MSD distrib. Also, the 3 -4 degree retard I posted about was using an MSD timing light. Using my old Craftsman dial back, I got 5 degrees retard.

The craftsman is correct.

MSD distrib. Also, the 3 -4 degree retard I posted about was using an MSD timing light. Using my old Craftsman dial back, I got 5 degrees retard.

I still think that is backwards. A faster light will read a higher timing number before top

So you’re essentially running on 30 degrees. What story do the plugs tell?MSD distrib. Also, the 3 -4 degree retard I posted about was using an MSD timing light. Using my old Craftsman dial back, I got 5 degrees retard.

What rpm are you setting timing (35 degrees) at? What is your timing number at 4600 rpm?MSD distrib. Also, the 3 -4 degree retard I posted about was using an MSD timing light. Using my old Craftsman dial back, I got 5 degrees retard.

You need some help with that? You're gettin purdy old, you know.Hold on. I’m trying to get an engine on the dyno.

I need to look at my notes I took this morning

You need some help with that? You're gettin purdy old, you know.

Lets do the unicorn head motor before I put it in.lol I got it on there. Tomorrow I start making pulls on that one. It will only be a few pulls as it’s been across the pump before. This is just a little check out before it goes to the customer.

Pretend your timing light is a pistol. With the engine spinning slowly you take two shots in rapid succession when you see the 36 degree before top dead center mark line up with the pointer on the cover. Because you are an excellent marksman the first bullet hits the 36 degree Mark. The second bullet fired (representing the slower timing light) will hit a number that is smaller before top dead center.Hold on. I’m trying to get an engine on the dyno.

I need to look at my notes I took this morning

MSD distrib. Also, the 3 -4 degree retard I posted about was using an MSD timing light. Using my old Craftsman dial back, I got 5 degrees retard.

Larry is around. Might be able ask him. (He responded to some of my emails about Dynomation 5 and the skewed power curve with Chrysler cams. Figured out here with Jim's help that the cam info had made incorrect assumptions about the .006 durations)I believe this literature is from the days when Mullen helped Larry Atherton and Warren with their R&D in So. Cal.

Probably. The copy editing and checking only got worse with later editions.Is that a misprint? Should it read "12:1 - 35 to 36" degrees instead of "35 to 60" ?

I wonder if the timing curves shown are as seen on a distributor machine or read directly from the running engine on the dyno? It's interesting that the chart doesn't show any retard after the timing is all in. I can't read the print at the bottom of the chart but it looks like it skips from 1300 rpm to 4000 rpm and I can't read if that is distributor or engine rpm.

I believe the research that A&W Performance did on ignition curves can be used to program the MSD grid system.Larry is around. Might be able ask him. (He responded to some of my emails about Dynomation 5 and the skewed power curve with Chrysler cams. Figured out here with Jim's help that the cam info had made incorrect assumptions about the .006 durations)

I beleive the reason for the fast advance to a 'limit' was an inheritance from success in class racing doing this with dual point distributors. Circle back to that at the bottom.

Probably. The copy editing and checking only got worse with later editions.

That looks to be the same graph the was further simplified in later editions.

This is from my copy of Engine, Speed Secrets View attachment 1716481055

View attachment 1716481054

When waiting for my tach drive distributor, John Soemer - a former Stock class racer related the story of removing the heavy spring and going slower. I think he said that at the tech seminars they were telling racers not to do it, and son of a gun the factory guys were right.

