You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lean idle. Rich cruise.

- Thread starter aaronk785

- Start date

-

9secRR

Well-Known Member

Locked out at 37* at idle which is at 1500 rpm.Where is the timing at 5800 and at 7000?

You probably need 2 degrees more at 7000 than you do at 5800.

Are you foot breaking or on the trans brake?

Damn. I had one more question and I forgot it. If I think of it it I’ll ask.

Trans brake

9secRR

Well-Known Member

I haven’t fired car up with the new ignition. Hopefully Saturday

TT5.9mag

Two atmospheres are better than one

@Newbomb Turk have you tested a 7AL-3 on your machine yet? Should he expect 3-4 degrees of retard like the other MSD boxes?

fasttcars

Well-Known Member

While working at AMS engines we would dyno about every second day. Just by locking out the distributor on a healthy street engine would stabilize the curve and would add a automatic 10hp. Not to sure what this guy is talking about since the common knowledge after 100's of dyno tests shows the timing is more stable so helps increase power. With a big stall converter the advance is going to be all in anyways so the main variance is not having weights and springs to flop around. Never once heard in my decades of building that it cost 20-30 HP. No logical reason for it to. The logical reasoning and proof shows otherwise. Can ask any of the top builders in the world. It's also well known that retarding the timing at the top of every gear can pickup MPH so if the timing does happen to drop a bit by swell that can be a positive advantage. Possibly one distributor that they used has a issue which caused negative results on a full throttle dyno pull. Most Mopar guys have known forever that they love a super fast advance getting all the timing in ASAP. That was the benefit of the light weight springs. When timing was all in by 1800RPM what exact full throttle timing curve is even happening lol. Honestly for going fast who really cares about picking up some performance under part throttle low speed rides. We aren't pulling a dang trailer up the mountains in our Hot rods lol. Which may be the point that's being refered to since it is a possibility to pickup some potential very low speed performance with a vaccum advance curve that adds extra timing. Both very different scenarios. One that really doesn't matter much in a full throttle race car. The other is to help save at the pump. I've tried both several times on my own street and race vehicles. The higher performance ones idled and ran much better with locked timing. The mild ones have a vaccum advance for increased economy but it's a noticeable difference in which ones have the more stable timing under heavy throttle.i want to see time slips that prove this? if it's 20-30 HP more HP, the ET and MPH will change.

To add power valve selection is also ones friend for tuning cruise enrichment. Blocked power valves noticeably run much different while cruising. They even sound different. I know one great tuner that tunes some multiple thousand HP street cars who uses a very different approach that's normally used with power valves but with great success.

Last edited:

TT5.9mag

Two atmospheres are better than one

Well you got one thing correct.Not to sure what this guy is talking about

fasttcars

Well-Known Member

What kind of carb is used? Power valve size? Remember plugs are the soldiers on the front line and the only ones that will truly tell you what's happening. Like Andy said you can't always trust AFR meters. Plugs you can always trust. What heat range of plug? Does the carb have a secondary idle setting screw? Front and back should be set equal. Remember KISS keep it simple before totally changing everything out of whack in the carb. I see it all to many times. 02 says one thing plugs tell a whole other story. Just the angle and position of the 02 will change the readings. It's not a mild cam anymore which really changes the effectiveness of the 02 metering. Most turbo EFi that use 02 tuning run shorter duration much wider LSA which will give much more accurate readings. That's why even over 1000HP boosted cars idle much smoother. The 5000hp stuff is a different story again. . Are you trying to get fuel economy,go fast or somewhere in between?Idle screws are at 7/8 out now. Turning them out makes cruise richen up. Jetted down 4 sizes in front and still super rich at cruise and wot.

Pulling timing in high gear or adding timing in high gear has been a debate for many, many years. The answer is "do what the car wants".

There is some good theory behind both and it has to do with the fuel curve of the carb. Adding or pulling timing is often a crutch to fix a fuel curve issue. EFI engines might not need timing correction going down the track. And what works on the dyno might not work at the track. They dyno loading is a lot different than the load that the engine sees in the car going thru the gears. So the timing curve that picks up power on the dyno might not be the best at the track.

There is some good theory behind both and it has to do with the fuel curve of the carb. Adding or pulling timing is often a crutch to fix a fuel curve issue. EFI engines might not need timing correction going down the track. And what works on the dyno might not work at the track. They dyno loading is a lot different than the load that the engine sees in the car going thru the gears. So the timing curve that picks up power on the dyno might not be the best at the track.

