Awesome Mattax! I’ve ever seen that on a graph like that. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Too much timing?

- Thread starter dartfreak75

- Start date

-

Your welcome.Awesome Mattax! I’ve ever seen that on a graph like that. Thanks

It took some effort to find published distillation curves, especially for street type fuels. Then making graphs out them wasn't to difficult.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,913

- Reaction score

- 12,263

At idle, and keeping the speed constant, just tug on the V-can until the speed no longer increases. Now you have found the optimum idle timing at that rpm. Don't be surprised to see the timing climb to deep into the 20s and higher.

If you continue to add advance past the optimum point, the speed goes down because the crank is no longer in the best position to receive it so the pressure is trying to ram the rod into the crank instead of turning it.

Think of it this way; remember as a kid blowing on one of those whirlygigs you made in play-school? If you blew at just the right angle. you could get maximum speed. Same idea . You set the initial, to get the max pressure to the crank when it is in just the right position.

But that is at idle with no load on it. Just one condition of millions of possibilities.

I keep telling you guys, as to power, the engine doesn't hardly care what the timing is, until the stall rpm, and then doesn't care, as long as the curve is fairly linear, until full-power,WOT at about 3400/3600. That is the zone we have to concentrate on getting right. With 3.55s and 27s, and in 2.45 low gear, this happens between about 18 mph and 28 mph.

That is where your power-timing has to be spot on, erring on conservative every single time..... because this is the zone your engine will spend most of it's life.

now; lets say the power-timing has to be not more than 24* at stall of 2400. and not more than 34* at 3400. The rpm range is 1000rpm, and the timing range is 10degrees. That computes to 10/1000 X 10= 1.0 degree per 100 rpm. That is your mandatory maximum power-timing curve. Now for a pair of same length springs, extrapolate 1 degree per 100, back to say 1000 from 24* at 2400. I get an idle-timing of ;

(2400 less 1000/100) x 1.0=14 degrees beginning at 1000rpm.

Ok now; I don't care what you set your idle-timing to, but if 24* at 2400 is the max, with single-stage springs rated at 1.0 degrees per 100 rpm, if it is not 14* at idle; it will be DEAD WRONG from stall to 3400. And remember, in the example I used, these are the MAXIMUM.

Next, go put your engine on the dyno, and measure it's peak power with optimum timing, then with 3 degrees too much, then with 3 degrees not enough. Firstly; the engine will lose more power with 3* too much timing than with 3* not enough. But more importantly, what are the numbers? Sometimes the numbers are so small as to be almost meaningless. But lets say you get 7hp at 5200 rpm. Now go back to 2400rpm. Take a guess how much power you will lose with 3* not enough timing, at 2400rpm.

But you say, what has power-timing to do with what I feel at PT at under 18 mph?

Answer; EVERYTHING. For a HotRodder, your Power-timing has to set the tone/be the baseline, for all your engine's timing needs; and the thing we use to flush out the timing for PT use, is the Vcan. With a decent compression engine, you can modify your Vcan to supply up to 24 degrees over and above the power-timing at any rpm between idle and say 3400, rpm depending on how you the tuner set it up.

So with just 14* mechanical timing at 700rpm, you could change this to 14+24=38*@2400. And say you are taking off normally and the 24* stays in all the way to 3400, where it is now 34+24=58*; or

Say you floor it right off idle. the vacuum falls to below what you have set the V-can to, the engine spools up to stall(2400 in my example) and the beast takes off. or

Say you are just motoring to the icecream store, at some modest power level, and the Vcan is bringing in only 12*. Now your timing is say 18* mechanical plus 12 in the can =30degrees.

Lets suppose that in these examples ,all of them are acceptable to your engine with no detonation. I mean you tuned it to be right.....

Now; tell me again , how an initial Idle-timing of more than 14* in this example, would be helpful.

In these examples, all the settings are such that the maximum pressure in the chamber is delivered to the crank at or just after the decades old proven best point, in the which the crank can transfer that pressure in the most efficient way. Neither more nor less timing will produce more efficiency nor more power, because you the tuner, have paid attention to your engine, never mind what some guys on the internet tout.

If you build your timing curves on the wrong baseline, you will never get it right. And for a street HotRod, the V-can is your engine's best friend.

