I can't wait to watch a video of the small block running. I think you'll notice a difference going down the road!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65 Barracuda daily driver

- Thread starter 65barracudaLA

- Start date

-

JDMopar

Well-Known Member

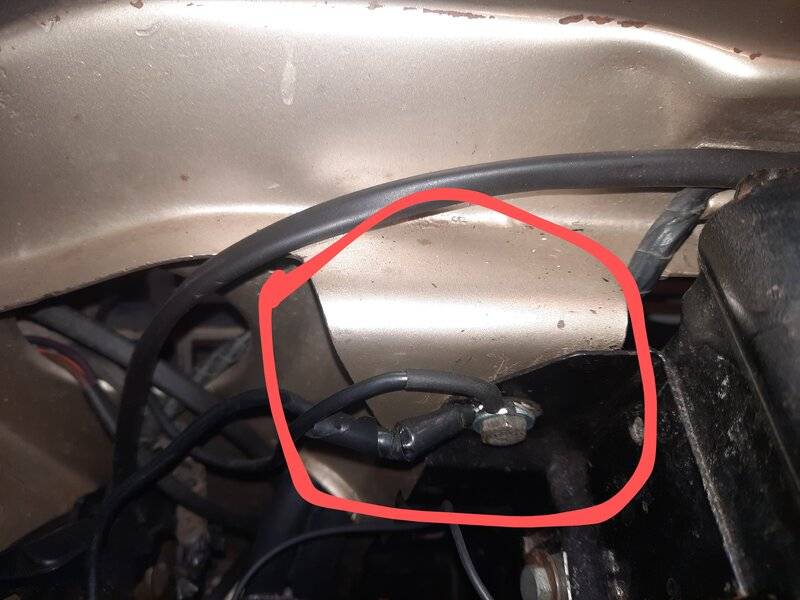

Never seen one of those bolts with that skinny of a head. I wonder if it's been milled down for clearance?

dibbons

Well-Known Member

On my '65 when installing the TTI exhaust, I did not agree with starting at the rear-that just won't work at all if you ask me. It was near impossible fitting in the passenger side head pipe, but I finally found a way to do it (and now I forget what my strategy was, unfortunately). Then to prevent the same header pipe from rubbing on the Torqueflite transmission (near the oil pan) I did have to shim the passenger side motor mount up a little bit with a small metal plate (I think it was only 1/8" or so-not any more than 1/4" for sure). Holes behind the rear seat do have to be drilled for the large muffler brackets. Then I had to find a longer rubber brake line hose (rear) to prevent the driver's side tail pipe from rubbing on it (but that might have been an interference problem only because a previous owner had swapped in an 8 3/4" differential).