9secRR

Well-Known Member

you are correct.While working at AMS engines we would dyno about every second day. Just by locking out the distributor on a healthy street engine would stabilize the curve and would add a automatic 10hp. Not to sure what this guy is talking about since the common knowledge after 100's of dyno tests shows the timing is more stable so helps increase power. With a big stall converter the advance is going to be all in anyways so the main variance is not having weights and springs to flop around. Never once heard in my decades of building that it cost 20-30 HP. No logical reason for it to. The logical reasoning and proof shows otherwise. Can ask any of the top builders in the world. It's also well known that retarding the timing at the top of every gear can pickup MPH so if the timing does happen to drop a bit by swell that can be a positive advantage. Possibly one distributor that they used has a issue which caused negative results on a full throttle dyno pull. Most Mopar guys have known forever that they love a super fast advance getting all the timing in ASAP. That was the benefit of the light weight springs. When timing was all in by 1800RPM what exact full throttle timing curve is even happening lol. Honestly for going fast who really cares about picking up some performance under part throttle low speed rides. We aren't pulling a dang trailer up the mountains in our Hot rods lol. Which may be the point that's being refered to since it is a possibility to pickup some potential very low speed performance with a vaccum advance curve that adds extra timing. Both very different scenarios. One that really doesn't matter much in a full throttle race car. The other is to help save at the pump. I've tried both several times on my own street and race vehicles. The higher performance ones idled and ran much better with locked timing. The mild ones have a vaccum advance for increased economy but it's a noticeable difference in which ones have the more stable timing under heavy throttle.

To add power valve selection is also ones friend for tuning cruise enrichment. Blocked power valves noticeably run much different while cruising. They even sound different. I know one great tuner that tunes some multiple thousand HP street cars who uses a very different approach that's normally used with power valves but with great success.

9secRR

Well-Known Member

Pulling timing in high gear or adding timing in high gear has been a debate for many, many years. The answer is "do what the car wants".

There is some good theory behind both and it has to do with the fuel curve of the carb. Adding or pulling timing is often a crutch to fix a fuel curve issue. EFI engines might not need timing correction going down the track. And what works on the dyno might not work at the track. They dyno loading is a lot different than the load that the engine sees in the car going thru the gears. So the timing curve that picks up power on the dyno might not be the best at the track.

i asked to see time slips to back up this theory since the dyno is completely different the the track.

Locked out at 37* at idle which is at 1500 rpm.

Trans brake

Ok, I doubt you have 37 degrees at 5800 and up. And probably less than that even at lower RPM.

All ignition boxes retard with RPM. They don’t retard at the same RPM and at the same rate, even comparing boxes with the same part number.

Other than not knowing exactly what the timing really is, you’d probably be one of the few I left locked out. But that’s pretty rare.

If you were foot braking it, I’d probably still have a curve in it. Getting from low RPM at the hit to stall speed goes much cleaner with a curve.

@Newbomb Turk have you tested a 7AL-3 on your machine yet? Should he expect 3-4 degrees of retard like the other MSD boxes?

I haven’t. But it will retard. At what RPM and how much there is no way of telling until you test for it.

While working at AMS engines we would dyno about every second day. Just by locking out the distributor on a healthy street engine would stabilize the curve and would add a automatic 10hp. Not to sure what this guy is talking about since the common knowledge after 100's of dyno tests shows the timing is more stable so helps increase power. With a big stall converter the advance is going to be all in anyways so the main variance is not having weights and springs to flop around. Never once heard in my decades of building that it cost 20-30 HP. No logical reason for it to. The logical reasoning and proof shows otherwise. Can ask any of the top builders in the world. It's also well known that retarding the timing at the top of every gear can pickup MPH so if the timing does happen to drop a bit by swell that can be a positive advantage. Possibly one distributor that they used has a issue which caused negative results on a full throttle dyno pull. Most Mopar guys have known forever that they love a super fast advance getting all the timing in ASAP. That was the benefit of the light weight springs. When timing was all in by 1800RPM what exact full throttle timing curve is even happening lol. Honestly for going fast who really cares about picking up some performance under part throttle low speed rides. We aren't pulling a dang trailer up the mountains in our Hot rods lol. Which may be the point that's being refered to since it is a possibility to pickup some potential very low speed performance with a vaccum advance curve that adds extra timing. Both very different scenarios. One that really doesn't matter much in a full throttle race car. The other is to help save at the pump. I've tried both several times on my own street and race vehicles. The higher performance ones idled and ran much better with locked timing. The mild ones have a vaccum advance for increased economy but it's a noticeable difference in which ones have the more stable timing under heavy throttle.

To add power valve selection is also ones friend for tuning cruise enrichment. Blocked power valves noticeably run much different while cruising. They even sound different. I know one great tuner that tunes some multiple thousand HP street cars who uses a very different approach that's normally used with power valves but with great success.

