That's actually shaping up nice. Are these still the practice heads?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X-Head Porting....

- Thread starter DentalDart

- Start date

-

That's actually shaping up nice. Are these still the practice heads?

Yes these are still the practice heads.

This is were i think your are making your mistake. i would leave this "as is"

View attachment 1715682222

There is just 1 casting flaw at the stop directly where it arches down though

Round and smooth.

I would suggest ruffing in all your intake port, and then, do that attention to details.

By this time you will have gained the skills to be able to make it round and smooth with a bur.

just my thoughts.

I would suggest ruffing in all your intake port, and then, do that attention to details.

By this time you will have gained the skills to be able to make it round and smooth with a bur.

just my thoughts.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

I used to run a speed control... but it seemed to kill the grinders faster. The windings aren't dialed for the lack of amperage?? Regardless.. i thumb the grinder on and off.... i use a slow drill with my 1/2 for detail and guide bowl widening.. it removes quite a bit for the speed.Maybe its because I made my living carrying concrete blocks, shoveling dirt, running jack hammers, cutting walls with demo saws, etc. all day every day for 30 years, but I just don't seem to have the problems with the electric grinders. Mine catches and jerks once in a while, but it has never gotten away from me. It is a toy compared to what I did for work.

Anyhow, sorry Dental Dart, that I got this thread into a grinder debate. I will stay out of it now.

At some point I'll post a video of me just doing a port And I'll bet I get some funny responses on how i go about it.

Grind on!

MOPAROFFICIAL

If it has tits, it's a liabilititty.

1. Yes I've pretty much stopped using the electric die grinder. To much speed and to little control. Most everything naw is being done with the smaller electric foredom knock off grinder and the hand drill. I cut down my burrs that I bent due to helicoptering and they are much more controllable in the hand drill and are actually working much better.

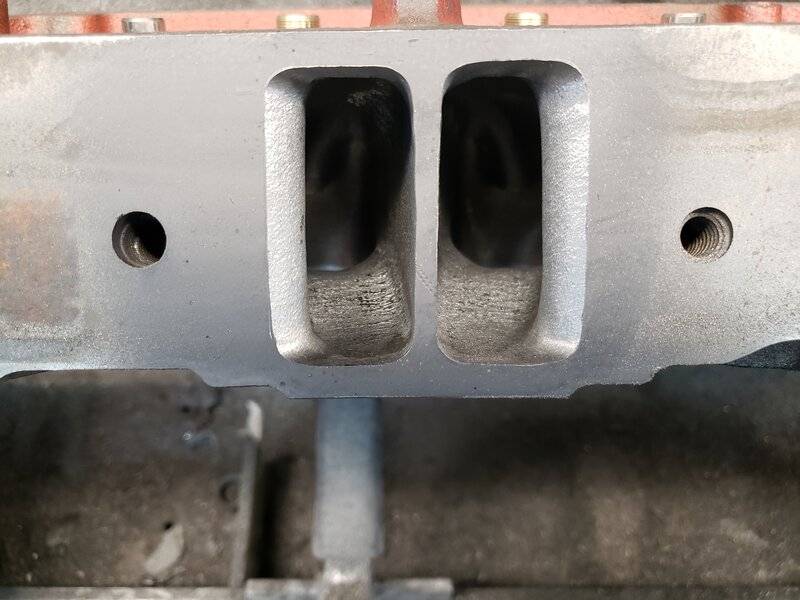

As far as the SSR and waterfall... thats where I'm wanting to take the little hump our right? As you can see, I worked on it some more tonight, for maybe 30 minutes. Just with the electric hand drill and I think it looks and feels much better. Its a much more smooth transition.

Yes the first port and bowl sucked... I may mess with it a touch more and see if I can clean it up. Just for ***** an giggles.

I agree with the valve job, when I do my "real" heads ill have a good valve job done on them. Right now just practicing on free 99 heads that were destined for the dump.

Now to just clean up the guide on this port.

View attachment 1715682202

View attachment 1715682203

Rectangle to circle. Thats the bowl transition

yellow rose

Overnight Sensation

I used to run a speed control... but it seemed to kill the grinders faster. The windings aren't dialed for the lack of amperage?? Regardless.. i thumb the grinder on and off.... i use a slow drill with my 1/2 for detail and guide bowl widening.. it removes quite a bit for the speed.

At some point I'll post a video of me just doing a port And I'll bet I get some funny responses on how i go about it.

Grind on!

