USCG CHARGER

Well-Known Member

- Joined

- Apr 25, 2007

- Messages

- 2,486

- Reaction score

- 49

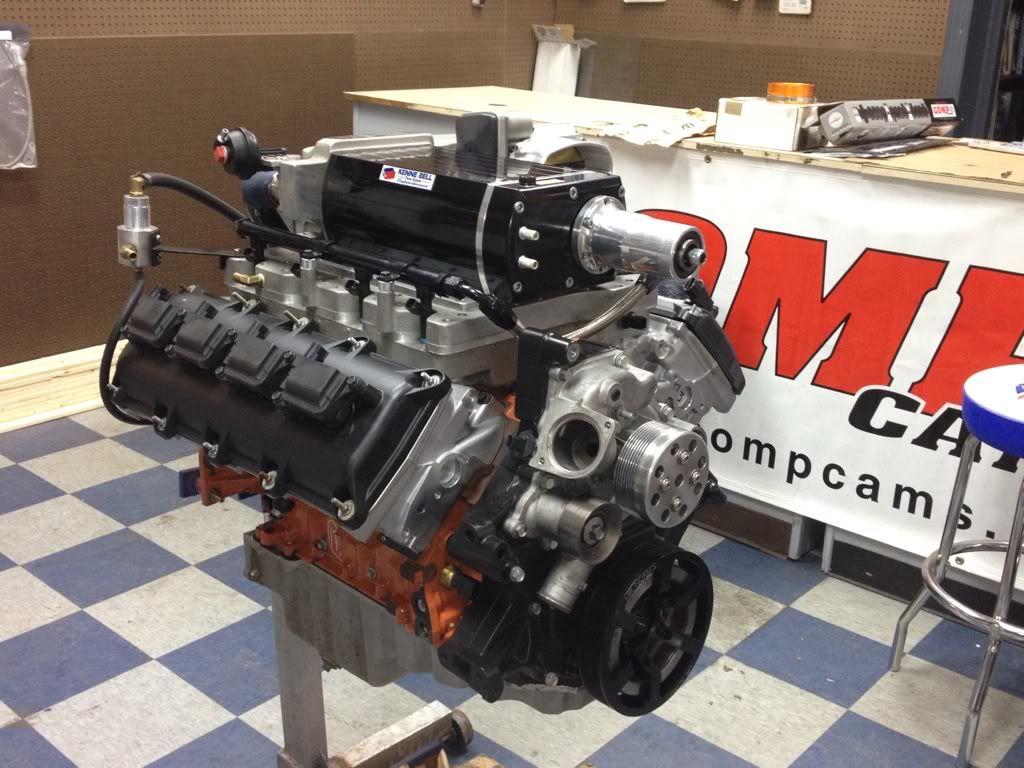

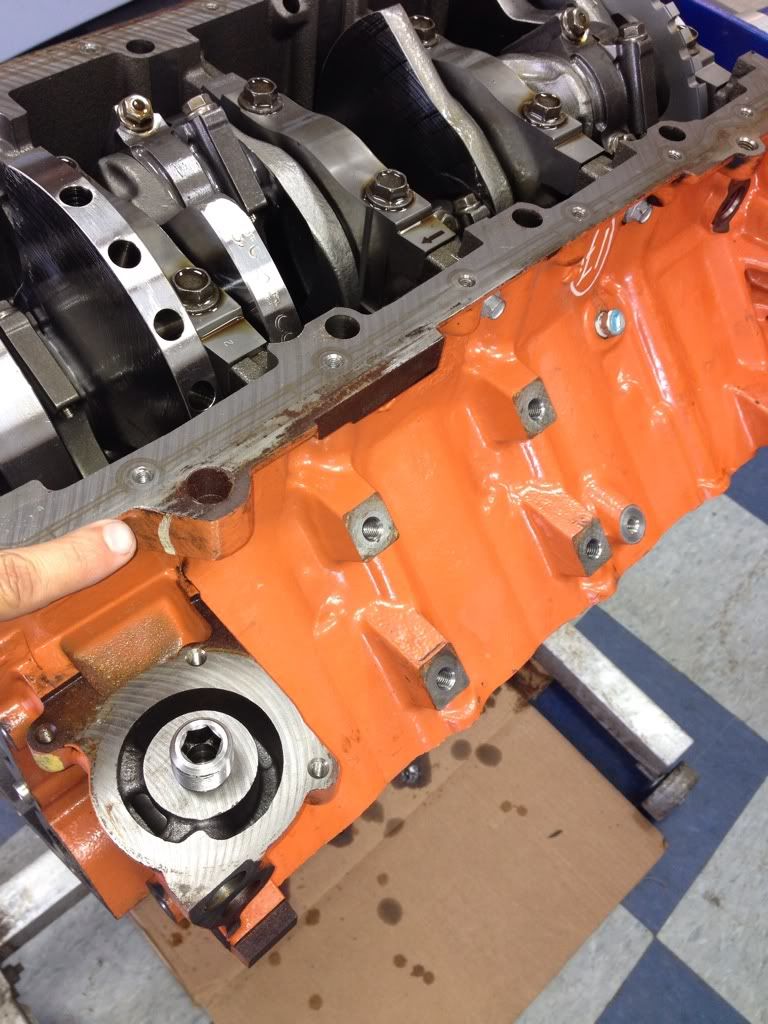

As many know I'm doing a hemi swap in my 68 Dart. On 12 Mar I decided to pull the trigger on some goodies for the build so I called up Dave Webber at Moder Muscle Performance Group ordered a set of his ported 6.1 heads with 625 springs, retainers, and guides, custom cam, forged drop in pistons with new rings, cometic head gasket, new rod bolts, etc. I also made a phone call to my friend AJ Hemituner and bought a complete 6.1 engine. He wanted to send it to me assembled but I wanted it un-assembled so I could put the goodies on it from MMP. After seeing a smoking deal on a used KB I scooped it right up and now had all the parts in place within 10 days from nothing to everything. That's a very remarkable turn around time on this.

