Arthur Sperotto

Well-Known Member

For context, my car is a '71 Dart with a 360, hp somewhere around 450-500. 727 trans.

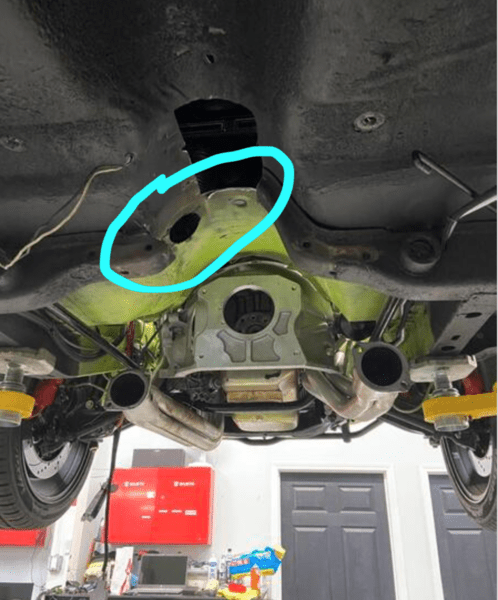

There is ONE thing keeping me from purchasing a TKX PerfectFit kit from Silver Sport Transmissions. The cut you have to make to the upper part of the torsion bar crossmember. They supply a crossmember for the TKX, but that only replaces the lower part. Unfortunately, I don't have numerical data to analyze how much that upper section is actually used by the torsion bars, but from my eye calculator, it looks to be important. Here is a picture of how it would look like: (pic from @jcolman )

Short of fabricating a replacement piece (which I'm not very comfortable doing with my current skills...), I was hoping to get suggestions of alternatives. I was wondering if frame connectors and torque boxes from US Car Tool would be adequate? Again, using the "eye calculator", it looks like they would give the twisting forces from the torsion bars more places to go. I contacted ToddRon Restorations but unfortunately no offerings for the TKX there.

Thank you in advance for any suggestions!

There is ONE thing keeping me from purchasing a TKX PerfectFit kit from Silver Sport Transmissions. The cut you have to make to the upper part of the torsion bar crossmember. They supply a crossmember for the TKX, but that only replaces the lower part. Unfortunately, I don't have numerical data to analyze how much that upper section is actually used by the torsion bars, but from my eye calculator, it looks to be important. Here is a picture of how it would look like: (pic from @jcolman )

Short of fabricating a replacement piece (which I'm not very comfortable doing with my current skills...), I was hoping to get suggestions of alternatives. I was wondering if frame connectors and torque boxes from US Car Tool would be adequate? Again, using the "eye calculator", it looks like they would give the twisting forces from the torsion bars more places to go. I contacted ToddRon Restorations but unfortunately no offerings for the TKX there.

Thank you in advance for any suggestions!