Well good. Glad you got it taken care of. I have confidence in your repair. I never have had much luck getting the seal out without loosening the mains, either. I think I've been able to do it maybe twice.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

James’ 1974 W200 build

- Thread starter mopardude318

- Start date

-

Okay put oil in it yesterday, and a new Wix filter.... it’s 95% better. There’s an ever so slight “looks like it’s gonna drip” from the rear seal area. Doesn’t seem to sling oil while I drive everything looks clean, but when I park it, it will weep a small tiny bit, but not drop.

I can live with that. I’m good. LOL.

Can’t get it perfect when you’re on your back and have oil dripping in your face. LOL.

I can live with that. I’m good. LOL.

Can’t get it perfect when you’re on your back and have oil dripping in your face. LOL.

Last edited:

Okay I got the exhaust done today. It’s an okay job, it sounds okay, not as loud as I thought it should be. Lol. 2.5” from the headers, crossover into the 2.5” Y-pipe, then from there 3” into the muffler and out the back. It’s done and I can drive it around. Still need a set of shocks. LOL

How's your front drive shaft angle.

After a 6" Superlift spring kit mine was yoke binding at the transfer case. Even after wedge shims on the Dana 44. My rear is an 8-3/4 and had no issues on that end. 74 W100 long bed. Did not change my intermediate shaft. Did you lower the T-case?

After a 6" Superlift spring kit mine was yoke binding at the transfer case. Even after wedge shims on the Dana 44. My rear is an 8-3/4 and had no issues on that end. 74 W100 long bed. Did not change my intermediate shaft. Did you lower the T-case?

How's your front drive shaft angle.

After a 6" Superlift spring kit mine was yoke binding at the transfer case. Even after wedge shims on the Dana 44. My rear is an 8-3/4 and had no issues on that end. 74 W100 long bed. Did not change my intermediate shaft. Did you lower the T-case?

man that’s odd. You shouldn’t have an issue, being a divorced transfer case gives you more leeway for driveline angles.

I have a Dana 60 up front. I changed all yokes and U-joints to 1410, which is the same as a 1350 only Wider, they give you a little more angle allowance as well. I have a 4” spring lift and 1” shackle and spring mount lift. I did not move my transfer case.

not sure why you have binding issues

Muffler just looks like a swole spot in the pipe. lol

LOL. Yea it’s just a little bullet muffler. Dynomax knock off, I’d rather he used an actual DynoMax Race Bullet like I specified, but guess that’s what he had in stock to get the job done. I dunno.Muffler just looks like a swole spot in the pipe. lol

I got more things to worry about like my damn clutch that’s not releasing all the way, I adjusted it both ways... throw out bearing close to the pressure plate fingers, still not releasing on it own, same thing when I adjust it with the bearing riding on the fingers. I don’t know, I think I got a Bum pressure plate from Mcleod...

LOL. Yea it’s just a little bullet muffler. Dynomax knock off, I’d rather he used an actual DynoMax Race Bullet like I specified, but guess that’s what he had in stock to get the job done. I dunno.

I got more things to worry about like my damn clutch that’s not releasing all the way, I adjusted it both ways... throw out bearing close to the pressure plate fingers, still not releasing on it own, same thing when I adjust it with the bearing riding on the fingers. I don’t know, I think I got a Bum pressure plate from Mcleod...

What type clutch? B&B or diaphragm?

Diaphragm. There is no over center spring on these clutch pedals. I don’t think trucks have them?What type clutch? B&B or diaphragm?

this clutch kit

McLeod Racing 75208 McLeod Super StreetPro Clutch Kits | Summit Racing

Diaphragm. There is no over center spring on these clutch pedals. I don’t think trucks have them?

this clutch kit

McLeod Racing 75208 McLeod Super StreetPro Clutch Kits | Summit Racing

It's not supposed to have one with the diaphragm clutch anyway. You 100% sure it doesn't have one?

Yes sir I’m sure cuz I was under there looking for one to remove it. lolIt's not supposed to have one with the diaphragm clutch anyway. You 100% sure it doesn't have one?

