The project proceeded again during the Christmas break.

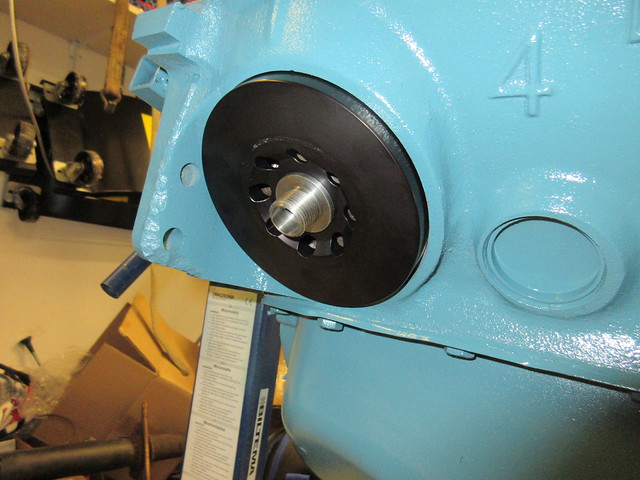

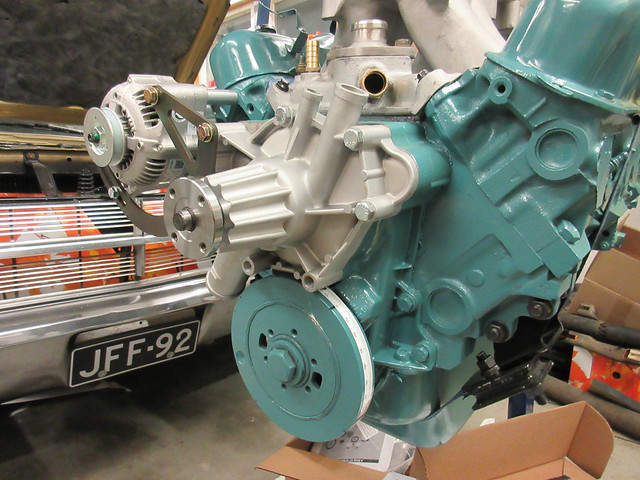

I got the engine prepared (used POR15 Metal Ready) and painted.

