KENTON

Well-Known Member

nice fix on them grills

[/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL] [/URL]

[/URL]So my company sends me down to Roswell for the week. I didn't find any crashed UFOs but I did stumble upon someone's red 68 fastback parked in their yard. It's got custom wheels and is missing the trunk panel. Anyone on here own this car? Sure looks good!

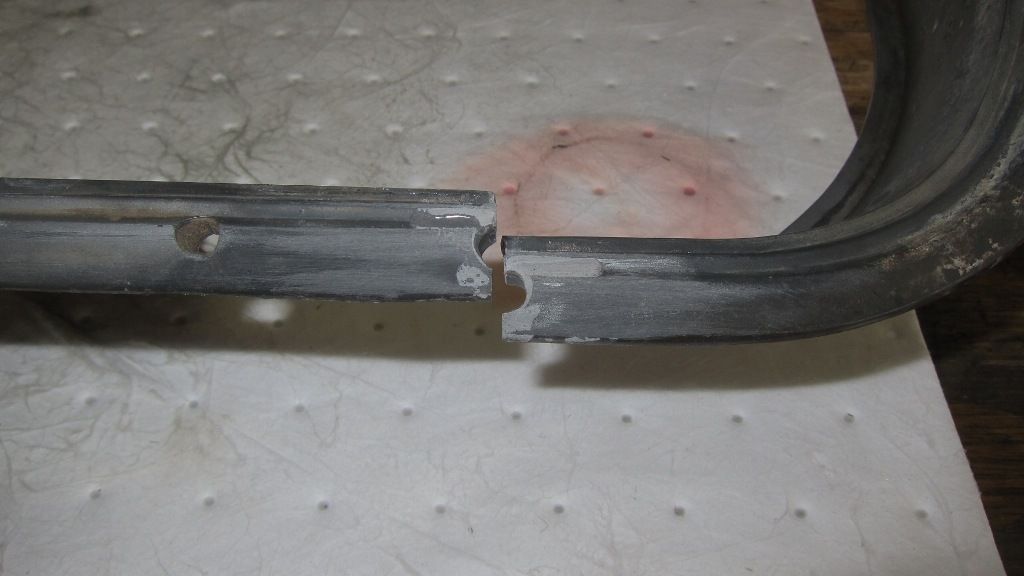

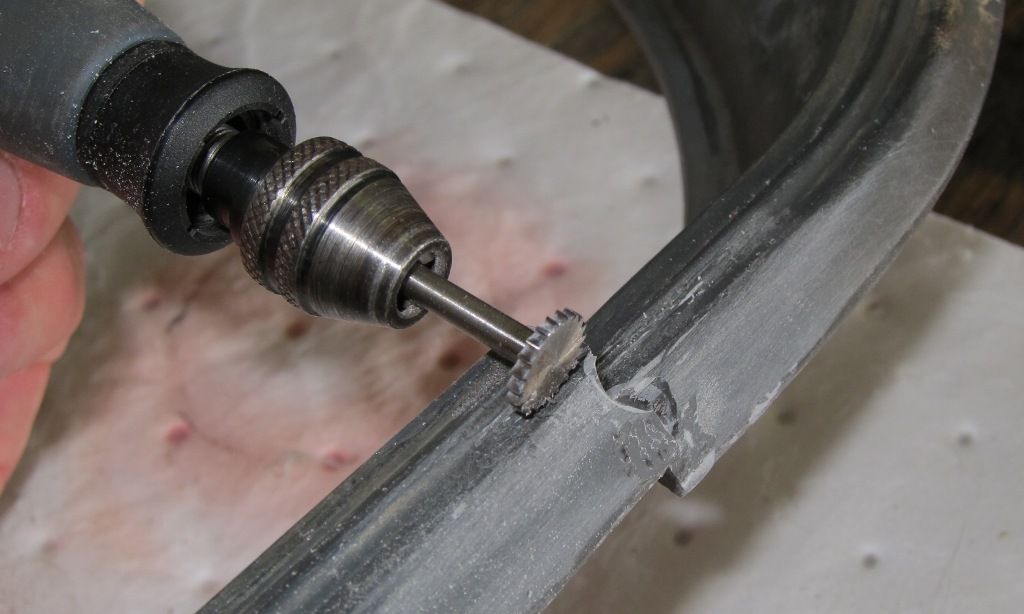

Grille with the honeycomb installed. This looks so nice in person, you have no idea.

http://smg.photobucket.com/user/vr6pilot/media/Red Fish/IMG_2268_zps16eed39b.jpg.html

you're a hell if a writer!

[/URL]

[/URL] [/URL]

[/URL]