so, i finally am caught up enough from the aftermath of my vacation to post an update.

short version: even though i broke it, i had a blast at RTTH7.

long version (get a cup of coffee and sit. it may be long)

i spent about 4 days after my last update getting the car as clean and detailed as it has been since the full resto. its really quite sad how neglected i let this car become. cleaned everything but the undercarriage. waxed/buffed it, armor all, cleaned the inside of the wheels, detailed/touched up under hood, etc. car was really looking great. i should have taken pictures then, but i didn't. theme for the weekend, really.

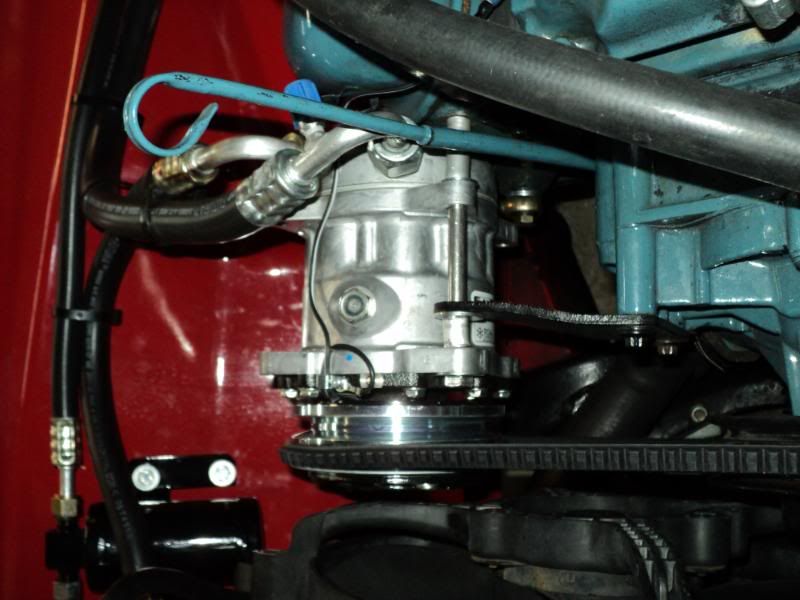

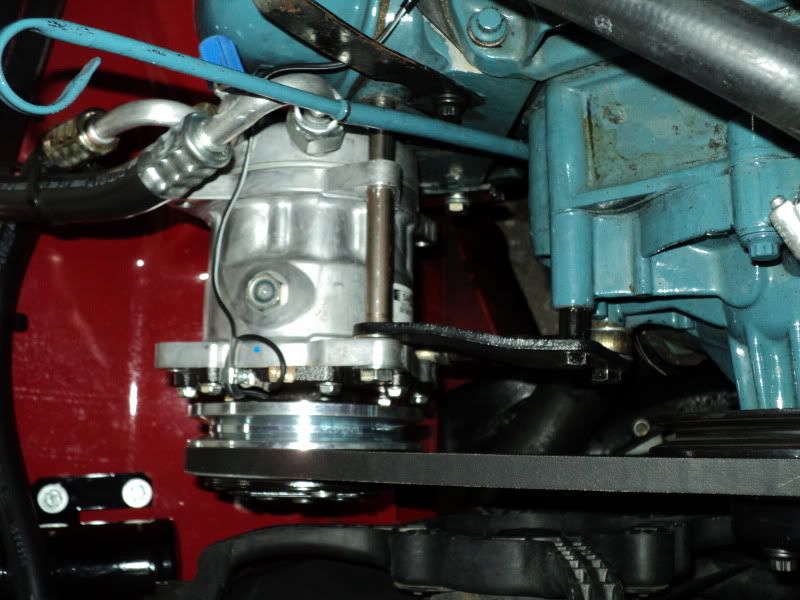

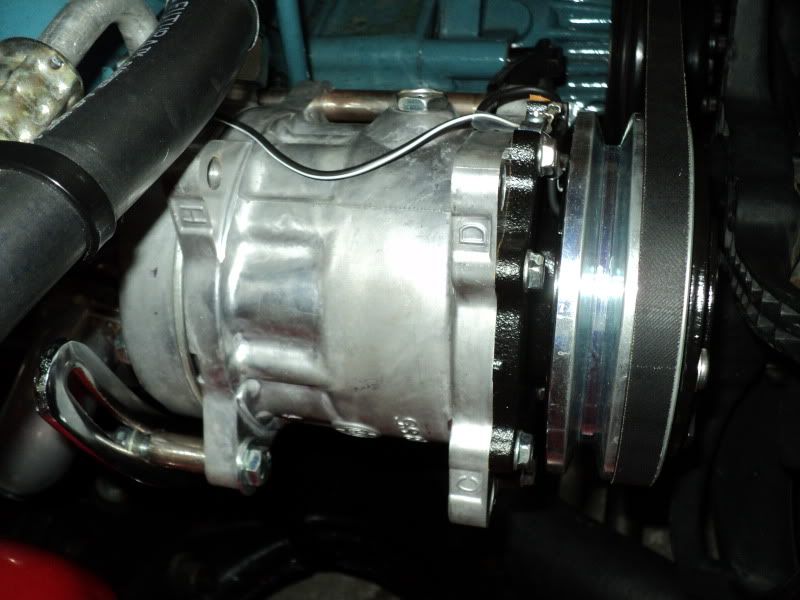

I drove the car down to my fathers shop (the one in pictures with a lift) for him to do a tech inspection on. on the drive down, found my AC compressor wasn't kicking on. so i added that to the list.

he found a LOT of play in my idler arm, so we swapped that out under the lifetime warranty. i also put the first new pair of wiper blades on the car since the late 90's. they were desperately needed (used a spare set of refills that i found in the storage, cut to correct length. free is good!!)

those were the only issues i found then. fixed them both, and put the cover on it.

Thursday morning, we loaded the truck. little cloudy, but it was nice that it wasn't so hot. about the time i uncovered the car and backed it off the lift, the bottom dropped out. driving, pounding rain. right on my fresh detail job.

oh well, i built the car this time to drive, not polish.

we got it strapped down, changed into dry clothes, and headed for pigeon forge. had rain almost the whole way. when we got up there, sun was back out.

the GPS was wrong, though. instead of the toy box, we wound up at a dead end in a cemetery. interesting getting the trailer and truck out of there.

got to the hotel, registered for the event, got the car off the trailer, and walked across the six lanes to a little diner. good eats, and nice to spend time with my dad. the other p-t.com guys started rolling in, and we sat in the parking lot swapping stories and eyeballing cars until after dark. it was nice, and work only called me three times. which was even better.

Friday morning, we got the car all cleaned up the best we could in the hotel paring lot. spray detailer, microfiber towels, and a little bit of drying with a waterblade and some spare hotel towels. car was looking good again.