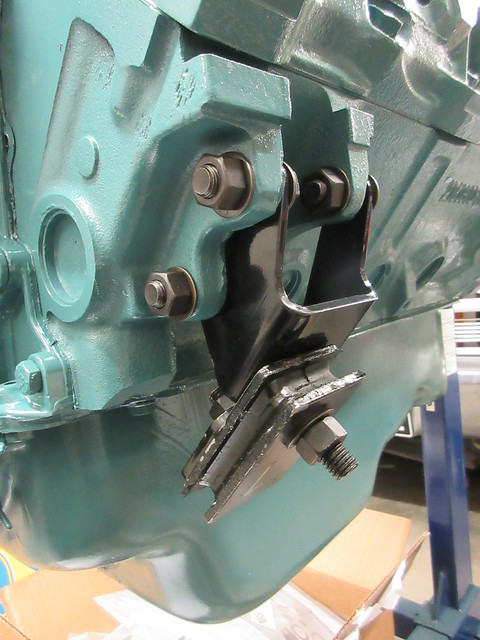

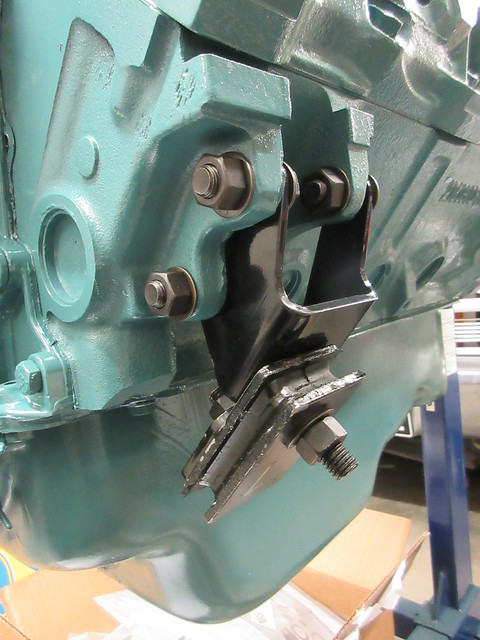

Got my Schumacher engine mounts, seems to be perfect

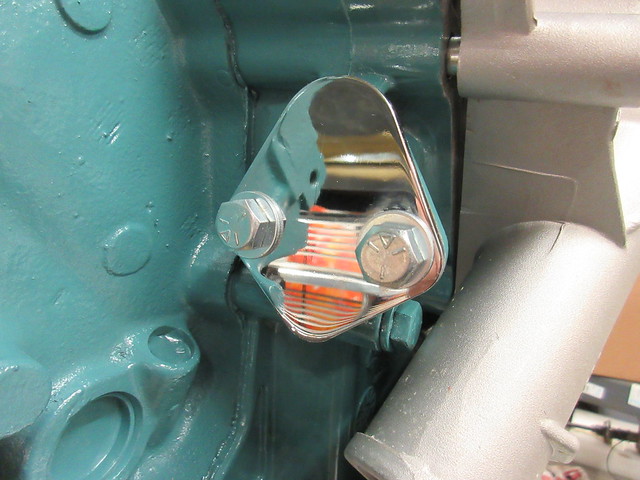

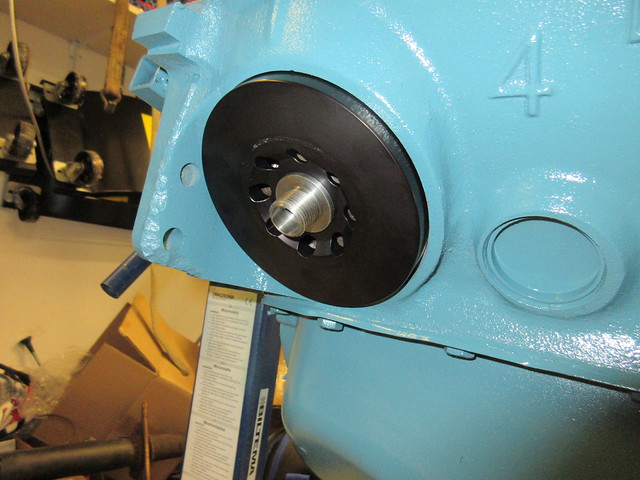

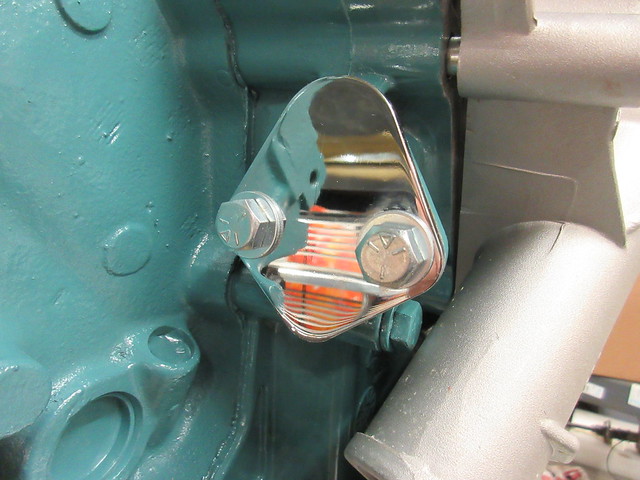

The engine was missing the oil filter base plate and fitting, seemed to be pretty rare

parts. Luckily available from Summit and not with too bad price. Also ordered

the fuel pump block off plate, carb studs, carb throttle linkage.

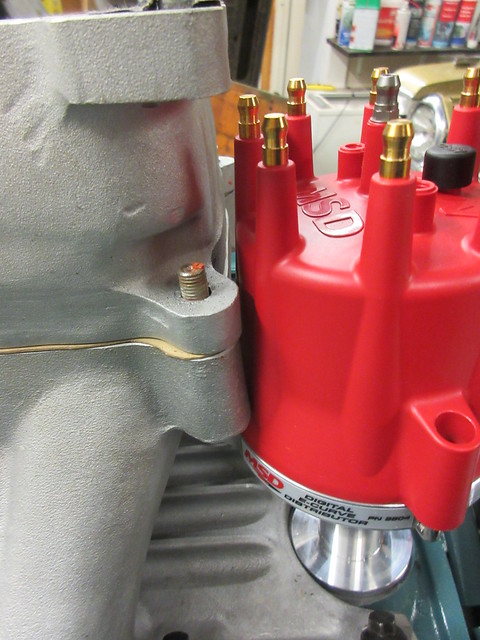

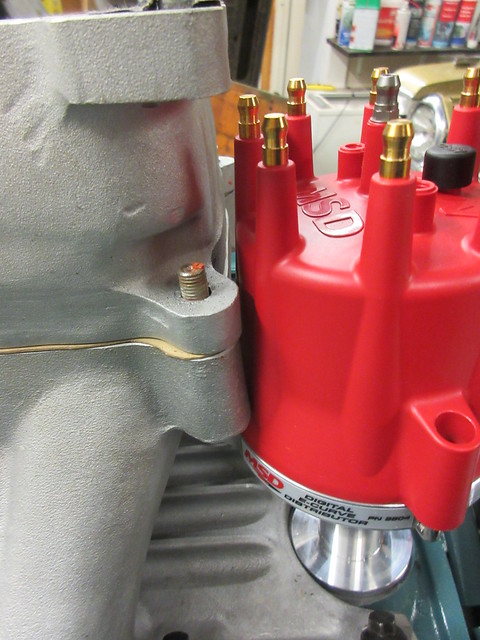

Then the bigger effort to install the intake manifold. I read several threads

in this forum and I think I got it now. And of course I had to test how it looks in full height

The distributor seems to be a tight fit. The carbs would propably be better off with

side way installation, the throttle does not open fully on the carb with the choke as one lever is rubbing the intake.

