Same cleaner I use for most everything 100LL AV gas...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your home made tools

- Thread starter fishy68

- Start date

-

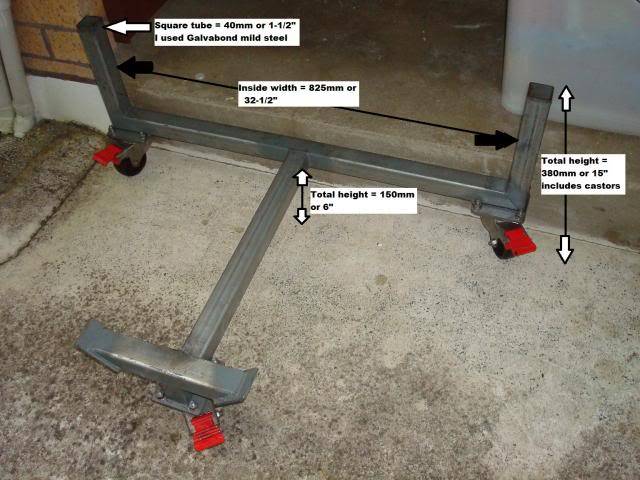

K-Frame holder for moving an engine around the garage...or shop

Especially handy if you have access to a hoist...

Has been used a few times now, and well worth the time to build.

Especially handy if you have access to a hoist...

Has been used a few times now, and well worth the time to build.

Dfr360cuda

Diagnosis... Plum Crazy.

Not home made but I just did this. When I change oil, I put the drain pan in a plastic mortar box. Now, when you take the oil filter off a Dakota and the oil drips onto the crossmember and runs everywhere less makes it onto the driveway.

Also... the mortar box serves as a parts cleaner.

Also... the mortar box serves as a parts cleaner.

Max Wedgie

Well-Known Member

Very neat thread, with a lot of neat ideas..

Made this light with a magnetic mount on the back and a couple of outlets for working under the the post lift. I've also used it on the engine lift. That magnet is fairly strong as it has yet to fall off of anything, and the lights can be pointed towards the work area.

I also hand crocheted the beer can holder nearly 30 years ago. And the beer in it is all I can afford since beer money is being used to put the car back together

Made this light with a magnetic mount on the back and a couple of outlets for working under the the post lift. I've also used it on the engine lift. That magnet is fairly strong as it has yet to fall off of anything, and the lights can be pointed towards the work area.

I also hand crocheted the beer can holder nearly 30 years ago. And the beer in it is all I can afford since beer money is being used to put the car back together

diymirage

HP@idle > hondaHP@redline

I'll snap a little tomorrow, but I build a "remote starter"

Two lengths of wire (red and black, doesn't get any fancier then that) with an alligator clip on the end, attached to a simple push button

(The push button was left over from a new gun modified

It was an electric belt fed nerf gun

Real cool, but the motor always ran so it gave away your position

I bought the push button and installed it in the handle, so you squeeze the handle to turn on the motor and the pull the trigger for the kill

Anyways, stuff all that in 8 inches of left over PVC pipe and it even has a handle

Two lengths of wire (red and black, doesn't get any fancier then that) with an alligator clip on the end, attached to a simple push button

(The push button was left over from a new gun modified

It was an electric belt fed nerf gun

Real cool, but the motor always ran so it gave away your position

I bought the push button and installed it in the handle, so you squeeze the handle to turn on the motor and the pull the trigger for the kill

Anyways, stuff all that in 8 inches of left over PVC pipe and it even has a handle

shittyslant6

Well-Known Member

bent coat hanger. makes a good oil pan scraper.

Also, I don't really make tools, but I do use tools incorrectly in order to get stuff done.

like using two wrenches to tighten head bolts instead of a tourqe wrench

Also, I don't really make tools, but I do use tools incorrectly in order to get stuff done.

like using two wrenches to tighten head bolts instead of a tourqe wrench

Max Wedgie

Well-Known Member

The base is a magnet, and the sockets can be found at any auto parts store.

Last edited:

Here’s my tools for shorting a dana rear I made up. Old floating axel from the dana I cut down plus the setup arbors for saddles from the miller factory gear setup. I welded the 8-3/4 axel bearing race to the floating axel then trued it all on the lathe, cutting the other end to slip in the saddle pieces.