And you know why?

Because, your engine will spend it's entire life, except maybe 1% of it, at some other throttle position,less than WOT; so why worry about 7 hp at 5200rpm much less 3hp at 3400, much less on the power at sub-stall rpm, which you can easily manipulate with either the V-can, or with throttle position.

And finally; you have got to set your transfer-slot exposure just right, to prevent an off-idle tip-in hesitation. The transfers should be your primary low-rpm and idle fuel supply.

If your slot is too small, the transfer fuel will be reduced in volume, (which you can augment with the mixture screws for idle, and the idle will be just fine), and the transfer fuel delivery rate will slow down, which, at tip-in, will take time to start up again, ergo the hesitation.

If an automatic, going into gear, the new load will be too high for the starving transfers, and the engine will just stall.

After setting the transfer slot exposure, the only way you have of setting the idle-speed, is with idle timing. So, if you start with some, in my opinion, fantastic Idle-Timing, your exposure is GUARANTEED to be too small. If you do that, you will pull yur hair out trying to keep the engine from stalling when you put it into gear, and it will be impossible with pump-shot, to solve the tip-in hesitation..

Don't be that guy

At the risk of pizzing off a few gurus, forget about targeting fantastic Idle-timing numbers; 12 to 16 will get your transfers into the ballpark. Then after you get the Power-Timing worked out from stall to ~3400/3600, start dialing in the Vcan to give you back the PT timing your engine will crave.

Btw, in my examples, YES, I biased the numbers to prove my point. Your targets are specific to your engine, and 1.0degrees per 100rpm may not be achievable with your parts; don't be thinking your combo wants or needs 1.0, let her tell you what she wants. To do that, I installed a dash-mounted, dial-back, timing-retard box with a range of 15 degrees. Which made it fairly easy.

If you continue to add advance past the optimum point, the speed goes down because the crank is no longer in the best position to receive it so the pressure is trying to ram the rod into the crank instead of turning it.

Think of it this way; remember as a kid blowing on one of those whirlygigs you made in play-school? If you blew at just the right angle. you could get maximum speed. Same idea . You set the initial, to get the max pressure to the crank when it is in just the right position.

But that is at idle with no load on it. Just one condition of millions of possibilities.

I keep telling you guys, as to power, the engine doesn't hardly care what the timing is, until the stall rpm, and then doesn't care, as long as the curve is fairly linear, until full-power,WOT at about 3400/3600. That is the zone we have to concentrate on getting right. With 3.55s and 27s, and in 2.45 low gear, this happens between about 18 mph and 28 mph.

That is where your power-timing has to be spot on, erring on conservative every single time..... because this is the zone your engine will spend most of it's life.

now; lets say the power-timing has to be not more than 24* at stall of 2400. and not more than 34* at 3400. The rpm range is 1000rpm, and the timing range is 10degrees. That computes to 10/1000 X 10= 1.0 degree per 100 rpm. That is your mandatory maximum power-timing curve. Now for a pair of same length springs, extrapolate 1 degree per 100, back to say 1000 from 24* at 2400. I get an idle-timing of ;

(2400 less 1000/100) x 1.0=14 degrees beginning at 1000rpm.

Ok now; I don't care what you set your idle-timing to, but if 24* at 2400 is the max, with single-stage springs rated at 1.0 degrees per 100 rpm, if it is not 14* at idle; it will be DEAD WRONG from stall to 3400. And remember, in the example I used, these are the MAXIMUM.

Next, go put your engine on the dyno, and measure it's peak power with optimum timing, then with 3 degrees too much, then with 3 degrees not enough. Firstly; the engine will lose more power with 3* too much timing than with 3* not enough. But more importantly, what are the numbers? Sometimes the numbers are so small as to be almost meaningless. But lets say you get 7hp at 5200 rpm. Now go back to 2400rpm. Take a guess how much power you will lose with 3* not enough timing, at 2400rpm.

But you say, what has power-timing to do with what I feel at PT at under 18 mph?

Answer; EVERYTHING. For a HotRodder, your Power-timing has to set the tone/be the baseline, for all your engine's timing needs; and the thing we use to flush out the timing for PT use, is the Vcan. With a decent compression engine, you can modify your Vcan to supply up to 24 degrees over and above the power-timing at any rpm between idle and say 3400, rpm depending on how you the tuner set it up.

