Here's my 2 cents.

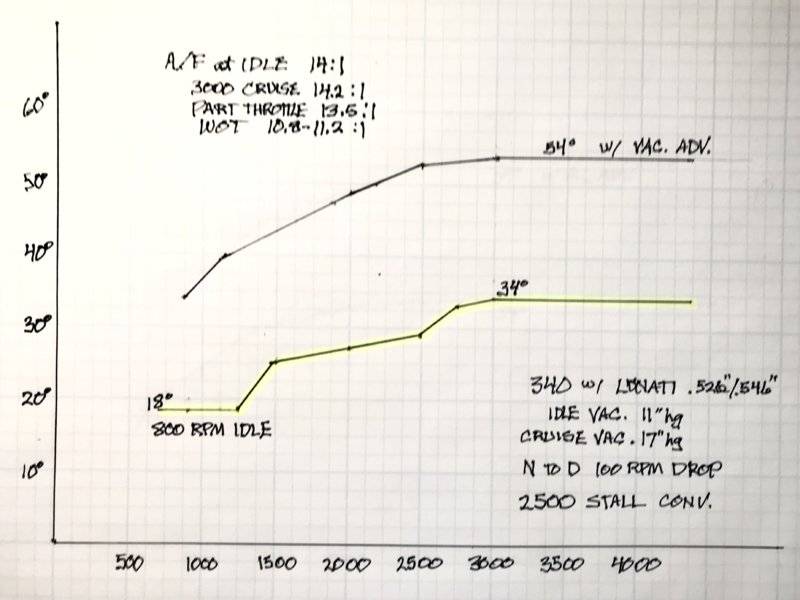

N to D drop is good. Leave the initial at 18 at 700 to 800 rpm.

It might be a little more chipper coming off idle if the advance started before 1200 rpm.

> On a Chrysler advance, that would be done by reducing the primary spring's tension. If the MSD does not havea primary and secondary spring, might have to take a little tension off of both.

> This suggestion assumes ported source for vacuum advance. Not sure sooner mechanical start will be helpful if using manifold source.

The touchy area for too much part throttle timing is 1800 to 2800 rpm. With the steep gearing in the car it may not cause audible gurgle. Or it may not show up until the engine is heat soaked. Heat soaked being something like 2 - 3 hours into a road trip.

Bottom line is that I'd stick with Chrysler's recommendation on that total for timing at cruise rpm, 50*. Take a little vacuum advance out of the curve.

>Should be able to do that by increasing the spring pressure on the diaphram - and that should delay the start. I haven't messed with MSD distributor but I'm assuming that option is there.

The AFR caught my eye.

Part throttle AFR should go leaner than cruise AFR.

If the car cruising at 60 mph, 17"Hg, 3000 rpm and the AFR is 14.2:1

Then as throttle is applied for a hill or increase of speed, AFR should go leaner until the throttle is so far open that vacuum drops to 8 to 11" Hg. Only then (when the power valve or step up rod opens) should the AFR get richer.

Its best to make the timing change

or make the carb changes and retest. The AFR interpretation by the WBO2 often will change with a timing change. So its best to have a new baseline AFR or we will be unsure whether changes in the AFR readout were caused by carb adjustments or timing change.

Chrysler recomendation reprint in the last illustration How To Limit and Adjust Chrysler Vacuum Advance Cans

Definately in the ballpark now.

Definately in the ballpark now.