where is the shear sleeve on your bushings pictured, They do not have them installed only the sleeve between the washers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adjustable Strut Rods

- Thread starter Wagon of Death

- Start date

-

You forgot that your adjustable strut has a swivel built on it. And you actually believe your self that the strut rod holds the LCA in place on the K-member due to stiffness . Your making a fool of yourself with some of your comments . Do you press the pin in the bushing and keep them lubed up? is there room for lube. LOL. Doesn't most of the kits require the outer sleeve and inner sleeve to be kept in place.

No, I did not forget. They have a heim joint, which is NOT a "swivel". And the heim is not inline with the LCA. It's not parallel with the LCA. It's at an angle and then turned partially on its side so it tracks with the motion of the strut rod. It will not allow motion in the direction you're talking about. In order for the strut rod to allow the LCA to move backward, it would have to rotate inward. It can't, because the stiffer poly or Delrin bushing does not compress much (if any, in the case of Delrin) in that direction. If you'd used them, you would know that.

The Delrin bushings have no sleeves, and do press directly into the LCA's. They are lubed on install, but Delrin is a self lubricating material. So no ongoing lubrication is needed on the outside. They don't spin in the LCA anyway, the inner part of the bushing rotates on the LCA pin. That fit is slightly looser, and is lubricated on install. It can be relubricated with the greaseable pins I use, but again, Delrin is self lubricating so it shouldn't be necessary.

Several different poly bushings are now available. The ones from Proforged come with their own new inner and outer sleeves. Apparently you aren't familiar with those, but I suppose that's not surprising. The older style re-use the outer shell. With greaseable pins no inner shell is needed because the pin has a larger outer diameter, eliminating the need for the inner shell. Again, if you were truly familiar with any of these parts you should know that.

Honestly, it seems to me like you aren't familiar enough with the poly and Delrin LCA bushings to make any recommendation about their use or maintenance at all. Your opinion is all based on assumptions and guessing, and badly at that.

How about those poly strut rod bushings with no shear sleeves. I guess they worked just fine on your car also.

I've never used them. They aren't used with adjustable strut rods. Again it seems like you should probably understand that, but I suppose you don't.

I don't recommend them either, the stock strut rods depend on all that squishy rubber to fit because their length is generic. The stock strut rods are a "one size fits most" deal, and when you eliminate all that rubber flex the strut rods have to be the right length, not just vaguely close like they were before. I always recommend adjustable strut rods with poly or Delrin bushings. Suspension is a system, it all has to work together and when you upgrade one part you need to upgrade the ones around it too.

Truly, if you want to use poly strut rod bushings you should be ready to modify the strut rods to be the correct length, because most likely they won't be. This is pretty easy to see, the OE bushings are big and bulky, there's a ton of flex and slop. The strut rods did not have to be all that accurately sized. When you install poly bushings, a lot of that flex goes away. And that means you have to check and make sure the strut rods are actually the right length. And if they're not, you have to adjust the length. You can't just slap this stuff together and call it good, poly and rubber have different properties and requirements.

You know? Back 10's and thousand miles ago before you they sold adjustable struts . You can love them all you want. To me and many others that have a grasp on reality they are scrap for street use.

I have almost 100k street miles on my adjustable strut rods. They work great. The aluminum set on my Challenger has over 70k miles by themselves, and are still in excellent condition. I drive year round, they've seen plenty of unpaved roads and snow. They've actually been one of the most durable parts of the whole set up.

I have just seen to many cars come here with problems and not because they were installed wrong. I didn't install any of them. Every one but you installs them improperly. You know "They pick things up ! they put things down" Again they are ripped before you put them in. Figure it out.

Buddy, I HAVE figured it out. Quite honestly, based on your silly questions and irrelevant "ah-hah" moments where you think you've made a point that isn't physically possible, I seriously doubt your ability to even know when something has been properly installed. The picture you posted earlier of the LCA hanging off the pin confirms that. Anyone with a basic understanding of suspension can look at that picture and tell something is wrong, and yet you thought that was a normal installation. Someone that has as much experience as you should know better.

Did you ever drive your car on Pa. rolling hills with all the pot holes we have in the north east. They don't stay in place the arm moves away from the K-member.

More BS. PA isn't special, California has plenty of mountain roads worse than anything you've got and I drive them. Hell I drive unpaved roads with my car, pretty common where I'm from in the foothills so everytime I visit family the cars see gravel. The arms can't move away from the K member because the adjustable strut rod doesn't move like that, doesn't matter how big the pot hole is they're not going backward.

where is the shear sleeve on your bushings pictured, They do not have them installed only the sleeve between the washers.

View attachment 1715478104

Here, I highlighted the shear sleeves for you.

Maybe this will help your visualization skills. Sleeve installed in a set of bushings. The washers go on the outside of the bushings, just in case you weren't sure.

I had a set laying around because hey, adjustable strut rods don't need them so they were left over.

Again, I'm pretty sure you don't even know what you're talking about here. This is basic stuff you're screwing up. The poly parts do not look like the originals. It's a different material, it functions differently, the design is different.

Last edited:

Alright, I hate bumping myself but I think this is VERY relevant.

I finally found the picture that oldmanmopar was using to talk about all the problems with poly bushings, passing it off like it was a completed and correct install.

This picture.

Clearly that's not good right? Well here's the deal, I thought it looked familiar. That picture is from this thread Pivot shaft problems

And when you go to that thread, where that picture is posted, you find out that the original poster was having issues installing his lower control arms. It clearly states, right in the post with the picture, that the control arm IS NOT FULLY INSTALLED in that picture.

So what does that mean? Oldmanmopar pulled that picture, passed it off as a completed installation when it clearly was not, and was trying to use it as an example as why poly bushings are bad. Give me a break!

Not only that, but if you go back and check on that thread, you find out that the OP has now correctly installed the parts and they look like this

Fully seated against the K and the LCA like they're supposed to be. So oldmanmopar's great example, that he referred back to over and over again? Well, it's total BS. It was an incomplete install that has now been fixed, and oldmanmopar completely misrepresented it. Or maybe completely misunderstood it, not sure which is actually worse.

And hey, I guess I'm not the only one that can correctly install a poly bushing huh? Props to @DentalDart for working through the problem. Wonder if he knows oldmanmopar stole his picture and passed it off as something else?

I finally found the picture that oldmanmopar was using to talk about all the problems with poly bushings, passing it off like it was a completed and correct install.

This picture.

Clearly that's not good right? Well here's the deal, I thought it looked familiar. That picture is from this thread Pivot shaft problems

And when you go to that thread, where that picture is posted, you find out that the original poster was having issues installing his lower control arms. It clearly states, right in the post with the picture, that the control arm IS NOT FULLY INSTALLED in that picture.

So what does that mean? Oldmanmopar pulled that picture, passed it off as a completed installation when it clearly was not, and was trying to use it as an example as why poly bushings are bad. Give me a break!

Not only that, but if you go back and check on that thread, you find out that the OP has now correctly installed the parts and they look like this

Fully seated against the K and the LCA like they're supposed to be. So oldmanmopar's great example, that he referred back to over and over again? Well, it's total BS. It was an incomplete install that has now been fixed, and oldmanmopar completely misrepresented it. Or maybe completely misunderstood it, not sure which is actually worse.

And hey, I guess I'm not the only one that can correctly install a poly bushing huh? Props to @DentalDart for working through the problem. Wonder if he knows oldmanmopar stole his picture and passed it off as something else?

Those are called spacers your arrows are pointing to that keep the washers at the correct distance apart. Slip the spacers out and and where are the sleeves? I don't see them. The spacer goes on the rod between the washers . The shear/wear sleeve would be against the Hole in the K-member with bushing material between the sleeve and the spacer. You really don't have a clue do you?

The picture I posted from another thread was a reference on how the bushing can be off the pin while still in place with the strut rod attached. not as something that I installed. Something you mentioned that holds the control arm from doing what is pictured

There were a couple of members here last night and your explanation of these bushings and how they work was brought up. They all said the same thing. You will never understand logic.

What holds the control arm on the pin? It cannot be the strut. That is common sense. It would have to be the torsion bar clip.

And what stops the K-member from shearing off the material between the edge of the k-member hole and the spacer between the washers. The one piece rubber on the early struts would wear through over time . That is why they upgraded them to two piece and added the steel,

The poly style material just without the sleeve shears off. The second picture of the bushings without the spacer slid through shows the steel is built into the bushing . The spacer is not slid through. If you want I can go get a spacer and slide one through so you can see the two at one time.

That picture you have the arrows on was a waist of your time. You show nothing on it but your ignorance. Look closely at the pictures of the used bushings. Do you see the steel molded into them. the Poly bushings do not have that . They shear off almost immediately.

An adjustable strut is a good item. But not when used in conjunction with lubed up poly struts. By your own explanation of what holds the arm in place would not be there. The arm has a swivel built on it. The arm could pivot off the pin. Are you blind?

Notice the steel molded in the bushingx below the poly bushings do not have.

The picture I posted from another thread was a reference on how the bushing can be off the pin while still in place with the strut rod attached. not as something that I installed. Something you mentioned that holds the control arm from doing what is pictured

There were a couple of members here last night and your explanation of these bushings and how they work was brought up. They all said the same thing. You will never understand logic.

What holds the control arm on the pin? It cannot be the strut. That is common sense. It would have to be the torsion bar clip.

And what stops the K-member from shearing off the material between the edge of the k-member hole and the spacer between the washers. The one piece rubber on the early struts would wear through over time . That is why they upgraded them to two piece and added the steel,

The poly style material just without the sleeve shears off. The second picture of the bushings without the spacer slid through shows the steel is built into the bushing . The spacer is not slid through. If you want I can go get a spacer and slide one through so you can see the two at one time.

That picture you have the arrows on was a waist of your time. You show nothing on it but your ignorance. Look closely at the pictures of the used bushings. Do you see the steel molded into them. the Poly bushings do not have that . They shear off almost immediately.

An adjustable strut is a good item. But not when used in conjunction with lubed up poly struts. By your own explanation of what holds the arm in place would not be there. The arm has a swivel built on it. The arm could pivot off the pin. Are you blind?

Notice the steel molded in the bushingx below the poly bushings do not have.

fishmarket

Well-Known Member

That picture you have the arrows on was a waist of your time. You show nothing on it but your ignorance. Look closely at the pictures of the used bushings. Do you see the steel molded into them. the Poly bushings do not have that . They shear off almost immediately.

An adjustable strut is a good item. But not when used in conjunction with lubed up poly struts. By your own explanation of what holds the arm in place would not be there. The arm has a swivel built on it. The arm could pivot off the pin. Are you blind?

You lost me.... how the hell could the arm pivot off the pin? The “swivel” end of the strut rod is fixed to the k-member. The LCA end of the the strut is just as the OEM unit, through the tube in the arm with a nut on the back. There is no “swivel” on the control arm end of the strut. It is physically impossible for the arm to pivot off the pin. Have you ever installed a set of Hotchkis or QA1 adjustable strut rods? Torsion bar clips keeping the arm from falling off? Get ahold of yourself. You’ve never installed a set of these adjustable strut rods and obviously are “blind” to how they work, even though it has been explained to you, thoroughly, over and over. You’ve made your personal opinions widely known, valid or otherwise. Time to move on. You aren’t going to change my mind and a lot of others here as well. You can call us blind, tell us our torsion bar clips are keeping us from driving over our fronts wheels, whatever you want but in the least, if you are going to call out someone else’s reasoning as a “waist of time” , please use the appropriate WASTE in your rebuttal.

This is the definition of irony.

fishmarket

Well-Known Member

You forgot that your adjustable strut has a swivel built on it. And you actually believe your self that the strut rod holds the LCA in place on the K-member due to stiffness . Your making a fool of yourself with some of your comments .