So with just 14* mechanical timing at 700rpm, you could change this to 14+24=38*@2400. And say you are taking off normally and the 24* stays in all the way to 3400, where it is now 34+24=58*; or

Say you floor it right off idle. the vacuum falls to below what you have set the V-can to, the engine spools up to stall(2400 in my example) and the beast takes off. or

Say you are just motoring to the icecream store, at some modest power level, and the Vcan is bringing in only 12*. Now your timing is say 18* mechanical plus 12 in the can =30degrees.

Lets suppose that in these examples ,all of them are acceptable to your engine with no detonation. I mean you tuned it to be right.....

Now; tell me again , how an initial Idle-timing of more than 14* in this example, would be helpful.

In these examples, all the settings are such that the maximum pressure in the chamber is delivered to the crank at or just after the decades old proven best point, in the which the crank can transfer that pressure in the most efficient way. Neither more nor less timing will produce more efficiency nor more power, because you the tuner, have paid attention to your engine, never mind what some guys on the internet tout.

If you build your timing curves on the wrong baseline, you will never get it right. And for a street HotRod, the V-can is your engine's best friend.

And you know why?

Because, your engine will spend it's entire life, except maybe 1% of it, at some other throttle position,less than WOT; so why worry about 7 hp at 5200rpm much less 3hp at 3400, much less on the power at sub-stall rpm, which you can easily manipulate with either the V-can, or with throttle position.

And finally; you have got to set your transfer-slot exposure just right, to prevent an off-idle tip-in hesitation. The transfers should be your primary low-rpm and idle fuel supply.

If your slot is too small, the transfer fuel will be reduced in volume, (which you can augment with the mixture screws for idle, and the idle will be just fine), and the transfer fuel delivery rate will slow down, which, at tip-in, will take time to start up again, ergo the hesitation.

If an automatic, going into gear, the new load will be too high for the starving transfers, and the engine will just stall.

After setting the transfer slot exposure, the only way you have of setting the idle-speed, is with idle timing. So, if you start with some, in my opinion, fantastic Idle-Timing, your exposure is GUARANTEED to be too small. If you do that, you will pull yur hair out trying to keep the engine from stalling when you put it into gear, and it will be impossible with pump-shot, to solve the tip-in hesitation..

Don't be that guy

At the risk of pizzing off a few gurus, forget about targeting fantastic Idle-timing numbers; 12 to 16 will get your transfers into the ballpark. Then after you get the Power-Timing worked out from stall to ~3400/3600, start dialing in the Vcan to give you back the PT timing your engine will crave.

Btw, in my examples, YES, I biased the numbers to prove my point. Your targets are specific to your engine, and 1.0degrees per 100rpm may not be achievable with your parts; don't be thinking your combo wants or needs 1.0, let her tell you what she wants. To do that, I installed a dash-mounted, dial-back, timing-retard box with a range of 15 degrees. Which made it fairly easy.

Last edited:

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,913

- Reaction score

- 12,263

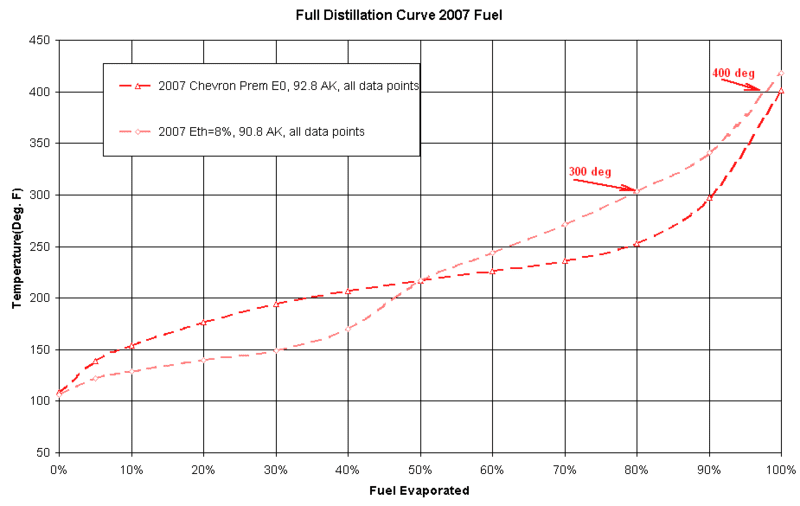

Nice chart @MattaxFor example, this 8% eth fuel began to vaporze just over 100 degrees F, same as the non-eth. But it required over 300 degrees to vaporize the last 20% of the fuel.