and 90 degree oil filter adaptor

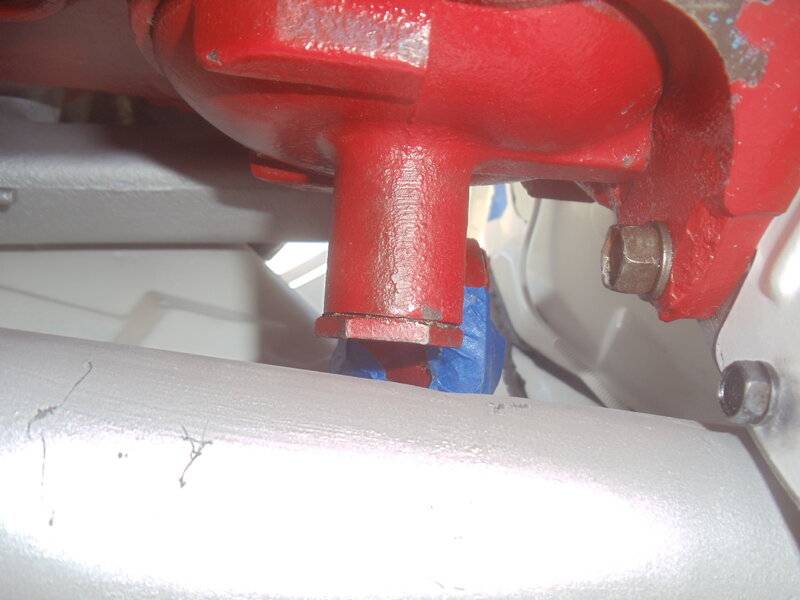

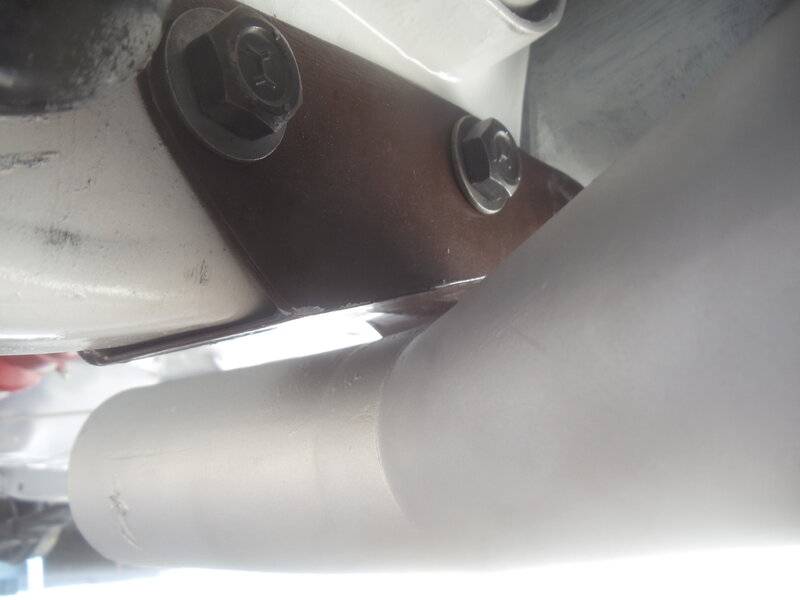

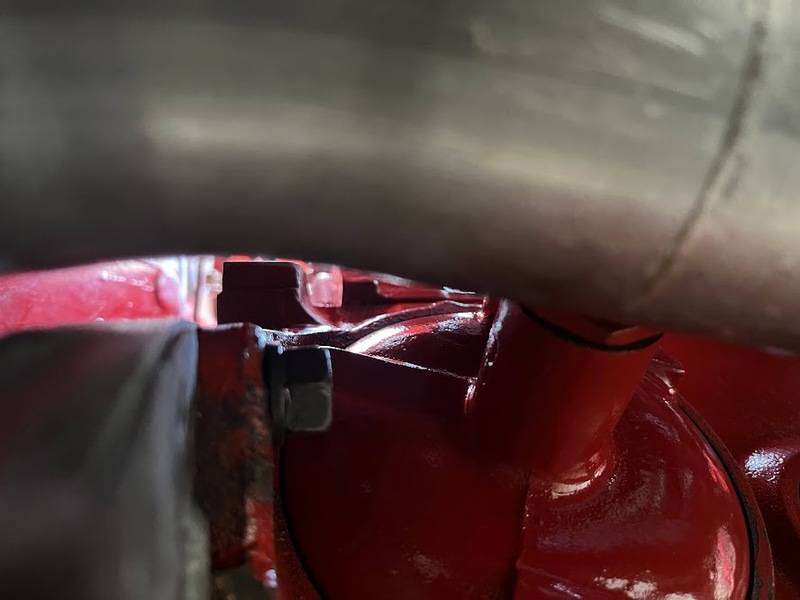

A few years later I tore the entire exhaust system loose when the clamp on the H-pipe got hung up on a huge speed bump (the clamp was installed with the ends of the "u" and the nuts pointing straight down, which limited clearance just enough to cause a problem. Photo #1 shows the passenger side motor mount shim I used. The other photos show the tight clearances with the passenger side torsion bar, Torqueflite oil pan, (probably before the shim was placed), the oil filter adaptor bolt, and the transmission crossmember clearance on the passenger side.