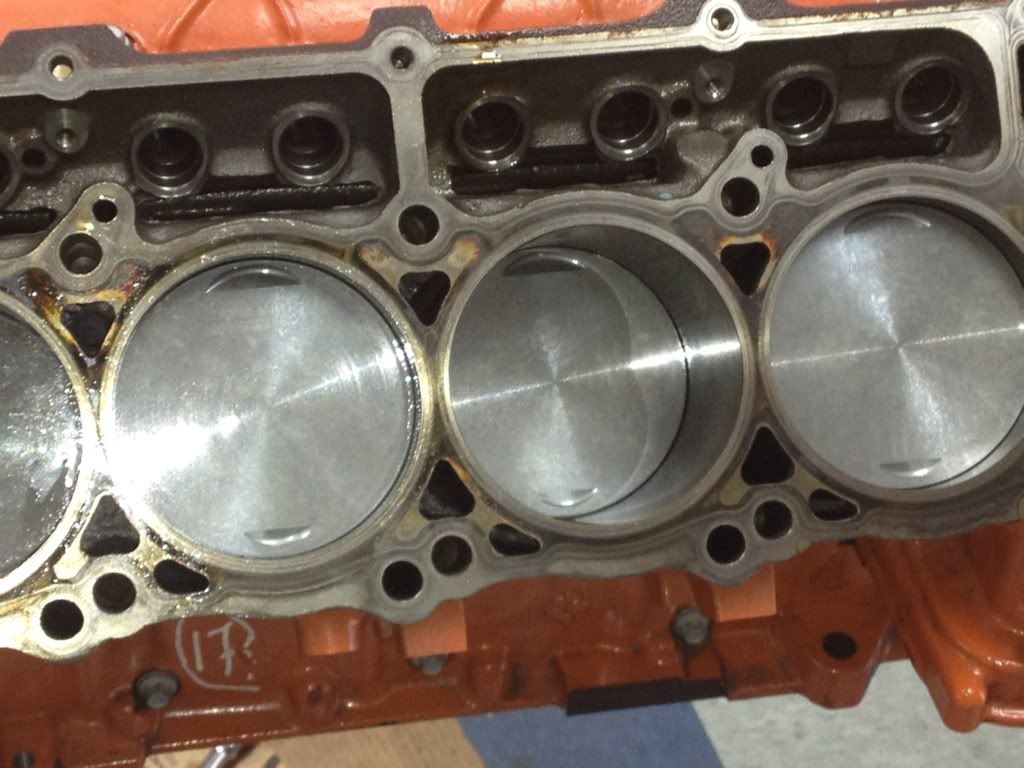

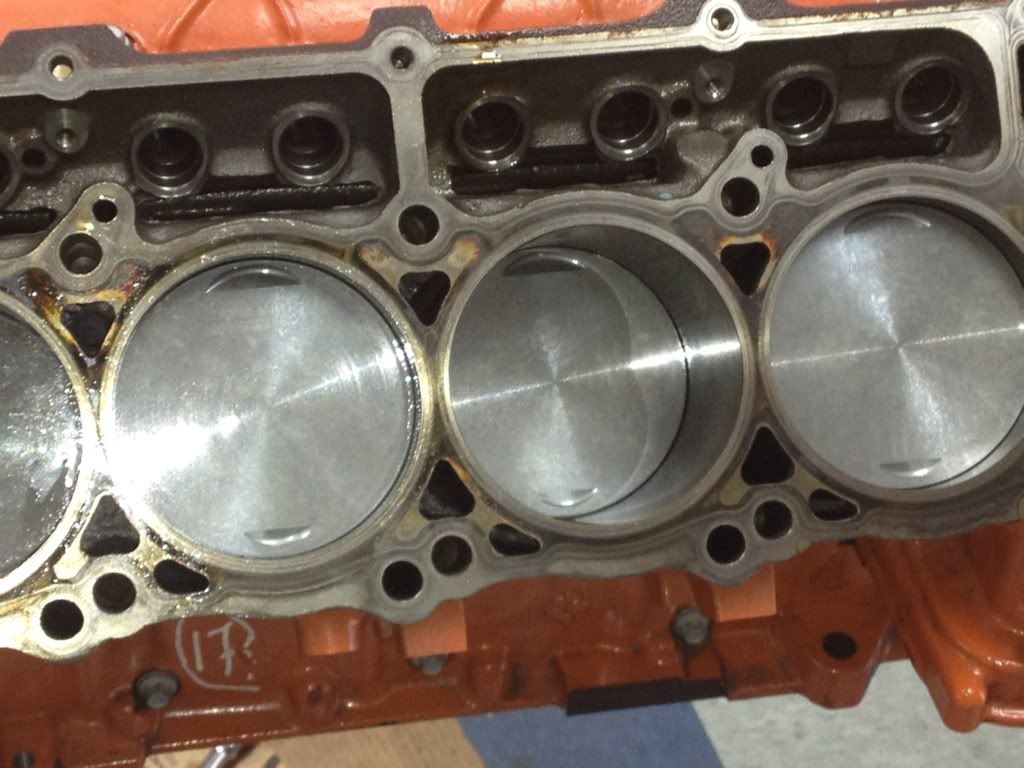

Next I called up my buddy Jeff (Popeye's Hemi) and asked for his assistance to assemble this mountain of parts. Jeff arrived Friday night grabbed so beers went to the shop and the labor began. We both were unsure as to what to gap the new rings at so i called very intelligent individuals in the know and they gave what they would gap them for my build. So after a lot of reading and talking on the phone we decided on the top and second gaps along with the bottom rings. We purchased a hand wheel to gap the rings to our specs. If you've never gaped a ring it takes a long time to measure each cylinder gap the ring put in back in the cyl, measure again, grind a little, put it back, you get the point... very time consuming. After 3-4 hours we were complete and are very satisfied with our work.

