1st test intake manifold flows for the OOTB Holley Strip Dominator and the OOTB Edelbrock 340 Victor.

Strip Dominator port window is .970 X 2.150 = 2.086 sq. in.

340 Victor port window is 1.000 X 2.015 = 2.015 sq. in

Port #.............Strip D............340 V

1)....................257 cfm...........256 cfm

2)....................257..................257

3)....................251..................261

4)....................262..................261

5)....................261..................263

6)....................264..................261

7)....................256..................257

8)....................259..................257......................it all seems pretty equal

So then, after bolting the intake manifold to the head we get this...............

Air flow through the cylinder head with the manifold installed is hard to correlate. The flows are all over the place at different lifts. Maximum flows came somewhere between .500-.600 lift. So I'm going to list only the maximum flow for each port and say we are way off of the port flow through the head by itself, generally 30 cfm or more.

Port #.....Strip Dom intake & head/intake only............340 Victor head & intake/ intake

1)................267/257 @ .600......................................257/256 @ .500

2)................262/257 @ .550......................................262/257 @ .550

3)................251/251 @ .600......................................259/261 @ .600

4)................256/262 @ .550......................................254/261 @ .500

5)................259/261 @ .600......................................257/263 @ .500

6)................262/264 @ .550......................................262/261 @ .550

7)................264/256 @ .600......................................261/257 @ .550

8)................262/259 @ .550......................................267/257 @ .550

In some cases the flow increased through the through the intake head combination over the flow through the intake only, and sometimes it decreased or stayed the same.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T.N.A.C.C.B.P.P. EQ360

- Thread starter IQ52

- Start date

-

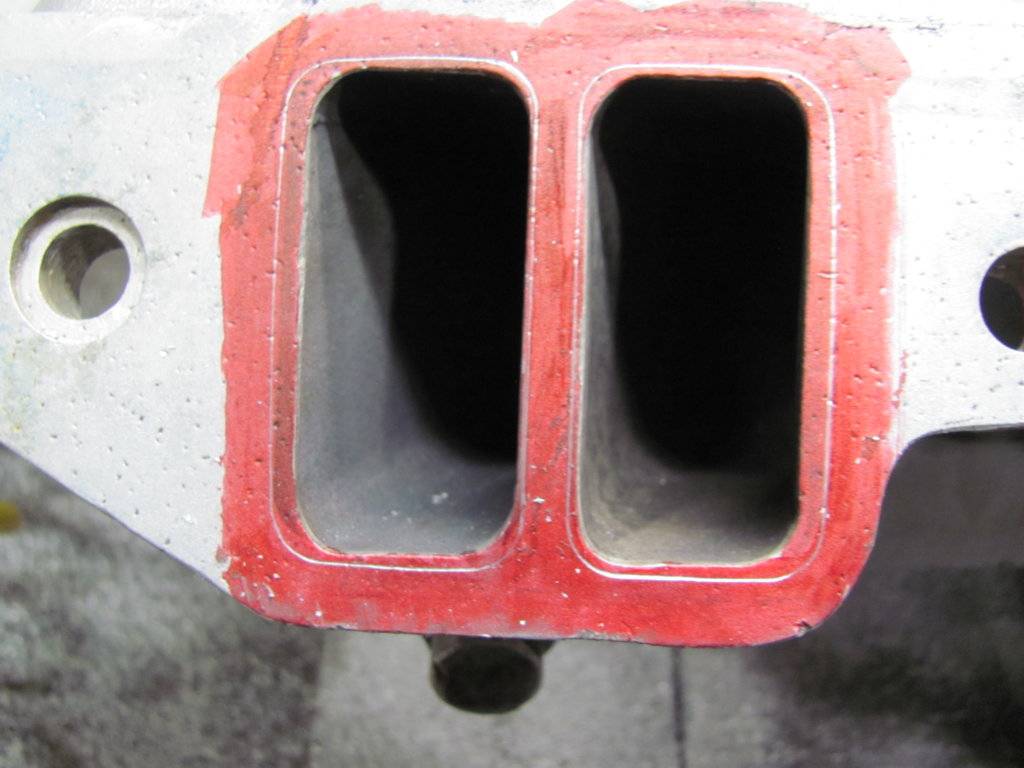

The Strip Dominator.............1 & 3 roughed in and 5 & 7 waiting. I have to go to the longer stemmed burrs later and go deeper into the ports. Trouble is there isn't a lot meat in the port walls to work with.

