Ok, so limited time with it today. AJ, as always thanks for the reply! Next step is to do the T-port sync. I didnt want to dig into the carb until later as Im not too confident in getting it done "quickly" lol.

What I did today was install air cleaner, turn out IMS screws 2 full turns, that gave me 14" HG at choke port.

Fine tuned both independently until I got approx 15" HG, and in park idle was approx 725. Leaned out IMS(clockwise) until I got rpm to drop to approx 710 rpm in park. In gear 600 rpm. At this point IMS screws were 1 3/8" turns out. Initial timing 25*(vac plugged)50* All in at 3500 rpm(vac plugged)

Yeah, I see what you are doing, but it is just barely working.And it is only good for idling when fully warmed up. How does it take being put into gear?And how well does it take small amounts of throttle?

See; in my world you are doing it backwards. You may get to a similar place, but it's a lot more work.

And then you can see that 50 less 25 = 25* in the Dist. If your engine likes 36* (no more!, and NOT 50*) of power-timing then your idle-timing will have to be 36 less 25=11* initial. Let's talk about that for a sec.

If you retard the timing from the current 25* to the no-mods-required 11*, then the idle will slow right down and the idle vacuum will also drop. To keep the engine running, you will need to crank the speed screw in. This will run the throttle valves up the transfer slots and richen up the idle mixture. Maybe it will be too-rich now, and so you will need to close up the "IMS", some. The thing is, 1.375 turns is pretty close as it is now. But, by your own admission, you currently leaned them out from a best of 2 to the current 1.375. That's not normal. Normal in my world is slightly richened up from best lean idle( maybe 1/4T). This prevents sags on tip in, and is a big help in keeping a cold engine running without a choke. So that is what I would do.

The way that you have it now; if it takes only about a 110rpm hit when going into gear, and if it is happy at 600 in gear, and if it stays running when cold without too much baby-sitting, and if the starter doesn't kick back, and if it doesn't detonate!, (phew that's a lot of ifs), then there is no reason that you would have to retard the initial.

But, But, BUT, you cannot run 50* of power-timing! It matters not that you cannot hear detonation; there is no SBM ever built to run on pump gas that will survive 50* at full-load-WOT. I have to wonder if you know what detonation sounds like.........

So if you really want to run 25* initial, then you are going to have to modify the centrifugal advance mechanism.

Furthermore the all in by 3500 is a bit tardy. It is however pretty safe, if you are having trouble hearing or identifying Detonation. I would leave modifying that for later.

And at 2000 rpm with vac can hooked back up, approx 60*(approximation as my tab and balancer doesnt read that high accurately.) 60* may be ok or it may not, but after you limit your power timing this will change, so don't worry about it for now.

Im not sure exactly how to analyze these readings, but I will take a stab at it later.

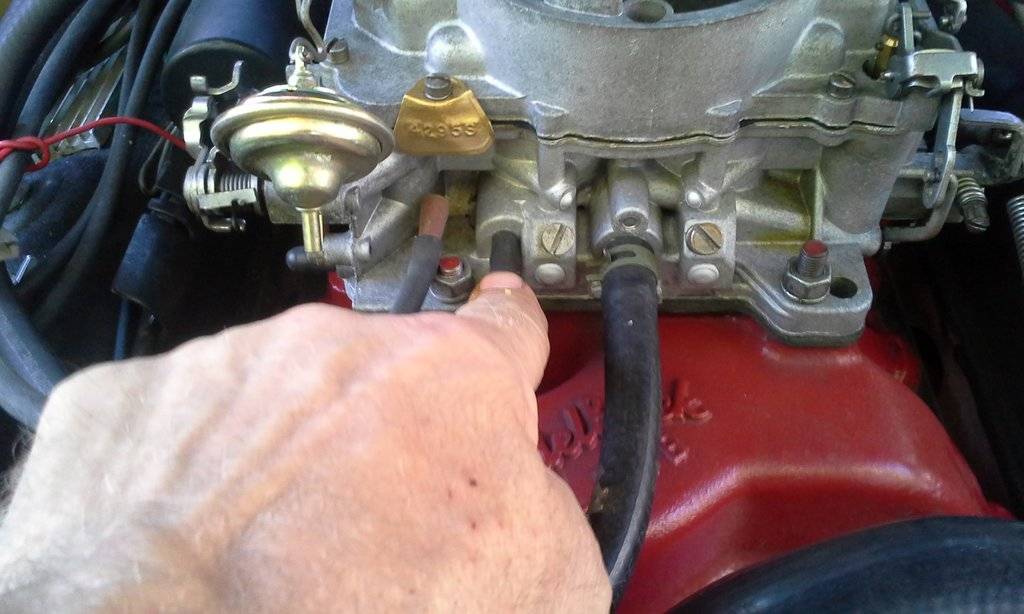

Oh more info, Carter 4295S has 16-405 factory metering rods(3step). Rebuild kit didnt come with new jets, so those are originals too. As are the springs, but I dont think they are the issue as it idle they are all the way down?? Correct me if Im wrong. At idle, the only circuit that is supposed to be active is the slow-speed circuit, which is the transfer slots and the "IMS"

Dist has 7r stamped on vac can arm, so thats 14* of vac advance correct? Yes

Thanks again!