It needed over 400 degrees to completely vaporize all of the fuel.

Which is part of the reason, that I set my DCr so high, and set the minimum coolant temp to 207*, and she often idles with header temps at the ports being in the range of 450 +/- 25 degrees. Now granted some of that heat could be due to the exhaust still burning in the header due to my retarded idle-timing of just 14*, and partly because of the relatively short time spent in extraction of just 105*. But I did what I could, running 87E10 at 180 to 185 psi.

The previous cam had 111* of extraction, and did way better in every area except power after 5000 rpm or so.

I will never again, willingly, run pressure lower than about 160psi, with a carburator, on 87E10. The fuel in the old tanks just will not remain fresh enough, long enough, and the engine ends up with not enough VOCs to start on, or idle decently. And at the other end 10 or 20% or more won't burn either, so is it any wonder the engine uses a a lot of gas?

No wonder at all.

Check out the cross-over at 50%; is that about 212*F? lol.

Check out the 100% burn at 425*F for 8%

I would run hotter than 207, but 207 allows me to run a 7psi cap, and so, my hoses last for decades, not to mention my rad is from 1973; which, if my math is right is coming 48 or more years old . I mean, until recently, a guy could buy a lotta gas for the price of a new rad.........

I think you lost the OP, or maybe we all did. LOL.

@dartfreak75

Whatever the engine has in it, you can tune to it.

The whole discussion about an expected range of initial and typical best high rpm timing under full load is to keep what you are testing in the ballpark.

Lets go over what is known and not known about the advance.

OK. This is possible when using two primary springs, but that still doesn't explain the top end.

The way to settle what the advance looks like is to get it to idle slow and then lock down the distributor and increase rpm.

If you can get 600 or 650 rpm great.

maybe do the low speed ones twice because one the engine is hot there is a better chance of idling it slow.

Try to measure with increasing rpm rather than letting off the throttle as there is some uh er slop.

You can

measure the rpm for every increase in a degree (or two)

or

measure the timing for every 100 or 150 or 200 rpm. In the mid and upper rpms you can space that out to every 250 or 500 rpm.

Whichever is more convenient.

For 3500 to 4500 rpm I usually just do something that is almost like winging it. I open the throttle quick take a quick measurement and let it come back down.

If it doesnt feel safe to you dont do it. We all of differnt risk tolerances for different things.

When you have that all written down, we can plot it out.

Then you'll know what the advance is doing.

Also, if you are later going to use this lwith vacuum advance you can also see where problems may occur and head them off.

Even if timing is not advancing until 1000 rpm, there's a big difference if its dropping 50 rpm vs. 200 rpm when placed in gear. One is pretty good for a cammed engine the other shows a lack of power.

@dartfreak75

Whatever the engine has in it, you can tune to it.

The whole discussion about an expected range of initial and typical best high rpm timing under full load is to keep what you are testing in the ballpark.

Lets go over what is known and not known about the advance.

I had about 34 total when I was at 14 intial

These are showing quite a bit different amounts of advance. 20 and 26. I wouldn't call one or the other correct at this point.14 and checked the total again im getting 40 total without vacuum

I will check the timing with the idle reduced to see if the mechanical is advancing at 850rpm

14 and started over same thing this time used 700 rpm

The timing didn't change at any rpm below 1000 600-1000 it doesn't change over 1100 the mechanical advance starts to open up and kick in I played with the idle speed went all the way down to it almost dying all the way up to 990 and the timing never changed

OK. This is possible when using two primary springs, but that still doesn't explain the top end.

The way to settle what the advance looks like is to get it to idle slow and then lock down the distributor and increase rpm.

If you can get 600 or 650 rpm great.

maybe do the low speed ones twice because one the engine is hot there is a better chance of idling it slow.