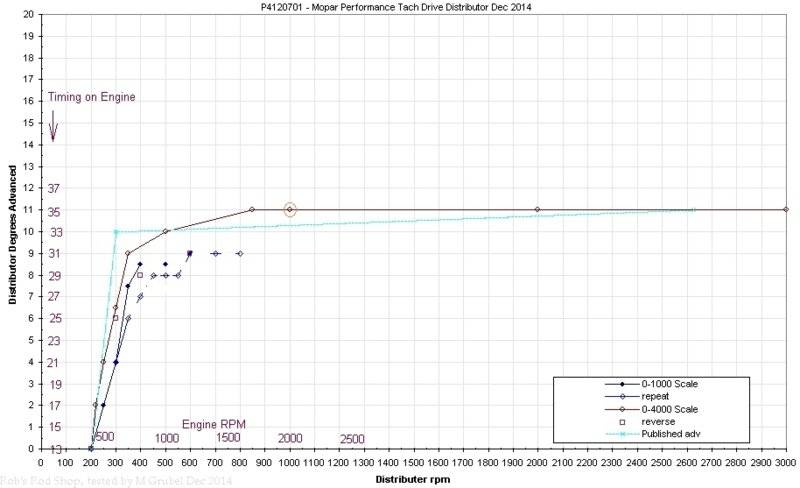

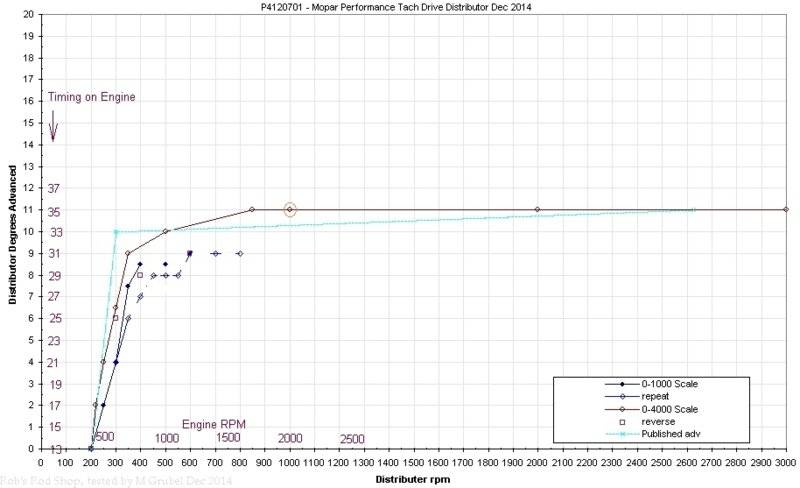

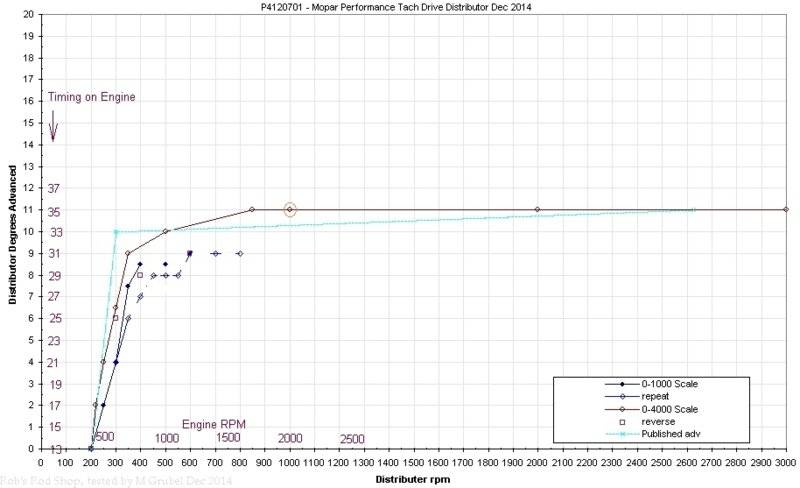

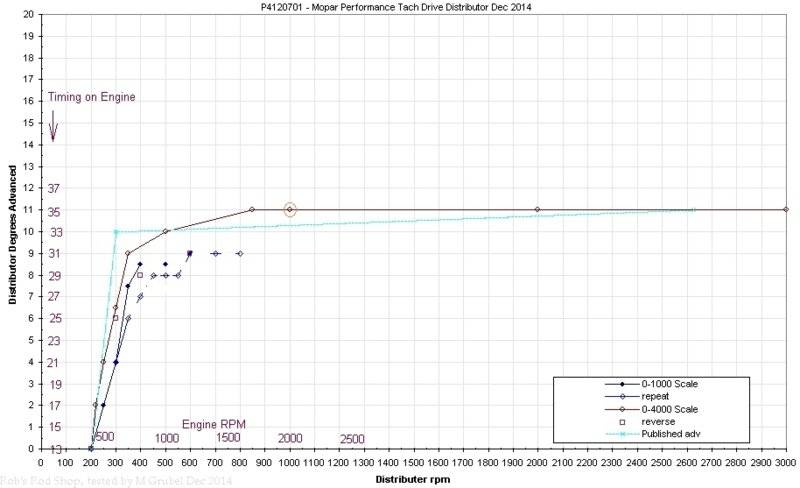

In the thread linked below I posted the above graph with my measurements on a Excel graph.

See if this helps. This a the advance curve of a SB tach drive distributor I ran on a machine. The blue line is from the mopar book pictured earlier in the thread.

Timing is in distributor degrees and rpm.

Marked up on the graph is a circle and timing in crank degrees and rpm. The circle represents the timing on an engine when the distributor is set to 35* at 2000 rpm.

On the DC graph you posted it looks like about 3 crankshaft degrees of advance over about 7000 engine rpm. Less than 1/2 degree per 1000 rpm. The footnote list only list mechanical reasons for the advance compensation. No mention of slew rates or modules. Is this for a dual point distributor?Larry is around. Might be able ask him. (He responded to some of my emails about Dynomation 5 and the skewed power curve with Chrysler cams. Figured out here with Jim's help that the cam info had made incorrect assumptions about the .006 durations)

I beleive the reason for the fast advance to a 'limit' was an inheritance from success in class racing doing this with dual point distributors. Circle back to that at the bottom.

Probably. The copy editing and checking only got worse with later editions.

That looks to be the same graph the was further simplified in later editions.

This is from my copy of Engine, Speed Secrets View attachment 1716481055

View attachment 1716481054

When waiting for my tach drive distributor, John Soemer - a former Stock class racer related the story of removing the heavy spring and going slower. I think he said that at the tech seminars they were telling racers not to do it, and son of a gun the factory guys were right.

In the thread linked below I posted the above graph with my measurements on a Excel graph.

See if this helps. This a the advance curve of a SB tach drive distributor I ran on a machine. The blue line is from the mopar book pictured earlier in the thread.

Timing is in distributor degrees and rpm.