and 90 degree oil filter adaptor

A few years later I tore the entire exhaust system loose when the clamp on the H-pipe got hung up on a huge speed bump (the clamp was installed with the ends of the "u" and the nuts pointing straight down, which limited clearance just enough to cause a problem. Photo #1 shows the passenger side motor mount shim I used. The other photos show the tight clearances with the passenger side torsion bar, Torqueflite oil pan, (probably before the shim was placed), the oil filter adaptor bolt, and the transmission crossmember clearance on the passenger side.

Last edited:

Slantsix64

Well-Known Member

i never ran a oil filter adapter when i had my early abody with a 318 just used the small filter, and ran the stock manifolds for that year. Same with my 67 and 68 barracuda used the small oil filter with magnum manifolds on passenger side.

JDMopar

Well-Known Member

I'm gonna steal your pic in post #600. Looks like I will need an adapter also, because every one of them that I have is the later version with the slant on the oil filter side.

65barracudaLA

Well-Known Member

Can't wait either...I can't wait to watch a video of the small block running. I think you'll notice a difference going down the road!!

65barracudaLA

Well-Known Member

The tti instructions called for milling down the head. If you scroll up a bit you can see that I accomplished that with a hand saw. Probably not the best way to do it, but it worked...Never seen one of those bolts with that skinny of a head. I wonder if it's been milled down for clearance?

65barracudaLA

Well-Known Member

Hi Dibbons, I've been following your build and noticed that you are apparently the only one on FABO who has installed the tti exhaust on a '65 Barracuda. Thanks for your tips - I will probably still have a few questions. I checked and per tti instructions/ specs the engine should be in the right position. I'll shim it if I run into further issues. One question I have right away: How much did you have to shorten the H-pipe? The same exhaust is supposed to also fit a Dart, which has a 2" longer wheelbase. When I mocked it up, it looked like it needed to be shortened more than that though.On my '65 when installing the TTI exhaust, I did not agree with starting at the rear-that just won't work at all if you ask me. It was near impossible fitting in the passenger side head pipe, but I finally found a way to do it (and now I forget what my strategy was, unfortunately). Then to prevent the same header pipe from rubbing on the Torqueflite transmission (near the oil pan) I did have to shim the passenger side motor mount up a little bit with a small metal plate (I think it was only 1/8" or so-not any more than 1/4" for sure). Holes behind the rear seat do have to be drilled for the large muffler brackets. Then I had to find a longer rubber brake line hose (rear) to prevent the driver's side tail pipe from rubbing on it (but that might have been an interference problem only because a previous owner had swapped in an 8 3/4" differential).

and 90 degree oil filter adaptor

A few years later I tore the entire exhaust system loose when the clamp on the H-pipe got hung up on a huge speed bump (the clamp was installed with the ends of the "u" and the nuts pointing straight down, which limited clearance just enough to cause a problem. Photo #1 shows the passenger side motor mount shim I used. The other photos show the tight clearances with the passenger side torsion bar, Torqueflite oil pan, (probably before the shim was placed), the oil filter adaptor bolt, and the transmission crossmember clearance on the passenger side.

View attachment 1716031167

View attachment 1716031168

View attachment 1716031169

View attachment 1716031171

View attachment 1716031172

65barracudaLA

Well-Known Member

Make sure it's part number #2463661...I'm gonna steal your pic in post #600. Looks like I will need an adapter also, because every one of them that I have is the later version with the slant on the oil filter side.

dibbons

Well-Known Member

Unfortunately, the first time the TTI system was installed was by a local shop, if they did any cutting I am not aware of it. When I shimmed the passenger side motor mount, I used a carpenter's level in order to get the motor just right (photo #1). The shop never used a shim and they set it up so the whole system hung too low. I re-installed everything TTI and improved the fit during the recent restoration. Here is a photo of the "H" pipe from my build thread if that helps (photo #2).One question I have right away: How much did you have to shorten the H-pipe?

