abodyjoe

Well-Known Member

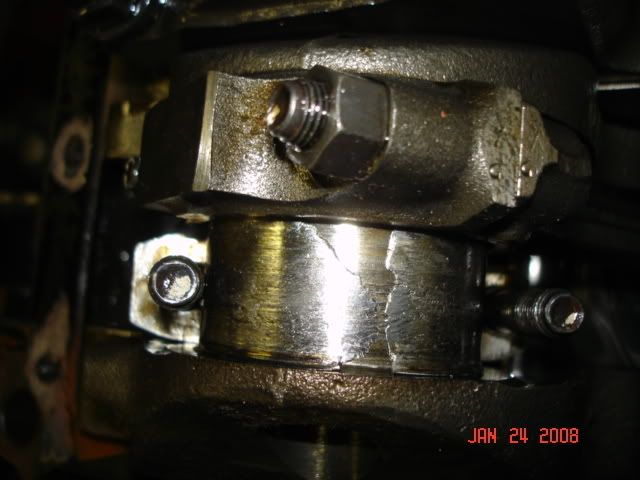

well it spun #1 bearing.. #2 looks prety bad too. just have to figure out what i want to do now.... i should have a set of rods in the shed so i can replace these two and i may have a crank out there too. if not i have a couple 360 motors that i should be able to rob one from. not sure if this crank is able to be cut... still have to pull the rest apoart and see if there is any more damage.

would be a good time to make it a 408. lol...

would be a good time to make it a 408. lol...