Ok sent the deposit on the x block, will pick up after vacation which starts Monday. So towards the end of the month.

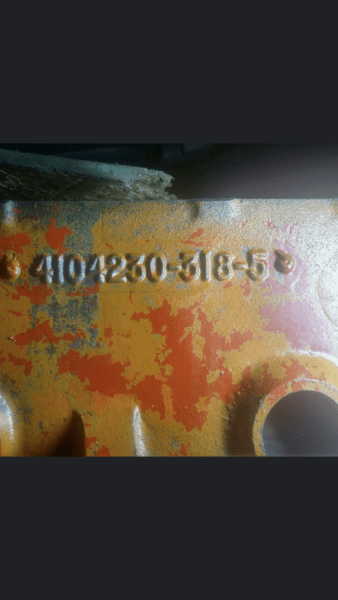

It was run as a .030 318 in an arrow ran 6.60 so a mild build. The bore is a fresh 4.04 Should be a good candidate for strong stroker engine.

It was run as a .030 318 in an arrow ran 6.60 so a mild build. The bore is a fresh 4.04 Should be a good candidate for strong stroker engine.