Last edited:

65barracudaLA

Well-Known Member

Oil filter adapter is in!

Looks like I'll have to cut off quite a bit:

Looks like I'll have to cut off quite a bit:

65barracudaLA

Well-Known Member

Very, very sore, but very, very happy, because the exhaust is 95% in! The driver side downpipe is touching the torsion bar, so I might have to shim the engine on that side. Other than that I just have to bolt on the clamps and tighten everything once the torsion bar issue is solved.

Test fitting before cutting. Gonna have to figure out how to keep the shift cable from being melted by the exhaust:

I had to cut off 6-1/4" . The tti instructions said that "the pipes may require shortening the outlet end of the pipes by no more than 2 inches". They're probably referring to the 2" longer wheelbase of a Dart, but it simply wouldn't have fit hadn't I cut them this much. Measured twice (good thing, first measurement was off) and started sawing. Mixed feelings about cutting into a $1,000+ exhaust when the instructions tell you not to:

One side kinda in:

The second cut actually came out pretty nice (first one not so much):

Second one in. Very difficult to push (hammer) the pipes into the mufflers. Didn't take a photo, but I put a 2x4 behind the mufflers and used a ratchet strap between the 2x4 and the H-pipe connector. It was just a small ratchet strap and it kinda worked, but a bigger one would have made it even easier.:

Daylight's gone, but I got exhaust:

Looking at this photo I guess I need to straighten out the hangers a bit:

Already thinking about changing the tail pipes haha:

Test fitting before cutting. Gonna have to figure out how to keep the shift cable from being melted by the exhaust:

I had to cut off 6-1/4" . The tti instructions said that "the pipes may require shortening the outlet end of the pipes by no more than 2 inches". They're probably referring to the 2" longer wheelbase of a Dart, but it simply wouldn't have fit hadn't I cut them this much. Measured twice (good thing, first measurement was off) and started sawing. Mixed feelings about cutting into a $1,000+ exhaust when the instructions tell you not to:

One side kinda in:

The second cut actually came out pretty nice (first one not so much):

Second one in. Very difficult to push (hammer) the pipes into the mufflers. Didn't take a photo, but I put a 2x4 behind the mufflers and used a ratchet strap between the 2x4 and the H-pipe connector. It was just a small ratchet strap and it kinda worked, but a bigger one would have made it even easier.:

Daylight's gone, but I got exhaust:

Looking at this photo I guess I need to straighten out the hangers a bit:

Already thinking about changing the tail pipes haha:

dibbons

Well-Known Member

My transmission shift cables got melted by the driver's side TTI head pipe. The factory clamp that retains the cable is too close and the cable will get burned. I ended up clamping the cables onto the floorboard after having wrapped them in high-temp silicone sheathing. Even now the clearance is minimal and I will have to keep an eye on things. Not really necessary, but I fabricated driver's side exhaust manifold braces (last photo).

Last edited:

65barracudaLA

Well-Known Member

My transmission shift cables got melted by the driver's side TTI head pipe. The factory clamp that retains the cable is too close and the cable will get burned. I ended up clamping the cables onto the floorboard after having wrapped them in high-temp silicone sheathing. Even now the clearance is minimal and I will have to keep an eye on things. Not really necessary, but I fabricated driver's side exhaust manifold braces (last photo).

View attachment 1716032541

View attachment 1716032542

View attachment 1716032543

View attachment 1716032545

Thank you @dibbons, I'll have to do something like that. I'll also have to find those little exhaust braces.

65barracudaLA

Well-Known Member

Also, I double checked and the Dart actually has a wheelbase of 111" vs the 106" of the Valiants and Barracudas (and Dart wagons!). So the 6-1/4" is not that far off from the 5" difference, if that's what it was.

65barracudaLA

Well-Known Member

I love painting stuff... I know I don't have a 340, but I was driving the car for 13 years with V8 badges even though it "only" had a slant 6. I call it wishful thinking... In the end I want to put a '65 Commando air cleaner on it, which is also not going to be 100% accurate haha.

