You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Charger

- Thread starter 1967 'cuda

- Start date

-

1967 'cuda

Dropped on Head as a Baby

One step forward, - two steps back. It seems inevitable that whenever Spence has made a new decision on parts for the car I cringe. Often it has meant that a portion of the build that was nearing completion is either going to be defunct or I'll have to go back to Google searches to teach myself new stuff. Unforeseen consequences of Spencer's purchases aren't noticed until long afterwards.

One problem that showed up after the decision to go with the 8/71 - Hemi combo cropped up when Spence wanted to run a 3" blower belt with it (on the street). We needed room between the front of the engine for:

an alternator

power steering pump

3" blower belt

a thick radiator

electric fans

All that would have to fit behind the core support.

There wasn't room. Spence did not want to eliminate the factory core support in lieu of some new streamlined version because it had the stamped oem serial numbers on it showing it was original to a real R/T. To further complicate matters we couldn't find anyone who'd manufactured the alternator or power steering brackets for a supercharged Hemi WITH a 3" blower belt.

One problem that showed up after the decision to go with the 8/71 - Hemi combo cropped up when Spence wanted to run a 3" blower belt with it (on the street). We needed room between the front of the engine for:

an alternator

power steering pump

3" blower belt

a thick radiator

electric fans

All that would have to fit behind the core support.

There wasn't room. Spence did not want to eliminate the factory core support in lieu of some new streamlined version because it had the stamped oem serial numbers on it showing it was original to a real R/T. To further complicate matters we couldn't find anyone who'd manufactured the alternator or power steering brackets for a supercharged Hemi WITH a 3" blower belt.

sireland67

Well-Known Member

I am not pushing daisy's yet, just moving a lot slower.Goosh sireland, - I thought that at least one of us would be dead by now. - Maybe that's just my neighbor's wishful thinking.

1967 'cuda

Dropped on Head as a Baby

To overcome the lack of room we decided to move the radiator in front of the core support. Keeping the new motor cool was of upmost importance. Research had shown that our best choice for a radiator would be a multi-pass crossflow design. The coolant would be forced (by design) to flow back & forth through the radiator giving it more ability to transfer heat away before recirculating back to the engine. Spence ordered one to fit our application.

When it arrived we found a new issue. The radiator's fill inlet was partly overshadowed by the core support. I had to modify the new radiator. I cut the filler neck off the radiator and built an offset to weld back on.

When it arrived we found a new issue. The radiator's fill inlet was partly overshadowed by the core support. I had to modify the new radiator. I cut the filler neck off the radiator and built an offset to weld back on.

MAD Skills!!!!

1967 'cuda

Dropped on Head as a Baby

I don't think the quality of my work has reached 'MAD Skills' level yet. I would say that I'm more at a 'pissed off' or 'bent out of shape' skill level.MAD Skills!!!!

1967 'cuda

Dropped on Head as a Baby

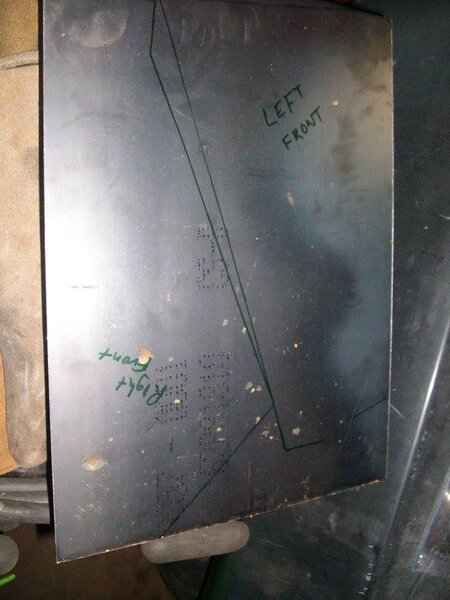

Although Spence was determined to keep the core support intact with the stamped VIN numbers, I was able to convince him that the billet overflow reservoir he bought could look better if mounted on a smoother surface. The holes for the factory radiator mounting were not going to be used anymore and we needed to tweak the opening size to accommodate the new radiator/fan shroud.

The decision was made to retain the top of the core support but modify the rest. The bottom of tthat support was damaged already and needed repair anyway.

A 90' lip next to the new opening would add strength to an otherwise flat panel that would have flexed.

After making paper templates we cut new steel to match the pieces we were replacing.