I verified I have the proper clutch fork and linkage. Z bar is in top shape all rebuilt with New clips and bushings.

okay I’m laying under there and the clutch it is fact releasing all the way when I have a helper push the clutch. I think something inside the transmission is wrong. I rebuilt the son of a gun, but I may have some clearances too tight, causing a drag or cluster gear may be spinning or some ****. Damn I don’t know. Might have to pull it and check all the in the service manual.

Taking the truck apart again. Blew a head gasket, I’m pulling the engine and trans. I have another NP435 I had rebuilt professionally, so I’ll pull my trans apart and see what I screwed up in this one. Heads will be sent to IMM Engines to open the chambers to 70cc to lower my compression to a more pump friendly 9.9. Port job will also be done with new valves & springs to match a new solid lifter flat tappet cam.

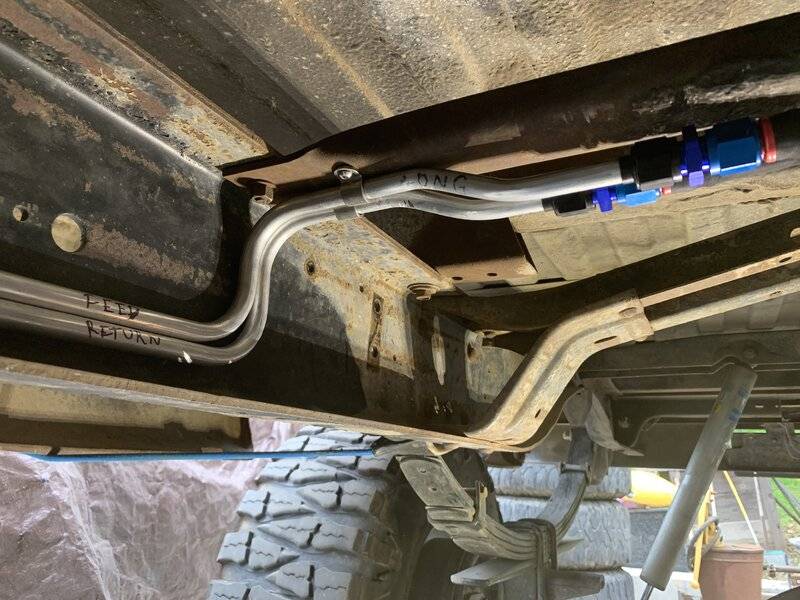

I removed the fuel tank. Drilled a couple holes for the Aeromotive in tank pump. Will have 1/2” feed and return lines. Trying out a stand alone floatless sending unit, because there isn’t one with the Aeromotive setup.

It might work. Worth a try.

j par

Well-Known Member

Did you notice that elbow that you took out and put that AN fitting in for the breather it had a check ball in it?...It might work. Worth a try.

View attachment 1715828291

View attachment 1715828293

View attachment 1715828294

Yes, at the end of the hose there was something molded into the hose itself. I think it was just a really small hole, like it necked down really tiny inside, not a check valve.Did you notice that elbow that you took out and put that AN fitting in for the breather it had a check ball in it?...

But because the factory sender had a 1/2 tube on top that went to the filler neck overflow, I drilled the original vent hole a little larger to accommodate that AN fitting and I’ll now use that as the filler tube over flow. And then use the vent on the Aeromotive unit plumbed to a rollover valve... hope that works.

I just have to figure out how I’m gonna replicate this filler tube. This one here leaks.

It’s 2” on the tank and necks down to 1-3/4 on the metal fill tube under the truck.

they don’t reproduce these. Lame.

It’s 2” on the tank and necks down to 1-3/4 on the metal fill tube under the truck.

they don’t reproduce these. Lame.

Okay I cut it out just now. Don’t know if a piece went missing over the years or not. That’s it.

j par

Well-Known Member

I was just dealing with that as I was hooking up the Factory lines that I refurbished. I swore that it was clogged but then I got to cleaning it out and it rattled.. then I figured out it was a check valve... For the life of me I've seen one of those around my shop and I searched and I searched and I searched a couple days ago... The reason I noticed is because about an hour ago I stumbled upon it when I wasn't looking for it just like I knew I would one day...Yes, at the end of the hose there was something molded into the hose itself. I think it was just a really small hole, like it necked down really tiny inside, not a check valve.