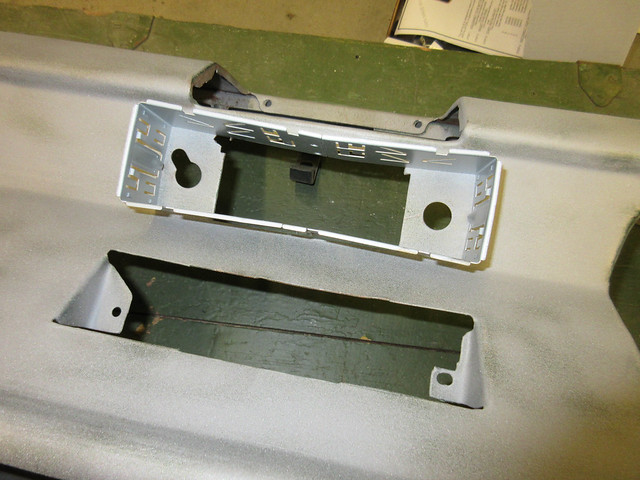

I had also some time to start planning the sheet metal activities in the trunk.

This is how it looked inside the trunk:

And this is how it looked under the car:

I grinded the patch weldings and the end result is like this. A bit better to continue from this

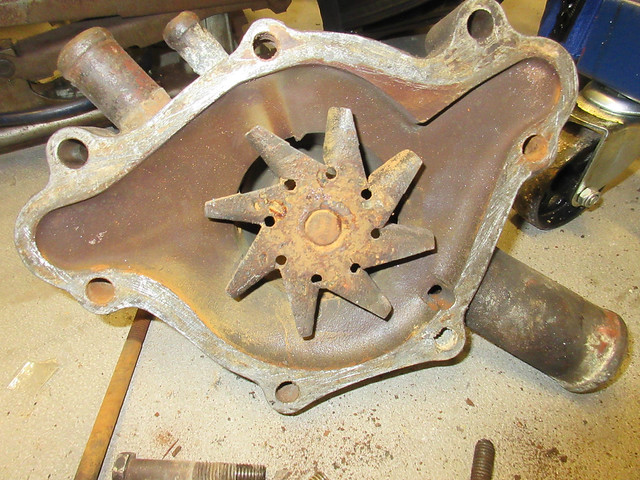

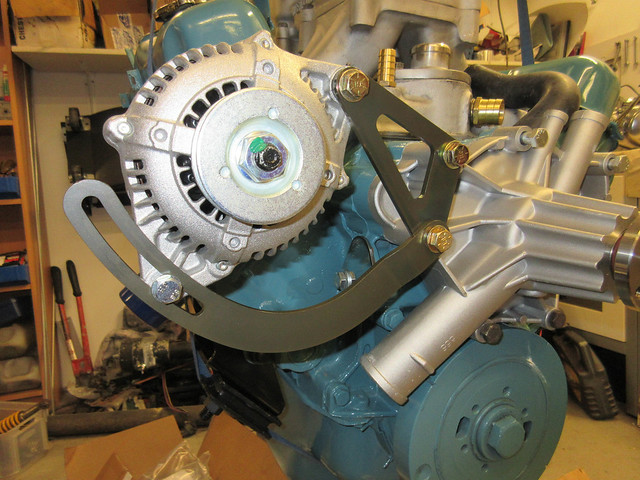

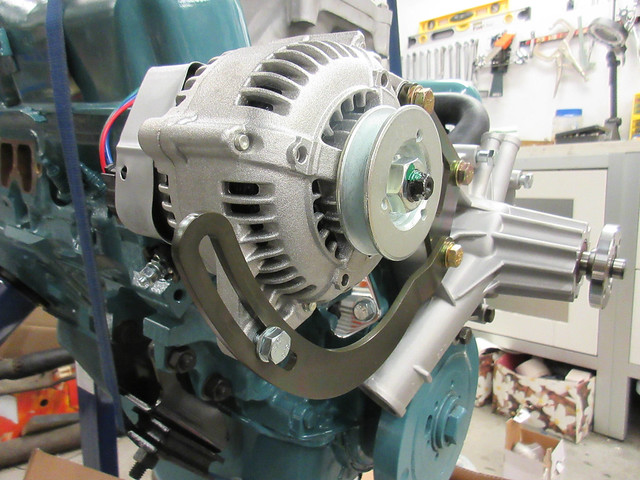

I also got the new water pump, but I am currently waiting for the alternator bracket kit from AREngineering (

http://arengineering.com/products/denso-60-amp-kit-for-small-blocks/).

I decided to use the Denso 60 Amp type alternator as the American Autowire kit prefers the voltage reg internally.

I managed to find such an alternator from Finland too so I should be ready as soon as the package arrives. Should be next week.