we applied the event decals, and i went to just double check everything before running tail of the dragon. learned that my AC was still not working, and neither were my cooling fans. the problem with the AC was a bad binary switch (jumped it with a piece of 8 gage wire), and the cooling fans were a bad relay. found an advance down the road about a mile, picked up a 5 dollar relay, put it in in the parking lot, and the fans worked. made it back in time for a sand which from the cooler and to meet up with everyone before the cruise. we also realized on the ride back from the parts store that the electrics in the passengers side seat were only working intermittently. turned out that my ground screw had come loose. 10 seconds with a 7mm wrench and we were back in business.

left for the cruise with a couple we had met at the diner the night before. gentleman's name was Jeff, and i forget his wifes name. they drove a 67 vette on a tube chassis with an LS7. wicked, fast, beautiful car. and very, very nice people. we hung out with them most of the weekend.

about 9 miles in, the car was running very, very hot. pulled over, and Jeff, as well as a young guy with a 67 camaro, and a 67 GTO convertible pull in to check on us. turns out the hot side prong on my snap switch for my fans had snapped off. side of the road fix was to straight wire the fans to the charge stud on the back of the alternator. just loosen the nut and pull the wire off so it doesn't drain the battery when parked. left it that way the rest of the weekend, cause i had a spare back home.

ran the whole dragon, and had fun. had lunch with dad, Jeff, and his wife, as well as a guy in a late model camaro that had joined up with us at the dragon. good eats at the gift shop, pricey though.

and that road is incredible, its no wonder so many people get hurt being stupid on it. you should see the tree of shame. truly incredible. and kind of heartbreaking, knowing how much pain and misery, and even death was involved in making that tree.

after lunch, we got flagged by a guy saying that there was a GTO broken down a little ways up the road. turned out to be the same one that stopped to help earlier. we jerry-rigged his alternator charge stud back together the best we could, jumped him off, and started back to precision hot rods for dinner. he was well ahead of us, as we were taking out time and enjoying the scenery.

about 10 miles later, we met back up with him. our patch held, but the exciter inside the one wire alternator didn't. gave him a ride to pick up his truck and trailer, and met another really cool guy. Jeff and his wife, as well as the young guy in the white and orange camaro, stayed to help as well.

dinner at precision was good, and their shop is incredible. I'm a no-talent hack compared to those guys. and you should see the industrial equipment they build in the next building. truly impressive.

got back to the hotel and passed out. long day.