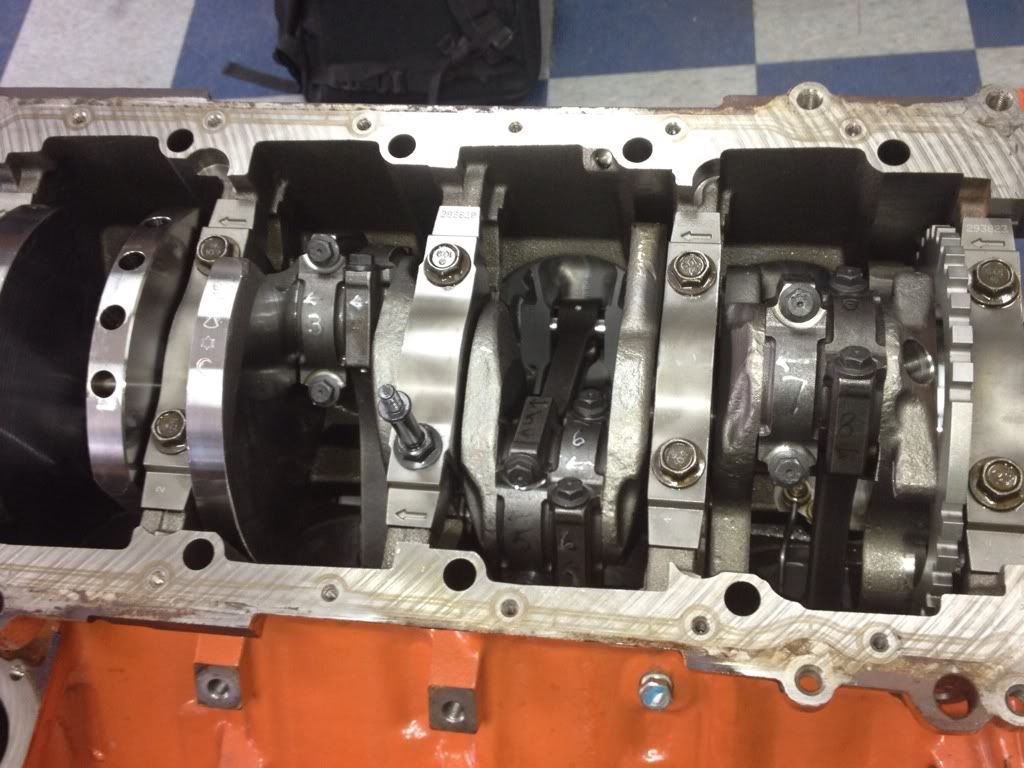

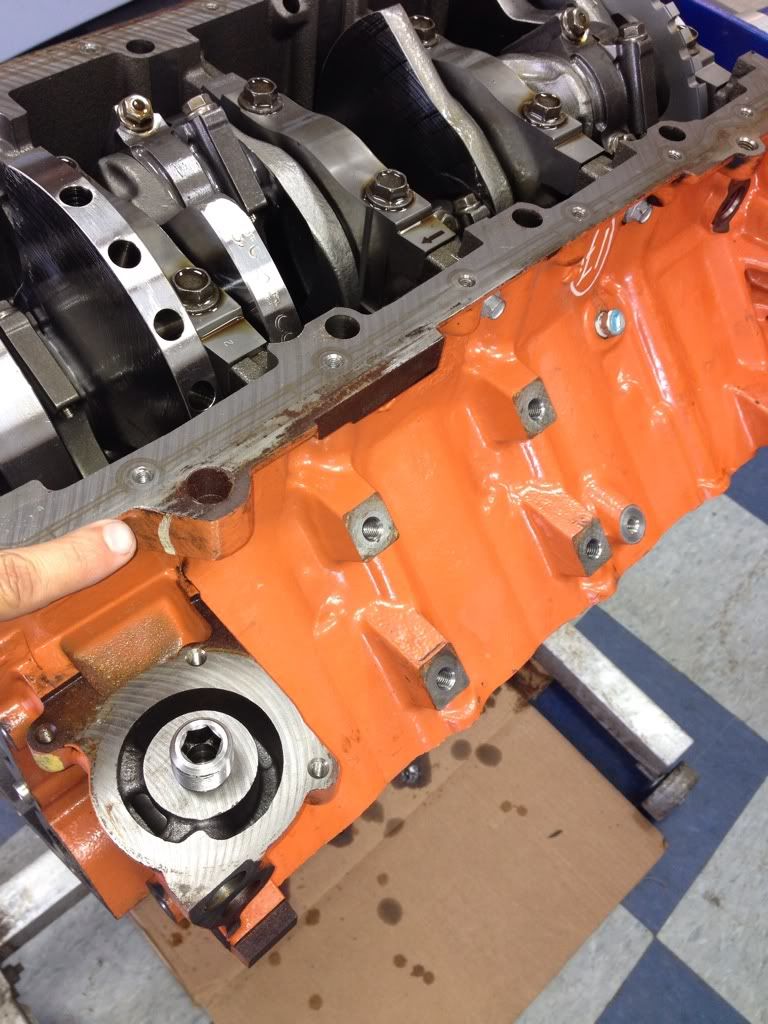

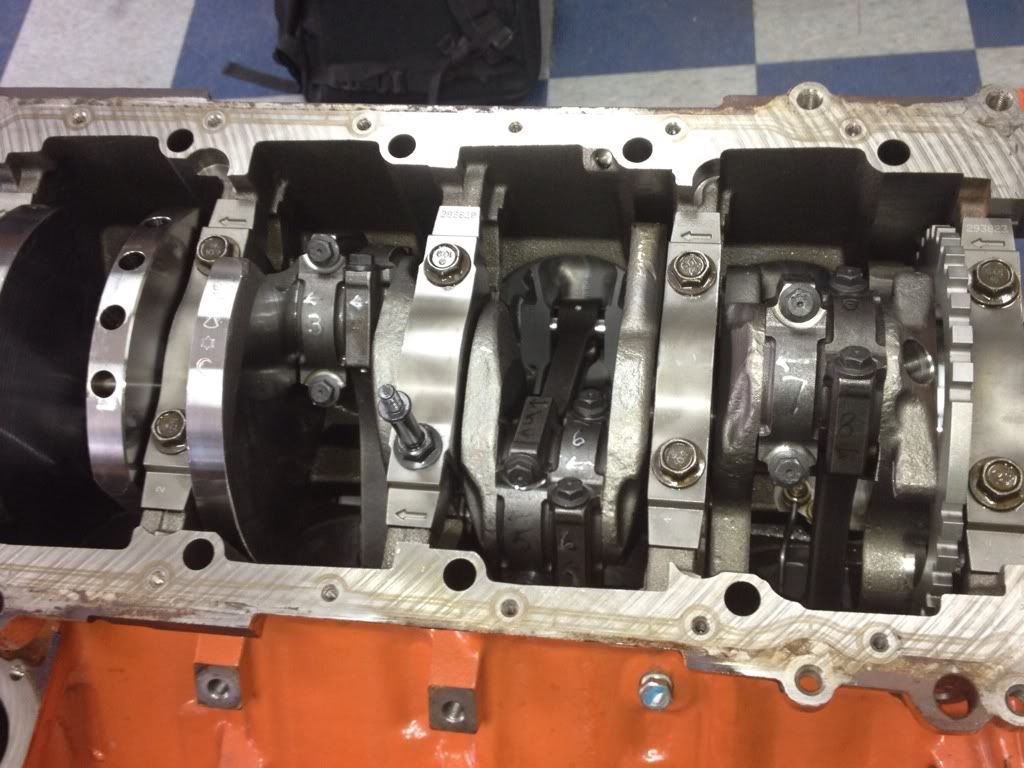

Time of assembly... We were smart enough to mark each rod and cap by a number and the direction it was facing before disassemble. This made a assembly easy and had two check points (our marks and the pistons had larger valve reliefs with obviously go on the top of each cyl). We used a crappy ring compressor that we fought a few pistons with but other than that they all went in with out a hitch. Something we did was to rotate the crank with the crank journals down so when we installed the piston a rod it couldn't reach it a smack it possible causing damage to it or the rod. We used this same level of attention to detail throughout this entire build. Every Bolt was spec and torqued, all new gaskets, assembly lube, etc.

I wanted to thank Scott 1fst4dr as I asked a lot of question and we shipped parts back and forth within a few days.. He's top notch in my book. Also Dave Webber and AJ for putting up with the numerous phone calls and obviously the bad *** parts to make this all happen. Jeff for the time you took to help me out ..very cool ( love the sound of the 300 BTW) SICK!