The plenum is a disaster, and the blend into the ports really sucks. So rather that weld it up, I'm going to put it in the mill and uniformly cut a bunch of it out and make a spacer that drops down into the plenum to reshape it. Then, blend the plenum into the ports.

The owner of this engine is a silent watcher on the forum, and I bet he is going, "Dear God, how much is this going to cost me?"

Nothing my friend. I've just wanted to try this for awhile, so, they're on me. You didn't ask for any of these modifications. I just want it to run good.

The plenum is a disaster, and the blend into the ports really sucks. So rather that weld it up, I'm going to put it in the mill and uniformly cut a bunch of it out and make a spacer that drops down into the plenum to reshape it. Then, blend the plenum into the ports.

The owner of this engine is a silent watcher on the forum, and I bet he is going, "Dear God, how much is this going to cost me?"

Nothing my friend. I've just wanted to try this for awhile, so, they're on me. You didn't ask for any of these modifications. I just want it to run good.

yellow rose

Overnight Sensation

The Strip Dominator.............1 & 3 roughed in and 5 & 7 waiting. I have to go to the longer stemmed burrs later and go deeper into the ports. Trouble is there isn't a lot meat in the port walls to work with.

View attachment 1715115349 View attachment 1715115350

The plenum is a disaster, and the blend into the ports really sucks. So rather that weld it up, I'm going to put it in the mill and uniformly cut a bunch of it out and make a spacer that drops down into the plenum to reshape it. Then, blend the plenum into the ports.

The owner of this engine is a silent watcher on the forum, and I bet he is going, "Dear God, how much is this going to cost me?"

Nothing my friend. I've just wanted to try this for awhile, so, they're on me. You didn't ask for any of these modifications. I just want it to run good.

Even though it's a royal PITA I always weld that plenum up. I wish I had to flow sheets from the testing I did but it was way better after welding. It's just a bunch of work. I did the SD I'm running now. If I had to do it again, I would have done more welding on the outside of the plenum, especially where the runners join. My intake it mighty thin there.

yellow rose

Overnight Sensation

BTW...your casting looks much better than mine. I'd rather start with the MP intake, but the SD is what I had.

I do not know for sure. But I suspect the entire rpm range.What rpm range will these mods enhance the most? Or should I say which stages effect which rpm ranges?

MOPAROFFICIAL

Oogliboogli

Air speed.

MOPAROFFICIAL

Oogliboogli

Cc every runner, make molds.Are you saying the airspeed will increase vs cfm?

All apart of the process.

With a bit of port work and nothing done on the plenum, the intake manifold ports are all now flowing between 292-306 cfm.

So now we are waiting for the 3/4" thick aluminum plate to show up so we can make the adapter to fit down inside the manifold carburetor base. I'll make 4150 adapter .450" deep that reshapes the plenum opening and at the same time raises the carburetor .300". It should give me a good blend into the ports.

So now we are waiting for the 3/4" thick aluminum plate to show up so we can make the adapter to fit down inside the manifold carburetor base. I'll make 4150 adapter .450" deep that reshapes the plenum opening and at the same time raises the carburetor .300". It should give me a good blend into the ports.

MOPAROFFICIAL

Oogliboogli

With a bit of port work and nothing done on the plenum, the intake manifold ports are all now flowing between 292-306 cfm.

So now we are waiting for the 3/4" thick aluminum plate to show up so we can make the adapter to fit down inside the manifold carburetor base. I'll make 4150 adapter .450" deep that reshapes the plenum opening and at the same time raises the carburetor .300". It should give me a good blend into the ports.

View attachment 1715116564

Now that's what I'm talk'n about.

I'm finding out it isn't all that simple. I'm learning that it has much to do with the different cylinder heads and intake manifolds. Presently I've gained about 45 cfm by porting the intake runners and gained very little with the intake/head combination. I've got to get the carburetor base and plenum done and see what happens.So if I have a head that flows 297 what do I want my intake manifold ports flowing at ideally?