Saturday morning was the autocross. cleaned the car up again, and noticed that my thermostat housing gasket had started leaking again. topped off the radiator, and went through tech. no prob.

bill had the event set up so each run group got two sessions of 6 runs each. i was car #8, so i was in the first run group. the track was HUGE. more like a low speed road course than an autocross. biggest autocross course i have EVER been on. hell, it was bigger than most go-cart and motorcycle tracks Ive been on. just huge.

my first run, i broke. blew the thermostat gasket clean out from between the manifold and housing, covering my windshield and car in coolant. i didn't think the little leak was anything big, but i didn't account for the pressure spike when i pulled the trigger for WFO to 6500 RPM.

lost my whole first session getting a new gasket and the car put back together. dad jumped in the truck and ran down to a parts store, grabbed some antifreeze and a gasket, came back, and we stuck it back together.

second session i was running pretty good. had a bit of trouble with tire rub, resulting in a mangled front right fender lip.

the story is pretty cool, really.

snap throttle over steer.

i backed off when the back end broke free. tires locked up, bringing the back end of the car around even more. full opposite lock four wheel drift. when the tires finally caught traction again, i was still at opposite lock. the shocks and springs are soft enough that the body rocked over HARD, catching the front tire pretty good. actually hit my passenger in the face with a rubber chunk.

got all six runs in. my fastest time of the second session (my first) put me solidly in the middle of the pack for everyones first session. so i felt pretty good about that. add that to being the only torsion bar mopar there, and i felt really good. especially with as mild as my car is. there were three other mopars. bills charger (full on XV level 3 suspension), shafi's kuda (coil overs, hemi, etc) and a Dakota RT.

had dinner at the toy box, with the best steak i have had in a very long time. thanks again, Alfred.

Sunday was the drag strip. 1/8the mile. first time i had been on a strip since the late 90's. so i was a little rusty. the car fighting me didn't help. i did not make a single clean pass before breaking.

every pass, it had a very nasty bog and layed down through first gear. only got 5 runs in, so i never had time to even think about tuning it.

launched good and straight though, and pulled like a freaking freight train in second. when i didn't miss it power shifting.

my best run was an 8.6 something. which is 14's in the quarter. best 60 ft of 2.6 seconds, with no wheel spin. that should tell you how bad she was running through first.

