Our axle measured square also. It didn't work. We shimmed the rear springs and copied the location for the inboard kit. That is why we are making our new car with adjustable perches. Turn of a wrench you can move the rear front or back on either side.I was attempting a test and tune Saturday. I was going to try Vikings recommended shock settings. Double check my bar adjustment. Viking suggested my shocks were topping out.....I have extensions for the rear may try to get some bayonet extensions for the front. I really double that though but it won't hurt to try. And no I haven't touched a thing yet but I have to get my 60 foot times consistent so it's happening. I did verify the rear axle was square in the car though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Burn out issues

- Thread starter 66Valiant528

- Start date

-

You know, I was just thinking that just because the rear is square in the car doesn't mean it wouldn't benefit from a shim on the left. Thank you for the follow up. I appreciate everyone's input. Trying to get a consistant Mopar to make the brand Xrs to see the light.

famous bob

mopar misfit

Thanks Bob but have split mono leaf set up from Calvert

that isnt a sure fire thing , I replaced a front half on the pass. side , still had to make and add my own to acheive levelness before the bar adjustment ---------------??

Well it's Epping tomorrow. More videos and some shock adjustments.

Went to Epping. Set the rear bars with a friend Mike in the car. Made them equal. Instead of preloading the right. Adjusted the shocks to the specs Viking recommended.12 c 5 R in the front and stiff 9 c and 14 r. Pushed the brake pedal harder than I ever have and set the line lock. A good burn out with no rear end sway! 1.586 60 foot 10.278 at a new high mph at 133.67 at a low 6200 through the trap.

Next run exploded the tires at launch and all through 2nd. Went back to the pits. 2 hours later I decided I'd run the car without the hood. Took it off to find my moroso crank breather grommet had split and oil had sprayed onto the headers....2 and done. Didn't think having a fire was worth taking a shot with duct/electrical tape.

So I can't verify my shock settings were good but the 5 guys I was with all racing said the track conditions had deteriorated since it got warm. That I should use the right lane, which I did. Only plus was I cut an .059 light.

Thanks everyone for the support and suggestions. Hey and I must say I'm so happy racing fuel prices are not as bad as I thought they would be. At least here. 57.50 for 5 gal of 110 leaded 61 for 5 at LVD

Next run exploded the tires at launch and all through 2nd. Went back to the pits. 2 hours later I decided I'd run the car without the hood. Took it off to find my moroso crank breather grommet had split and oil had sprayed onto the headers....2 and done. Didn't think having a fire was worth taking a shot with duct/electrical tape.

So I can't verify my shock settings were good but the 5 guys I was with all racing said the track conditions had deteriorated since it got warm. That I should use the right lane, which I did. Only plus was I cut an .059 light.

Thanks everyone for the support and suggestions. Hey and I must say I'm so happy racing fuel prices are not as bad as I thought they would be. At least here. 57.50 for 5 gal of 110 leaded 61 for 5 at LVD

19DART66

Well-Known Member

Are you set up so you can get to the 6 adjusters on the pressure plate without taking the bellhousing off? If so try backing off on the adjusters one turn at a time till the clutch starts slipping in high gear(abort the run when the clutch starts to slips) then give the adjusters a half turn tighter at a time until the clutch locks back up in high gear. If the clutch still hits to hard on the launch you might have to add more centrifugal weight to the 3 levers and start the process again. Hopefully it wasn't the oil from the breather that made it spin that bad on your second run.

So I got a look at the video my friend Andy shot for me on the second run. Smoke pouring out of the front wheel house! Was oil from the breather grommet failure! Got under the rear tires! Glad my rev limiter was working cause I bounced off the limiter, shifted and bounced again and then let off the throttle cause I realized my run was done.

512Stroker

We are all here because we are not all there.

Years ago we had a problem like this on a rear engine rail. It was adjusted out with using unequal tire pressures. Dont know if this will help , just spit balling.How can I stop my car from fishtailing to the right every time I do my burnout? It has happened on every Mopar I have raced, which is 4, 68 Roadrunner, 71 Dart 360, 73 Duster 360 and now my Calvert Caltrac rear suspension 66 Valiant. Can't download videos.....sorry low tech....wtf. Line locks and front disc on all these cars.