Ok lol

While working at AMS engines we would dyno about every second day. Just by locking out the distributor on a healthy street engine would stabilize the curve and would add a automatic 10hp. Not to sure what this guy is talking about since the common knowledge after 100's of dyno tests shows the timing is more stable so helps increase power. With a big stall converter the advance is going to be all in anyways so the main variance is not having weights and springs to flop around. Never once heard in my decades of building that it cost 20-30 HP. No logical reason for it to. The logical reasoning and proof shows otherwise. Can ask any of the top builders in the world. It's also well known that retarding the timing at the top of every gear can pickup MPH so if the timing does happen to drop a bit by swell that can be a positive advantage. Possibly one distributor that they used has a issue which caused negative results on a full throttle dyno pull. Most Mopar guys have known forever that they love a super fast advance getting all the timing in ASAP. That was the benefit of the light weight springs. When timing was all in by 1800RPM what exact full throttle timing curve is even happening lol. Honestly for going fast who really cares about picking up some performance under part throttle low speed rides. We aren't pulling a dang trailer up the mountains in our Hot rods lol. Which may be the point that's being refered to since it is a possibility to pickup some potential very low speed performance with a vaccum advance curve that adds extra timing. Both very different scenarios. One that really doesn't matter much in a full throttle race car. The other is to help save at the pump. I've tried both several times on my own street and race vehicles. The higher performance ones idled and ran much better with locked timing. The mild ones have a vaccum advance for increased economy but it's a noticeable difference in which ones have the more stable timing under heavy throttle.

To add power valve selection is also ones friend for tuning cruise enrichment. Blocked power valves noticeably run much different while cruising. They even sound different. I know one great tuner that tunes some multiple thousand HP street cars who uses a very different approach that's normally used with power valves but with great success.

When locking out the timing did you account for retard?

Timing stability is easy to get if you aren’t married to some way of thinking.

I can tell by what you wrote you haven’t read what Bill Jenkins said in 1975. That science hasn’t changed.

Last edited:

Pulling timing in high gear or adding timing in high gear has been a debate for many, many years. The answer is "do what the car wants".

There is some good theory behind both and it has to do with the fuel curve of the carb. Adding or pulling timing is often a crutch to fix a fuel curve issue. EFI engines might not need timing correction going down the track. And what works on the dyno might not work at the track. They dyno loading is a lot different than the load that the engine sees in the car going thru the gears. So the timing curve that picks up power on the dyno might not be the best at the track.

I know some guys who weren’t traction limited were adding 3-4 degrees of timing at the hit to get the car moving and they pulled it out at the gear change.

I know the guys with powerglides didn’t do it because the engine didn’t want all that timing all the way through low gear.

fasttcars

Well-Known Member

That's one thing I would have added as well and completely agree on. The tune on the dyno isn't always the same as down the track. A cpl more variants that need to be taken into account but are in plain sight and not always considered which I've seen many not taken into consideration. The incoming air on the dyno is usually from straight above which also has a different effect from a vehicle traveling 100++ mph . I know many race teams in the highest ranks have specific dyno carbs and specific track carbs. The tune is usually different for each situation. Yes every specific combo can have a different outcome with a tune. On the same page in most cases very specific details have also had the same outcome. Luckily for us engines are basically a repeatable mathematical equation. If they weren't we would have to start from scratch everytime we took them out At least that can give us all a generalized baseline to start with that has worked in most situations. If things need to change drastically from what works in general form the first KISS rule is make sure the basics are covered. In most cases something was missed. Last venue should be making drastic changes.Pulling timing in high gear or adding timing in high gear has been a debate for many, many years. The answer is "do what the car wants".

There is some good theory behind both and it has to do with the fuel curve of the carb. Adding or pulling timing is often a crutch to fix a fuel curve issue. EFI engines might not need timing correction going down the track. And what works on the dyno might not work at the track. They dyno loading is a lot different than the load that the engine sees in the car going thru the gears. So the timing curve that picks up power on the dyno might not be the best at the track.

TT5.9mag

Two atmospheres are better than one

I know on Westech’s dyno the 7AL-3 box is a few degrees different (don’t remember more or less) than the other box they use (and I don’t remember which is the other box) but they account for it.I haven’t. But it will retard. At what RPM and how much there is no way of telling until you test for it.

I know on Westech’s dyno the 7AL-3 box is a few degrees different (don’t remember more or less) than the other box they use (and I don’t remember which is the other box) but they account for it.

That’s what you have to do. Account for it.

i asked to see time slips to back up this theory since the dyno is completely different the the track.

