Booster Dewey called this morning. The restored power brake booster is on its way home from Seattle...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

Scott's dart

Well-Known Member

Very basic but very easy to install and use. Nothing to get distracted with. Connect and play...

Out of Sight Audio - Hidden Bluetooth Audio and Hands Free Calling for Vintage and Classic Cars

Thanks! Love the build, gives me lots of ideas for when I start on my Duster!

Looks like Booster Dewey is now Booster Steve or Booster Exchange. Absolutely gorgeous work......

I disassembled the NOS master cylinder and this weekend we will be cleaning it up and installing the rebuild kit (it is 50 years old!). Also the distributor is going back together with new springs and FBO lockout plate, that will be coming this weekend here.

Jegs order came and we mounted the Keystones and make the white lettering shine. Spoiled brat....

I disassembled the NOS master cylinder and this weekend we will be cleaning it up and installing the rebuild kit (it is 50 years old!). Also the distributor is going back together with new springs and FBO lockout plate, that will be coming this weekend here.

Jegs order came and we mounted the Keystones and make the white lettering shine. Spoiled brat....

But doesn’t that smile make it worth the extra change?Looks like Booster Dewey is now Booster Steve or Booster Exchange. Absolutely gorgeous work......

View attachment 1715315498

I disassembled the NOS master cylinder and this weekend we will be cleaning it up and installing the rebuild kit (it is 50 years old!). Also the distributor is going back together with new springs and FBO lockout plate, that will be coming this weekend here.

Jegs order came and we mounted the Keystones and make the white lettering shine. Spoiled brat....

View attachment 1715315497 View attachment 1715315499

Scamp Rhonda

Well-Known Member

IMO Keystone Classics are perfect for that car. Also very period correct.Looks like Booster Dewey is now Booster Steve or Booster Exchange. Absolutely gorgeous work......

View attachment 1715315498

I disassembled the NOS master cylinder and this weekend we will be cleaning it up and installing the rebuild kit (it is 50 years old!). Also the distributor is going back together with new springs and FBO lockout plate, that will be coming this weekend here.

Jegs order came and we mounted the Keystones and make the white lettering shine. Spoiled brat....

View attachment 1715315497 View attachment 1715315499

Distributor.... Factory original that was pulled apart (not the shaft) and cleaned up. There is zero side to side play in the shaft so I am reusing it...

All the way in the bottom. This is a '73 car so we so some math. The factory ran them around 34 degrees all in on the advance and around 0 at idle so that is 34 degrees of mechanical advance. That says these likely around 17/18 degree weights (divide by 2 since the dizzy spins half as fast as the crank).

I used the softest springs from the FBO kit I bought for the Coronet..

Now the FBO plate that locks the weights to a fixed amount advance (old way was to weld blobs and file them off, this worth every penny it costs). I put it on the "10" mark so that means it will lock it down to 20 degrees of total advance at the crank. So if I want it to run at 34 degrees at high rpm my initial timing will be around 14 degrees. That worked great for the Coronet we will see what it does for this engine.

Not the upper shaft goes in.

Don't forget the bushing! Also you can see the blurry snap ring at the top of the shaft It is what hold the upper shaft on and is a PIA to remove or install....

The snap ring is way down in there.....

The vacuum advance had a lever that pulls in and are usually marked, this one is 11 so that is 22 degrees. If I am running all in at 34 and add 22 I get 56 degrees at cruise.. That is a bit more than I want but we will see how it really works once running.

Next the pickup plate and getting the advance pin in the hole while standing on one foot...

All the way in the bottom. This is a '73 car so we so some math. The factory ran them around 34 degrees all in on the advance and around 0 at idle so that is 34 degrees of mechanical advance. That says these likely around 17/18 degree weights (divide by 2 since the dizzy spins half as fast as the crank).

I used the softest springs from the FBO kit I bought for the Coronet..

Now the FBO plate that locks the weights to a fixed amount advance (old way was to weld blobs and file them off, this worth every penny it costs). I put it on the "10" mark so that means it will lock it down to 20 degrees of total advance at the crank. So if I want it to run at 34 degrees at high rpm my initial timing will be around 14 degrees. That worked great for the Coronet we will see what it does for this engine.

Not the upper shaft goes in.

Don't forget the bushing! Also you can see the blurry snap ring at the top of the shaft It is what hold the upper shaft on and is a PIA to remove or install....

