Wyrmrider

Well-Known Member

good question Richard

actually several related issues

First is quench as in quench the fire

Which is moving two cold surfaces (the piston and head) so close together that fire, detonation is not supported

Here the amount of fuel mixture is also made so small that there is not much to burn

David Vizard recommends .030 for a tight piston/ steel rod motor

I've gone lower than that on smaller bore motors

The second phenomena is "squish"

where the gas between the piston and head is squirted out into the combustion chamber as the piston come up to TDC

Usually this just promotes turbulence that gives better burn and allows somewhat less timing lead

but it can be directed for swirl or tumble if you want to get sophisticated

You can have too much of a good thing and blow out your fire

we had to reduce the squish pad on a blown alcohol motor

The challenge on open Chamber Mopars is the part of the chamber away from the spark plug

how to get it to quench

Speed-O-Motive and TMS Propane Performance welded up the chambers until we got KB to make the relatively inexpensive KB pistons (I also used custom forged pistons Nick Arias understood the problem first)

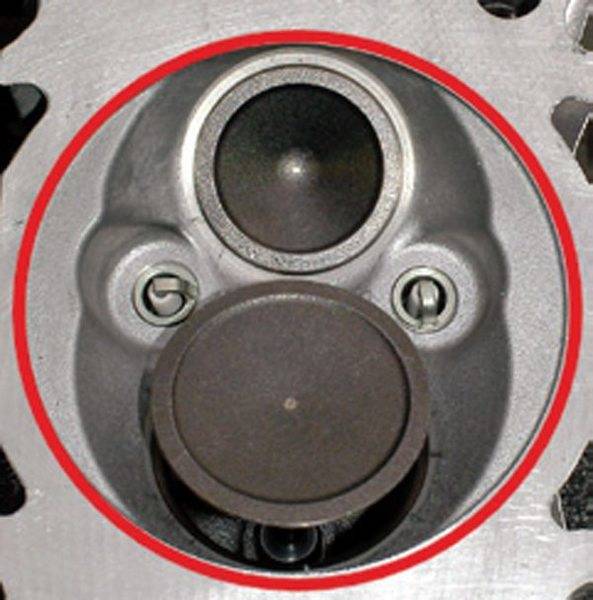

Note the two quench pads on the new Hemi from

Maximizing Cylinder Head Compression Ratios for More Power - Part 12

see also The Power Squeeze

actually several related issues

First is quench as in quench the fire

Which is moving two cold surfaces (the piston and head) so close together that fire, detonation is not supported

Here the amount of fuel mixture is also made so small that there is not much to burn

David Vizard recommends .030 for a tight piston/ steel rod motor

I've gone lower than that on smaller bore motors

The second phenomena is "squish"

where the gas between the piston and head is squirted out into the combustion chamber as the piston come up to TDC

Usually this just promotes turbulence that gives better burn and allows somewhat less timing lead

but it can be directed for swirl or tumble if you want to get sophisticated

You can have too much of a good thing and blow out your fire

we had to reduce the squish pad on a blown alcohol motor

The challenge on open Chamber Mopars is the part of the chamber away from the spark plug

how to get it to quench

Speed-O-Motive and TMS Propane Performance welded up the chambers until we got KB to make the relatively inexpensive KB pistons (I also used custom forged pistons Nick Arias understood the problem first)

Note the two quench pads on the new Hemi from

Maximizing Cylinder Head Compression Ratios for More Power - Part 12

see also The Power Squeeze

Last edited: