Good Morning All! One day work week for me this time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stop in for a cup of coffee

- Thread starter toolmanmike

- Start date

-

Morning!

16 with a high of 32 and some sun. Nice!

Lots of work this week.

16 with a high of 32 and some sun. Nice!

Lots of work this week.

Mornin yall. Supposed to be almost 80 here today.

- Joined

- Mar 17, 2018

- Messages

- 17,141

- Reaction score

- 41,854

One day closer to Spring! Happy Thursday all!

Moved Fargo from shop to storage. Im real happy with the brakes now. Installed the residual valves and new shoes,wheel cyls and gooder rear drums. Much better than it was before. Wasnt thinking when i noticed my left adjuster was worn out. Will pull one out of the parts diff i have. I figure out of 3 i should have a good one.

Eh I don’t trust myself to keep that nice and round and yeah I’d screw it

Chis, if you are talking a difference of 70.3 vs 70.6 mm that is about 12 thousandths of an inch. (average human hair is 0.003" so 4 ish) Sand paper wheel on die grinder would easily be done and barely touching it.

Good Morning all. Going to be in upper 30's to lower 40's for the next week plus. Sun feels so nice and snow is melting. With as much salt they have on the roads, it will be August before is washes off. Many places look like we are driving on gravel roads or the beach.

I saw this AMC project rolling through the powder coat shop yesterday, not sure of year, early 60's probably. Guy driving it in/out of there said the owner is deciding on power plants for it to include a possible Mazda rotary engine? That would be interesting.

that’s not a bad idea actually.I'd be thinking how to build a jig

Now here’s a question, could I not sand down the flat, outer edge of the center hub to let it clear as well?Chis, if you are talking a difference of 70.3 vs 70.6 mm that is about 12 thousandths of an inch. (average human hair is 0.003" so 4 ish) Sand paper wheel on die grinder would easily be done and barely touching it.

LOL get wheel extenders!

Put them on the front of the fargo, to fit the hubs and deal with the offset of the Caravan wheels.LOL get wheel extenders!

View attachment 1715696993

Now here’s a question, could I not sand down the flat, outer edge of the center hub to let it clear as well?

Yes, I am sure you could. Lightly touch it with a grinder while spinning the hub the best you could, but @Ddaddy had a good point. Do it once on the rims if only for memory. Change rotors in a hurry some time, throw wheels on, run on with impact and go....ooops. Or if you sold it, kids end up with it, etc. If you had a way to spin the rim so you could run a buff/sand wheel in the pilot, it could turn out just fine. It is a tiny amount of material you need to remove. Just my 2¢

Correct, I don’t disagree. But screwing up 50 bucks in rotors beats screwing up 600 in wheels.Yes, I am sure you could. Lightly touch it with a grinder while spinning the hub the best you could, but @Ddaddy had a good point. Do it once on the rims if only for memory. Change rotors in a hurry some time, throw wheels on, run on with impact and go....ooops. Or if you sold it, kids end up with it, etc. If you had a way to spin the rim so you could run a buff/sand wheel in the pilot, it could turn out just fine. It is a tiny amount of material you need to remove. Just my 2¢

oh it’s 730. Wheel shop opened, gonna call them. I’d feel much more comfortable having the wheels done professionally than by me doing it.

MomsDuster

Well-Known Member

FWIW Chris, I would sand out the rim. The amount needed wouldn’t even be measurable on a wheel balancer. Besides if you had to replace a hub on the side of the road you’re going to have to do it again. Just sand the wheel and be done with it.

The ford rims i put on the Barracuda had a similar problem. Flapwheel in the die grinder and it took just a touch to get them to fit. A couple rounds with the flapwheel inside the wheel will do it. Use a sharpie and mark the area you need to tune up. Buff til color from sharpie is gone. Probably 2 or three repeats and its done. Or,test fit wheel, snug, remove and grind away the scarred part that the hub created.

fitting parts like a machinist does is marking compound, test fit, and remove offending material and add marking compound and repeat until there are no marks. Just dont go all heavy handed.

fitting parts like a machinist does is marking compound, test fit, and remove offending material and add marking compound and repeat until there are no marks. Just dont go all heavy handed.

Actually, I bet a ridge reamer would work too

Or a hone?

So the talk with the wheel shop was interesting. If I bring them the rotor and the wheel, theyll make the wheel fit for 150 per wheel. If I want a new grove cut for the center caps and the caps worked to fit correctly, it’s 225 per wheel.

Unconventional

Well-Known Member

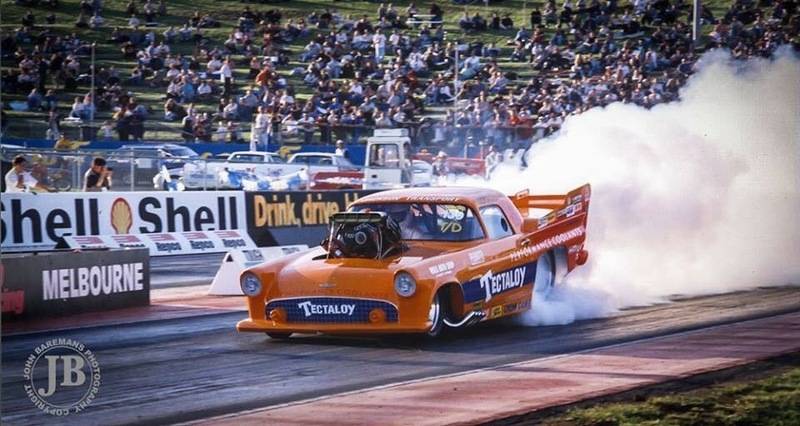

It's Thunderbird Thursday!

Good morning

Good morning

Chris dont over think it just do it!

Unconventional

Well-Known Member

Wheel question.

Are the wheels supposed to be centered by the hub?

Or centered by the tapered lug nuts and studs?

Are the wheels supposed to be centered by the hub?

Or centered by the tapered lug nuts and studs?

A56

Street Survivor

Morning java Kings and Queens(?lol)

Lug nuts I believe thats why they are tapered.

-

Similar threads

- Replies

- 9

- Views

- 663

- Replies

- 8

- Views

- 725