69fstbkcuda

Well-Known Member

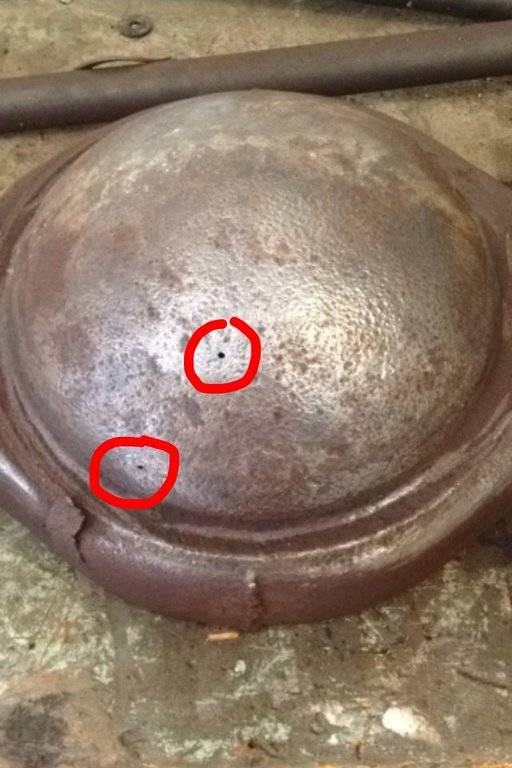

Trying to salvage an A-body 8 3/4. Everything is pretty solid except for the 2 pin holes I found while wire brushing. Is this repairable?

thanks I really don't wanna eat $400. I'm willing to try anything lol.I would lay a 1/16" steel plate on the inside (or outside) heat it and hammer it into the shape of the dome and weld it in. Then undercoat the outside to prevent any future rust!! It should last another 40 years.

treblig

I would agree except that I've repaired many corroded items and found that the corrosion is usually distributed around the area where you find a hole. So even if you open it up there will usually be section of very thin metal all around the hole making it difficult to get a good weld. For this reason I always try and put my weld (metal plate) as far from the hole as possible....that said, if the surrounding metal is solid then spot welding is the best course of action!!Depending on how handy you are with a welder, I would drill the holes open until you find solid metal, and then just stitch them closed. Simplest repair possible

It won't Solder worth a damn.

But it braze quite nicely. That's a solution I hadn't thought of before. I'd trust that more than jb weld. With a good experienced welder, they could braze the entire pitted surface and it would probably be pretty smooth too.

And the gold look would be tits under there

Definitely stored where it had water or something laying in it for awhile... It was a 2.5 hour away craigslist bought site unseen and had a friend pick it up... Got it put to me lolDid you blast it first?

That looks like it was stored with no center with the pan down in the great outdoors!

A drain plug would be handy.Pour some fluid in it, and let it puddle where you welded it.

Let it sit overnight.

If it holds run it, if not try again.

P.S. I would have fixed it also, and I would add a drain plug now while you have it out.