The snap ring is way down in there.....

The vacuum advance had a lever that pulls in and are usually marked, this one is 11 so that is 22 degrees. If I am running all in at 34 and add 22 I get 56 degrees at cruise.. That is a bit more than I want but we will see how it really works once running.

Next the pickup plate and getting the advance pin in the hole while standing on one foot...

Last edited:

Here are the FBO parts for setting the timing advance.

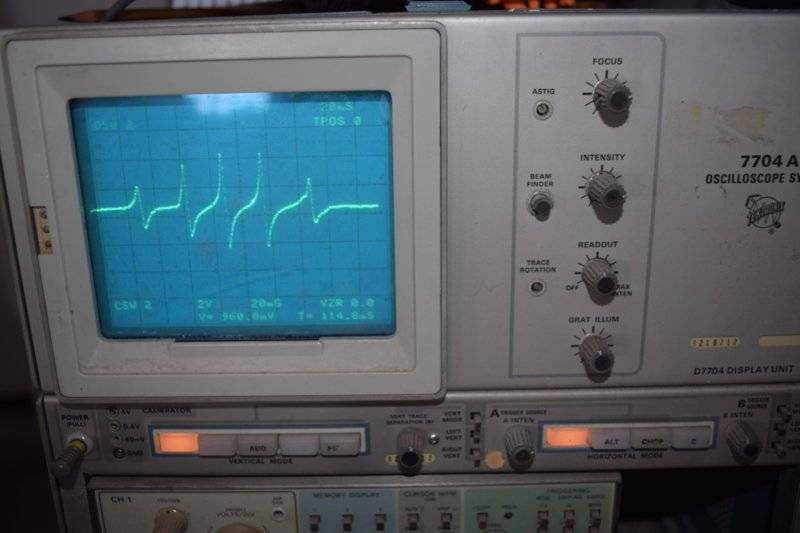

After setting the gap in the pickup to 0.008" we spun it while connected to the oscilloscope. Here is what the signal looks like. The sharp edge is when the sharp edge of the cam passes by the pick up pole.

So it turns out the hole I drilled for the aftermarket booster was needed to get the '73 booster in the '72. I installed a body plug in the old hole.

Now the NOS master cylinder. I disassembled it the other night and used my brake cylinder hone to clean up the bore.

First thing is the installed the flare bushing. Here is how I get them off. This an old tool for removing the emission plugs to get to idle screws on carbs. Remember those? Screw in and use the slide hammer to pull it out. Easy.

In this cylinder only the front tank has a check valve behind the flair bushing. The Coronet had one behind both. The kit was correct and only gave me one so make sure you note it when your pull it apart..

Just set them down in the housing.

I use the lines to thread in and push the flare bushing into the housing. You can feel them go in and bottom out..

Now lub up the bore and new pistons

Front one goes in first. Be careful to not cut them so go easy and twist slightly.

After setting the gap in the pickup to 0.008" we spun it while connected to the oscilloscope. Here is what the signal looks like. The sharp edge is when the sharp edge of the cam passes by the pick up pole.

So it turns out the hole I drilled for the aftermarket booster was needed to get the '73 booster in the '72. I installed a body plug in the old hole.

Now the NOS master cylinder. I disassembled it the other night and used my brake cylinder hone to clean up the bore.

First thing is the installed the flare bushing. Here is how I get them off. This an old tool for removing the emission plugs to get to idle screws on carbs. Remember those? Screw in and use the slide hammer to pull it out. Easy.

In this cylinder only the front tank has a check valve behind the flair bushing. The Coronet had one behind both. The kit was correct and only gave me one so make sure you note it when your pull it apart..

Just set them down in the housing.

I use the lines to thread in and push the flare bushing into the housing. You can feel them go in and bottom out..

Now lub up the bore and new pistons

Front one goes in first. Be careful to not cut them so go easy and twist slightly.

Last edited:

Now the rear tank piston.

It is tricky to get it in as you have to compress the spring and get the snap ring in. Kaelyn put in the snap ring while I pressed.

Now the set screw to hold it together.

Quick trip to the paint shop and all done. Look so much more 1972 than the aftermarket one....

Kick down linkage. Went to town to get some raw material. Steel rod and a fine thread bolt that fits the slotted adjustment linkage. Cut off the head and weld it on.

I used a grinder to make a few slots to bend the rod in 2 spots and welded a bolt shaft 90 degrees with a backup washer. I got frustrated and finished it with out many photos. You can see it in the engine shots. I have some springs coming Monday so I still need to weld on a bracket for the kick down return spring once I get it and figure out where it should go.

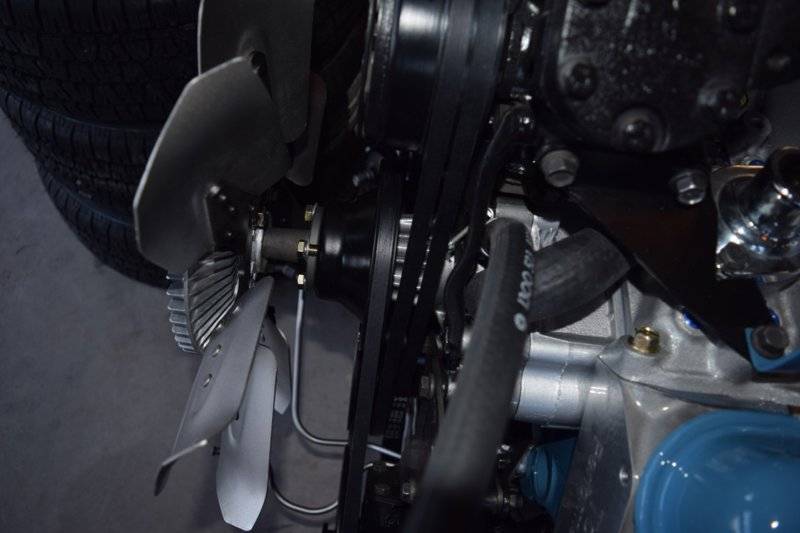

We bought a second set of plug wires and by mixing them we got the routing to be much more correct. Also the fan is now mounted and the AC bracket cut to clear. Need to decide if I want to weld a strengthening plate over it. I think I should.

Here is the photo shoot!

It is tricky to get it in as you have to compress the spring and get the snap ring in. Kaelyn put in the snap ring while I pressed.

Now the set screw to hold it together.

Quick trip to the paint shop and all done. Look so much more 1972 than the aftermarket one....

Kick down linkage. Went to town to get some raw material. Steel rod and a fine thread bolt that fits the slotted adjustment linkage. Cut off the head and weld it on.

I used a grinder to make a few slots to bend the rod in 2 spots and welded a bolt shaft 90 degrees with a backup washer. I got frustrated and finished it with out many photos. You can see it in the engine shots. I have some springs coming Monday so I still need to weld on a bracket for the kick down return spring once I get it and figure out where it should go.

We bought a second set of plug wires and by mixing them we got the routing to be much more correct. Also the fan is now mounted and the AC bracket cut to clear. Need to decide if I want to weld a strengthening plate over it. I think I should.

Here is the photo shoot!

More glamor shots.

Bitter sweet day....

Kaelyn installed the rubber buggy bumpers.

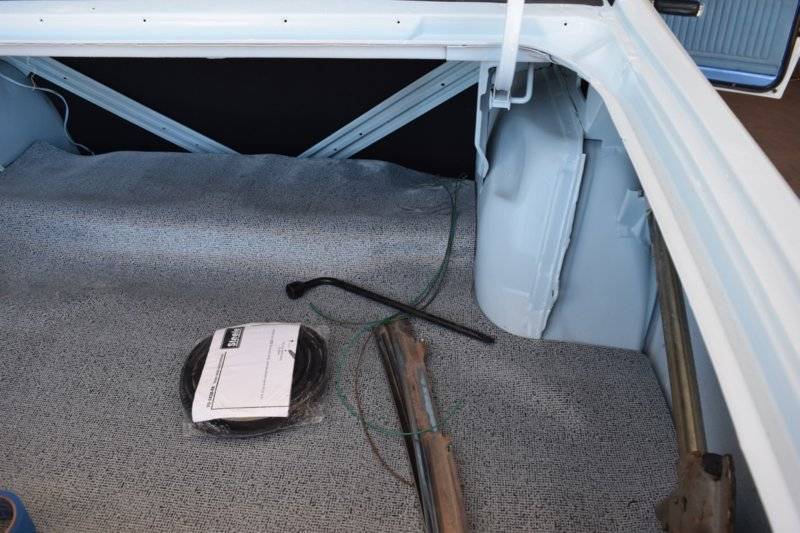

Then she wired up the Out Of Sight Radio for rear speakers... Her mother said she would buy her thumping rear speakers so we needed to run the rear speaker wires... sigh....

