octanejunkie

Mopar Padawan

Starting this thread to chronicle the build of an engine with text and photos for all to see. When completed, this motor will do into my 71 Scamp. I acquired a complete engine "kit" in the deal with the car this past christmas, the kit as I call it consisted of a '99 .030 over 360 magnum block, stock crank, stock heads, stock rods with pistons pre-mounted, center sump oil pan, windage tray, Air Gap manifold, oil pump, and most all other goodies required to build the long block - now I get to finish someone else's project.

Hopefully this level of documentation will assist others and allow me to go back and reference aspects of my build in the future - plus it is a good release for me to pour it out here rather than drive my family and friends nuts with car talk all day!

Let's begin

So I cleared out room in the garage last weekend, tossed a bunch of junk, and bought a new engine stand at Harbor Freight for $50. Assembled the stand, greased the wheels and the trunnion/sleeve and hung the block last night.

Here are a few pics of the block

Casting number is apparent, block is .030 over with good cross hatch in the bores, mild surface rust throughout and a virgin deck, or so it seems

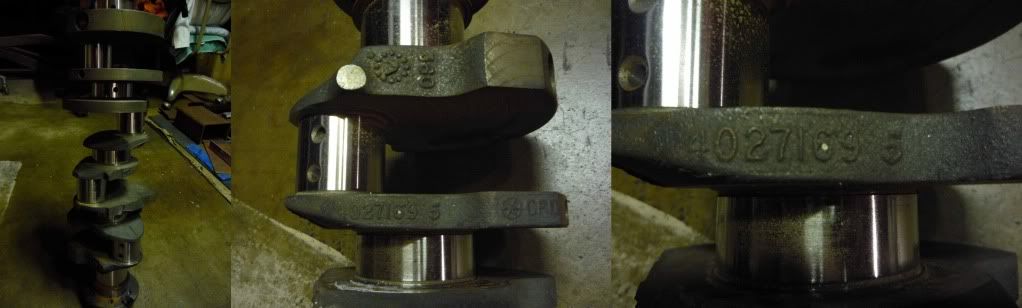

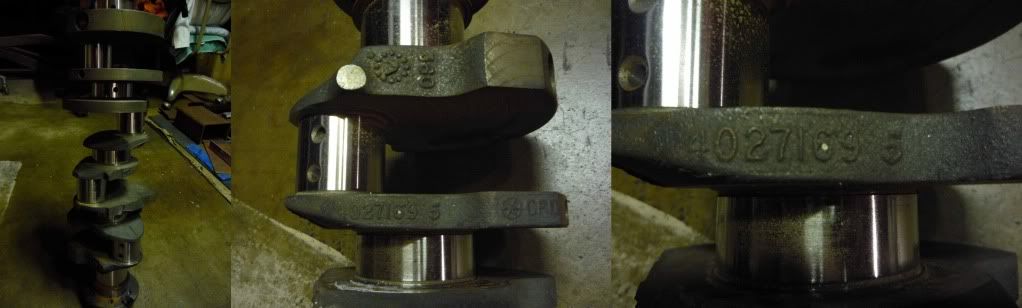

Here are a few pics of the crank

Casting number 40291695, standard crank (not turned,) balanced with journals polished - some mild surface rust up to clean otherwise ready to run

Here are a few pics of pistons and rods

Rods are stock and have not been checked for length/big end diameter, as far as I know. The pistons came mounted to the rods from the previous owner, so I guess I will see some indication of rod length consistency in the deck height mock up; assuming piston compression height is consistent! Part number of piston kit is Z8KH116CP30; .030 over flat top hypereutectic piston with 5cc volume.

The Plan

Mock-up the rotating assembly and measure the piston to deck clearance to determine deck height. Once I have that measurement I will pull it apart and take the block down to Kelly's Block Welding in Culver City, CA for square decking and hot tanking.

I have a list of things to detail on the block at this stage but would like to hear from other folks what they do at this point, what better is the internet and FABO if not for comparing notes.

I will be out of town for about a week so I don't expect to get much done before I get back, but I am dying to get this going! Stay tuned for updates...

Hopefully this level of documentation will assist others and allow me to go back and reference aspects of my build in the future - plus it is a good release for me to pour it out here rather than drive my family and friends nuts with car talk all day!

Let's begin

So I cleared out room in the garage last weekend, tossed a bunch of junk, and bought a new engine stand at Harbor Freight for $50. Assembled the stand, greased the wheels and the trunnion/sleeve and hung the block last night.

Here are a few pics of the block

Casting number is apparent, block is .030 over with good cross hatch in the bores, mild surface rust throughout and a virgin deck, or so it seems

Here are a few pics of the crank

Casting number 40291695, standard crank (not turned,) balanced with journals polished - some mild surface rust up to clean otherwise ready to run

Here are a few pics of pistons and rods

Rods are stock and have not been checked for length/big end diameter, as far as I know. The pistons came mounted to the rods from the previous owner, so I guess I will see some indication of rod length consistency in the deck height mock up; assuming piston compression height is consistent! Part number of piston kit is Z8KH116CP30; .030 over flat top hypereutectic piston with 5cc volume.

The Plan

Mock-up the rotating assembly and measure the piston to deck clearance to determine deck height. Once I have that measurement I will pull it apart and take the block down to Kelly's Block Welding in Culver City, CA for square decking and hot tanking.

I have a list of things to detail on the block at this stage but would like to hear from other folks what they do at this point, what better is the internet and FABO if not for comparing notes.

I will be out of town for about a week so I don't expect to get much done before I get back, but I am dying to get this going! Stay tuned for updates...