The decision was made to retain the top of the core support but modify the rest. The bottom of tthat support was damaged already and needed repair anyway.

A 90' lip next to the new opening would add strength to an otherwise flat panel that would have flexed.

After making paper templates we cut new steel to match the pieces we were replacing.

1967 'cuda

Dropped on Head as a Baby

AMD sells the core support stiffener that we used for the bottom. I think it was made to cover the original metal but ours was pretty beat up and we chose to eliminate it. Their piece does not come with a top lip like the original so we added one and welded the corners up because they come unwelded.

We also needed an access hole for wiring and vacuum lines to pass through. While at it I made mounts for the overflow tank.

Once everything was test fit I was ready for final welding.

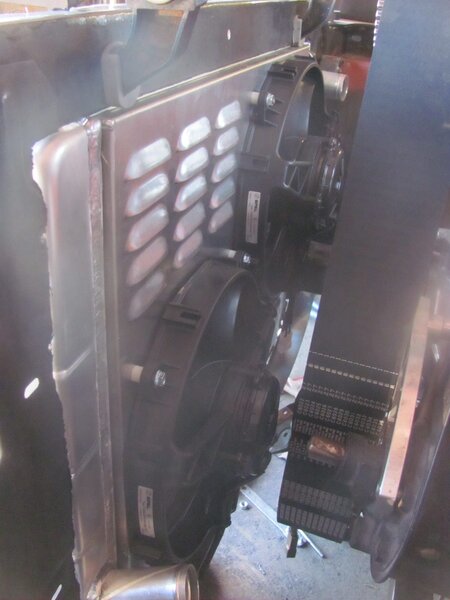

It's difficult to see from this camera angle but the offset radiator inlet was definitely necessary to clear that upper lip on the core support.

We also needed an access hole for wiring and vacuum lines to pass through. While at it I made mounts for the overflow tank.

Once everything was test fit I was ready for final welding.

It's difficult to see from this camera angle but the offset radiator inlet was definitely necessary to clear that upper lip on the core support.

1967 'cuda

Dropped on Head as a Baby

I hear nitrous can help with that!I am not pushing daisy's yet, just moving a lot slower.

340sFastback

Well-Known Member

That gonna cool that engine good radiator out front like that.

1967 'cuda

Dropped on Head as a Baby

By design the multi-pass crossflow should be a decent improvement over stock. Theoretically an all aluminum engine should dissipate heat faster than it's cast iron counterpart. Moving the radiator 3" further away from the heat source should also help. We'll be running a small oil cooler too. An electric water pump and electric cooling fans should keep it from overheating in slow moving traffic. It's also going to have a large oil capacity and that should help. A huge diameter exhaust can screw with proper back pressure and cost horsepower on a naturally aspirated motor but isn't really an issue with a boosted engine. I think they recommended a 4" exhaust. That should get excess heat away quicker.That gonna cool that engine good radiator out front like that.

Spence has been considering a water/methanol injection system to cool the intake mixture. If we add it the engine may be even less likely to get hot.

We've been using Evans Waterless coolant in all of our high performance motors for years now and I'm pretty sure Spence will want to use it here.

Because we're aware that more horsepower creates a lot of heat we've been doing our best to avoid potential overheating.

1967 'cuda

Dropped on Head as a Baby

More pictures from the core support work:

1967 'cuda

Dropped on Head as a Baby

Some more:

1967 'cuda

Dropped on Head as a Baby

More:

These next few pics show why the radiator's fill inlet had to be offset.

These next few pics show why the radiator's fill inlet had to be offset.

Last edited:

1967 'cuda

Dropped on Head as a Baby

More:

Some of these pics show clearances that necessitated moving the radiator.

Some of these pics show clearances that necessitated moving the radiator.

1967 'cuda

Dropped on Head as a Baby

That core support/radiator mod was a pain. I had to keep putting on (and taking back off) the front fenders/ grille assembly to check clearances & fit. The pictures don't show that those assemblies were attached/detached 20 to 30 times over the course of a week in order to get it done. That grille assembly is heavy and awkward to handle.

mygasser

Well-Known Member

have you mocked up the hood for clearance on the new radiator?

1967 'cuda

Dropped on Head as a Baby

The new Hemi is still in the crate. So far we've still been using the plastic mock up engine to locate placement & fit of all our components. We know the first hood we modified won't fit but we haven't gotten another one to replace it yet.have you mocked up the hood for clearance on the new radiator?

