MyD750

'71 Duster 340 TX9

As I'm between med issues/treatments/tests, I've been able to quickly slide in and do a bit more prep work in tear down of the Duster. I frequently take deep breaths and remind myself I probably did some of the same lame things when I was younger, that were done to the Duster. In getting things loosened on the exhaust, I've found 3 different types of bolts holding the factory exhaust manifold on. This seems to be a theme as I've found a mix of screws, nuts, bolts etc while disassembling. Hoping to get a lot more done in the next week and a half. Hopefully get the motor pulled and off to the machine shop. Not doing a whole lot to the motor, still have to see what's what inside. IF it's in pretty good, stock shape I'll probably just warm things up a bit inside with a CompCams Magnum stick (21-214-4) kit. Still contemplating headers, but not too hard. Cost to benefit just doesn't fit, and I'm not likely to do anything on the strip. I could always be convinced though...

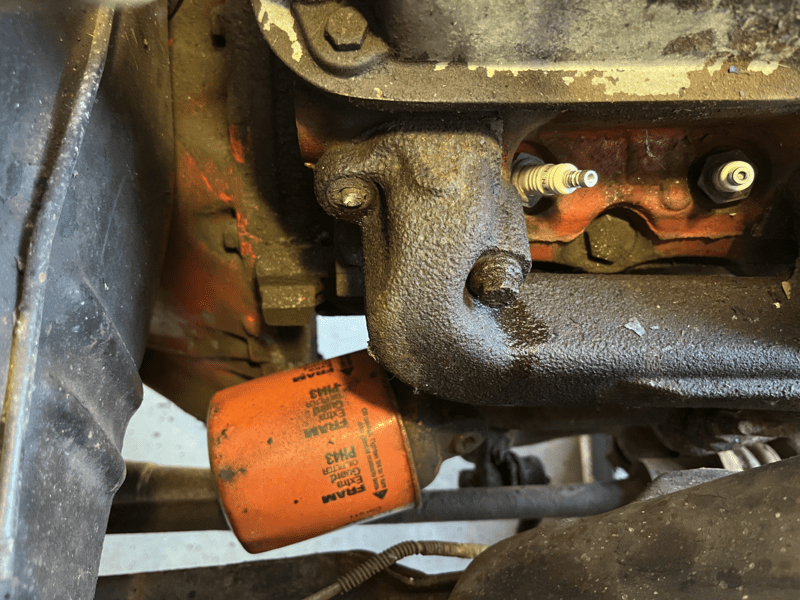

Here's a pic of bolt that busted off. It was so weak that I thought it was loosening (properly) then it snapped. Oh snap! And that Fram filter? Must be welded on. More to follow, especially on the motor pull. Take care, be safe.

Here's a pic of bolt that busted off. It was so weak that I thought it was loosening (properly) then it snapped. Oh snap! And that Fram filter? Must be welded on. More to follow, especially on the motor pull. Take care, be safe.