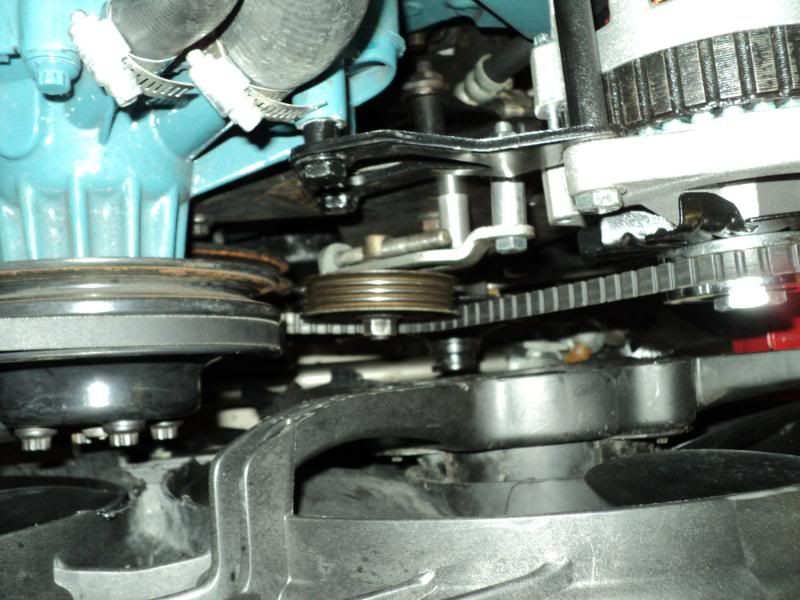

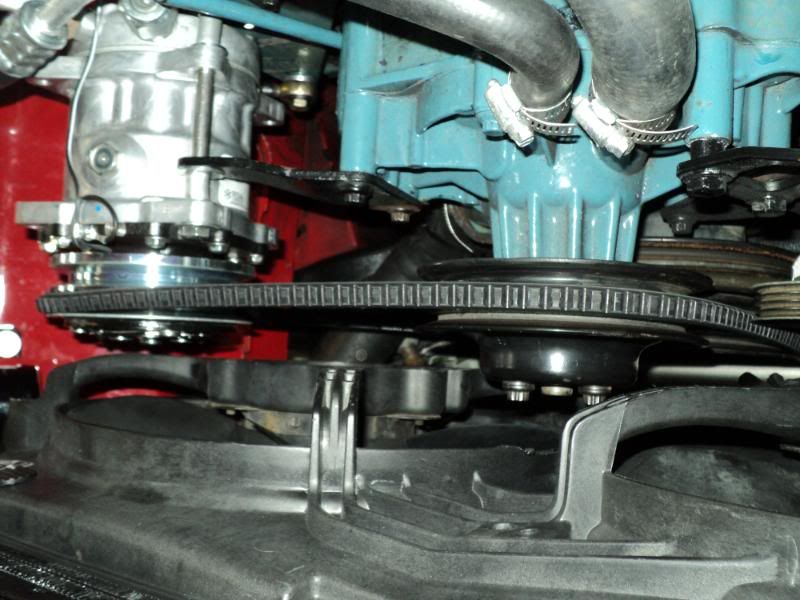

on my last pass, the car had had enough. i went to power shift second, and the clutch pedal stayed on the floor. had to get off the throttle from where i was bouncing it off the rev limiter, and kick the clutch pedal a few times. it came back, and i coasted the rest of the run. go to turn on the return road, and have no power steering. apparently while bouncing off the rev limiter, i threw the belts. with everything else, i was done. threw in the towel, parked it, and watched for a little while.

tossed my spare belts back on in the pits, pulled it on the trailer, and came home.

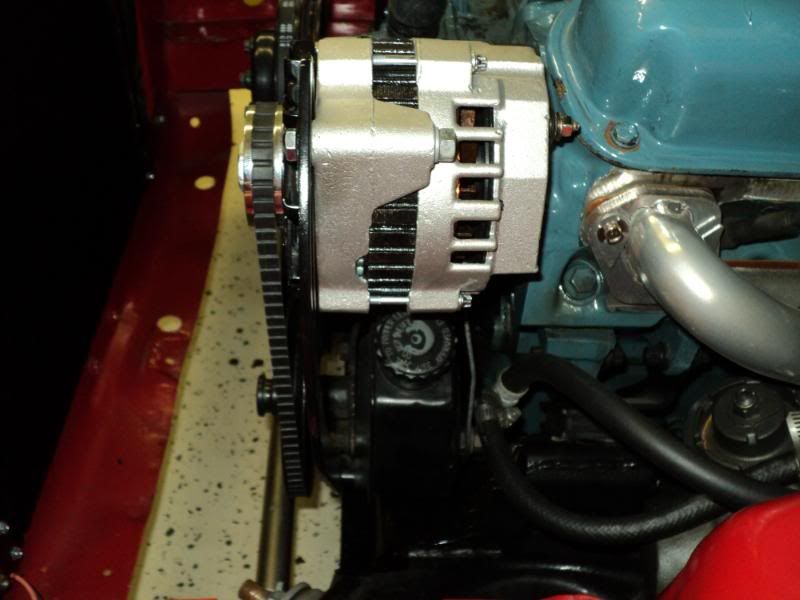

on the last run, my alternator also apparently caught fire. blackened, charred, and no longer charging.