Until you test the specific head and intake, you are not going to know what is needed. That's my opinion anyway.

What is it again?.........intake runner volume should be the same as the engine cubic inch size, or is it plenum size the same as the engine cubic inch size? Or plenum and runner combined? Or is it as simple as X(head port cfm) = intake manifold runner cfm? I don't know!

Humbug, I'm not going to know anything but what this engine does with what we give it.

I'm worried this thing will never run good. Because......I can't get any more from a pump gas engine than 629 HP from a RHS/Indy headed 424/360 and 787 HP from a RPM headed 451/400. I fear this engine will one big dog too.

The fun of experimentation ......

RAMM

Well-Known Member

I'm finding out it isn't all that simple.

Until you test the specific head and intake, you are not going to know what is needed. That's my opinion anyway.

Humbug, I'm not going to know anything but what this engine does with what we give it.

Agree with everything above^^^^.

This is not directed @ IQ52

Here's the thing--If you port your manifold for flow and flow only it will wind up WAY too big. Once you have a "catalog" of builds and experience that will be your guiding light. In cylinder CFM demand is what really determines output and that is really different from what the flowbench tells us. Then again Jim tells me I share too much. J.Rob

Ouch.......again. I think I said I'm more selfish with information than you are.Agree with everything above^^^^.

This is not directed @ IQ52

Here's the thing--If you port your manifold for flow and flow only it will wind up WAY too big. Once you have a "catalog" of builds and experience that will be your guiding light. In cylinder CFM demand is what really determines output and that is really different from what the flowbench tells us. Then again Jim tells me I share too much. J.Rob

Which would make you a nicer person.

Why am I selfish? Just a small person I guess. Don't have the money to continue.

I had an email yesterday from the west coast. This person has wanted me to do a set of iron heads for a year, but has never tried to bribe me with any money to do them. I have two of his engines here but no money from him to complete the engines. I'm not a bank to loan people money so's I can work on their engines.

Now they want me to help with these heads, for another engine for him I refused to start. Told him to take it someplace else, I'm retiring.

"Will big valves fit?" I don't know, I've never worked with those heads.......Here is how you check for yourself.

In the past I would have bought one of those heads just to look into it for them. Never got any money or respect for that.

"Can you port them?" No. We could have a year ago, but I'm retiring now.

"I found a guy in 'Cracker Jack City' that say's he can port them, but I don't think he's as good as you guys are." Huh.....respect? Maybe. But still no money for the past projects still sitting here half complete. I tell them, I work on your money, not mine. When your money runs out, I stop.

So, that is another reason why I'm retiring!

We are really good, but I guess not worth the effort my son and I put into these things. After all we're only two people in a 5th hand, 40' X 60' building (we bough and took down from a mine in the mountains and then re-erected by ourselves) and no fancy CNC machines. And a CNC machine has got to make you better! Right? If I had a $1/4 million machine I could be really good! Right? Oh, and be in debt up to my eyeballs.

I remember being in a contest. Most horsepower/dollar. We came in third. The engine performance/life was the important thing to me. I could have substituted cheaper parts for the short time of the contest and won. The winner called Cody and said, "If I had brought the best stuff I had, you La Roy's would have still kicked my ***!" That was the world to a couple of hicks from a mountain valley town of 1,000 people, 150 miles from the closest MacDonalds.

To the people that I have turned down engine builds for recently, "I'm sorry, I'm just burned out. Not your fault really, others have ruined it for you.

However, we have reserved enough energy to enthusiastically attack the engines we have left to do.

Today I get to do something really fun. Design a flip-up/flip-down license plate holder, to hide the winch roller fairlead for a 2017 pickup truck. Really!

Then back to the NACCBPPEQ360!

yellow rose

Overnight Sensation

Ouch.......again. I think I said I'm more selfish with information than you are.

Which would make you a nicer person.

Why am I selfish? Just a small person I guess. Don't have the money to continue.

I had an email yesterday from the west coast. This person has wanted me to do a set of iron heads for a year, but has never tried to bribe me with any money to do them. I have two of his engines here but no money from him to complete the engines. I'm not a bank to loan people money so's I can work on their engines.

Now they want me to help with these heads, for another engine for him I refused to start. Told him to take it someplace else, I'm retiring.