It’s SLIGHTLY different going from the dyno to the track. It’s not like it’s some massive change.

While working at AMS engines we would dyno about every second day. Just by locking out the distributor on a healthy street engine would stabilize the curve and would add a automatic 10hp. Not to sure what this guy is talking about since the common knowledge after 100's of dyno tests shows the timing is more stable so helps increase power. With a big stall converter the advance is going to be all in anyways so the main variance is not having weights and springs to flop around. Never once heard in my decades of building that it cost 20-30 HP. No logical reason for it to. The logical reasoning and proof shows otherwise. Can ask any of the top builders in the world. It's also well known that retarding the timing at the top of every gear can pickup MPH so if the timing does happen to drop a bit by swell that can be a positive advantage. Possibly one distributor that they used has a issue which caused negative results on a full throttle dyno pull. Most Mopar guys have known forever that they love a super fast advance getting all the timing in ASAP. That was the benefit of the light weight springs. When timing was all in by 1800RPM what exact full throttle timing curve is even happening lol. Honestly for going fast who really cares about picking up some performance under part throttle low speed rides. We aren't pulling a dang trailer up the mountains in our Hot rods lol. Which may be the point that's being refered to since it is a possibility to pickup some potential very low speed performance with a vaccum advance curve that adds extra timing. Both very different scenarios. One that really doesn't matter much in a full throttle race car. The other is to help save at the pump. I've tried both several times on my own street and race vehicles. The higher performance ones idled and ran much better with locked timing. The mild ones have a vaccum advance for increased economy but it's a noticeable difference in which ones have the more stable timing under heavy throttle.

To add power valve selection is also ones friend for tuning cruise enrichment. Blocked power valves noticeably run much different while cruising. They even sound different. I know one great tuner that tunes some multiple thousand HP street cars who uses a very different approach that's normally used with power valves but with great success.

I guess the question is why you think a curve would slow the car down?

The absolute worst case scenario would be that the car ran the same.

And the engine would thank you for not beating the **** out of it around peak torque.

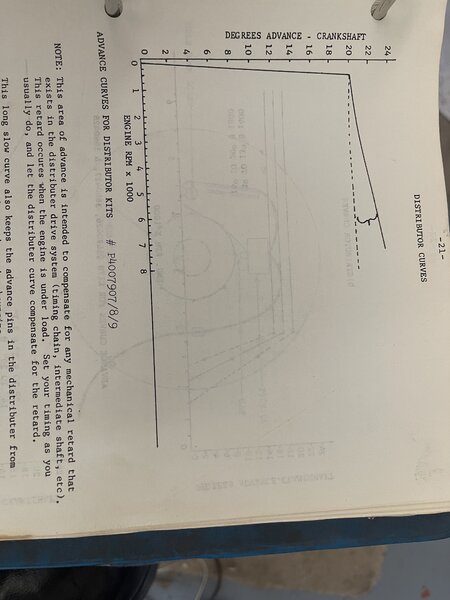

From 1979…

Look at the slope of the curve.

Look at the slope of the curve.

Some of you will get this.

mderoy340

Well-Known Member

@Newbomb TurkGet your timing sorted first. Then block the middle e bleed hole. The other two holes should be no bigger than .028 and .026 would be best.

Then LOWER the idle feed restrictors down in the metering block. It’s a simple drill and tap modification.

You don’t want a jet (the idle feed restricters) above fuel level. Why they almost always stick them up high I can’t say. It’s just stupid but they keep doing it.

You’re idle feed restriction should only be .026-.028 and the idle air bleed should start in the .068-.072 range to start.

Your .028 main air bleed isn’t bad but .026 would most likely be better.

Then you’ll need T slot restricters. They ALL need them. For a single 750 I start at .072ish and tune them from there.

Once you do all that, block the power valve and leave the primary main jets alone. Go drive the car. On flat level ground you want the SMALLEST main jet at a cruise you can get without getting a lean surge. That is cruising on the main jet, not on the T slot so depending on gearing and tire size you’ll want to be cruising at 3000 rpm or so. Any lower than that and you might still be getting fuel from the T slot and you don’t want that.

Once you have your cruise A/F ratio correct you don’t touch the primary main jets again unless you are changing your cruise A/F ratio.

Put your power valve back in and you can tune for WOT. If you are lean you add fuel to the primary side by increasing the size of the power valve channel restrictors and the secondary main jet.

It’s a bit of work but the end result is worth the effort.

Are you suggesting T slot restrictors in the front and/or back? I run a 4 corrner Demon DP. Thanks

-

Similar threads

- Replies

- 95

- Views

- 7K