I didn't mean for it to sound like I'm against degreeing a cam. When I talked about myself and my friends back in the day didn't do that because we didn't know any better and we just got lucky. I like how you described the process of elimination when a engine isn't running correctly or isn't making good power.Dan, it’s not about not having problems. Its about doing it RIGHT, so the end user KNOWS where the cam is installed EXACTLY because that is what matters.

So let’s say you dot to dot that cam and we put it on the dyno. And it’s ****. Doesn’t make the power it should. Where do we start? Simple things first. Ignition timing. Valve lash. Blame the dyno. That’s about it. Now you’re just guessing at why it’s a pig.

One then has to assume if you won’t or can’t degree a cam (no one should assemble an engine if you can’t degree a cam, correctly measure and determine the correct amount of piston to valve clearance and correctly measure for compression ratio but that’s my opinion because if you don’t do that you have no idea why the engine makes the power it does) that you cut every other corner you can. So we are back to square one. WTF is wrong. We have no idea because nothing was verified.

Same thing going to the track, except now you’ve added in a whole set of new possible issues to try and sort out if the car doesn’t “run the number” and if you didn’t do all the above so you know and put it on the dyno you are just guessing.

Just because something runs after its put together doesn’t mean is correct.

Why Dan are YOU so personally opposed to degreeing a cam? Because you defend NOT doing it. As a machinist and an engine builder it’s appalling that guys refuse to get out the “back in the day” mode and never learn or do anything new to make the process better.

So why Dan are you so vehemently against degreeing every cam, every time?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What could cause this? 360 problems ####update####

- Thread starter ike61

- Start date

-

I built my first piston stop in about 1972. NINETEEN SEVENTY TWO and I still have it, why? Because I started finding stuff like Fords (yeah I built one of them, too) with balancers that slipped, and I've found a few Mopars that slipped. MOST OF THE MOPARS that I've run across that were wrong on the balancer mark were newer/ older engines with differing timing covers, in other words and early engine with late timing cover or vice versa and now the marks just plain way WAY off. So, "piston stop" to the rescue

Then I started reading about cams with built in retard/ advance from "straight up." This actually started happening in the "smog ere" back in the 70's

Then I started reading about manufacturing tolerances that can "add up" in the wrong direction

Then I started reading about Chinese/ other imported parts that were just plain out of tolerance

Then I started reading about cams with built in retard/ advance from "straight up." This actually started happening in the "smog ere" back in the 70's

Then I started reading about manufacturing tolerances that can "add up" in the wrong direction

Then I started reading about Chinese/ other imported parts that were just plain out of tolerance

I think that's the one I had in mind. Still, very affordable.Actually rob I think this is it and it's gone up a bit. I believe this is the one I have, which used to be about a hundred

Summit Racing SUM-G1056-16 Summit Racing™ Cam Degreeing Kits | Summit Racing

Free Shipping - Summit Racing™ Cam Degreeing Kits with qualifying orders of $109. Shop Camshaft Degree Kits at Summit Racing.www.summitracing.com

I'm surprised that anyone hasn't learned how to degree without a wheel.

Dan, fact is you gotta remember the Chineese do everything upside down and backwards half the time !I've installed many a cam and timing chain and never degreed them. Lined up the dots and no problem. I'm not saying that it shouldn't be done it's I never had any problems with the valve's hitting the pistons and we installed performance cams the same way

That's no joke. I think that's why I can't buy a Chinese air gap intake manifold and cylinder heads, especially when edelbrock is made and machined here in the states. Is trick flow made here?Dan, fact is you gotta remember the Chineese do everything upside down and backwards half the time !

How about going through 3 sets of pushrods to get a set that were close in tolerance to one anotherI agree. comparing parts is one of my pet peeves, I like to know if a new part is within spec of an old.

You ever found a new valve shorter than the advertised spec.

Rat Bastid

Dunamis Metron

I didn't mean for it to sound like I'm against degreeing a cam. When I talked about myself and my friends back in the day didn't do that because we didn't know any better and we just got lucky. I like how you described the process of elimination when a engine isn't running correctly or isn't making good power.

I couldn’t get out of high school auto shop without knowing how to degree a cam. And that was 1980-1981. And you had to do @.050 and ICL methods.

That's where I learned how to check without a wheel.I couldn’t get out of high school auto shop without knowing how to degree a cam. And that was 1980-1981. And you had to do @.050 and ICL methods.

I think it was called the Isky split overlap method.

Rat Bastid

Dunamis Metron

That's where I learned how to check without a wheel.

I think it was called the Isky split overlap method.