I figured it out! You actually think that there is a swivel on the control arm side of the adjustable strut rod! Haha, that’s why you believe the control arm can fall off of the pin and that the strut rod doesn’t hold the arm in place through its cycle. Ah, finally put to rest. You were just misinformed. Glad we found the source of all this “ignorance”.

Hotchkis 14385: Adjustable Strut Rods 1967-76 Chrysler A-Body | JEGS

Wow I cannot believe how you came up with the arm cannot move. Put a socket swivel on the end of an extension and then put the ratchet on the other end. Hold the swivel and see if you can move the ratchet with the extension. I cannot believe how ignorant some of you are

Wow I cannot believe how you came up with the arm cannot move. Put a socket swivel on the end of an extension and then put the ratchet on the other end. Hold the swivel and see if you can move the ratchet with the extension. I cannot believe how ignorant some of you are

fishmarket

Well-Known Member

Hotchkis 14385: Adjustable Strut Rods 1967-76 Chrysler A-Body | JEGS

Wow I cannot believe how you came up with the arm cannot move. Put a socket swivel on the end of an extension and then put the ratchet on the other end. Hold the swivel and see if you can move the ratchet with the extension. I cannot believe how ignorant some of you are

Ok, now hold the same swivel and push and/or pull it in and out to simulate the actual forces that a lower control arm strut rod combo would incur. What happens? The extension falls off and lands on your foot because the ratchet isn’t riding on a pivot shaft.

fishmarket

Well-Known Member

Here are a few quick explanations of a strut rods function I acquired via the inter webs.

The first is from Global West Suspension. (Ford)

———————————————————————————-

1. “The strut rod, also called brake reaction strut rod, attaches at the front cross member under the radiator and extend back to the lower control arm. The strut supports the lower arm from moving fore or aft during acceleration or braking. The factory uses a rubber bushing to attach the strut rod to the cross member.

The strut rod also performs an alignment function; it adjust caster. Caster provides straight-line stability and is used for improving corner entry. Caster is also contributes to a self-aligning action after the car comes out of a turn. If the bushings go bad, the car will wander, dart during braking, and cause the toe to change (thus creating more tire wear).”

———————————————————————————-

Hmmmm. I’m sure their just out to procure a few more $ from all the “ignorants”....

The second is directly from from Firm Feel’s website, in reference to their a-body adjustable strut rods.

———————————————————————————

2. “We built these adjustable struts to properly locate the LCA (lower control arm). If you are running urethane or nylon LCA bushings and urethane strut bushings

your strut length is now more critical to insure the LCA doesn't slip back or forward on the pivot pin. Otherwise your LCA inner pivot will be " floating," so the front end alignment (toe setting) will not stay put.

your strut length is now more critical to insure the LCA doesn't slip back or forward on the pivot pin. Otherwise your LCA inner pivot will be " floating," so the front end alignment (toe setting) will not stay put.

You want positive caster AND you want a stable toe setting.

We recommend you preassemble your LCA / Strut assembly and sweep it up and down to make sure every thing move smoothly and the LCA inner pivot stays pulled up snug in position against the LCA pin shoulder, then assemble the rest of the suspension.”

———————————————————————————-

Wow! Deja vu eh? It’s what everyone has been saying all along. Weird. Is Firm Feel really a respected vender in the Mopar community though? (Sarc)..... Pretty sure most folks here would say absolutely! Ignorant?

The third description is simply from hotchkis’ website in reference to their a-body adjustable strut rods.

———————————————————————————-

3. “Hotchkis Sport Suspension 14385 1967-1976 Dodge A Body Adjustable Strut Rods. Dramatically improve the cornering performance traction and steering response of your Dart Demon or Valiant with Hotchkis Sport Suspension Adjustable Strut Rods. Designed to positively locate the lower arm these strut rods will improve responsiveness and driver control. The adjustable design features 5/8 in. high articulation rod ends CNC bent brackets and lightweight TIG-welded 7/8 in. tubing. The part is finished off in a lustrous nickel look powder coated finish blending form and function. Features: TIG-welded Lightweight 7/8 in. Tubing Rigid High Quality 5/8 in. High Articulation Rod Ends. CNC Bent Brackets High Quality Hardware Lustrous Nickel look powder coated finish. Benefits: Positively positions lower Arm and Improves Responsiveness. Adjustable design with Rigid 5/8 in. High Articulation Rod Ends. Improves Caster Removes unwanted play and excessive movement in the front suspension. Bolt In Installation. We recommend upgrading to our 21366 Polyurethane lower control arm bushings for use with this part.”

———————————————————————————-

Again? They must be trying to trick “blind, ignorant” enthusiasts into blowing their hard earned dough. I’m guessing that hotchkis challenger that’s pulling a G in those auto cross corners has SUPER BIG torsion bar clips... you know, so they don’t run over the front wheels when they slip right off the control arm pivot pin. Snake oil I’m sure.

Here is a pic from the Hot Rod article titled “How to Rehab Mopar Front Suspension”

———————————————————————————-

4. https://www.hotrod.com/uploads/sites/21/2017/01/mopar-lower-control-arm-attachment.jpg?fit=around|29:16

———————————————————————————-

Why doesn’t this “ignorant, blind” car lover simply slide the attached control arm/strut rod assembly into the k-member and on the pivot pin, one at a time? I mean, the strut rod in no way keeps the control arm from moving forward or backwards right? How could it with that swivel and all? Duh

Lastly, here is a video on YouTube, produced by MOOG of all people. It shows how to inspect strut rod bushings. You’ll probably notice that the second line in the video states that the purpose of a strut rod is to control fore and aft movement of the control arm....

———————————————————————————-

5.

———————————————————————————-

Holy crap! Your absolutely right! A worldwide conspiracy involving all of the accredited, aftermarket suspension venders in an effort to exploit our “blind, ignorant”, automotive hobby, loving asses!

It’s your turn Oldmanmopar, break out that Cobalt ratchet, swivel socket and extension. It’s time to save all the helpless idiots from the things that only YOU know. I feel a life changing YouTube tutorial coming on. Even if it does insult 7/8ths of the populace.