Good luck

No I didn't drill the hole in the bell to access them because I was afraid it would not be SFI legal. But I can access them. There is a cover that unbolts. But I only use the clutch at launch. The rest of the time I just pull the levers and the pressure plate is always engaged. Clutch seems fine. ThanksAre you set up so you can get to the 6 adjusters on the pressure plate without taking the bellhousing off? If so try backing off on the adjusters one turn at a time till the clutch starts slipping in high gear(abort the run when the clutch starts to slips) then give the adjusters a half turn tighter at a time until the clutch locks back up in high gear. If the clutch still hits to hard on the launch you might have to add more centrifugal weight to the 3 levers and start the process again. Hopefully it wasn't the oil from the breather that made it spin that bad on your second run.

604B1duster

Well-Known Member

- Joined

- Dec 30, 2007

- Messages

- 1,623

- Reaction score

- 917

Went to Epping. Set the rear bars with a friend Mike in the car. Made them equal. Instead of preloading the right. Adjusted the shocks to the specs Viking recommended.12 c 5 R in the front and stiff 9 c and 14 r. Pushed the brake pedal harder than I ever have and set the line lock. A good burn out with no rear end sway! 1.586 60 foot 10.278 at a new high mph at 133.67 at a low 6200 through the trap.

Next run exploded the tires at launch and all through 2nd. Went back to the pits. 2 hours later I decided I'd run the car without the hood. Took it off to find my moroso crank breather grommet had split and oil had sprayed onto the headers....2 and done. Didn't think having a fire was worth taking a shot with duct/electrical tape.

So I can't verify my shock settings were good but the 5 guys I was with all racing said the track conditions had deteriorated since it got warm. That I should use the right lane, which I did. Only plus was I cut an .059 light.

Thanks everyone for the support and suggestions. Hey and I must say I'm so happy racing fuel prices are not as bad as I thought they would be. At least here. 57.50 for 5 gal of 110 leaded 61 for 5 at LVD

View attachment 1715940655

View attachment 1715940657

View attachment 1715940658

That’s what I’m talking about it !

So when your at the track and you see guys sliding around trying to smoke em up,

tell them to put some leg in it

I’ll look for your car on mopar day at LVD and say hello, ... if you’re going to be there ?

Last edited:

19DART66

Well-Known Member

That is the main purpose of the Soft-Loc clutch is to control the launch. If you are dropping more than 1000 to 1200 rpm on the launch you will lose in your 60' time which we all know has the biggest effect on the whole run. So you need to adjust the bass pressure for the launch and centrifugal weights to keep the clutch locked up for the rest of the run. On my best 60' at MusclePalooza, I turn my bass down from 5 turns to 4 turns ( my base pressure is 150# at zero turns) that took the car from 800# bass to 670# bass ( dropped the car from 1.62 to 1.50 60' on a marginal track ). My centrifugal weights are 13 grams per lever/finger for a total of 39 grams ( the levers/fingers are set to add 39# per gram at 6400 rpm ) so that is 1521# of centrifugal plus the 670# bass for 2191# at 6400 rpm. With a sintered iron clutch disc the hotter it gets the less pressure it needs to lock it up. Now this is all dependent on your horsepower, torque, first gear ratio, rear gear, tire size, and weight no two cars are the same. Good Luck and do not be afraid to mess with those clutch settings. When you get the clutch set for the 60' your car has the power for, you will be knocking on the 9 second bracket.