Try to measure with increasing rpm rather than letting off the throttle as there is some uh er slop.

You can

measure the rpm for every increase in a degree (or two)

or

measure the timing for every 100 or 150 or 200 rpm. In the mid and upper rpms you can space that out to every 250 or 500 rpm.

Whichever is more convenient.

For 3500 to 4500 rpm I usually just do something that is almost like winging it. I open the throttle quick take a quick measurement and let it come back down.

If it doesnt feel safe to you dont do it. We all of differnt risk tolerances for different things.

When you have that all written down, we can plot it out.

Then you'll know what the advance is doing.

Also, if you are later going to use this lwith vacuum advance you can also see where problems may occur and head them off.

This was two questions.which is it 650 or 750 ? where is the timing at in gear ?

Even if timing is not advancing until 1000 rpm, there's a big difference if its dropping 50 rpm vs. 200 rpm when placed in gear. One is pretty good for a cammed engine the other shows a lack of power.

I used @318willrun method of timing i started with my idle at 800 in neutral bumped the timing up a couple degrees till the idle increased then reset the idle and continued to do that until it no longer increased the idle then took about 3 or 4 degrees out of it I ended up at 24 degrees! That seems like alot of initial timing to me. Im not getting any starter kick back it seems to run good i haven't driven it yet with this setup I wanted to check with yall first and make sure I don't damage anything by running to much. I know without vacuum I had about 34 total when I was at 14 intial so that's gonna put me at like 44 total now. That seems like too much to me?

View attachment 1715734380

View attachment 1715734381

Lesson here is never us a 318willrun method.... LOL

- You used the first method for ballpark initial. "no starter kick back and it seems to run good" (most engines do when they get what they want)

- You didn't use the second method of setting total, which includes welding slots or FBO plate

- Thirdly, if you are going to use my methods, and use a VA, you'd better be tuning to VA also. I don't run the VA on any of my "hot rod" applications.

- Last... For those that don't know, here are the two videos in which the "318willrun Methods" in question ...

Last edited:

shittyslant6

Well-Known Member

hot damn.At idle, and keeping the speed constant, just tug on the V-can until the speed no longer increases. Now you have found the optimum idle timing at that rpm. Don't be surprised to see the timing climb to deep into the 20s and higher.

If you continue to add advance past the optimum point, the speed goes down because the crank is no longer in the best position to receive it so the pressure is trying to ram the rod into the crank instead of turning it.

Think of it this way; remember as a kid blowing on one of those whirlygigs you made in play-school? If you blew at just the right angle. you could get maximum speed. Same idea . You set the initial, to get the max pressure to the crank when it is in just the right position.

But that is at idle with no load on it. Just one condition of millions of possibilities.

I keep telling you guys, as to power, the engine doesn't hardly care what the timing is, until the stall rpm, and then doesn't care, as long as the curve is fairly linear, until full-power,WOT at about 3400/3600. That is the zone we have to concentrate on getting right. With 3.55s and 27s, and in 2.45 low gear, this happens between about 18 mph and 28 mph.

That is where your power-timing has to be spot on, erring on conservative every single time..... because this is the zone your engine will spend most of it's life.

now; lets say the power-timing has to be not more than 24* at stall of 2400. and not more than 34* at 3400. The rpm range is 1000rpm, and the timing range is 10degrees. That computes to 10/1000 X 10= 1.0 degree per 100 rpm. That is your mandatory maximum power-timing curve. Now for a pair of same length springs, extrapolate 1 degree per 100, back to say 1000 from 24* at 2400. I get an idle-timing of ;

(2400 less 1000/100) x 1.0=14 degrees beginning at 1000rpm.

Ok now; I don't care what you set your idle-timing to, but if 24* at 2400 is the max, with single-stage springs rated at 1.0 degrees per 100 rpm, if it is not 14* at idle; it will be DEAD WRONG from stall to 3400. And remember, in the example I used, these are the MAXIMUM.

Next, go put your engine on the dyno, and measure it's peak power with optimum timing, then with 3 degrees too much, then with 3 degrees not enough. Firstly; the engine will lose more power with 3* too much timing than with 3* not enough. But more importantly, what are the numbers? Sometimes the numbers are so small as to be almost meaningless. But lets say you get 7hp at 5200 rpm. Now go back to 2400rpm. Take a guess how much power you will lose with 3* not enough timing, at 2400rpm.