Make vulcanized rubber bushings great again!

The first is from Global West Suspension. (Ford)

———————————————————————————-

1. “The strut rod, also called brake reaction strut rod, attaches at the front cross member under the radiator and extend back to the lower control arm. The strut supports the lower arm from moving fore or aft during acceleration or braking. The factory uses a rubber bushing to attach the strut rod to the cross member.

The strut rod also performs an alignment function; it adjust caster. Caster provides straight-line stability and is used for improving corner entry. Caster is also contributes to a self-aligning action after the car comes out of a turn. If the bushings go bad, the car will wander, dart during braking, and cause the toe to change (thus creating more tire wear).”

———————————————————————————-

Hmmmm. I’m sure their just out to procure a few more $ from all the “ignorants”....

The second is directly from from Firm Feel’s website, in reference to their a-body adjustable strut rods.

———————————————————————————

2. “We built these adjustable struts to properly locate the LCA (lower control arm). If you are running urethane or nylon LCA bushings and urethane strut bushings

You want positive caster AND you want a stable toe setting.

We recommend you preassemble your LCA / Strut assembly and sweep it up and down to make sure every thing move smoothly and the LCA inner pivot stays pulled up snug in position against the LCA pin shoulder, then assemble the rest of the suspension.”

———————————————————————————-

Wow! Deja vu eh? It’s what everyone has been saying all along. Weird. Is Firm Feel really a respected vender in the Mopar community though? (Sarc)..... Pretty sure most folks here would say absolutely! Ignorant?

The third description is simply from hotchkis’ website in reference to their a-body adjustable strut rods.

———————————————————————————-

3. “Hotchkis Sport Suspension 14385 1967-1976 Dodge A Body Adjustable Strut Rods. Dramatically improve the cornering performance traction and steering response of your Dart Demon or Valiant with Hotchkis Sport Suspension Adjustable Strut Rods. Designed to positively locate the lower arm these strut rods will improve responsiveness and driver control. The adjustable design features 5/8 in. high articulation rod ends CNC bent brackets and lightweight TIG-welded 7/8 in. tubing. The part is finished off in a lustrous nickel look powder coated finish blending form and function. Features: TIG-welded Lightweight 7/8 in. Tubing Rigid High Quality 5/8 in. High Articulation Rod Ends. CNC Bent Brackets High Quality Hardware Lustrous Nickel look powder coated finish. Benefits: Positively positions lower Arm and Improves Responsiveness. Adjustable design with Rigid 5/8 in. High Articulation Rod Ends. Improves Caster Removes unwanted play and excessive movement in the front suspension. Bolt In Installation. We recommend upgrading to our 21366 Polyurethane lower control arm bushings for use with this part.”

———————————————————————————-

Again? They must be trying to trick “blind, ignorant” enthusiasts into blowing their hard earned dough. I’m guessing that hotchkis challenger that’s pulling a G in those auto cross corners has SUPER BIG torsion bar clips... you know, so they don’t run over the front wheels when they slip right off the control arm pivot pin. Snake oil I’m sure.

Here is a pic from the Hot Rod article titled “How to Rehab Mopar Front Suspension”

———————————————————————————-

4. https://www.hotrod.com/uploads/sites/21/2017/01/mopar-lower-control-arm-attachment.jpg?fit=around|29:16

———————————————————————————-

Why doesn’t this “ignorant, blind” car lover simply slide the attached control arm/strut rod assembly into the k-member and on the pivot pin, one at a time? I mean, the strut rod in no way keeps the control arm from moving forward or backwards right? How could it with that swivel and all? Duh

Lastly, here is a video on YouTube, produced by MOOG of all people. It shows how to inspect strut rod bushings. You’ll probably notice that the second line in the video states that the purpose of a strut rod is to control fore and aft movement of the control arm....

———————————————————————————-

5.

———————————————————————————-

Holy crap! Your absolutely right! A worldwide conspiracy involving all of the accredited, aftermarket suspension venders in an effort to exploit our “blind, ignorant”, automotive hobby, loving asses!

It’s your turn Oldmanmopar, break out that Cobalt ratchet, swivel socket and extension. It’s time to save all the helpless idiots from the things that only YOU know. I feel a life changing YouTube tutorial coming on. Even if it does insult 7/8ths of the populace.

Make vulcanized rubber bushings great again!

Last edited:

The picture I posted from another thread was a reference on how the bushing can be off the pin while still in place with the strut rod attached. not as something that I installed. Something you mentioned that holds the control arm from doing what is pictured

I know it's not something you installed, because DentalDart installed it remember? I know, you didn't bother to link it because then everyone else would see what was actually going on in that picture.

That picture can't be "a reference on how the bushing can be off the pin with the strut rod attached" Wanna know why? Because in that picture the strut rod isn't fully installed. And the lower control arm pivot isn't inserted fully in the K frame, and the pivot nut isn't torqued. Hell the torsion bars aren't installed.

It's literally a picture with the suspension only half installed. All it proves is that you can't tell the difference from a completed installation and one that's in progress.

There were a couple of members here last night and your explanation of these bushings and how they work was brought up. They all said the same thing. You will never understand logic.

That's too funny. Let's try some logic, since you like to use examples.

The flat earth society holds a meeting. 10,000 people show up. Does that mean the Earth is flat now? Of course not. It just means that the 10,000 mouth breathing idiots that showed up for the meeting are all wrong. Opinions can't change facts. Doesn't matter how many people believe it.

On that note, how about the logical fallacy you just committed - Argumentum ad populum. Otherwise known as the "bandwagon fallacy" if the Latin's too tough for you. Go ahead, google it. Short version is, I don't care if you and a couple other guys don't understand what you're talking about, because it doesn't change the facts. Get a hundred members and have a good laugh at my expense, doesn't change a thing. Just don't drop the hammer with a loose control arm on the way home eh?

What holds the control arm on the pin? It cannot be the strut. That is common sense. It would have to be the torsion bar clip.

So- you're saying that the strut rod, whose only function as a part of the suspension is to limit the fore/aft movement of the control arm- isn't what holds the control arm on the pin?

That's not common sense bud. That's flat out stupidity. Strut rods were literally designed for that purpose.

Those are called spacers your arrows are pointing to that keep the washers at the correct distance apart. Slip the spacers out and and where are the sleeves? I don't see them. The spacer goes on the rod between the washers . The shear/wear sleeve would be against the Hole in the K-member with bushing material between the sleeve and the spacer. You really don't have a clue do you?

And what stops the K-member from shearing off the material between the edge of the k-member hole and the spacer between the washers. The one piece rubber on the early struts would wear through over time . That is why they upgraded them to two piece and added the steel,

The poly style material just without the sleeve shears off. The second picture of the bushings without the spacer slid through shows the steel is built into the bushing . The spacer is not slid through. If you want I can go get a spacer and slide one through so you can see the two at one time.

That picture you have the arrows on was a waist of your time. You show nothing on it but your ignorance. Look closely at the pictures of the used bushings. Do you see the steel molded into them. the Poly bushings do not have that . They shear off almost immediately.

An adjustable strut is a good item. But not when used in conjunction with lubed up poly struts. By your own explanation of what holds the arm in place would not be there. The arm has a swivel built on it. The arm could pivot off the pin. Are you blind?

View attachment 1715478291

Notice the steel molded in the bushingx below the poly bushings do not have.

View attachment 1715478294

Hey check this out. Factory original bushings with over 91k miles on them. No "shear sleeve". Also, they're intact at 46 years old after 91k miles. Nothing sheared off. I have two sets, both off '74's. I never saw the set on my '71, they were so deteriorated the only thing left was the washers and the "spacer".

So, seems like the "shear sleeves" aren't necessary at all then? Since the factory made every A body from 1973-1976 without them? That's right, they stopped making them the way you think is the only right way to do it over 47 years ago.

Here's a little side by side comparison for you. The poly strut rods bushings have all the same basic components as these factory strut rod bushings from my '74 Duster.

Here are a few quick explanations of a strut rods function I acquired via the inter webs.

The first is from Global West Suspension. (Ford)

———————————————————————————-

1. “The strut rod, also called brake reaction strut rod, attaches at the front cross member under the radiator and extend back to the lower control arm. The strut supports the lower arm from moving fore or aft during acceleration or braking. The factory uses a rubber bushing to attach the strut rod to the cross member.

The strut rod also performs an alignment function; it adjust caster. Caster provides straight-line stability and is used for improving corner entry. Caster is also contributes to a self-aligning action after the car comes out of a turn. If the bushings go bad, the car will wander, dart during braking, and cause the toe to change (thus creating more tire wear).”

———————————————————————————-

Hmmmm. I’m sure their just out to procure a few more $ from all the “ignorants”....

The second is directly from from Firm Feel’s website, in reference to their a-body adjustable strut rods.

———————————————————————————

2. “We built these adjustable struts to properly locate the LCA (lower control arm). If you are running urethane or nylon LCA bushings and urethane strut bushings

your strut length is now more critical to insure the LCA doesn't slip back or forward on the pivot pin. Otherwise your LCA inner pivot will be " floating," so the front end alignment (toe setting) will not stay put.

You want positive caster AND you want a stable toe setting.

We recommend you preassemble your LCA / Strut assembly and sweep it up and down to make sure every thing move smoothly and the LCA inner pivot stays pulled up snug in position against the LCA pin shoulder, then assemble the rest of the suspension.”

———————————————————————————-

Wow! Deja vu eh? It’s what everyone has been saying all along. Weird. Is Firm Feel really a respected vender in the Mopar community though? (Sarc)..... Pretty sure most folks here would say absolutely! Ignorant?

The third description is simply from hotchkis’ website in reference to their a-body adjustable strut rods.

———————————————————————————-

3. “Hotchkis Sport Suspension 14385 1967-1976 Dodge A Body Adjustable Strut Rods. Dramatically improve the cornering performance traction and steering response of your Dart Demon or Valiant with Hotchkis Sport Suspension Adjustable Strut Rods. Designed to positively locate the lower arm these strut rods will improve responsiveness and driver control. The adjustable design features 5/8 in. high articulation rod ends CNC bent brackets and lightweight TIG-welded 7/8 in. tubing. The part is finished off in a lustrous nickel look powder coated finish blending form and function. Features: TIG-welded Lightweight 7/8 in. Tubing Rigid High Quality 5/8 in. High Articulation Rod Ends. CNC Bent Brackets High Quality Hardware Lustrous Nickel look powder coated finish. Benefits: Positively positions lower Arm and Improves Responsiveness. Adjustable design with Rigid 5/8 in. High Articulation Rod Ends. Improves Caster Removes unwanted play and excessive movement in the front suspension. Bolt In Installation. We recommend upgrading to our 21366 Polyurethane lower control arm bushings for use with this part.”

———————————————————————————-

Again? They must be trying to trick “blind, ignorant” enthusiasts into blowing their hard earned dough. I’m guessing that hotchkis challenger that’s pulling a G in those auto cross corners has SUPER BIG torsion bar clips... you know, so they don’t run over the front wheels when they slip right off the control arm pivot pin. Snake oil I’m sure.

Here is a pic from the Hot Rod article titled “How to Rehab Mopar Front Suspension”

———————————————————————————-

4. https://www.hotrod.com/uploads/sites/21/2017/01/mopar-lower-control-arm-attachment.jpg?fit=around|29:16

———————————————————————————-

Why doesn’t this “ignorant, blind” car lover simply slide the attached control arm/strut rod assembly into the k-member and on the pivot pin, one at a time? I mean, the strut rod in no way keeps the control arm from moving forward or backwards right? How could it with that swivel and all? Duh

Lastly, here is a video on YouTube, produced by MOOG of all people. It shows how to inspect strut rod bushings. You’ll probably notice that the second line in the video states that the purpose of a strut rod is to control fore and aft movement of the control arm....

———————————————————————————-

5.

———————————————————————————-

Holy crap! Your absolutely right! A worldwide conspiracy involving all of the accredited, aftermarket suspension venders in an effort to exploit our “blind, ignorant”, automotive hobby, loving asses!

It’s your turn Oldmanmopar, break out that Cobalt ratchet, swivel socket and extension. It’s time to save all the helpless idiots from the things that only YOU know. I feel a life changing YouTube tutorial coming on. Even if it does insult 7/8ths of the populace.

Make vulcanized rubber bushings great again!

What!!! The entire purpose of the strut rod is to locate the LCA on the pivot pin?

It can't be! It's like, it's like that's the only reason they're even on the car! Wait, who said that? The company that makes the rubber bushings Oldmanmopar likes? Can't be!!! They even said it so casually, like they expect that everyone should just understand that's an accepted fact about strut rods!

You are a really stupid person. Keep on typing. Rubber won't shear off like that junk does. I guess I pulled those struts I have pictured with the sleeves out of my ***. LMFAO

Oh yeah, The strut fastened to the LCA at the Ball joint holds the LCA at the K-member. And then add a swivel in the mix with an adjustable strut. Since your calling names. I'll join in. You were stupid when I came on this site and you get dumber every day.

Did you every see a K-member hole wore from the strut wearing into it? Probably not your K-members are made of a special material like your scrap bushings you swear by.

LMFAO. Your showing a rubber bushing wore almost through. And next to bushings that have less the half the protrusion without a female receptacle. You are picturing exactly the problem and rubber takes friction way better then those poly scrap You are using. That is why you lube the LCA bushings. They wear and turn to powder. You were not thinking with your dip stick Jimmy. when you posted these pictures.

.

Oh yeah, The strut fastened to the LCA at the Ball joint holds the LCA at the K-member. And then add a swivel in the mix with an adjustable strut. Since your calling names. I'll join in. You were stupid when I came on this site and you get dumber every day.

Did you every see a K-member hole wore from the strut wearing into it? Probably not your K-members are made of a special material like your scrap bushings you swear by.

LMFAO. Your showing a rubber bushing wore almost through. And next to bushings that have less the half the protrusion without a female receptacle. You are picturing exactly the problem and rubber takes friction way better then those poly scrap You are using. That is why you lube the LCA bushings. They wear and turn to powder. You were not thinking with your dip stick Jimmy. when you posted these pictures.

.

mopowers

Well-Known Member

Are there any poly strut rod bushings out there that are the correct thickness and that don't push the wheel-end of the LCA rearward as compared to stock?

Dfr360cuda

Diagnosis... Plum Crazy.

Unbiased opinion.......

I just got PST 1.03 torsion bars for my 68. I'm pretty satisfied with their stuff.

I bought my rebuild kit from PST for my 74. It came with the OEM style and poly LCA bushings. The poly slid right into the old outer shell. The pin slid right into the bushing. No press, slid right in. I assumed that maybe the bushing expanded in the shell and tightened up when you torqued down the pin. I used the OEM style. PA roads you know.

Also, maybe you could include the split pins for the strut rods in the PST kit.

I just got PST 1.03 torsion bars for my 68. I'm pretty satisfied with their stuff.

I bought my rebuild kit from PST for my 74. It came with the OEM style and poly LCA bushings. The poly slid right into the old outer shell. The pin slid right into the bushing. No press, slid right in. I assumed that maybe the bushing expanded in the shell and tightened up when you torqued down the pin. I used the OEM style. PA roads you know.

Also, maybe you could include the split pins for the strut rods in the PST kit.

Duane

Well-Known Member

Wow quite the debate went on here. I think both of these guys are partially right. I do not agree that the factory lca bushing holds the arm in place, but I do not believe that the strut does either. IMHO I think they were on the right track about the torsion bar, but not the clips. As was mentioned previously, a suspension is a system.Are there any poly strut rod bushings out there that are the correct thickness and that don't push the wheel-end of the LCA rearward as compared to stock?

I recently installed nylon lower control arms bushings, and rms strut rods with

A heim joint on the end. During the install I did indeed see how the arm can just slide back if the strut length was not correct. I adjusted my struts while pivoting the arm up and down to find the arms natural position up against the pin. I think the more correct terminology is that the strut locates the arm in the correct location.

But assessing the weight of a vehicle and the braking forces involved, there is no way that I believe that the strut keeps it there.

The strut is at an angle. It's purpose is not to keep the arm up against the pin, but to keep the arm square to maintain toe pattern.

This is mentioned in the Mopar chassis book. Your toe setting may get done at an alignment shop at rest, but the struts are what keeps the toe setting dynamically while driving or braking.

Once the correct strut length is determined to position the arm against the pin, your torsion bars would be installed and tensioned.

The bars are supposed to be driven in right up against the arm further locating the arm against the pins. It's a system.

Once you tension the torsion bar enough to support ride height, think about how much the front end of your car weighs. All that weight is concentrated on those six torsion bar hexes. You just try to slide that bar back with all that load on it. It ain't gonna come out.

I think of the clips like the cotter pin on a ball joint assembly.

If you installed the joint correctly, and torqued the nut to spec, it should never come undone. The cotter pin is just an insurance policy against complete disassembly, but by design should never really be needed. I think both those guys are both partially right, and to some degree partially wrong, but this too is just my opinion.

Cheers to you and stay healthy during this time.

Last edited:

Wow quite the debate went on here. I think both of these guys are partially right. I do not agree that the factory lca bushing holds the arm in place, but I do not believe that the strut does either. IMHO I think they were on the right track about the torsion bar, but not the clips. As was mentioned previously, a suspension is a system.

I recently installed nylon lower control arms bushings, and rms strut rods with

A heim joint on the end. During the install I did indeed see how the arm can just slide back if the strut length was not correct. I adjusted my struts while pivoting the arm up and down to find the arms natural position up against the pin. I think the more correct terminology is that the strut locates the arm in the correct location.

But assessing the weight of a vehicle and the braking forces involved, there is no way that I believe that the strut keeps it there.

The strut is at an angle. It's purpose is not to keep the arm up against the pin, but to keep the arm square to maintain toe pattern.

This is mentioned in the Mopar chassis book. Your toe setting may get done at an alignment shop at rest, but the struts are what keeps the toe setting dynamically while driving or braking.

Once the correct strut length is determined to position the arm against the pin, your torsion bars would be installed and tensioned.

The bars are supposed to be driven in right up against the arm further locating the arm against the pins. It's a system.

Once you tension the torsion bar enough to support ride height, think about how much the front end of your car weighs. All that weight is concentrated on those six torsion bar hexes. You just try to slide that bar back with all that load on it. It ain't gonna come out.

I think of the clips like the cotter pin on a ball joint assembly.

If you installed the joint correctly, and torqued the nut to spec, it should never come undone. The cotter pin is just an insurance policy against complete disassembly, but by design should never really be needed. I think both those guys are both partially right, and to some degree partially wrong, but this too is just my opinion.

Cheers to you and stay healthy during this time.

Oh I shouldn’t even bother.

The torsion bar can slide back and forth too. Most cars have a good 1/4” or more between the end of the bar and the clip.

Here you go. A ~1/4” gap, so nothing to positively keep the bar from sliding back. Which means it can’t keep the LCA from moving back either.

Now, torsion bars don’t slide around freely because they’re usually loaded. But keep in mind that as the suspension works up and down the load on the hexes varies quite a bit, and at full extension of the suspension there may be very little force on the hexes depending on how the adjusters are set. The bars can move. If the anchors are greased and the bars are fully unloaded they can slide right out by hand. Doesn’t usually happen if they’ve been in there for 20 years, but I’ve done it on bars I’ve installed recently.

The strut rod locates the LCA. Not the rubber in the control arm bushing, not the torsion bars. If the LCA was held positively in place by the rubber in the bushings or by the torsion bars, there’d be no need for the strut rod at all. And if there was no need for a strut rod, you’d better believe the factory would have left them out.

mopowers

Well-Known Member

Oh I shouldn’t even bother.

The torsion bar can slide back and forth too. Most cars have a good 1/4” or more between the end of the bar and the clip.

Here you go. A ~1/4” gap, so nothing to positively keep the bar from sliding back. Which means it can’t keep the LCA from moving back either.

View attachment 1715510340

View attachment 1715510341

Now, torsion bars don’t slide around freely because they’re usually loaded. But keep in mind that as the suspension works up and down the load on the hexes varies quite a bit, and at full extension of the suspension there may be very little force on the hexes depending on how the adjusters are set. The bars can move. If the anchors are greased and the bars are fully unloaded they can slide right out by hand. Doesn’t usually happen if they’ve been in there for 20 years, but I’ve done it on bars I’ve installed recently.

The strut rod locates the LCA. Not the rubber in the control arm bushing, not the torsion bars. If the LCA was held positively in place by the rubber in the bushings or by the torsion bars, there’d be no need for the strut rod at all. And if there was no need for a strut rod, you’d better believe the factory would have left them out.

Is there value in adding shims to tighten the gap between the spring clip and the torsion bar?

Also, do you know of any poly strut rod bushing that are the correct thickness and locate the wheel side of the LCA in the correct location? Seems like if one would want to run poly strut rod bushings, they'd either have to modify the bushing, or use adjustable strut rods.

Duane

Well-Known Member

Most of what I said you just repeated. I agree the adjustable strut locates the arm, that's how I did it too. I agree the torsion bar clips do not hold the arm and that they usually do not even touch the torsion bar. Whenever I have removed a torsion bar I have always found the best way to get all the tension off is unbolt the upper ball joint so the arm can drop even lower.Oh I shouldn’t even bother.

The torsion bar can slide back and forth too. Most cars have a good 1/4” or more between the end of the bar and the clip.

Here you go. A ~1/4” gap, so nothing to positively keep the bar from sliding back. Which means it can’t keep the LCA from moving back either.

View attachment 1715510340

View attachment 1715510341

Now, torsion bars don’t slide around freely because they’re usually loaded. But keep in mind that as the suspension works up and down the load on the hexes varies quite a bit, and at full extension of the suspension there may be very little force on the hexes depending on how the adjusters are set. The bars can move. If the anchors are greased and the bars are fully unloaded they can slide right out by hand. Doesn’t usually happen if they’ve been in there for 20 years, but I’ve done it on bars I’ve installed recently.

The strut rod locates the LCA. Not the rubber in the control arm bushing, not the torsion bars. If the LCA was held positively in place by the rubber in the bushings or by the torsion bars, there’d be no need for the strut rod at all. And if there was no need for a strut rod, you’d better believe the factory would have left them out.

My point is that the torsion bar imho works as part of a system along with the strut to keep the arm on the pin. Those bars cannot slide back easily at all even when partially unloaded.

I am not trying to get into a heated debate with the two of you.

I am just saying that I think both of you were partially right in different areas. But that is just my opinion.

Stay healthy my friend.

Last edited:

Duane

Well-Known Member

Well possibly, but it's also possible that the gap between the clip and the bar is intentional to allow for expansion. As some of the posted pictures show, Chrysler left quite a space there, so it must not be an issue if everything else is installed correctly.Is there value in adding shims to tighten the gap between the spring clip and the torsion bar?

Also, do you know of any poly strut rod bushing that are the correct thickness and locate the wheel side of the LCA in the correct location? Seems like if one would want to run poly strut rod bushings, they'd either have to modify the bushing, or use adjustable strut rods.

Is there value in adding shims to tighten the gap between the spring clip and the torsion bar?

Also, do you know of any poly strut rod bushing that are the correct thickness and locate the wheel side of the LCA in the correct location? Seems like if one would want to run poly strut rod bushings, they'd either have to modify the bushing, or use adjustable strut rods.