One thing at a time!!! I know there's a great deal of adjustment available. I went with what McLeod recommended and haven't touched it since install. I have the bars on lower holes for a softer hit too.That is the main purpose of the Soft-Loc clutch is to control the launch. If you are dropping more than 1000 to 1200 rpm on the launch you will lose in your 60' time which we all know has the biggest effect on the whole run. So you need to adjust the bass pressure for the launch and centrifugal weights to keep the clutch locked up for the rest of the run. On my best 60' at MusclePalooza, I turn my bass down from 5 turns to 4 turns ( my base pressure is 150# at zero turns) that took the car from 800# bass to 670# bass ( dropped the car from 1.62 to 1.50 60' on a marginal track ). My centrifugal weights are 13 grams per lever/finger for a total of 39 grams ( the levers/fingers are set to add 39# per gram at 6400 rpm ) so that is 1521# of centrifugal plus the 670# bass for 2191# at 6400 rpm. With a sintered iron clutch disc the hotter it gets the less pressure it needs to lock it up. Now this is all dependent on your horsepower, torque, first gear ratio, rear gear, tire size, and weight no two cars are the same. Good Luck and do not be afraid to mess with those clutch settings. When you get the clutch set for the 60' your car has the power for, you will be knocking on the 9 second bracket.

weedburner

Well-Known Member

What happens inside the bellhousing is key to bringing the engine and chassis together as an efficient package. Most chassis adjustments revolve around what the clutch or converter does, so it makes sense to get the clutch in the ballpark first before moving on to other things.

Far easier to tune that clutch if you just throw away the weights and then put just enough spring in it to hold after shifting into high gear. From there use one of my ClutchTamers to dial in the amount of slip you need during launch. Eliminates the centrifugal vs base balancing act, makes adjusting the clutch much less of a guessing game.

......if it slips too much or not enough going into high gear, you know you need to adjust the springs.

......if it slips too much or not enough during launch, you dial that in with the 'tamer from the driver's seat.

You end up with a clutch that allows you to launch from 7200 or higher on a poor surface without knocking the tires loose, also less wear/tear/adjusting on your Lenco's clutch packs. No need to change the setup for "good" prep, as the clutch is already optimized to let the engine sing at the top of its lungs with a dead hooked chassis.

The above setup has been in winner's circle at NHRA's US Nats, allows you to take advantage of higher launch rpm without knocking the tires loose. There's 86% more stored energy available for launch if you can stick 7500 vs settling for 5500. NHRA's prep guys love 'tamers because they "don't rip the **** out of the track". Your tires will last longer too, you might even want to try radials

Grant

Far easier to tune that clutch if you just throw away the weights and then put just enough spring in it to hold after shifting into high gear. From there use one of my ClutchTamers to dial in the amount of slip you need during launch. Eliminates the centrifugal vs base balancing act, makes adjusting the clutch much less of a guessing game.

......if it slips too much or not enough going into high gear, you know you need to adjust the springs.

......if it slips too much or not enough during launch, you dial that in with the 'tamer from the driver's seat.

You end up with a clutch that allows you to launch from 7200 or higher on a poor surface without knocking the tires loose, also less wear/tear/adjusting on your Lenco's clutch packs. No need to change the setup for "good" prep, as the clutch is already optimized to let the engine sing at the top of its lungs with a dead hooked chassis.

The above setup has been in winner's circle at NHRA's US Nats, allows you to take advantage of higher launch rpm without knocking the tires loose. There's 86% more stored energy available for launch if you can stick 7500 vs settling for 5500. NHRA's prep guys love 'tamers because they "don't rip the **** out of the track". Your tires will last longer too, you might even want to try radials

Grant

Ive read about clutchtamers. As far as holding in high gear there is never any engine disengagement with the clutch. Dump the clutch at launch and that's it. As far as weights I put the lightest ones again per McLeods recommendation, and they are easily changed. I don't doubt that it could use some fine tuning. And I did like the whole underdash clutch tamer set up. I could try one on my street A833. Organic Raybestos faced 10.5 disc with a 3 finger B&B pressure plate. We set the springs and finger height at Boston Clutch. Big Lakewood bell. 143 tooth Hayes flywheel. Heavy car heavy flywheel! But in the Valiant I dump at launch and that's it. Where and when the locker does what it does seems to be under control. My Roadrunner just blows its tires. Thank you for your recommendation.