I tried to toggle the switch on my electric grinder, but I never got the hang of it.

It’s funny because the other day I caught myself working the trigger on my air grinder. First time I ever knew I did it.

It’s things like that I can’t teach. I don’t realize I do them. Then when I try and explain how I do something I get pissed because I’m not sure how I do it, without doing it and thinking about doing it.

It’s strange how the human mind works. You develop techniques as you learn to do something and you never consciously you are doing it.

That’s why time behind the grinder is what counts.

yellow rose

Overnight Sensation

There is just 1 casting flaw at the stop directly where it arches down thoughI wanted to try to remove it then call it good there.

If that is a practice head and it’s really scrap, don’t be afraid to go too far to “see” what that looks and feels like. Practice on the short turns. Keep shaping the guide boss down until it “looks” wrong. Blow a hole through the main bolt boss that is in the common wall of the intake ports. Now that I said that, I’ll need to go out and see if I blew through my iron heads. That may not happen on iron, but it will on aluminum heads most of the time.

Going too far now will help you learn what it is when you are doing it for real. Don’t worry about grinding through the pushrod pinch too.

Now is the time to experiment.

Also, if you don’t have a sonic tester, a 1/8th inch drill bit is your friend. If you aren’t sure how thick something it, drill a hole in it. You may be surprised how thin some of this stuff is.

PRH

Well-Known Member

As the port starts to move more and more air from the porting done in the areas other than the SSR, the shape of the SSR itself becomes more and more of a player in the final result.

Working on being able to get the correct shape is way more important than being able to make them pretty.

Nothing wrong with pretty........ but it’s way less effective(or not effective at all) than having the shape right.

Working on being able to get the correct shape is way more important than being able to make them pretty.

Nothing wrong with pretty........ but it’s way less effective(or not effective at all) than having the shape right.

As the port starts to move more and more air from the porting done in the areas other than the SSR, the shape of the SSR itself becomes more and more of a player in the final result.

Working on being able to get the correct shape is way more important than being able to make them pretty.

Nothing wrong with pretty........ but it’s way less effective(or not effective at all) than having the shape right.

Have any pictures on hand of what the SSR shape should be?

PRH

Well-Known Member

I don’t have any ported SB heads here...... and even if I did....... you can’t really see the SSR profile(what it looks like from the side).

A good one and a bad one can look pretty much the same when viewed from the entrance or bowl.

There are some pics in my T/A head thread....... but you really can’t evaluate the SSR from them.

That’s where experience and the flow bench come in.

T/A heads

In the not too distant future I’ll be going through another set of “well used” T/A heads.

They will end up getting all 16 seats installed.

I’ll get some pics aimed at the SSR when I do them.

I seem to recall there being some X head SSR shots in one of the recent build threads by RAMM.

Another 416 Stroker Build-Pic Heavy

A good one and a bad one can look pretty much the same when viewed from the entrance or bowl.

There are some pics in my T/A head thread....... but you really can’t evaluate the SSR from them.

That’s where experience and the flow bench come in.

T/A heads

In the not too distant future I’ll be going through another set of “well used” T/A heads.

They will end up getting all 16 seats installed.

I’ll get some pics aimed at the SSR when I do them.

I seem to recall there being some X head SSR shots in one of the recent build threads by RAMM.

Another 416 Stroker Build-Pic Heavy

Last edited:

@PRH I dont know what exactly the SSR is... but I think I found found the heads @RAMM ported that you referenced and they were for a recent 416 build. He was able to get 263 cfm max on his bench.

Just from glancing he didn't take much off the sides of valve guide (?), imo. It looks like he shortened the valve guide down I think he said 3/8in or something along those lines. (please don't beat me up if you did take a lot off and I misrepresented what you really did).

I'm posting them here so I and any other people can look at them. I'll also repost the other ports from another thread I think a guy in Europe did named KMA..

First pictures from RAMM and last ones from KMA

Just from glancing he didn't take much off the sides of valve guide (?), imo. It looks like he shortened the valve guide down I think he said 3/8in or something along those lines. (please don't beat me up if you did take a lot off and I misrepresented what you really did).

I'm posting them here so I and any other people can look at them. I'll also repost the other ports from another thread I think a guy in Europe did named KMA..

First pictures from RAMM and last ones from KMA

yellow rose

Overnight Sensation

The short side radius or short turn is the floor of the port where it makes the turn into the valve seat.