Marked up on the graph is a circle and timing in crank degrees and rpm. The circle represents the timing on an engine when the distributor is set to 35* at 2000 rpm.

It looks like what they were trying to achieve by adding 3 degrees of advance over 7000 rpm on a distributor machine was to end up with a curve that remained flat as measured in a running engine? That is interesting because it doesn't compensate by adding or subtracting timing for changes in VE in the curve. Either in this case it didn't need it or they didn't test to see if it did need it. My suspicion is that a deviation from a flat curve (as observerd on the running engine) will be combination / application specific. As will the amount of horsepower gained or lost from a deviation of the flat curve be combination/ application specific. For now I'm going to assume these test were not done with electronic ignition but the same theory probably applies. You just have to compensate for the additional timing loss if there is any. Using a distributor machine to measure a timing curve with points is pretty straight forward but maybe not so much with electronic ignition. The strobe in a distributor machine when using a points distributor is triggered by the mechanical grounding of the points. I suspect the low voltage AC output of a pickup coil is not going to directly power the strobe in the distributor machine. I suspect it needs some circuitry to convert that ac signal to a ground which introduces a slew rate for the distributor machine. This is why I feel when testing on the distributor machine with electronic ignition it is best to use the entire ignition system and use a timing light for the strobe sourced from the secondary ignition being tested. The distributor machine is basically just spinning the distributor.Larry is around. Might be able ask him. (He responded to some of my emails about Dynomation 5 and the skewed power curve with Chrysler cams. Figured out here with Jim's help that the cam info had made incorrect assumptions about the .006 durations)

I beleive the reason for the fast advance to a 'limit' was an inheritance from success in class racing doing this with dual point distributors. Circle back to that at the bottom.