Yep. You won’t know exactly where it is, but you’ll know if it’s advanced, retarded or straight up.

autopar3000

Well-Known Member

Here's how the setup looks on the 5.9 Magnum I put into my car a couple years back. I could see how someone might line up the dot from the keyway instead of the correct one. I suppose the manufacturer could also screw up and simply not put the dot on the crank sprocket, leading the builder to believe the dot on the keyway is the right one.

There's really no excuse, the piston is not near TDC with the key straight up.Here's how the setup looks on the 5.9 Magnum I put into my car a couple years back. I could see how someone might line up the dot from the keyway instead of the correct one. I suppose the manufacturer could also screw up and simply not put the dot on the crank sprocket, leading the builder to believe the dot on the keyway is the right one.

View attachment 1716059851

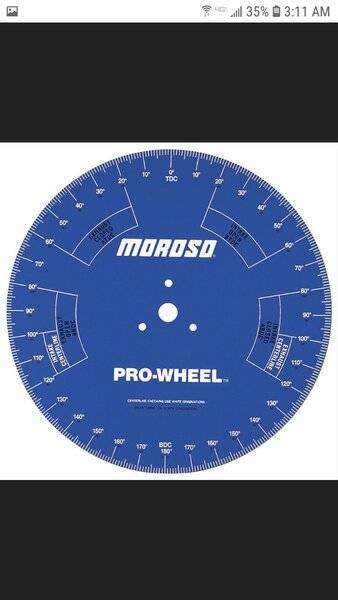

Here you go guys download this degree wheel print it to the size you want, and stick it on an old road sign, cut to fit proper diameter.

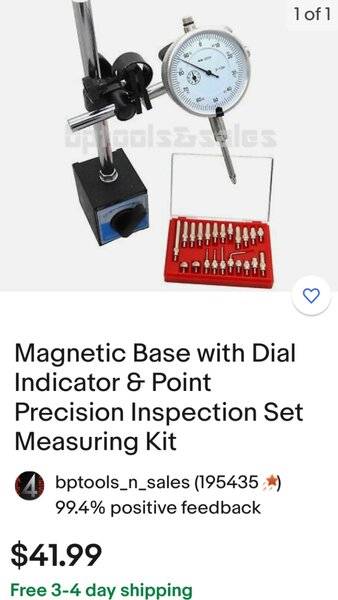

Then buy the dial indicator set from ebay.

Then make up a piston stop from an old spark plug like > 67dart273

All set, everything you need to degree your cam for 50 bucks and a little time.

☆☆☆☆☆

Then buy the dial indicator set from ebay.

Then make up a piston stop from an old spark plug like > 67dart273

All set, everything you need to degree your cam for 50 bucks and a little time.

☆☆☆☆☆

I bought an actual degree wheel for cams, an it does double duty measuring angles of bend on my hydraulic steel tubing bender for 1" and 1 1/2" .090 ths wall steel tubing.

Secondary Benefits to the original plan.

☆☆☆☆☆

Secondary Benefits to the original plan.

☆☆☆☆☆

I bought an actual degree wheel for cams, an it does double duty measuring angles of bend on my hydraulic steel tubing bender for 1" and 1 1/2" .090 ths wall steel tubing.

Secondary Benefits to the original plan.

☆☆☆☆☆

Good for setting advance on distributors too without a machine. Put a long pointer taped to rotor, twist advance, note change, multiply by 2.

Hillbilly Tools Inc.

And on point with this thread. Crank keyway points inline with #1 cylinder, cam key will make a roughly 90* angle if drawing line with #1 cylinder/keyway line. If they don't intersect over there, you have an issue. Tools are CHEAP now compared to buying Starrett .001-.0001 dial indicators back in the 70-80's... $$$$

When tearing stuff down, take a dang picture to get an idea of how it should look when going back together. So much easier now than in the past when you had to sketch out stuff, like drum brake assemblies before tearing them down. Snap a photo for reference. Plenty of pics on the net for reference as well.

Last edited:

i once paid extra for that. crazy verna and big wendy were tender, yet rough.That's where I learned how to check without a wheel.

I think it was called the Isky split overlap method.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 26,613

- Reaction score

- 13,847

This is just too easy;If the cam is still installed you can do a quick-check without taking the front off.

1) roll the crank around until # 6 piston is at TDC and on what would be it's compression stroke. You can tell this by the fact that the lifters do not move when you shuttle the crank back and forth. If this is not the case, then the cam is NOT in right; go to step 4.