But you say, what has power-timing to do with what I feel at PT at under 18 mph?

Answer; EVERYTHING. For a HotRodder, your Power-timing has to set the tone/be the baseline, for all your engine's timing needs; and the thing we use to flush out the timing for PT use, is the Vcan. With a decent compression engine, you can modify your Vcan to supply up to 24 degrees over and above the power-timing at any rpm between idle and say 3400, rpm depending on how you the tuner set it up.

So with just 14* mechanical timing at 700rpm, you could change this to 14+24=38*@2400. And say you are taking off normally and the 24* stays in all the way to 3400, where it is now 34+24=58*; or

Say you floor it right off idle. the vacuum falls to below what you have set the V-can to, the engine spools up to stall(2400 in my example) and the beast takes off. or

Say you are just motoring to the icecream store, at some modest power level, and the Vcan is bringing in only 12*. Now your timing is say 18* mechanical plus 12 in the can =30degrees.

Lets suppose that in these examples ,all of them are acceptable to your engine with no detonation. I mean you tuned it to be right.....

Now; tell me again , how an initial Idle-timing of more than 14* in this example, would be helpful.

In these examples, all the settings are such that the maximum pressure in the chamber is delivered to the crank at or just after the decades old proven best point, in the which the crank can transfer that pressure in the most efficient way. Neither more nor less timing will produce more efficiency nor more power, because you the tuner, have paid attention to your engine, never mind what some guys on the internet tout.

If you build your timing curves on the wrong baseline, you will never get it right. And for a street HotRod, the V-can is your engine's best friend.

And you know why?

Because, your engine will spend it's entire life, except maybe 1% of it, at some other throttle position,less than WOT; so why worry about 7 hp at 5200rpm much less 3hp at 3400, much less on the power at sub-stall rpm, which you can easily manipulate with either the V-can, or with throttle position.

And finally; you have got to set your transfer-slot exposure just right, to prevent an off-idle tip-in hesitation. The transfers should be your primary low-rpm and idle fuel supply.

If your slot is too small, the transfer fuel will be reduced in volume, (which you can augment with the mixture screws for idle, and the idle will be just fine), and the transfer fuel delivery rate will slow down, which, at tip-in, will take time to start up again, ergo the hesitation.

If an automatic, going into gear, the new load will be too high for the starving transfers, and the engine will just stall.

After setting the transfer slot exposure, the only way you have of setting the idle-speed, is with idle timing. So, if you start with some, in my opinion, fantastic Idle-Timing, your exposure is GUARANTEED to be too small. If you do that, you will pull yur hair out trying to keep the engine from stalling when you put it into gear, and it will be impossible with pump-shot, to solve the tip-in hesitation..

Don't be that guy

At the risk of pizzing off a few gurus, forget about targeting fantastic Idle-timing numbers; 12 to 16 will get your transfers into the ballpark. Then after you get the Power-Timing worked out from stall to ~3400/3600, start dialing in the Vcan to give you back the PT timing your engine will crave.

Btw, in my examples, YES, I biased the numbers to prove my point. Your targets are specific to your engine, and 1.0degrees per 100rpm may not be achievable with your parts; don't be thinking your combo wants or needs 1.0, let her tell you what she wants. To do that, I installed a dash-mounted, dial-back, timing-retard box with a range of 15 degrees. Which made it fairly easy.

ever thought of writing this all down in a book?

almost every technical thread you reply with paragraphs of technical wizardry.

here's why I'm suggesting you measure the advance.Its set at 20 intital right now and the bottom end feels good.

Assuming that 20 initial is at 850 rpm and lets compare to a Chrsyler built MP distributor with the initial set at 12* at same rpm.

IF there are two primary springs, whgich would explain the advance not moving until 1100 rpm, maybe the timing looks like this.

it might be a little weaker at idle, but in low speed driving feel really good. It probably will even be OK with vacuum advance, except maybe on the highway or interstate. just generalizing here

And if that same advance was set at 14* 850 rpm, the engine might respond a bit like an old dog (assuming the Mopar Performance advance is close to what the engine wants).

