RAMM

Well-Known Member

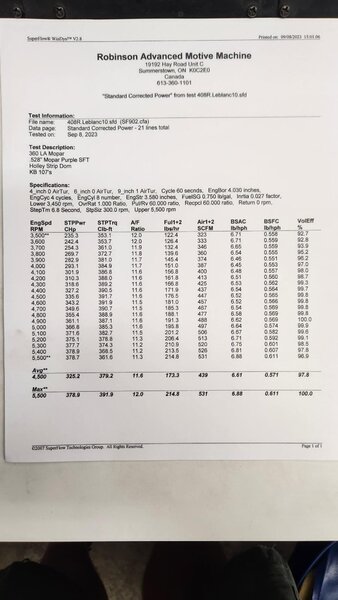

This project has been a long time coming to completion but here we are. It is a very straight forward 360 w/ J heads w/no real work other than a good valve job and resurfacing , positive seals etc... 1.88"/1.60" valves? I didn't do them or take them apart as they were very fresh. The bottom end is just a 4.030" KB 107 piston, W Magnum Rods/ARP bolts, balanced and an old new Mopar .528" SFT with a Holley Strip SP. The customer supplied nearly everything including the 273 iron rockers and banana groove shafts.

Broke it in today for 20 minutes with Joe Gibs 15W50 BR oil, locked out timing @ 37* and the same GB 650 I used a week ago on the 408. It ran excellent and sounded nasty compared to the 408 on account of the 9" of idle vac. Pulled it numerous times on Esso 91 and 34-35* was best with no spacer other than the dumb little steel "gasket" you have to use to seal up a square bore to a spread bore. Yes it was very rich but like the 408 this is not the customers carb and I am only verifying the engine makes the expected power and doesn't leak/smoke/make bad noises or act weird. Could I jet it and change the oil to a thinner Vr1 10w30 and make more power? Yes I'm sure it would respond. Could I spend excessive time exploring carb spacers and lash loops/timing loops and gain more? Yes likely, only to find out the customer doesn't have hood clearance for anything more than a .062" carb gasket. I did spend some time checking / adjusting lash and more time again setting up a dial indicator and measuring valve lift on all valves (.498"-.509") and then compression testing all cylinders (175 psi). All in all this engine is healthy with great 50 psi oil @ 180* oil/water @ 900rpm and 380hp/390tq. It should move the 1st gen Dakota just fine I would imagine. Just sharing another SBM build that contains ZERO exotic parts or porting and what to expect. J.Rob

Broke it in today for 20 minutes with Joe Gibs 15W50 BR oil, locked out timing @ 37* and the same GB 650 I used a week ago on the 408. It ran excellent and sounded nasty compared to the 408 on account of the 9" of idle vac. Pulled it numerous times on Esso 91 and 34-35* was best with no spacer other than the dumb little steel "gasket" you have to use to seal up a square bore to a spread bore. Yes it was very rich but like the 408 this is not the customers carb and I am only verifying the engine makes the expected power and doesn't leak/smoke/make bad noises or act weird. Could I jet it and change the oil to a thinner Vr1 10w30 and make more power? Yes I'm sure it would respond. Could I spend excessive time exploring carb spacers and lash loops/timing loops and gain more? Yes likely, only to find out the customer doesn't have hood clearance for anything more than a .062" carb gasket. I did spend some time checking / adjusting lash and more time again setting up a dial indicator and measuring valve lift on all valves (.498"-.509") and then compression testing all cylinders (175 psi). All in all this engine is healthy with great 50 psi oil @ 180* oil/water @ 900rpm and 380hp/390tq. It should move the 1st gen Dakota just fine I would imagine. Just sharing another SBM build that contains ZERO exotic parts or porting and what to expect. J.Rob