Well we hooked up the Coronet for a vacuum source to test the operation of the heater box...

Just took this picture because the Coronet is just so damn cool....

We tried to fix the leaking valve but no joy...

Completely depressed we finished up the fuel system at the tank... ready for gas back here...

Tried to cheer her up by mocking up the Klassics....

Kaelyn installed the rubber buggy bumpers.

Then she wired up the Out Of Sight Radio for rear speakers... Her mother said she would buy her thumping rear speakers so we needed to run the rear speaker wires... sigh....

Well we hooked up the Coronet for a vacuum source to test the operation of the heater box...

Just took this picture because the Coronet is just so damn cool....

We tried to fix the leaking valve but no joy...

Completely depressed we finished up the fuel system at the tank... ready for gas back here...

Tried to cheer her up by mocking up the Klassics....

Well crap the Accurate Exhaust I ordered today will be here Thursday.... We need to get that power train stuffed in the body!

No problem. Sleep is overrated anyhow.Well crap the Accurate Exhaust I ordered today will be here Thursday.... We need to get that power train stuffed in the body!

Spent the late morning and lunch with Bob from Glenray Radiator and his friend. He stopped by to get paid for the Duster radiator/shroud/heater core and to pickup the original from my Coronet for a core. Really nice guy.

Dug out the original Duster rear axle and removed the emergency brake cables and just loosely clamped it in the car so we can use it to pivot the body up the install the power train.

While working on this the UPS man came and the Accurate Exhaust box came!

We put the front bumper on this evening but the one bracket was bent and I did not notice it. A dozen or two smacks with the sledge hammer got it close. Need to get some lock and flat washers from the hardware store in the morning and get it bolted in. Then I can get the straps around it and the brackets to lift the body.

Dug out the original Duster rear axle and removed the emergency brake cables and just loosely clamped it in the car so we can use it to pivot the body up the install the power train.

While working on this the UPS man came and the Accurate Exhaust box came!

We put the front bumper on this evening but the one bracket was bent and I did not notice it. A dozen or two smacks with the sledge hammer got it close. Need to get some lock and flat washers from the hardware store in the morning and get it bolted in. Then I can get the straps around it and the brackets to lift the body.

I wasn't feeling good yesterday so not a lot got done. I made a new kick down rod from the correct diameter material and got the springs all connected. It is ready to go. I also welded the reinforcement plates on the AC bracket I had to cut for the clearance of the thermostat in the Performer Manifold.

Today we wired the heat riser flapper open (it was still perfectly functional with the bimetallic spring!) and made a bracket to hold the fuel line from the filter up to the carb so it won't have the ability to rock into the AC belts. Then we got busy....

Mighty 318 ready to be installed...

Bumper on and double strapped to the engine crane for lifting...

Ready to roll into place.

Up-see-daisy and under she goes.

Kaelyn is torquing down the 4 big K-Frame bolts.

One side all reassembled.

All pretty in place..

Ready for Kaelyn to assemble the left hand side.

Today we wired the heat riser flapper open (it was still perfectly functional with the bimetallic spring!) and made a bracket to hold the fuel line from the filter up to the carb so it won't have the ability to rock into the AC belts. Then we got busy....

Mighty 318 ready to be installed...

Bumper on and double strapped to the engine crane for lifting...

Ready to roll into place.

Up-see-daisy and under she goes.

Kaelyn is torquing down the 4 big K-Frame bolts.

One side all reassembled.

All pretty in place..

Ready for Kaelyn to assemble the left hand side.

Kaelyn did this side by herself...

I forgot to buy torsion bar booties so we can't put the torsion bars in and get it on the floor..... Arrrrrrgggggg.....

Yup I hate those uni-lugs as much as I remembered from 35+ years ago...

I forgot to buy torsion bar booties so we can't put the torsion bars in and get it on the floor..... Arrrrrrgggggg.....

Yup I hate those uni-lugs as much as I remembered from 35+ years ago...

Last edited:

One little trick... A 2" PVC street 90 or this threaded 90 makes a great dual purpose tool...