Probably. The copy editing and checking only got worse with later editions.

That looks to be the same graph the was further simplified in later editions.

This is from my copy of Engine, Speed Secrets View attachment 1716481055

View attachment 1716481054

When waiting for my tach drive distributor, John Soemer - a former Stock class racer related the story of removing the heavy spring and going slower. I think he said that at the tech seminars they were telling racers not to do it, and son of a gun the factory guys were right.

In the thread linked below I posted the above graph with my measurements on a Excel graph.

See if this helps. This a the advance curve of a SB tach drive distributor I ran on a machine. The blue line is from the mopar book pictured earlier in the thread.

Timing is in distributor degrees and rpm.

Marked up on the graph is a circle and timing in crank degrees and rpm. The circle represents the timing on an engine when the distributor is set to 35* at 2000 rpm.

As far as I have ever known those are supposed to be for the magnetic impulse race distributors. By the time this version was published dual points were no longer available from DC. I beleive the P parts listed there may have been the spring kits or the conversion packages. Those p/n are no longer listed in my 1989 catalog and I can't find the matching price list which sometimes included older parts no longer shown in the glossy catalog. The distributor advance I measured was on a race distributor bought around 1989.On the DC graph you posted it looks like about 3 crankshaft degrees of advance over about 7000 engine rpm. Less than 1/2 degree per 1000 rpm. The footnote list only list mechanical reasons for the advance compensation. No mention of slew rates or modules. Is this for a dual point distributor?

When this was done they were still transitioning from dual point to electronic. As I describe in the linked thread, clearly their focus was on the fastest classes in drag racing. The base line was what had worked well with dual points. Key things for them seem to have been; 'best' timing for the power band, and easy hot starting. Right or wrong, they didn't see idle as important or developing a curve as a good use of their resources.It looks like what they were trying to achieve by adding 3 degrees of advance over 7000 rpm on a distributor machine was to end up with a curve that remained flat as measured in a running engine? That is interesting because it doesn't compensate by adding or subtracting timing for changes in VE in the curve.

*We know its the real reason because we've heard it from the horses mouth's that they lost e.t. and mph going from dual point to electronic with the exact same advance set up. It wasn't just my co-worker. And it wan't just Tuner. As Tuner pointed out in his post, this stuff was in Jenkin's book on the small block Chevy. All of the guys running 'heads up' if you will were running into this.

Tuner described the same lesson except it was with a GM.

"A-B-A-B it was faster with the GM dual-points distributor, even though the spark energy was higher with the electronic, a GM Magna-Pulse, and the electronic had the same “curve” except for the retard after the “total” was reached at 2500. Jenkins book “The Small Block Chevrolet Racing Engine” details the high-RPM curve and explains his reasoning"

And for those who like to experiment with computer simulations, I posted some locked timing, vs. basic ramped timing power comparisons using Dynomation 5. lets revisit timing post 41

Bill Jones posted some of his tests of timing retard in this thread.

He's calling it hysterisis. The phenomenon is the same even if at that point he didn't know the full cause.

Losing 4 degrees of timing. - Don Terrill’s Speed-Talk

And here in the middle of hte page he describes how the factory (GM) compensated for slew in the distributor.

HEI Timing Issue - Page 2 - Don Terrill’s Speed-Talk

More discussions on slew.

Spark lead - Don Terrill’s Speed-Talk

and this one with some of the 'retard built in' history bubbling into the light.