2) Go to the #1 piston. Lay a straight-edge across the lifters. Shuttle the crank a few degrees either way until the straightedge contacts each of the two lifters in at least two places. The straightedge should be about parallel to the deck. Now read the degrees on the timing tab, relative to the TDC mark on the balancer.

3) Assuming the TDC mark is correct, it should be within about 4 degrees of TDC on the timing tab, and the piston should be within a few thousands of the deck, or at least from TDC. If this is not the case, then the cam is NOT in right; go to step 4.

4) Now you are justified in pulling the front off. When you get there,

Make sure the cam-key is installed and the Bolt is torqued properly

when you go to do the New install, you do the exact same thing.

1) You put the #1 piston at TDC.

2) You put the cam in, remove the timing key, rotate it to split-overlap on the #1

3) assemble the chain dot-to-dot, and slip it on.

4) LOOK at the alignment of the keyways:

If the two are not even in the same window; verify numbers 1 and 2

If still synced, one of the sprockets is marked wrong. figure out which way the cam sprocket has to go, and how far, to get into the window, then make it so.

Once the keyways are thus in the ballpark, re-install the cam key, then re-install the timing set.

With the crank thus at TDC#1, and the cam at split overlap on #1, I guarantee the cam-timing is close enough that the engine will run and will run really well. At this point, for a streeter, degreeing the cam is IMO, just a formality.

The cam thus installed, is MOST LIKELY, somewhere between 4 degrees advanced and straight up, +/- maybe 2 degrees; and I guarantee you that only the dyno is gonna find the WOT power difference.

Where the observable power difference will be felt is between stall rpm and about 3200+/-200 rpm, because of the change in cylinder pressure. If you have a typical high-stall convertor around 3000rpm; you may never know if the cam is out, and not knowing, you will never care.

But:

If you have a clutch with hiway gears; well #1, you need to pay closer attention to the combo in the first place, cuz cylinder pressure is gonna make or break the fun-factor.

--------------------

Here's my proof;

My first cam, in my 367 combo, was the 292/292/108.

I degreed it at 0* advanced because theoretically with 11.3Scr the cylinder pressure should have been awesome, and the top-end was, but the bottom was IMO pretty soft.

Before the summer was over, I had retimed that cam three more times from 4* retarded to 8* advanced.

Here's the deal, that cam simply did not like the combo of A833/3.55s. It ran like a cat on fire with 4.30s, but even a Smog-era Teener runs pretty good with that combo.

I really wanted to run the 3.55s, having traded away my rarely used 4.10s straight up, to get them. I decided that 292cam was not for me, and sold it straight away, to a racer. BTW, that cam measured about 249@.050

The point is this; timed anywhere from 8 Advanced to 4 retarded, on the street with street tires, and the A833/3.55 combo, the after-3500 performance difference was immeasurable, by my butt-dyno.

The next cam was a complete blast to drive.. this was a 223/230/110@.050 and made so much pressure that I ended up running it at 2* retarded, and she loved it, pulling to waaaay past 6000 thru the Edelbrock heads. That cam spent most of it's short life running up to 7000/7200 on the street cuz 60mph was ~7100 at the top of First gear, and the sound of a 367 screaming at 7200 thru dual 3" pipes, to me, was/is, intoxicating. I would never have changed this cam, had it not begun to drop lobes.

The Final cam, installed in 2004 is a 230/237/110 . This cam dropped the cylinder pressure quite a bit, when in at 2* retarded and 10.95 Scr; so it got re-timed to +2*, in the following winter, where it has been ever since.. This brought the pressure to around 177psi..

-------------------------------

I suppose that if you had a low-pressure smaller engine, it might be more sensitive to cylinder pressure loss from cam-timing; but again, with a 3000 stall, I doubt you'll ever feel it.

BUT, with a clutch, I guarantee you can can feel the low-rpm difference.

For a clutched 318, the Wallace Calculator predicts that;

>at 8/1 and Ica of 62* will make 120 psi@ a V/P of 91, a very modest number

>at 8/1 with an Ica at 58*, this is predicted to climb to 125psi@ V/P of 97. This is an increase of; 97/91=plus 6.6 %, a very worthwhile move.