The number one porting gain is the valve job. The best port work in the world won’t fix a bad valve job. Once the VJ is established, any port shaping you do from there out either way has diminishing returns as far as flow goes.

The most important part of shaping the port is one inch either way from the valve job.

The number one porting gain is the valve job. The best port work in the world won’t fix a bad valve job. Once the VJ is established, any port shaping you do from there out either way has diminishing returns as far as flow goes.

The most important part of shaping the port is one inch either way from the valve job.

The short side radius or short turn is the floor of the port where it makes the turn into the valve seat.

The number one porting gain is the valve job. The best port work in the world won’t fix a bad valve job. Once the VJ is established, any port shaping you do from there out either way has diminishing returns as far as flow goes.

The most important part of shaping the port is one inch either way from the valve job.

Thanks! I have read and heard the vj is the most important part of the port work and that 1in into the ports.

These are just practice heads so no vj's, only working on the ports and bowls... real heads would get vj's from the shop

Just need the family to go to bed and I can try this new fancy 25 dollar handpiece out... could have got it for 18 bucks but it wouldn't have come until March, so paid the 7 bucks extra for the one with another flex shaft and was able to get it in a couple of days. Idk where RAMM gets his used foredoms as they probably cost the same as this one lol.

The top was coming off, seemed like it it just held on by being forced on the metal shaft. No big deal as long as it works, which it does after doing some quick tests with the new burr..

The top was coming off, seemed like it it just held on by being forced on the metal shaft. No big deal as long as it works, which it does after doing some quick tests with the new burr..

MOPAROFFICIAL

If it has tits, it's a liabilititty.

I couldn't see myself using something that small having it bite and go dance around out of my hand and ruin a seat, valve job, or break ...who knows. Im sure you get used to it, but the vibration has less dampening by the co pact size im assuming.

I couldn't see myself using something that small having it bite and go dance around out of my hand and ruin a seat, valve job, or break ...who knows. Im sure you get used to it, but the vibration has less dampening by the co pact size im assuming.

The burr? Yea its small, but I was told earlier in the thread that the other burrs I got were to big... so I have gotten a couple of smaller burrs. Now I have the SL-5 and SL-3, the one above is the sl3.

My plan is to use the bigger burrs when I want to remove more mass, and then smaller burrs when I want to refine. That's similar to what I do when doing dental work. Idk how it will work but im sure it will be nice to try.

I actually think its going to take some getting used to running the burrs in the electric hand piece, because it seems to spin much faster than my hand drill and even the pneumatic die grinder. Its much more quiet though lol.

RAMM

Well-Known Member

Idk where RAMM gets his used foredoms as they probably cost the same as this one lol.

View attachment 1715683214

Pretty sure you made a small mistake as I don't own and have never used a Foredom. I have 2 big electrics, and 3 or so pneumatics with the standard 1/4" collets on all. No harm no foul. J.Rob

Pretty sure you made a small mistake as I don't own and have never used a Foredom. I have 2 big electrics, and 3 or so pneumatics with the standard 1/4" collets on all. No harm no foul. J.Rob

Yea I did, my apologies. Now I can't remember which thread one of you mopar masters said he gets used foredoms.

Does that have a throttle control or just on off?Just need the family to go to bed and I can try this new fancy 25 dollar handpiece out... could have got it for 18 bucks but it wouldn't have come until March, so paid the 7 bucks extra for the one with another flex shaft and was able to get it in a couple of days. Idk where RAMM gets his used foredoms as they probably cost the same as this one lol.

The top was coming off, seemed like it it just held on by being forced on the metal shaft. No big deal as long as it works, which it does after doing some quick tests with the new burr..

View attachment 1715683214

Does that have a throttle control or just on off?

It plugs into my foot speed controller. The foot controller is from Harbor freight and its supposed to be variable but its not to much of a variable, mainly feels like on and off.

yellow rose

Overnight Sensation

Yea I did, my apologies. Now I can't remember which thread one of you mopar masters said he gets used foredoms.

I think PBR uses a Foredom.

Ok critique me!

I dont know how to make the valve guide shorter, but everything else is "done"

This is 1 port with about 1hr today.

I dont know how to make the valve guide shorter, but everything else is "done"

This is 1 port with about 1hr today.

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Hard to see.

It's shiny.

Does the bowl feel smooth n round with your fingers and do you have snap gauges to measure the bowl mid/throat cs?

It's shiny.

Does the bowl feel smooth n round with your fingers and do you have snap gauges to measure the bowl mid/throat cs?

-