HEI Retarding - Don Terrill’s Speed-Talk

Another thought. The reason given for the mechanical loss of timing are clearances in the timing chain, intermediate gear, etc.. What are the chances that this would be the same for each motor? Also is it possible that it may not be linear with rpm for every motor? If there is variation, what would be the scale of that variation?Larry is around. Might be able ask him. (He responded to some of my emails about Dynomation 5 and the skewed power curve with Chrysler cams. Figured out here with Jim's help that the cam info had made incorrect assumptions about the .006 durations)

I beleive the reason for the fast advance to a 'limit' was an inheritance from success in class racing doing this with dual point distributors. Circle back to that at the bottom.

Probably. The copy editing and checking only got worse with later editions.

That looks to be the same graph the was further simplified in later editions.

This is from my copy of Engine, Speed Secrets View attachment 1716481055

View attachment 1716481054

When waiting for my tach drive distributor, John Soemer - a former Stock class racer related the story of removing the heavy spring and going slower. I think he said that at the tech seminars they were telling racers not to do it, and son of a gun the factory guys were right.

In the thread linked below I posted the above graph with my measurements on a Excel graph.

See if this helps. This a the advance curve of a SB tach drive distributor I ran on a machine. The blue line is from the mopar book pictured earlier in the thread.

Timing is in distributor degrees and rpm.

Marked up on the graph is a circle and timing in crank degrees and rpm. The circle represents the timing on an engine when the distributor is set to 35* at 2000 rpm.

Still reading through all of this. The quote below from tuner is what I suspected. It gives the purpose of the curve ( as measured on the distributor machine ) and hints that not all motors will want to be a flat curve (as measured on the running engine).Here's the links

Still reading through all of this. The quote below from tuner is what I suspected. It gives the purpose of the curve ( as measured on the distributor machine ) and hints that not all motors will want to be a flat curve (as measured on the running engine).

Tuner:

"The mechanical advance compensates for the retard in the electronics to provide a flat static total or continue to advance all the way through the RPM range, however the engine likes it and you set it up."

Jenkins and his nylon cam gear...Another thought. The reason given for the mechanical loss of timing are clearances in the timing chain, intermediate gear, etc.. What are the chances that this would be the same for each motor? Also is it possible that it may not be linear with rpm for every motor? If there is variation, what would be the scale of that variation?

I don't think I'm misinterpreting what he wrote but what you're saying is he didn't write what he intended to write?Im pretty sure that’s not what he means.

He is saying you need to address the retard with the curve. Even a points distributor, which doesnt retard wants a curve.

I know you are hung up on testing this on a distributor machine but I’m not sure why. You can CLEARLY test for retard on a test bench and do it far more accurately than trying to do it in a car.

And doing it in the car means doing it with a timing light, which adds in error. I know what the retard is on my machine like the ignition will run in the car. Any variation of that is from the timing light.

Jenkins and his nylon cam gear...

"The reason given for the mechanical loss of timing are clearances in the timing chain, intermediate gear, etc." Quoting 92b

Would the scale of timing variation on a mechanically driven distributor be proportionally effected by the loading (and unloading) of the crank to cam and cam to distributor drive/oil pump.

Perhaps, the load slightly decreases as the efficiency of the drive mechanism increases, and thus the slight vernation, (dog leg) is needed to compensate as in A&W's published data.

I don't think I'm misinterpreting what he wrote but what you're saying is he didn't write what he intended to write?

I agree wholeheartedly. We're in the century of crank triggers and data recorders, but some of us are budget constrained, so the old R&D comes into play.Right. I believe that testing was done with points so the only loss of timing issues would be mechanical issues like junk timing chains and such. Or point bounce.

When you add electronics in you add in slew rate and that changes everything.

I believe that is one reason why two identical ignition systems can produce different power. One box retards sooner (or later as may be the case) and/or it retards more. My testing has shown repeatedly none of these boxes retard the same. Not in amount or in the rpm when it starts retarding.