Been too many years ago, so I don't have pics, but I reconditioned a 1970 Duster. I found a 340 Rallye dash in the junk yard (we're talking like 1988), custom crafted '70 340 stripes out of 3M stuff I got from my job, and installed 340 stickers I found from some aftermarket supplier. It was a /6 '70 Duster with 340 "stuff" and rallye wheels.

Sold it to my brother for less than I had into it. He managed to side swipe a bank (steep hill of dirt, not a money supply house), hit a cow, and showed me where he did his "jump"; went airborne, took a swig of his beer, put the beer back between his legs, then landed...

He told me how he would pull up to a stop light next to a 5.0 Mustang revving the crap out of the engine, blush, and timidly putz away from the light.

I did that car because of what I had, and what I wanted to have. What you did is expressing your "automotive creativity" as you see it. Go For It!!

Sold it to my brother for less than I had into it. He managed to side swipe a bank (steep hill of dirt, not a money supply house), hit a cow, and showed me where he did his "jump"; went airborne, took a swig of his beer, put the beer back between his legs, then landed...

He told me how he would pull up to a stop light next to a 5.0 Mustang revving the crap out of the engine, blush, and timidly putz away from the light.

I did that car because of what I had, and what I wanted to have. What you did is expressing your "automotive creativity" as you see it. Go For It!!

65barracudaLA

Well-Known Member

Making progress... I was gonna re-use the Champion radiator that I got new for the slant 6 about 4-5 years ago, but I realized that the lower hose has a smaller diameter and I wasn't sure if that radiator was enough to cool the 318 with the A/C (that's still waiting to be hooked up for the first time). Anyways, I ordered another Champion radiator, this time in black, because it looks a bit more stock. With shipping and tax around 270 bucks not too bad. I was thinking about getting one of the cheap ebay ones for like 150, but you never know what you get and I was very happy with my last Champion.

Anyways, the driver side exhaust manifold that I already installed in the car has a couple of bad repairs and is cracked in two spot. At the last CPW Fall Fling I got this one, but it was rusty. I wanted to get it sandblasted, but no one nearby was going to do it for a reasonable price. A friend recommended Azusa Refinishing Company and they did it for 25 bucks! If you're in SoCal, I highly recommend them. One other place quoted me $150... I painted it with VHT Flameproof Flat Aluminum and cured it in the oven. I'll have to lift the engine out a bit again to get this one in, but that will hopefully be the last time I need to move the engine.

I also found a solution to my transmission dipstick/ tube issues. I have 3 dipsticks and three tubes and none of them fit. I haven't confirmed this, but it appears the '65 V8 tube is shorter than the slant 6 one. I have a short one, but couldn't find a matching short dipstick. So I cut 2-7/8" of the top of the slant one, which doesn't fit because it hits the exhaust manifold due to a difference curvature. But adding to the top of the short one clears the manifold. I wrapped some metal from a can around the tubes and secured it with hose clamps and now it should work and give me an accurate reading.

I almost finished converting my radio to bluetooth. All I need to do is solder the light and power source to the original radio connector and add a ground.

No one ever tells you that working on cars is 90% cleaning parts... I did a lot of cleaning and refinishing over the weekend.

After the exhaust manifold the next big task is to get all the wiring adjusted to the small block and lots of soldering. Back when I didn't know better I cut of a bunch of the original connectors and replaced them with these ugly parts store connectors. Luckily I kept the original ones and now I'm going to solder them back into the harnesses. I started with the light/ turn signal/ horn harness and it was incredibly dirty... I will try to keep my engine ay a lot cleaner in the future.