Went I do dump the clutch at 7200 maybe it'll be time to mess with the soft locker.

weedburner

Well-Known Member

Ive read about clutchtamers. As far as holding in high gear there is never any engine disengagement with the clutch. Dump the clutch at launch and that's it. As far as weights I put the lightest ones again per McLeods recommendation, and they are easily changed. I don't doubt that it could use some fine tuning.

Something has to give after the gearchange, either clutch, tires, clutch packs in the Lenco, or something breaks in the drivetrain. Its just physics, a lot of energy has to go somewhere almost instantly.

Ideally you want the clutch to slip just enough to hold in high gear, which serves to tighten up the rpm range that the engine operates in. Tighter the range that the engine operates in, the higher on the horsepower curve it can stay. Much the same advantage a drag race 5spd has over a 4spd. I have a lot of customers that clutchless shift the GF101a, you are going to be quicker if it takes a little time for the clutch to pull the engine down. If the clutch pulls the engine down to quick after the shift, you either suffer more rpm loss than you need to or it knocks the tires loose. Either one will cost you ET.

In your case the 'tamer would only serve to give you the slip needed to keep engine rpm up during a dead hook launch.

Grant

I would think its the clutch pack in the Lenco that's getting abused. The disc isn't going anywhere as the pressure plate stays engaged, I believe. If I had the money.....I think I might get a data recorder. At this point thats not happening. Thanks again.Something has to give after the gearchange, either clutch, tires, clutch packs in the Lenco, or something breaks in the drivetrain. Its just physics, a lot of energy has to go somewhere almost instantly.

Ideally you want the clutch to slip just enough to hold in high gear, which serves to tighten up the rpm range that the engine operates in. Tighter the range that the engine operates in, the higher on the horsepower curve it can stay. Much the same advantage a drag race 5spd has over a 4spd. I have a lot of customers that clutchless shift the GF101a, you are going to be quicker if it takes a little time for the clutch to pull the engine down. If the clutch pulls the engine down to quick after the shift, you either suffer more rpm loss than you need to or it knocks the tires loose. Either one will cost you ET.

In your case the 'tamer would only serve to give you the slip needed to keep engine rpm up during a dead hook launch.

Grant

Last edited:

19DART66

Well-Known Member

66Valiant528 you are absolutely right, the clutch packs in the Lenco are taking the biggest hit if the clutch is not set up right, that's what Grant is trying to tell you. That is why a properly set up ClutchTamer or Soft-Loc clutch will keep the rest of the drivetrain living longer and make your car quicker, with a lower maintenance cost. The Soft-Loc works on pressure and rpm ( as rpm goes up more pressure is added to lock up the clutch and when rpm drops the pressure drops unlocking the clutch) as in the launch and gear shifts. The ClutchTamer works on time (as in how long it takes for the clutch to go from just before peak lock up to full lock up) At launch and gear change it resets the timer. They both work equally well just different ways of achieving the same outcome, I am sure Grant could explain it better than I. So all you guys and gals that are running stick cars and do not what to spend the money on a Soft-Loc style clutch you better get a ClutchTamer, because you are leaving a lot of your cars ET on the starting line.

The only time I disengage the pressure plate is on launch. That's the only time the soft locker does what it does. After that it's just shift at 7200. The pressure plate has clamped the disc. Ya it has counter weights on the pressure plate fingers to add more clamping load. The rpms do drop and honestly I haven't paid attention to what rpm but there doesn't appear to be any slip. I'm believing that the clutch tamer is for stepping on the clutch at each shift and of coarse at launch. Thats not what I do. Thanks for your input though.

weedburner

Well-Known Member

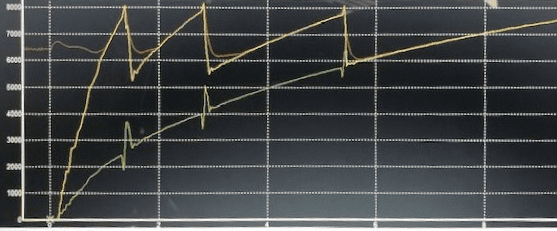

Here's a graph of some clutchless shifts with an adjustable clutch. Note that after the 1/2 shift the engine only got pulled down to around 6250, but the input shaft got pulled down to around 5250. That area between the engine trace and the input shaft traces represents clutch slip, but they also represent gains in power production. While the clutch was slipping, the engine averaged more combustion cycles per second than it would have if the clutch had not slipped.