But because the factory sender had a 1/2 tube on top that went to the filler neck overflow, I drilled the original vent hole a little larger to accommodate that AN fitting and I’ll now use that as the filler tube over flow. And then use the vent on the Aeromotive unit plumbed to a rollover valve... hope that works.

Gas tank installed. started on the fuel lines this weekend. It’ll be raining all this week. I’m working under a tarp. I need one of them Costco carports. Used to be $225, now they are $350! ;<

j par

Well-Known Member

That looks like some real quality work there!...Gas tank installed. started on the fuel lines this weekend. It’ll be raining all this week. I’m working under a tarp. I need one of them Costco carports. Used to be $225, now they are $350! ;<

View attachment 1715835707

View attachment 1715835708

View attachment 1715835709

View attachment 1715835710

View attachment 1715835711

View attachment 1715835712

View attachment 1715835713

View attachment 1715835714

It's weird on my club cab it actually runs to the outside then back inside of the frame. It's a nice place for me to put a fuel filter...

I'm on my second Costco garage. I lost my first one last winter due to my negligence of not pushing the snow off the top of it. It lasted 5 years and really could have lasted a lot longer. I have friends and customers with other types of garages but I feel the Costco one is by far superior and has more options. And easily set up. One tip for these garages is definitely put the whole thing together and don't leave the front or back off of it as all of it together is its own support. Also any word you can put it to keep it out of the wind... If not tie that sucker down to 5 gallon buckets of cement at each post...

Thank you, it sure is time consuming, I’ve had those lines in and out 45 times, trying to get the bends right. LOL.That looks like some real quality work there!...

It's weird on my club cab it actually runs to the outside then back inside of the frame. It's a nice place for me to put a fuel filter...

I'm on my second Costco garage. I lost my first one last winter due to my negligence of not pushing the snow off the top of it. It lasted 5 years and really could have lasted a lot longer. I have friends and customers with other types of garages but I feel the Costco one is by far superior and has more options. And easily set up. One tip for these garages is definitely put the whole thing together and don't leave the front or back off of it as all of it together is its own support. Also any word you can put it to keep it out of the wind... If not tie that sucker down to 5 gallon buckets of cement at each post...

The original fuel line also was inside the frame, then ran through it to the outside to pass the transfer case then came back inside. The 2 pieces were joined with rubber hose. I don’t know why they did that. I prefer to keep everything inside the frame.

My first Costco carport was excellent, I bought it and put it up. A month later we had a wind storm and it flew away turned into a pretzel. Was not too happy about that!! Costly mistake!

j par

Well-Known Member

Yes where that rubber hose comes out and goes back in is where I put one of those clear fuel filters with those hose clamps that have a built-in finger twist...Thank you, it sure is time consuming, I’ve had those lines in and out 45 times, trying to get the bends right. LOL.

The original fuel line also was inside the frame, then ran through it to the outside to pass the transfer case then came back inside. The 2 pieces were joined with rubber hose. I don’t know why they did that. I prefer to keep everything inside the frame.

My first Costco carport was excellent, I bought it and put it up. A month later we had a wind storm and it flew away turned into a pretzel. Was not too happy about that!! Costly mistake!

That way it's easy to see if it's clogged or dirty and no tools are needed to change it if need be on the fly...

j par

Well-Known Member

I reread through some of this and was looking for the size of rims that you're using? 15, 16, 16-1/2? Reason I'm asking is for the disc brakes. I have the original 16 and 1/2 and not sure if I could do a 15...?..I did a disc brake conversion on the Drum brake Dana 44. I used Chevy parts off a 10 bolt front end. it’s all about the same stuff

also hurt that 360 couple weeks ago like I said in the crank breakers thread..dropped a valve. Lead foot Lenny. LOL

View attachment 1715687639 View attachment 1715687640 View attachment 1715687642 View attachment 1715687644 View attachment 1715687645 View attachment 1715687646 P

The fuel line stuff is great. You said the exhaust isn't as loud as you had hoped. If you take that dumbfuck cross over/wye off and run real duals, you will get that crisp sound back. Cross overs suck dead rotten roach infested, puss droolin, bleedin elephant elephant balls.

-

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 8

- Views

- 1K