>at 10/1; and Ica of 58, is predicted to make 168psi@ V/P of 131, and 131/91 is an increase of 44% over base; so your clutched car is gonna really feel that.

read about V/P here;

The 225 is ........................~ 87

The Smog 318 comes in at ~107

the 318 @9.2 is .................. 133

the 340@10/1 is ................~120

the 360@ 8/1 is ................ ~113

the 5.2M@9.2 is ................~123 with cam retimed to straight up

the 5.9M I think at 9.2 is ....~154 also retimed to straight up

the '68/440Magnum@10/1 ~ 159 cam in at straight up;

A 416 stroker ;

with a 270/276/108 cam, straight up at 9.5 to 1; V/P of 156

With a 276/286/108 cam at 4* advanced and 10/1 V/P of 171

my 367; @11.3 .....~V/P of 170 with the former 223/230/110 cam

My 367; @11.0 .....~V/P of 158 with the current 230/237/110 cam.

my 367; @11.3.....~V/P of 143 with the 292/108 cam in at plus 4*

>here you can really see the difference in V/P, going from the 292(249@050) to the 223@.050 (270/276/110Hughes), and why I pulled that stinking 292/108. That 143VP was not what I had wanted.

>As for the swap from the 223 to the 230 cam, I really felt this loss of the V/P, and swapped away the regular A833, for a Commando, to get the lower first gear. After that it was better. The loss of V/P from 170 to 158 was 7.6%. The gain of the low-gear from 2.66 to 3.09, was 16.2% for a net gain of 8.6%, bringing the performance of the 170V/P right back; AND more importantly, the 3.55s were back on the table.

--------------------------

You might think ,

maybe not, IDK,

that a V/P of 170 is excessive ............ and IMO, you'd be right. But; not in 22 years, have I ever said "dammit I need a stroker"; and, if you ever get a chance to take a low-rpm ride in a car with such a generous V/P, I guarantee that you will be impressed.

For example;

In town, just cruising around, I out-shift at 2800.

This will get me;

20.5 in first, 33.0 in Second, 45.2 in Third, and 63.3 in Fourth; all of which are close to typical speed-limits up here..

On the shifts, the Rs will drop to 1740 into Second, 2040 into Third, and 2000 into Fourth. .................and 65 will be 2140 in GV-overdrive.

So in this example, my powerband needs to be from about 2000 to 2800.

This is where the very-high V/P really really shines.

You guys with low V/P engines, 3.55s, and Manual transmissions, just try this. You're gonna be using a lotta lotta throttle to keep up with me, while my throttle will be barely open. And that's why your city fuel-consumption sucks so bad.

OkOk, enough talk.

They didn't teach us anything about on how to that. They focused on automotive repair.I couldn’t get out of high school auto shop without knowing how to degree a cam. And that was 1980-1981. And you had to do @.050 and ICL methods.

Dan, fact is you gotta remember the Chineese do everything upside down and backwards half the time !

i once paid extra for that. crazy verna and big wendy were tender, yet rough.

You got that right.OkOk, enough talk.

You got ripped off. lolThey didn't teach us anything about on how to that. They focused on automotive repair.

We did everything rebuilt engines, transmissions, valve jobs, body work/paint, everything.

On Fridays we could work on our own cars, had a kid that had a pair of 64 GTO's he would bring in.

Rat Bastid

Dunamis Metron

You got ripped off. lol

We did everything rebuilt engines, transmissions, valve jobs, body work/paint, everything.

On Fridays we could work on our own cars, had a kid that had a pair of 64 GTO's he would bring in.

Yep, that’s what we did. All of it. If we were caught up and getting a B or better we could work on teachers cars (and we got paid for that) or we could bring in cars to work on that didn’t belong to us and get paid.

I had to bring in my bosses Pontiac Ventura with a 350 chevy in it. For some reason it snapped an exhaust rocker stud. We replaced the broken stud and made 50 bucks each, which was pretty good beer money in 1980.

TT5.9mag

Two atmospheres are better than one

My shop teacher, Mr Luft, taught us 3 very important things.

1. You want to go fast get a street bike

2. To make a million dollars drag racing, start with 2 million.

3. You want your junk to run correctly, degree the cam.

Thanks Mr. Luft

1. You want to go fast get a street bike

2. To make a million dollars drag racing, start with 2 million.

3. You want your junk to run correctly, degree the cam.

Thanks Mr. Luft

What he didn't teach you is never hide your weed and pipe in the glove box. lolMy shop teacher, Mr Luft, taught us 3 very important things.

1. You want to go fast get a street bike

2. To make a million dollars drag racing, start with 2 million.

3. You want your junk to run correctly, degree the cam.

Thanks Mr. Luft

-

Similar threads

- Replies

- 3

- Views

- 247

- Replies

- 33

- Views

- 1K

- Locked

[FOR SALE]

Hughes Custom Cam for 360 with 273 Manifolds

- Replies

- 4

- Views

- 844

- Replies

- 37

- Views

- 3K