached some pics so you could see what your 590 bucks shipped gets you. Yeah, they cost twice as much as a set of good chevy stud rockers. About the same as a set of racer browns with pushrods which are the only comparable setup I know of. But they are definitely high quality, and I have no reservations. They will withstand more punishment than a single studmount chevy rocker with greater accuracy and stability I am sure.

Anyone know who makes these rockers? They remind me of TD rockers. I posted a pic of the pushrod part# too. Anyone recognize that? They look like nice pushrods. They are ball/ball oil-through for a hyd roller setup and are 7.45 inch. Black oxide coated and no different than any comp pushrod I have seen...

If you are leary of using a magnum head because the rockers are less stable than the LA shaft system, these put things on a pretty much even playing field.