This wasn't my idea, but I saw this carburetor bench pressure tester in one of Harold Demes's videos. It was cheap and easy to make, and was very handy in setting the float levels & testing the needles/seats. I think the picture is pretty self explanatory, but it uses fuel line, a boat primer bulb, and a fuel pressure gauge teed into the line. Incredibly simple and incredibly useful!

Made up a simple line up bolt for installing flywheels. Screws back out with a simple flat blade screw driver.

Especially handy for the neutral balance flywheels and after market balance plates for the 360 external balanced engines.

360 ready to mount up to the Engine Run Stand.

Ready for a test fire and run in the new camshaft.

Especially handy for the neutral balance flywheels and after market balance plates for the 360 external balanced engines.

360 ready to mount up to the Engine Run Stand.

Ready for a test fire and run in the new camshaft.

JDMopar

Well-Known Member

Great idea George! I'm gonna make a WAG....and say the header collector bolted to the left motor mount support is a holster for your timing light.

I think you might be right!Great idea George! I'm gonna make a WAG....and say the header collector bolted to the left motor mount support is a holster for your timing light.

Great idea George! I'm gonna make a WAG....and say the header collector bolted to the left motor mount support is a holster for your timing light.

Yep, Holster for the Timing Light.

Handy to have it right there all hooked up ready to go.

Here is another little trick I am doing, using a new Points Distributor for the first start ups on the run stand.

With the points distributor you can see exactly when the points first open and fire the plugs, giving the ability to set the timing to 10 degrees BTDC before the engine even starts.

Will see how close I am when checking with the timing light on first start. The less variables the sooner the engine gets to 2000 rpm and properly breaks in the cam.

Max Wedgie

Well-Known Member

Here's a tool that I've used a number of times to install harmonic balancers.

Using this large nut, a 4 inch bolt, and a couple of washers with grease on them it turns fairly easy. Once the bolt bottoms out i can use the stock bolt to press it on the rest of the way.

I always put anti-seize on the crank hub and that helps a bunch.

You probably won't find the large piece at a hardware store. It's used for power line construction.

Using this large nut, a 4 inch bolt, and a couple of washers with grease on them it turns fairly easy. Once the bolt bottoms out i can use the stock bolt to press it on the rest of the way.

I always put anti-seize on the crank hub and that helps a bunch.

You probably won't find the large piece at a hardware store. It's used for power line construction.

Where did you get the weight?Made up a simple line up bolt for installing flywheels. Screws back out with a simple flat blade screw driver.

Especially handy for the neutral balance flywheels and after market balance plates for the 360 external balanced engines.

View attachment 1715746330

View attachment 1715746331

View attachment 1715746332

View attachment 1715746333

360 ready to mount up to the Engine Run Stand.

View attachment 1715746334

Ready for a test fire and run in the new camshaft.

View attachment 1715746335

View attachment 1715746336

Yote

Well-Known Member

Can’t find a small hose ? This one was made with the insulation from a small braided electrical wire with the strands pulled out.

Yote

Love it!!View attachment 1715788751 Ever want to get that small shot of aerosol just where you want it but can’t reach it because the extension is too short ? Cut a short piece of the extension (it won’t flip off the nozzle as easily) and slip it into a small hose, and the longer piece in the other end of hose (this gives you better control of the end).

Can’t find a small hose ? This one was made with the insulation from a small braided electrical wire with the strands pulled out.

Yote

gzig5

Well-Known Member

Nice!View attachment 1715788751 Ever want to get that small shot of aerosol just where you want it but can’t reach it because the extension is too short ? Cut a short piece of the extension (it won’t flip off the nozzle as easily) and slip it into a small hose, and the longer piece in the other end of hose (this gives you better control of the end).

Can’t find a small hose ? This one was made with the insulation from a small braided electrical wire with the strands pulled out.

Yote

small heat shrink tube should work well for the flex hose

Scamp Rhonda

Well-Known Member

That just reminded me that I have to buy some shrink wrap. Amazon has a package of 580 some assorted pieces for $6.99. So I should have plenty left over for making spray nozzle extensions. Lol, great ideas from both of ya!Nice!

small heat shrink tube should work well for the flex hose

-

Similar threads

- Replies

- 3

- Views

- 555

- Replies

- 22

- Views

- 398

- Replies

- 13

- Views

- 844