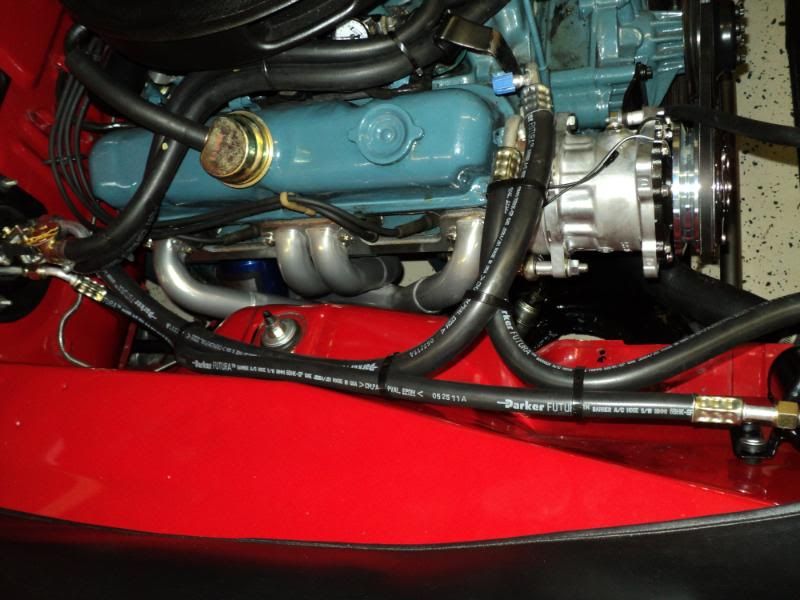

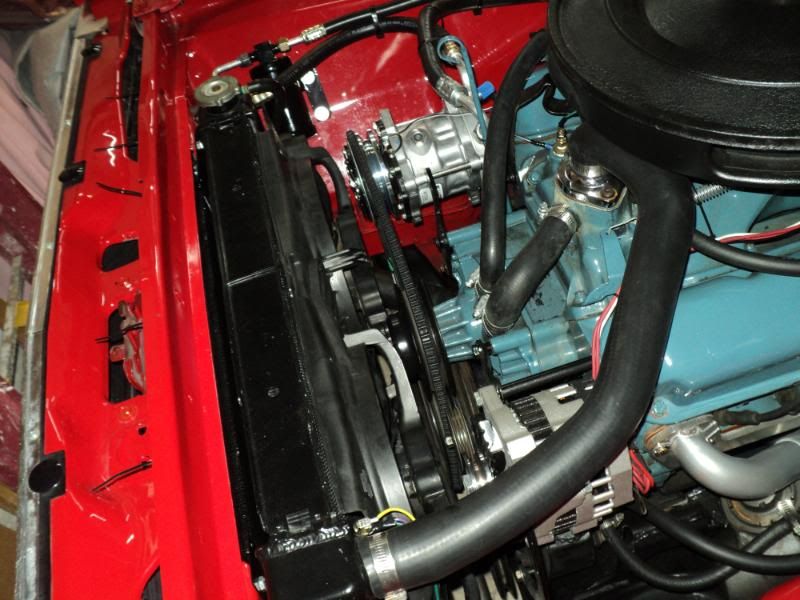

when i got it home, drained the coolant, fixed my wiring hacks, replaced the alternator, fixed the AC proper (bad connection at the binary), found my rear axle noise (drive shaft hitting muffler)

and yanked the single pane to finally put my dual plane in.

the dual plane is gasket matched, and the ports lined up very well. the bolt holes, however, don't. they are all drilled at the wrong angle. so i have to pull it back off, re machine the holes, and try it again.

so thats where we currently sit. i also did not manage to get ANY of my own pictures at the event. apparently my disc was not properly inserted into my camera, so they did not save. but other guys did take pics, which i will repost here for the sake of those that like to look.

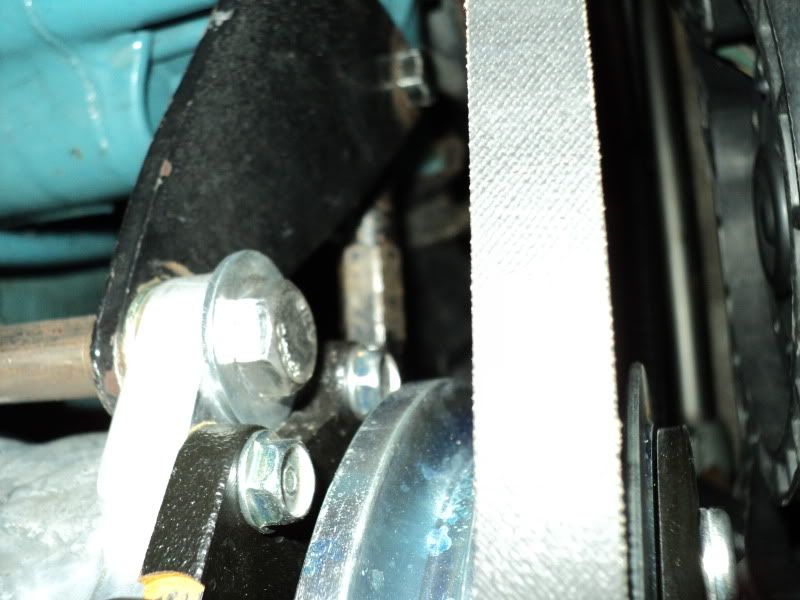

also, I'm going to be revising my sway bar mounts up front, upgrading shocks, ditching the lowering blocks for a better solution, and probably upgrading to 1 inch t-bars. she is very undersprung and damped right now. hopefully, i don't lose my incredible ride quality.

heres the pics: