You know what I’m talking about. Those hard to resist gasket removing buzz wheels that take gaskets off faster then, well let’s not go there. While nicely removing those gaskets you are also removing the nice flat gasket sealing surface on heads and intakes. We all hate this job but please guys learn how to remove gaskets the “right” way.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Public service announcements. Please don’t use these.

- Thread starter pittsburghracer

- Start date

-

Ooh, I hate when people bring in heads for surfacing or any type of work & they've been cleaned up with a wizzy wheel. It makes a ***** and a half to get them set up and hardly ever get lucky enough to nail a clean 1st pass.

I use a flat square edge carbide scraper only and very gently scrape.

I use a flat square edge carbide scraper only and very gently scrape.

Moparpuller

Well-Known Member

Super scrapers are cheap on Amazon. I have had the original wood handle ones for 10 years and they still work as good as new and get used almost dailyOoh, I hate when people bring in heads for surfacing or any type of work & they've been cleaned up with a wizzy wheel. It makes a ***** and a half to get them set up and hardly ever get lucky enough to nail a clean 1st pass.

I use a flat square edge carbide scraper only and very gently scrape.

I'll have to check those out, my scrapers hurt my wallet off of the Cornwell truck.Super scrapers are cheap on Amazon. I have had the original wood handle ones for 10 years and they still work as good as new and get used almost daily

Just checked them out I agree when mine wears out I'll get those

Screw that. Let um do it and find out the hard way.

Lol, I've had to weld aluminum heads because of idiots trying to remove their own gaskets, so called mechanics too (used car dealer mechanic)Screw that. Let um do it and find out the hard way.

I’m pretty handy with a single edged razor blade. I go through about 400 a year. Mostly body work though I use them for gasket cleaning. And cuticle trimming. Lol

Super scrapers are cheap on Amazon. I have had the original wood handle ones for 10 years and they still work as good as new and get used almost daily

Wholly crap that would blow my budget.

3M Scotch Brite?You know what I’m talking about. Those hard to resist gasket removing buzz wheels that take gaskets off faster then, well let’s not go there. While nicely removing those gaskets you are also removing the nice flat gasket sealing surface on heads and intakes. We all hate this job but please guys learn how to remove gaskets the “right” way.

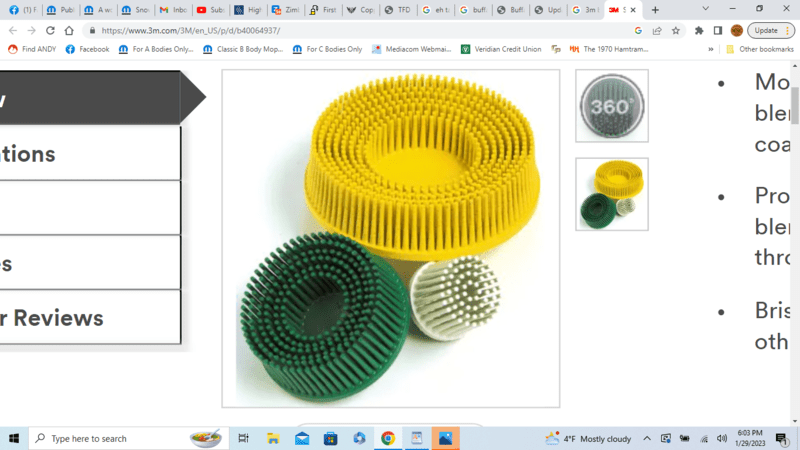

3m makes a plastic fingered Roloc that works good.

Moparpuller

Well-Known Member

A guy at work has the cheaper plastic handled ones and they are made just as good. The handles just aren’t as comfortableWholly crap that would blow my budget.

I like a razorblade scraper. You can't get violent with them but the blades are so thin, sharp, and flexible it will slice through about anything.A guy at work has the cheaper plastic handled ones and they are made just as good. The handles just aren’t as comfortable

Moparpuller

Well-Known Member

The carbides are about perfect as long as you hold them nice and flat

I like a razorblade scraper. You can't get violent with them but the blades are so thin, sharp, and flexible it will slice through about anything.

This is what I use too and if I have time I’ll dunk it in my parts cleaner overnight and let the cleaner soften things up some.

True but you have to remember, carbide is harder than the cast iron surface. It is easy to scratch and gouge if you're not careful.The carbides are about perfect as long as you hold them nice and flat

GM had a lot of bearing failures under warranty. Most of the failures had a intake manifold replaced or resealed prior and #M Scotch Brite pads were use. They switched to Bristle Disc and the issues went away. WOW I sold cases of these.

Ironracer

Gearhead

Butchers.Lol, I've had to weld aluminum heads because of idiots trying to remove their own gaskets, so called mechanics too (used car dealer mechanic)

mopowers

Well-Known Member

Is it any different for cast iron block and head sealing surfaces as opposed to aluminum? I saw a video recently where Steve Dulcich was using a wire wheel to clean the deck surfaces of a block.

bristles disc. Thanks. Couldnt remember what they were called. An almost worn out black flexible abrasive disc makes short work of most freeze plug holes or whatever you want to call them.GM had a lot of bearing failures under warranty. Most of the failures had a intake manifold replaced or resealed prior and #M Scotch Brite pads were use. They switched to Bristle Disc and the issues went away. WOW I sold cases of these.

View attachment 1716041463

Yeah, unskilled parts changers tooButchers.

Ironracer

Gearhead

Lol, not even a mechanic !Yeah, unskilled parts changers too

Let me edit this real quick,We use a wire wheel on blocks, works well but that's only before boring and honing and it goes in the hot tank and pressure washed afterwards .Is it any different for cast iron block and head sealing surfaces as opposed to aluminum? I saw a video recently where Steve Dulcich was using a wire wheel to clean the deck surfaces of a block.

Ford's suck they had asbestos gaskets so wire wheel is a no go !

Last edited:

So will the fingers on a machined surface if ya slipI like a razorblade scraper. You can't get violent with them but the blades are so thin, sharp, and flexible it will slice through about anything.

i bought the super scraper 3 piece set 20+ years ago and it still works like day one. it was dough then, and it's still dough now but a great investment.

titan and ares make a really decent 2 piece set that are very comparable for sub $30

titan and ares make a really decent 2 piece set that are very comparable for sub $30

dusterbing the peace

FABO pyrite member

Bristle discs are THEEE best! I knock off the main chunks with the standard scraper first; but let the XX,000 rpm do the finish work!!!GM had a lot of bearing failures under warranty. Most of the failures had a intake manifold replaced or resealed prior and #M Scotch Brite pads were use. They switched to Bristle Disc and the issues went away. WOW I sold cases of these.

View attachment 1716041463

-

Similar threads

- Replies

- 6

- Views

- 394

- Replies

- 11

- Views

- 1K

- Replies

- 35

- Views

- 3K

- Locked

- Replies

- 1

- Views

- 2K