Even with the slip, you still see sizable wheelspeed spikes after the shift. Those are caused by centrifugal assist. The clutch didn't slip much at all at first, rpm had to come down before centrifugal relaxed enough to allow the clutch to start slipping.

When you eliminate centrifugal assist and use just enough static to get a controlled amount of clutch slip in high gear, the clutch can then start slipping as soon as the lever is pulled, which in-turn reduces the intensity of the wheelspeed spikes. Instead of the hockey stick shaped fall of the engine rpm trace, you end up with a more gradual linear straight line instead. Less wear/tear on the drivetrain, and the straight-line profile adds even more area between the engine and input shaft traces.

Grant

Even with the slip, you still see sizable wheelspeed spikes after the shift. Those are caused by centrifugal assist. The clutch didn't slip much at all at first, rpm had to come down before centrifugal relaxed enough to allow the clutch to start slipping.

When you eliminate centrifugal assist and use just enough static to get a controlled amount of clutch slip in high gear, the clutch can then start slipping as soon as the lever is pulled, which in-turn reduces the intensity of the wheelspeed spikes. Instead of the hockey stick shaped fall of the engine rpm trace, you end up with a more gradual linear straight line instead. Less wear/tear on the drivetrain, and the straight-line profile adds even more area between the engine and input shaft traces.

Grant

Wow that's some impressive input. Transmission input shaft rpm vs engine rpm. Honestly I never thought about it. I guess I should give it more thought. Hell my build plan was pretty simple. A body BB stick style trans chassis work and rear end.

I have engine dyno sheets and mytrans gear ratios. Maybe if I put a pick up on the pinion I can get some info that can help me see where I can improve my basic clutch set up. But I don't have the cake for that right now so it'll have to wait.

I have engine dyno sheets and mytrans gear ratios. Maybe if I put a pick up on the pinion I can get some info that can help me see where I can improve my basic clutch set up. But I don't have the cake for that right now so it'll have to wait.

So are you telling me I should step on the clutch to take advantage of the soft lock ?

19DART66

Well-Known Member

It doesn't matter if you use the clutch or not when you shift gears, you take clamping force away (bass pressure/ the 6 adjusters on the pressure plate) until you get your best 60 foot time, then you add centrifugal weight to lock the clutch up in high gear. Every time you shift a gear the rpm will drop below lock up pressure and as the rpm come back up it will lock back up, with or without using the clutch for the shift. The last setting I had in the Dart at MusclePalooza the clutch was lock up at around 1500 lbs pressure, the 1 / 2 shift dropped to 1289 lbs, the 2 / 3 shift dropped to 1359 lbs, and the 3 / 4 shift dropped to 1441 lbs. All of these drops in pressure will make the clutch slip until the bass and centrifugal pressure came back up to 1500 lbs. which on this clutch set up was around 4900 to 5000 rpm and this is what makes the car quicker because the rpm stay up to keep the horsepower up making the clutch act kind of like a torque converter. There are companies out there that specialize in these clutches for pro class racers, call one and tell the tech what's going on and he will probably give you a whole different clutch set up than you have, most likely tell you to forget everything the McLeod tech told you. McLeod usually give out the same generic speech to everyone who asks questions about there Soft-Loc, which is the same speech in the paper work that comes with the clutch. I know I've talk to them.

19DART66

Well-Known Member

Look at Grants graft the lowest point of the yellow line and the lowest point of the orange line on every shift, the distance between the lowest points of each line is the clutch slippage which carries out till the clutch locks back up.

So much for set it and forget it! I believe I set the six springs right in the middle of there settings and have the lightest aluminum bolts and washers as counter weights.

Last edited:

-

Similar threads

- Replies

- 5

- Views

- 691

- Locked

- Replies

- 10

- Views

- 2K

- Replies

- 78

- Views

- 4K

- Locked

- Replies

- 3

- Views

- 2K