I'm pretty confident the radiator won't have clearance issues with the hood though because we've been using straight edges and tape measures to keep us at or below the height of our original clearances.

I'm hoping for a steel replacement hood so we don't have as much radio interference problems but Spence has toyed with the idea of going fiberglass. Chrysler moved antenna placement to the rear quarters on their fiberglass hooded TA Challengers and AAR Cudas to get rid of that issue. I moved my antenna to the rear quarter panel also on my '67 Barracuda after installing a 'glass hood. If he does choose fiberglass it will be easier to cut and modify though.

340sFastback

Well-Known Member

Aluminum Hemi yeah I thought cast iron block. Chopping major weight off that cars nose.

1967 'cuda

Dropped on Head as a Baby

Even though we'd purchased a new pair of AMD fenders we probably won't use them because we found a pair of fiberglass ones at a swap meet afterwards. They'll help shed a few more pounds too. - Once again I'm trying to convince Spence to use steel. I must say though that the body lines on the AMD fenders aren't as crisp as the originals. The fiberglass ones do have fitment issues but the body lines match better.Aluminum Hemi yeah I thought cast iron block. Chopping major weight off that cars nose.

I'd replaced all of the front sheetmetal on my '67 Barracuda with fiberglass and you couldn't tell the difference cosmetically.

1967 'cuda

Dropped on Head as a Baby

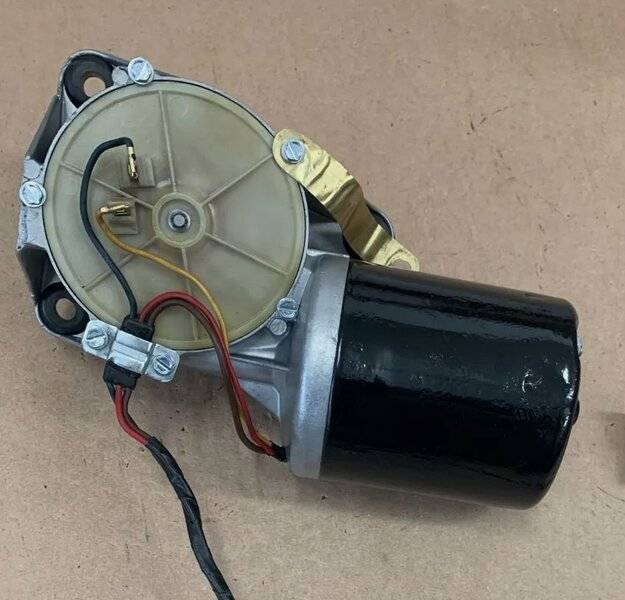

Not only did we have a clearance problem with the radiator but the same was true with the back of the motor. Two styles of windshield wiper motors were used back then. This is the type we had originally on the R/T.

It was obvious when we were planning on building the 6/71 supercharged 'B'' engine that there was insufficient clearance between the back of the blower and the wiper motor.

To cure the problem we bought this other style wiper motor that had also been used in these Chargers. WAH-LAH! Clearance problem solved!

As was so common with this project a new problem cropped up when Spence decided to install the 8/71 supercharged Hemi instead. Now there wasn't space for that 2nd wiper motor either.

Spence said he "didn't need no stinkin' windshield wipers" and wanted to leave out the system. He argued that he didn't plan on driving in the rain anyway. Due to the lack of clearance I was inclined to concede but knew that every bug, water puddle, sprinkler, etc.... would make him regret their absence.

After a lot of head scratching I decided to see if we could mount the wiper motor behind the firewall (beneath the dash).

Using the original mounting points for the wiper I thought I should see if I could simply move the motor back by making new mounting points behind the dash.

engine bay view:

under dash view:

Eliminating the factory AC/heater box did help to free up more space to work with.

Spencer did not want to totally remove all the original contours of the firewall but only the areas we had to for functionality.

It was obvious when we were planning on building the 6/71 supercharged 'B'' engine that there was insufficient clearance between the back of the blower and the wiper motor.

To cure the problem we bought this other style wiper motor that had also been used in these Chargers. WAH-LAH! Clearance problem solved!

As was so common with this project a new problem cropped up when Spence decided to install the 8/71 supercharged Hemi instead. Now there wasn't space for that 2nd wiper motor either.