Anyways, the driver side exhaust manifold that I already installed in the car has a couple of bad repairs and is cracked in two spot. At the last CPW Fall Fling I got this one, but it was rusty. I wanted to get it sandblasted, but no one nearby was going to do it for a reasonable price. A friend recommended Azusa Refinishing Company and they did it for 25 bucks! If you're in SoCal, I highly recommend them. One other place quoted me $150... I painted it with VHT Flameproof Flat Aluminum and cured it in the oven. I'll have to lift the engine out a bit again to get this one in, but that will hopefully be the last time I need to move the engine.

I also found a solution to my transmission dipstick/ tube issues. I have 3 dipsticks and three tubes and none of them fit. I haven't confirmed this, but it appears the '65 V8 tube is shorter than the slant 6 one. I have a short one, but couldn't find a matching short dipstick. So I cut 2-7/8" of the top of the slant one, which doesn't fit because it hits the exhaust manifold due to a difference curvature. But adding to the top of the short one clears the manifold. I wrapped some metal from a can around the tubes and secured it with hose clamps and now it should work and give me an accurate reading.

I almost finished converting my radio to bluetooth. All I need to do is solder the light and power source to the original radio connector and add a ground.

No one ever tells you that working on cars is 90% cleaning parts... I did a lot of cleaning and refinishing over the weekend.

After the exhaust manifold the next big task is to get all the wiring adjusted to the small block and lots of soldering. Back when I didn't know better I cut of a bunch of the original connectors and replaced them with these ugly parts store connectors. Luckily I kept the original ones and now I'm going to solder them back into the harnesses. I started with the light/ turn signal/ horn harness and it was incredibly dirty... I will try to keep my engine ay a lot cleaner in the future.

You have been very busy!! I'm with you, cleaning is a very time consuming process!!

65barracudaLA

Well-Known Member

Didn't take a lot of photos, but got a lot done. Replacement exhaust manifold is in and I really don't want to have to move the engine again. I shimmed the motor mount on the driver side 3/16" and now the exhaust has about 1/16" clearance to the torsion bars and some other spots. I wish it was a bit more, but the rest will clear itself over time haha. Gonna add some heat wrap in those tight spaces just in case. The 1.03" PST torsion bars are probably a bit too big for the tti exhaust.

Did lots of soldering and re-using those plastic housings that I cut off years ago.

Was bolting the exhaust down under the car and my neighbor walked by and captured the moment haha:

Good thing is that the exhaust is finally fully bolted into place. Took forever...

Somehow couldn't live with the way the radiator core support looked. When I bought the car almost 14 years ago I painted it flat black with a brush and it always bothered me. I was also pretty mangled by some collision before I bought it, so I straightened it as good as I could.

Got a few runs, but that just makes it look more like it was done in the factory haha. Better than brush marks. Hood and fenders will be replaced, so not paint on those.

Wire harness is pretty much done, so that can go in soon, then radiator, fluids, carb, distributor and fire it up?! So close!

Did lots of soldering and re-using those plastic housings that I cut off years ago.

Was bolting the exhaust down under the car and my neighbor walked by and captured the moment haha:

Good thing is that the exhaust is finally fully bolted into place. Took forever...

Somehow couldn't live with the way the radiator core support looked. When I bought the car almost 14 years ago I painted it flat black with a brush and it always bothered me. I was also pretty mangled by some collision before I bought it, so I straightened it as good as I could.

Got a few runs, but that just makes it look more like it was done in the factory haha. Better than brush marks. Hood and fenders will be replaced, so not paint on those.

Wire harness is pretty much done, so that can go in soon, then radiator, fluids, carb, distributor and fire it up?! So close!

65barracudaLA

Well-Known Member

Still working on the wiring, which is taking forever, but I'm fixing a lot of things I mickey-moused over the last almost 14 years. I needed a switched power source for the tach and it took me a while to figure out how to best do it.