"Will big valves fit?" I don't know, I've never worked with those heads.......Here is how you check for yourself.

In the past I would have bought one of those heads just to look into it for them. Never got any money or respect for that.

"Can you port them?" No. We could have a year ago, but I'm retiring now.

"I found a guy in 'Cracker Jack City' that say's he can port them, but I don't think he's as good as you guys are." Huh.....respect? Maybe. But still no money for the past projects still sitting here half complete. I tell them, I work on your money, not mine. When your money runs out, I stop.

So, that is another reason why I'm retiring!

We are really good, but I guess not worth the effort my son and I put into these things. After all we're only two people in a 5th hand, 40' X 60' building (we bough and took down from a mine in the mountains and then re-erected by ourselves) and no fancy CNC machines. And a CNC machine has got to make you better! Right? If I had a $1/4 million machine I could be really good! Right? Oh, and be in debt up to my eyeballs.

I remember being in a contest. Most horsepower/dollar. We came in third. The engine performance/life was the important thing to me. I could have substituted cheaper parts for the short time of the contest and won. The winner called Cody and said, "If I had brought the best stuff I had, you La Roy's would have still kicked my ***!" That was the world to a couple of hicks from a mountain valley town of 1,000 people, 150 miles from the closest MacDonalds.

To the people that I have turned down engine builds for recently, "I'm sorry, I'm just burned out. Not your fault really, others have ruined it for you.

However, we have reserved enough energy to enthusiastically attack the engines we have left to do.

Today I get to do something really fun. Design a flip-up/flip-down license plate holder, to hide the winch roller fairlead for a 2017 pickup truck. Really!

Then back to the NACCBPPEQ360!

And this is exactly why I don't do much of this work anymore. People think because it's their hobby, their fun time and they enjoy tinkering, that you enjoy it too and therefore you should be willing to help them have fun.

What bullshit.

For what a machine shop has in tooling, machines and other things, what the machinist has in time learning and what he knows isn't worth a damn to these small minded people. You DO get what you pay for.

And that's another thing. Most people think an engine builder is rolling in dough. Just burning C notes every weekend all weekend long. That's bullshit too. Most guys I know skimp by on an damn thin margin. And you NEVER make all the billable hours you should. I just pisses me off that engine shops get so little respect in this hobby. The real pisser is it doesn't come from people who are wholly ignorant of what it takes to do this. These are people who understand, not some joker off the street who can barely fuel his car and damn sure doesn't even change his own oil. It comes from people who KNOW (for the most part) what it takes.

stixx

Well-Known Member

Ouch.......again. I think I said I'm more selfish with information than you are.

Which would make you a nicer person.

Why am I selfish? Just a small person I guess. Don't have the money to continue.

I had an email yesterday from the west coast. This person has wanted me to do a set of iron heads for a year, but has never tried to bribe me with any money to do them. I have two of his engines here but no money from him to complete the engines. I'm not a bank to loan people money so's I can work on their engines.

Now they want me to help with these heads, for another engine for him I refused to start. Told him to take it someplace else, I'm retiring.

"Will big valves fit?" I don't know, I've never worked with those heads.......Here is how you check for yourself.

In the past I would have bought one of those heads just to look into it for them. Never got any money or respect for that.

"Can you port them?" No. We could have a year ago, but I'm retiring now.

"I found a guy in 'Cracker Jack City' that say's he can port them, but I don't think he's as good as you guys are." Huh.....respect? Maybe. But still no money for the past projects still sitting here half complete. I tell them, I work on your money, not mine. When your money runs out, I stop.

So, that is another reason why I'm retiring!

We are really good, but I guess not worth the effort my son and I put into these things. After all we're only two people in a 5th hand, 40' X 60' building (we bough and took down from a mine in the mountains and then re-erected by ourselves) and no fancy CNC machines. And a CNC machine has got to make you better! Right? If I had a $1/4 million machine I could be really good! Right? Oh, and be in debt up to my eyeballs.

I remember being in a contest. Most horsepower/dollar. We came in third. The engine performance/life was the important thing to me. I could have substituted cheaper parts for the short time of the contest and won. The winner called Cody and said, "If I had brought the best stuff I had, you La Roy's would have still kicked my ***!" That was the world to a couple of hicks from a mountain valley town of 1,000 people, 150 miles from the closest MacDonalds.