Next week I will put it in place mate it to the tranny, plug it in, and start on the custom headers. I'm hoping to get it to AJ for tuning a week prior to 27 Apr. Still a lot of work to be done but it should start moving fast now. Here are some pics of this weekend. These pic are not in order.. I think I got Jeff in one acting like he's doing something but still managing to pose! Go figure!

Next I called up my buddy Jeff (Popeye's Hemi) and asked for his assistance to assemble this mountain of parts. Jeff arrived Friday night grabbed so beers went to the shop and the labor began. We both were unsure as to what to gap the new rings at so i called very intelligent individuals in the know and they gave what they would gap them for my build. So after a lot of reading and talking on the phone we decided on the top and second gaps along with the bottom rings. We purchased a hand wheel to gap the rings to our specs. If you've never gaped a ring it takes a long time to measure each cylinder gap the ring put in back in the cyl, measure again, grind a little, put it back, you get the point... very time consuming. After 3-4 hours we were complete and are very satisfied with our work.

Time of assembly... We were smart enough to mark each rod and cap by a number and the direction it was facing before disassemble. This made a assembly easy and had two check points (our marks and the pistons had larger valve reliefs with obviously go on the top of each cyl). We used a crappy ring compressor that we fought a few pistons with but other than that they all went in with out a hitch. Something we did was to rotate the crank with the crank journals down so when we installed the piston a rod it couldn't reach it a smack it possible causing damage to it or the rod. We used this same level of attention to detail throughout this entire build. Every Bolt was spec and torqued, all new gaskets, assembly lube, etc.

I wanted to thank Scott 1fst4dr as I asked a lot of question and we shipped parts back and forth within a few days.. He's top notch in my book. Also Dave Webber and AJ for putting up with the numerous phone calls and obviously the bad *** parts to make this all happen. Jeff for the time you took to help me out ..very cool ( love the sound of the 300 BTW) SICK!

Next week I will put it in place mate it to the tranny, plug it in, and start on the custom headers. I'm hoping to get it to AJ for tuning a week prior to 27 Apr. Still a lot of work to be done but it should start moving fast now. Here are some pics of this weekend. These pic are not in order.. I think I got Jeff in one acting like he's doing something but still managing to pose! Go figure!