No, I don’t believe there’s any value in adding shims there. The torsion bars are captured, they can’t fall out. Some movement of the bar back and forth as the suspension works is inevitable, as it loads and unloads it also will lengthen and contract some. That’s a very small amount, but you wouldn’t want to completely prevent the bar from moving in those directions. Shim it tight enough and you might even break stuff. And they aren’t there to locate the LCA, that’s not their purpose.

As for the poly strut rod bushings, I don’t think any of the manufacturers really nailed the thickness. And just like adding the poly or Delrin LCA bushings, the thickness of the bushing becomes more critical because there’s less give in the material. So being a little bit off on thickness doesn’t just compress the bushing more, it starts moving parts.

The other thing is that the strut rod bushings have to allow for the up and down movement of the LCA. The poly is good because it limits the fore/aft movement, but it’s also bad because it will also limit the up and down travel, it will resist that movement and make binding more of an issue at the extremes of LCA travel. That’s why the adjustable strut rods are great, they limit the fore/aft movement of the LCA that you DON’T want AND make the up/down travel even easier/smoother.

Most of what I said you just repeated. I agree the adjustable strut locates the arm, that's how I did it too. I agree the torsion bar clips do not hold the arm and that they usually do not even touch the torsion bar. Whenever I have removed a torsion bar I have always found the best way to get all the tension off is unbolt the upper ball joint so the arm can drop even lower.

My point is that the torsion bar imho works as part of a system along with the strut to keep the arm on the pin. Those bars cannot slide back easily at all even when partially unloaded.

I am not trying to get into a heated debate with the two of you.

I am just saying that I think both of you were partially right in different areas. But that is just my opinion.

Stay healthy my friend.

I see your point, yes, when the bars are loaded they aren’t moving.

But the bars do move. They expand and contract as they’re loaded and unloaded. Really small amounts, but they move. And if the bars fully unload they can slide. With stock torsion bars that’s not much of an issue, but with larger aftermarket bars that have less offset it’s not uncommon to completely unload the bar at full extension. I have to run taller upper bumpstops to keep my adjusters loaded at full extension.

But here’s the thing, from an engineering perspective that means you can’t ever assume the bars will limit the back movement of the LCA. Even a small shift in position could change that effect. And fully unloading the suspension does. I’ve pulled torsion bars out by hand when they were unloaded, and as I’ve said before that doesn’t require the LCA to be detached depending on how your suspension is set up.

Basically if you can’t ALWAYS depend on the bars to hold the LCA from traveling, then you can’t design the suspension to depend on them at all.

yellow rose

Overnight Sensation

A bump so the next guy that wants to install Poly or Delrin LCA bushings and wants to do it correctly can find this, skip though the nonsense and learn how to do it.

I’m all for adjustable strut rods on everything, but they are a MUST for poly or delrin bushings.

Special thanks to @72bluNblu for all his posts on this. Largely because of his expertise on the subject and clear explanations of how this works, when I install my new poly bushings Monday I’ll also be installing QA1 adjustable strut rods to get it correct.

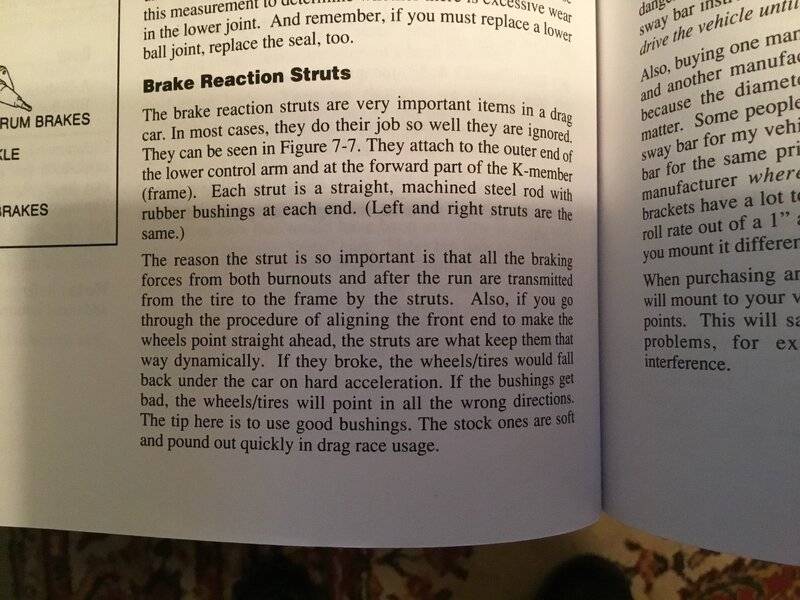

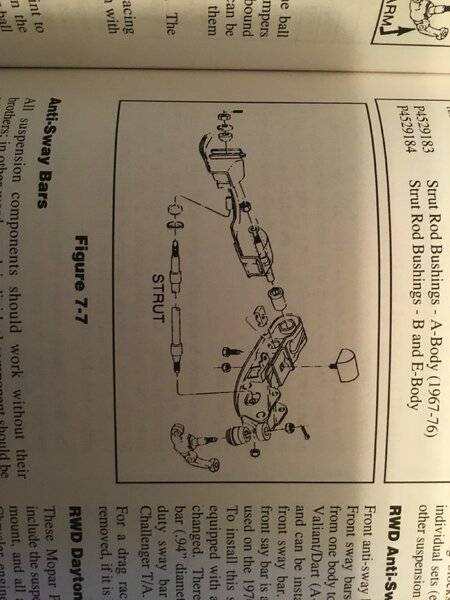

Here is what Chrysler says about the “brake reaction struts” and what they do.

I’m all for adjustable strut rods on everything, but they are a MUST for poly or delrin bushings.

Special thanks to @72bluNblu for all his posts on this. Largely because of his expertise on the subject and clear explanations of how this works, when I install my new poly bushings Monday I’ll also be installing QA1 adjustable strut rods to get it correct.

Here is what Chrysler says about the “brake reaction struts” and what they do.

-

Similar threads

- Replies

- 6

- Views

- 834

- Replies

- 31

- Views

- 1K

- Replies

- 6

- Views

- 671

- Replies

- 82

- Views

- 3K