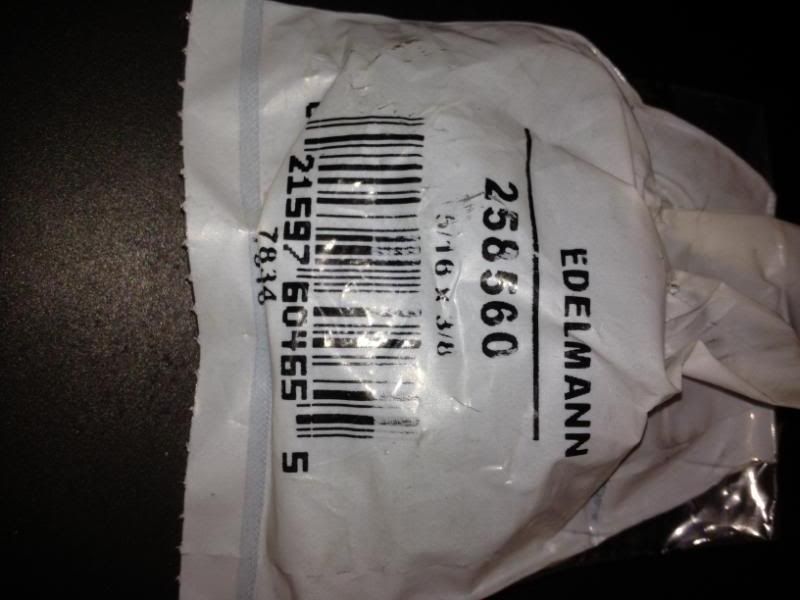

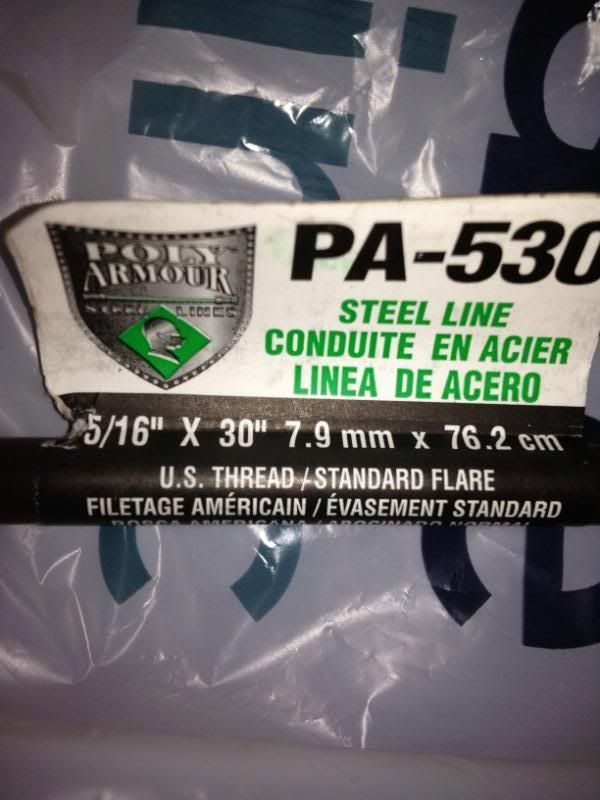

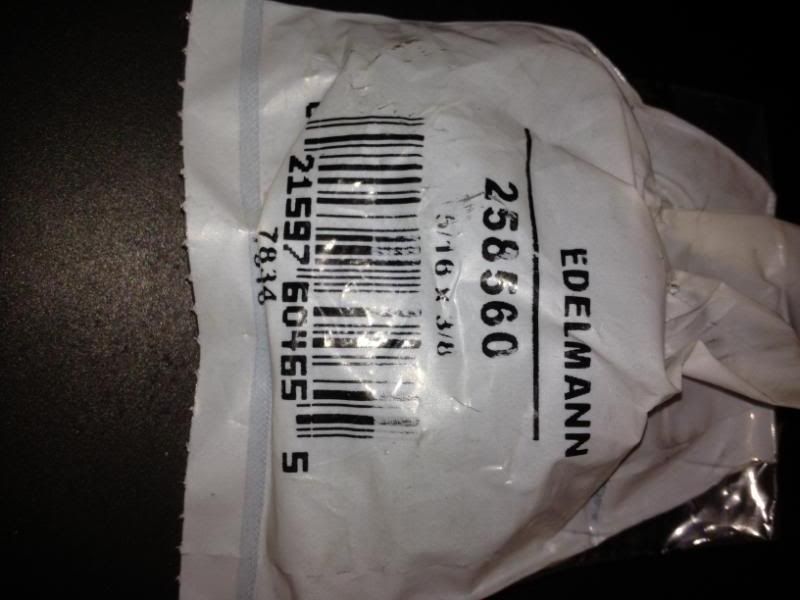

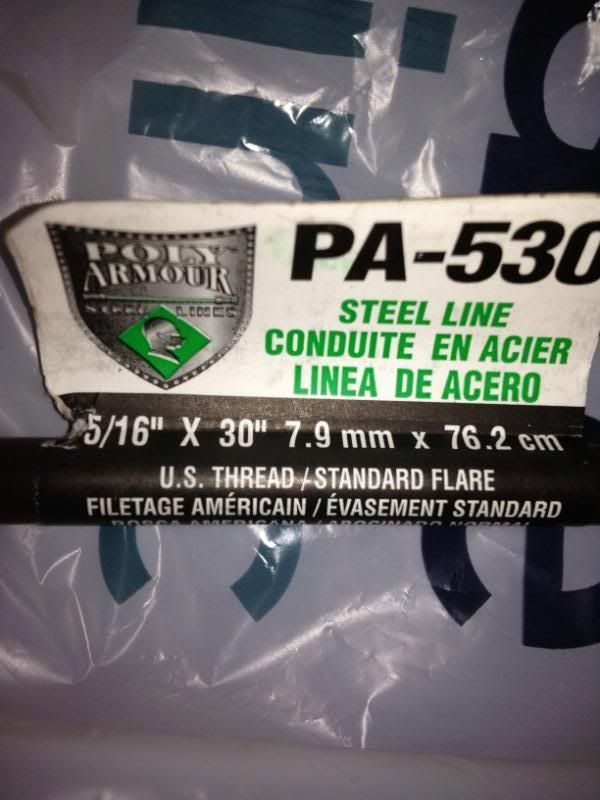

I had the unfortunate experience of an engine fire in the wife's Valiant. So I wanted to reduce the amount of rubber fuel line. Since I can't do anything about the rubber connection between the fuel pump and gas tank, I left that alone. I did after some research find a a fuel filter that allows solid metal lines from the fuel pump to the carb. I will let the pictures do the talking....