The shape of the advance curve matters!

Which means a really quick advance can be used.I don't run the VA on any of my "hot rod" applications.

The rpm range where too much mechanical timing really pings with vacuum advance is usually 2000-3000 rpm under light to moderate load. I've even had it happen on a drizzly day on a long trip at state highway speeds.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,913

- Reaction score

- 12,263

The shape of the advance curve matters!

The two-stage curve is, IMO, the key to making a hi-compression manual-trans combo, come alive. It allows for modest Idle-Timing, running to the target at stall, and then slowing down to prevent detonation after stall, yet still advancing to the limit for your gas, after; in the range of 3000 to 3600. That is how I have been able to run 87E10 at up to 195psi with alloy heads. The 360 has so much torque, that if there is a power lag from my hinge-point of 2800, to 3400, I have never felt it.

I think you lost the OP, or maybe we all did. LOL. @dartfreak75.

Unfortunately, that's all too popular a trend for him. He's just gotta show "how smart" he is while losing the person that was supposed to be helped down a proverbial chit filled toilet.

hot damn.

ever thought of writing this all down in a book?

WHERE exactly do you think HE'S gettin it from? LOL

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,913

- Reaction score

- 12,263

Don't get too excited, there are plenty of guys here that are waaaay smarter than me. Being semi retired at age 68, I just have the time to run my mouth. I know a little about a lot, but not particularly a lot about a little. There are quite a few guys here that do..... know a lot, in their chosen fields, and occasionally beyond.ever thought of writing this all down in a book?

However, I thank you for appreciating my long-winded posts; not everyone does. Some guys say that I'm a post-***** whatever that is, or that I just like to hear myself talk, lol. Well hey, I only have 12 promised years left in me, if the world doesn't end first, so maybe they are right.

Most of what I write (except for in the N&P Forum) comes from personal experience, but not all; and when it doesn't, I preface it with IMO. So whenever you see "IMO", you can separate my experience from my opinion, pretty simple. And just cuz I have a certain experience, doesn't mean someone else cannot have a different valid certain experience, in the very same area. This hobby is infused with many different ways to get to the same end-result. IMO, I have the best 360 combo ever built. In another's opinion, I shouldda built a 340 or a 318, or a smaller cam or a bigger one or why in heaven's name do I have alloy heads, etc. I doubt there is a perfect combo. For instance, my combo is on it's third iteration and I had high regards for each one. But this third iteration, IMO, is not as good as the previous one. Oh sure, I made it work, and it is faster/quicker/and more powerful than either of the first two,but IMO, the previous was more everything else, especially more fun, and most especially, easier on gas-money. So while each iteration started out as perfect for me, me changed, and then the combo was no longer perfect. I just try to help people not get into this type of situation in the first place.

Last edited:

Don't get too excited, there are plenty of guys here that are waaaay smarter than me. Being semi retired at age 68, I just have the time to run my mouth. I know a little about a lot, but not particularly a lot about a little. There are quite a few guys here that do..... know a lot, in their chosen fields, and occasionally beyond.

However, I thank you for appreciating my long-winded posts; not everyone does.

Some guys say that I'm a post-***** whatever that is, or that I just like to hear myself talk, lol. Well hey, I only have 12 promised years left in me, if the world doesn't end first, so maybe they are right.

Meh, you do a lot more than run your mouth. You help a ton of people......but you do have a bad habit of losing them in mega techno bullshit that doesn't need to be there. I fart a lot. We all have our faults.

Last edited:

yellow rose

Overnight Sensation

Meh, you do a lot more than run your mouth. You help a ton of people......but you do have a bad habit of losing them in mega techno bullshit that doesn't need to be there. I fart a lot. We all have our faults.

You could have left the second to last sentence out. Now I can’t I think that.

You could have left the second to last sentence out. Now I can’t I think that.

If you hold your nose to the east, you can probably smell it.

At least you live in Georgia! By the time that foul smell would drift to Texas it would not have the impact it once did! You guys are the best!If you hold your nose to the east, you can probably smell it.

dartfreak75

Restore it, Dont part it!