Cut 4 slots with a hacksaw like this:

Now it can slip over the upper ball joint rubber seal and when you smack the back with hammer it will expand as the seal seats down on the ball joint. Nice boot installer tool..

Now flip it over and it fits perfectly to drive the wheel bearing seals on the disk brakes!

Cut 4 slots with a hacksaw like this:

Now it can slip over the upper ball joint rubber seal and when you smack the back with hammer it will expand as the seal seats down on the ball joint. Nice boot installer tool..

Now flip it over and it fits perfectly to drive the wheel bearing seals on the disk brakes!

Day of details. Got all the underhood wiring done as well has heater hoses and AC hoses. Installed the new AC dryer and what the hell lets go for broke and pump her down!

35 year old RobinAir vacuum pump still going strong...

All the AC clamps restored and installed.

Sucking it down!

The low pressure switch is in the AC dryer. A 1972 the dryer is right there on the inner fender, the '73 AC system I installed the dryer is behind the grill so I had to extend the wires.

This is a GM valve that is 5/8". The original was 1/2" but NOS is $250, I can't see that. I plumbed a 5/8" nipple in the Edelbrock and ran it over here and out. I then added a reducer to 1/2" to go into the heater core.

5/8" to 1/2" reducer inline for the core.

Extended wires to the low pressure cut off switch.

Here is the dryer and cutoff switch.

35 year old RobinAir vacuum pump still going strong...

All the AC clamps restored and installed.

Sucking it down!

The low pressure switch is in the AC dryer. A 1972 the dryer is right there on the inner fender, the '73 AC system I installed the dryer is behind the grill so I had to extend the wires.

This is a GM valve that is 5/8". The original was 1/2" but NOS is $250, I can't see that. I plumbed a 5/8" nipple in the Edelbrock and ran it over here and out. I then added a reducer to 1/2" to go into the heater core.

5/8" to 1/2" reducer inline for the core.

Extended wires to the low pressure cut off switch.

Here is the dryer and cutoff switch.

Ok I think I screwed up..... The 7" wide 205R60's with the disk brakes hit the fender, only on the left side if they car bottoms out! grrrrr... Experts and I screwed?

Here is what I did with the coolant cutoff valve. I cut the mounting tab off the original and painted it "yellow chromate" and it is a good facsimile of the original.

Here it is as of 6pm tonight... so close yet so far... She is holding vacuum for over an hour, I think it is ready to charge with R134a!

Opened up the Accurate Exhaust box and started fitting it. Fits like a glove except for the tail pipe area and the chrome extensions. I may have the hangers backwards, I need to call them in the morning.

Here is what I did with the coolant cutoff valve. I cut the mounting tab off the original and painted it "yellow chromate" and it is a good facsimile of the original.

Here it is as of 6pm tonight... so close yet so far... She is holding vacuum for over an hour, I think it is ready to charge with R134a!

Opened up the Accurate Exhaust box and started fitting it. Fits like a glove except for the tail pipe area and the chrome extensions. I may have the hangers backwards, I need to call them in the morning.

On that heater hose from the valve to the core, check your local auto parts store and see if they have a hose that is 5/8 on one end and 1/2 on the other. I know they make them, I just don't know if you can find one in the length you need.

(Been there, done that.)

(Been there, done that.)

I checked some old notes.

Look up a Dayco 87301 or in that range. I was a huge nuisance at O'Reilly's when I built cars for a living.

Nice it is 13"...... It may be long enough! Thanks!

69_340_GTS

Well-Known Member

You should not be having rubbing issues with only 205 tires. What is the backspacing on the wheel? Or maybe your camber is just un-adjusted wayyyyyyy out at the top?

You should not be having rubbing issues with only 205 tires. What is the backspacing on the wheel? Or maybe your camber is just un-adjusted wayyyyyyy out at the top?

Camber is totally out of adjustment, 4” back spacing

69_340_GTS

Well-Known Member

4" is borderline. 4.50" would be a lot better with the discs. I have aftermarket discs on my '69 Dart, 4.63" b/s on my 7" wheels, with 225/60-15 tires, and there is ample clearance.

4" is borderline. 4.50" would be a lot better with the discs. I have aftermarket discs on my '69 Dart, 4.63" b/s on my 7" wheels, with 225/60-15 tires, and there is ample clearance.

Yea Kaelyn wanted Keystones and they no longer offer custom back spacing as of last year.

-