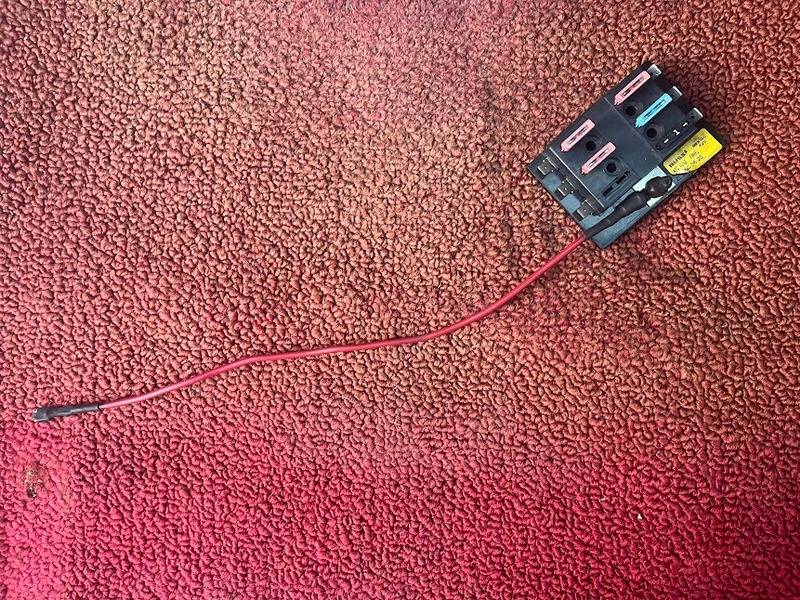

Before the Barracuda I had a '71 Beetle and when I bought it the previous owner was leaving the country, so he left a bunch of tools and stuff in the car - including this fuse block. I never knew what to do with it, so it's been sitting in a box for all this time. I'm currently only using one slot for the tach (with a 1A fuse), but if I ever want to add another accessory it will be super simple.

I read a lot about the fuse block here on FABO and a member explained (simplified) that the left three are battery power and always on and the two on the right are switched (heater & radio). The top row is protected by the fuses and bottom row is not. You should not connect anything to the bottom row - unless it is fused. Since I wanted to connect my secondary fuse block, it's very convenient that you can just use one of these tabs (red wire is the one going to the other fuse block).

Later today I will hook up the engine harness and then the battery and see if everything works. No photos, but I also installed the radio that I converted to bluetooth. Can't wait to see how that'll sound in the car.

Before the Barracuda I had a '71 Beetle and when I bought it the previous owner was leaving the country, so he left a bunch of tools and stuff in the car - including this fuse block. I never knew what to do with it, so it's been sitting in a box for all this time. I'm currently only using one slot for the tach (with a 1A fuse), but if I ever want to add another accessory it will be super simple.

I read a lot about the fuse block here on FABO and a member explained (simplified) that the left three are battery power and always on and the two on the right are switched (heater & radio). The top row is protected by the fuses and bottom row is not. You should not connect anything to the bottom row - unless it is fused. Since I wanted to connect my secondary fuse block, it's very convenient that you can just use one of these tabs (red wire is the one going to the other fuse block).

Later today I will hook up the engine harness and then the battery and see if everything works. No photos, but I also installed the radio that I converted to bluetooth. Can't wait to see how that'll sound in the car.

65barracudaLA

Well-Known Member

I've been wondering for a long time: What is this bracket for?

Here's a couple pics of the same tab on my 66. It curves under and serves as the mount for the radiator. (I still have wiring work too so dont look too closely, lol)

Here are pics with markups.

65barracudaLA

Well-Known Member

Here's a couple pics of the same tab on my 66. It curves under and serves as the mount for the radiator.

Thanks @66fyssh! Now I know I'll have to bend it down. I'm not gonna use a stock radiator, so the bracket might be useless, but ok.

Next question:

I'm trying to replace my rear shocks, but one of the upper nuts is on there so tight, I can't get it off. I already ruined it, so I need a new one. It doesn't appear to be stock '65 A-body, but if I can't find a replacement I might have to replace the stud as well. It's 1/2"-20 thread, but I can't find one anywhere.

Anyone know what they're called and where to find one?

-

Similar threads

- Replies

- 30

- Views

- 600