To the people that I have turned down engine builds for recently, "I'm sorry, I'm just burned out. Not your fault really, others have ruined it for you.

However, we have reserved enough energy to enthusiastically attack the engines we have left to do.

Today I get to do something really fun. Design a flip-up/flip-down license plate holder, to hide the winch roller fairlead for a 2017 pickup truck. Really!

Then back to the NACCBPPEQ360!

Really love these stories... though they have more than a sad touch to them.

But even though you are retiring because your "customers" are wearing you down I have the feeling

that you are looking back in pride, and I can only give it my full two thumbs up. It is the experience

of all that has happened to us in our lives that makes us "a wiser person".

Well, maybe not all of us, but definitely you.

Sorry for the clumsy wording, I am german after all.

Yours words are well written and not clumsy. Better than many Americans on the board by far.

IQ52, build one last one for yourself and go have some fun! In the mean time, “THANK YOU!” Very much l

IQ52, build one last one for yourself and go have some fun! In the mean time, “THANK YOU!” Very much l

Right, loved flowing the Olds C heads before and after bolting up the old school torker intake, quite enlightening........................esp. those outside ports.I'm finding out it isn't all that simple. I'm learning that it has much to do with the different cylinder heads and intake manifolds. Presently I've gained about 45 cfm by porting the intake runners and gained very little with the intake/head combination. I've got to get the carburetor base and plenum done and see what happens.

Until you test the specific head and intake, you are not going to know what is needed. That's my opinion anyway.

What is it again?.........intake runner volume should be the same as the engine cubic inch size, or is it plenum size the same as the engine cubic inch size? Or plenum and runner combined? Or is it as simple as X(head port cfm) = intake manifold runner cfm? I don't know!

Humbug, I'm not going to know anything but what this engine does with what we give it.

Another familiar tune, Your jukebox plays the same classics as well!! Unfortunately I didn't find a way to hit the "agree" button multiple times.....................................Ouch.......again. I think I said I'm more selfish with information than you are.

Which would make you a nicer person.

Why am I selfish? Just a small person I guess. Don't have the money to continue.

I had an email yesterday from the west coast. This person has wanted me to do a set of iron heads for a year, but has never tried to bribe me with any money to do them. I have two of his engines here but no money from him to complete the engines. I'm not a bank to loan people money so's I can work on their engines.

Now they want me to help with these heads, for another engine for him I refused to start. Told him to take it someplace else, I'm retiring.

"Will big valves fit?" I don't know, I've never worked with those heads.......Here is how you check for yourself.

In the past I would have bought one of those heads just to look into it for them. Never got any money or respect for that.

"Can you port them?" No. We could have a year ago, but I'm retiring now.

"I found a guy in 'Cracker Jack City' that say's he can port them, but I don't think he's as good as you guys are." Huh.....respect? Maybe. But still no money for the past projects still sitting here half complete. I tell them, I work on your money, not mine. When your money runs out, I stop.

So, that is another reason why I'm retiring!

We are really good, but I guess not worth the effort my son and I put into these things. After all we're only two people in a 5th hand, 40' X 60' building (we bough and took down from a mine in the mountains and then re-erected by ourselves) and no fancy CNC machines. And a CNC machine has got to make you better! Right? If I had a $1/4 million machine I could be really good! Right? Oh, and be in debt up to my eyeballs.

I remember being in a contest. Most horsepower/dollar. We came in third. The engine performance/life was the important thing to me. I could have substituted cheaper parts for the short time of the contest and won. The winner called Cody and said, "If I had brought the best stuff I had, you La Roy's would have still kicked my ***!" That was the world to a couple of hicks from a mountain valley town of 1,000 people, 150 miles from the closest MacDonalds.

To the people that I have turned down engine builds for recently, "I'm sorry, I'm just burned out. Not your fault really, others have ruined it for you.

However, we have reserved enough energy to enthusiastically attack the engines we have left to do.

Today I get to do something really fun. Design a flip-up/flip-down license plate holder, to hide the winch roller fairlead for a 2017 pickup truck. Really!

Then back to the NACCBPPEQ360!

-