Spence said he "didn't need no stinkin' windshield wipers" and wanted to leave out the system. He argued that he didn't plan on driving in the rain anyway. Due to the lack of clearance I was inclined to concede but knew that every bug, water puddle, sprinkler, etc.... would make him regret their absence.

After a lot of head scratching I decided to see if we could mount the wiper motor behind the firewall (beneath the dash).

Using the original mounting points for the wiper I thought I should see if I could simply move the motor back by making new mounting points behind the dash.

engine bay view:

under dash view:

Eliminating the factory AC/heater box did help to free up more space to work with.

Spencer did not want to totally remove all the original contours of the firewall but only the areas we had to for functionality.

1967 'cuda

Dropped on Head as a Baby

Obviously we did fill holes from AC/heater system. A Vintage Air system is going in later and will require different hole locations.

sireland67

Well-Known Member

I think your boys hobbies are your work.

1967 'cuda

Dropped on Head as a Baby

Well, he definitely has BIG ideas that usually make for a lot of work. I think he wants the Charger to be the 'biggest dawg in the fight' wherever he shows up with it. I used to have that perspective (though never achieved it).I think your boys hobbies are your work.

After building the '67 Barracuda to the point where it got too expensive to be a daily driver, I've lowered my expectations for what I want in a street car. That thing REALLY could use a Gear Vendors overdrive so I could enjoy it more. Ya, I love it at the strip & car shows but it's thirstier going down the highway than a fish on dry land.

Any mega-power builds I dream of now are track ideas. I still want plenty of 'go fast' on the road but I've got limits until fuel prices drop.

1967 'cuda

Dropped on Head as a Baby

Clearance problems are the bane of my existence. There's a reason why it's referred to as an elephant.

I knew that the factory Hemi cars had special provisions made for brake boosters because the heads and regular booster wanted to share the same space. They used a special mounting bracket that raised the booster away from the head. Even with it we'd heard that guys were saying the booster needed removal whenever the #7 spark plug needed removal.

Our Charger started life as a power disc brake car. Although it had been, half of the brake components were missing when we bought the car.

Now, when I'd built my '67 Cuda I chose to install disc brakes all the way around. - Manual disc brakes. It had began as a manual brake vehicle and I kept it that way. When it was completed, I liked the feel and braking was excellent. I didn't have worries about insufficient vacuum caused by camshaft selection.

4 wheel disc brakes were always planned from the get go on the Charger. We had the booster rebuilt but decided to purchase new discs & calipers from RIGHT STUFF DETAILING. I rebuilt the front suspension and installed the brakes. It was another portion of this project I assumed was finished. - - - well......

With the decision to run a Hemi came concerns about getting the special booster and bracketry. We opted to switch to manual brakes hoping the results would be as positive as it was with the Cuda.

We could have kept the rest of the brake assemblies but Spence had also made the decision to exchange the rebuilt front suspension for a HemiDenny front suspension with rack & pinion steering. Our front brake assembly wasn't compatible.

Holey Googlymoogly!! One step forward and two back again.

OMG! I've been living a gearhead version of Groundhog Day!

I knew that the factory Hemi cars had special provisions made for brake boosters because the heads and regular booster wanted to share the same space. They used a special mounting bracket that raised the booster away from the head. Even with it we'd heard that guys were saying the booster needed removal whenever the #7 spark plug needed removal.

Our Charger started life as a power disc brake car. Although it had been, half of the brake components were missing when we bought the car.

Now, when I'd built my '67 Cuda I chose to install disc brakes all the way around. - Manual disc brakes. It had began as a manual brake vehicle and I kept it that way. When it was completed, I liked the feel and braking was excellent. I didn't have worries about insufficient vacuum caused by camshaft selection.

4 wheel disc brakes were always planned from the get go on the Charger. We had the booster rebuilt but decided to purchase new discs & calipers from RIGHT STUFF DETAILING. I rebuilt the front suspension and installed the brakes. It was another portion of this project I assumed was finished. - - - well......

With the decision to run a Hemi came concerns about getting the special booster and bracketry. We opted to switch to manual brakes hoping the results would be as positive as it was with the Cuda.

We could have kept the rest of the brake assemblies but Spence had also made the decision to exchange the rebuilt front suspension for a HemiDenny front suspension with rack & pinion steering. Our front brake assembly wasn't compatible.

Holey Googlymoogly!! One step forward and two back again.

OMG! I've been living a gearhead version of Groundhog Day!

Last edited:

-

Similar threads

- Replies

- 77

- Views

- 5K