Thanks buddy yall didn't loose me im still here I have been busy at work I don't get on the internet much during the week when I'm working. I will be off on Saturday tho and we will continue this journey lol I gotta talk to Dana about my carb I may end up pulling it. I have a spare holley I can use for a min. Im gonna order the fbo kit and play around with the total some. Thanks for all your help you have shed a crap ton of light on this situation. I still have a bunch of questions but we'll ge to them as they come. I have a bad habit of jumping the gun on questions and once I start working on it I realize the questions I asked were pretty self explanatory.I think you lost the OP, or maybe we all did. LOL.

@dartfreak75

Whatever the engine has in it, you can tune to it.

The whole discussion about an expected range of initial and typical best high rpm timing under full load is to keep what you are testing in the ballpark.

Lets go over what is known and not known about the advance.

These are showing quite a bit different amounts of advance. 20 and 26. I wouldn't call one or the other correct at this point.

OK. This is possible when using two primary springs, but that still doesn't explain the top end.

The way to settle what the advance looks like is to get it to idle slow and then lock down the distributor and increase rpm.

If you can get 600 or 650 rpm great.

maybe do the low speed ones twice because one the engine is hot there is a better chance of idling it slow.

Try to measure with increasing rpm rather than letting off the throttle as there is some uh er slop.

You can

measure the rpm for every increase in a degree (or two)

or

measure the timing for every 100 or 150 or 200 rpm. In the mid and upper rpms you can space that out to every 250 or 500 rpm.

Whichever is more convenient.

For 3500 to 4500 rpm I usually just do something that is almost like winging it. I open the throttle quick take a quick measurement and let it come back down.

If it doesnt feel safe to you dont do it. We all of differnt risk tolerances for different things.

When you have that all written down, we can plot it out.

Then you'll know what the advance is doing.

Also, if you are later going to use this lwith vacuum advance you can also see where problems may occur and head them off.

This was two questions.

View attachment 1715735637

Even if timing is not advancing until 1000 rpm, there's a big difference if its dropping 50 rpm vs. 200 rpm when placed in gear. One is pretty good for a cammed engine the other shows a lack of power.

I just ordered the FBO kit (with springs & the book). Springs are backordered because they were not happy with the spring quality, so they found a different supplier. They have the plates in stock, just not the kit with the springs.Thanks buddy yall didn't loose me im still here I have been busy at work I don't get on the internet much during the week when I'm working. I will be off on Saturday tho and we will continue this journey lol I gotta talk to Dana about my carb I may end up pulling it. I have a spare holley I can use for a min. Im gonna order the fbo kit and play around with the total some. Thanks for all your help you have shed a crap ton of light on this situation. I still have a bunch of questions but we'll ge to them as they come. I have a bad habit of jumping the gun on questions and once I start working on it I realize the questions I asked were pretty self explanatory.

IMO you'll be better off measuring what the distributor is doing. Then go from there.Im gonna order the fbo kit and play around with the total some.

In general the FBO plate is more difficult to get a good curve shape with. It's fine if all that's needed is a straight line of advance but in general a shaped (aka two stage) advance will produce better overall results.

dartfreak75

Restore it, Dont part it!

Thats what I was gonna buy too the kit with the tuning book for like 69$.I just ordered the FBO kit (with springs & the book). Springs are backordered because they were not happy with the spring quality, so they found a different supplier. They have the plates in stock, just not the kit with the springs.

dartfreak75

Restore it, Dont part it!

I know what the distributor is doing the mechanical advance is starting somewhere around 1100 and im getting a total of 26 degrees advance from the mechanicalIMO you'll be better off measuring what the distributor is doing. Then go from there.

In general the FBO plate is more difficult to get a good curve shape with. It's fine if all that's needed is a straight line of advance but in general a shaped (aka two stage) advance will produce better overall results.

dartfreak75

Restore it, Dont part it!

Do I need to know more? Is there more to it than that? There has been alot of discussion i want to learn as much as possible. What do you think i need to know more about ?

I was under the impression that the plate simply limited total advance, and the springs were for tuning the curve.IMO you'll be better off measuring what the distributor is doing. Then go from there.

In general the FBO plate is more difficult to get a good curve shape with. It's fine if all that's needed is a straight line of advance but in general a shaped (aka two stage) advance will produce better overall results.

-