Think that's a good idea. Will see if I can work that out.Can you have a timing light on the engine the next time you run it on the dyno and write down what the advance is for different RPMs?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disappointing dyno results

- Thread starter jawbone

- Start date

-

Icetech

Well-Known Member

When you built it did you verify the timing mark on the balancer? stock 40+ year old balancer? If my brain is working right a spun outer ring would retard what you see on a timing light and it would only take like 1" of movement to do what's happening

What did you set the initial timing at?

And more important what is it all in?

When you built it did you verify the timing mark on the balancer? stock 40+ year old balancer? If my brain is working right a spun outer ring would retard what you see on a timing light and it would only take like 1" of movement to do what's happening

My machine shop buddy finds TDC and marks the balancer exactly where TDC is when he builds a motor... Good thought.

New balancer but timing mark not verified.When you built it did you verify the timing mark on the balancer? stock 40+ year old balancer? If my brain is working right a spun outer ring would retard what you see on a timing light and it would only take like 1" of movement to do what's happening

Icetech

Well-Known Member

Always verifyNew balancer but timing mark not verified.

New balancer but timing mark not verified.

New correct balancer with the mark on on the correct side for early small blocks?

This train of thought is making sense to me... at 2500 RPM the curve is about right... it tanks after that, right about when the mechanical advance goes all in..... do you have the tool to stuff in #1 to find TDC and double check the balancer line?

RustyRatRod

Caput villa stultus

Ok. I've read "cam was degreed and installed dot to dot" so many times now, I'm gonna vomit. That's no effin answer. I've asked for numbers several times. I'm tired of these stupid time wasting threads where no questions are ever answered so I'm out. This thread and you made the list. I tried to help, but you won't let me or pretty much anyone else do it. So screw it.

At spec (a few degrees) will get you a low horsepower rating. I bet it would sing at 15 btdc or there abouts. It makes a difference how Hoppy set up the advance and what the total is at 3000+.What did you set the initial timing at?

This whole thread is crazy. **** I would be checking the timing curve for sure I bet that ***** wants upward on 20 degrees initial, if you crank it up, then you need to limit the centrifugal timing to about 15 degrees, for a total around 35. Have the vacuum gauge hooked up. If the idle raises and it continues to gain vacuum you’re headed in the right direction. Tune that sum ***** junior

Mattax

Just the facts, ma'am

No it's a flat tappet. Do I need a smaller carb?

Here's my recap.:

Everyone who has said carb size (flow rating) is not related is correct.

I've illustrated the difference in running with secondaries and running the same carb on primaries. It doesn't change the curve really, just less and less HP gains from about 3000 rpm to the top. Vacuum starts to rise a bit as well.

While bigger can help to a point, too big is not a problem in this case.

if there was a MAP on the dyno log, we could say more about this aspect.

Your carb running rich won't cut horsepower that low. You need to go back to the basics and look at each component. The wrong pistons can lower compression. Your small cam isn't helping at all. Was the dyno run with headers?

Mostly agree. Running that rich is a part of the problem, or could be. It may be a combination of things that add up to the total disappointment. I've illustrated how much difference jetting can make on a chassis dyno here: About 10 hp for the entire power band.

Doesn't explain the curve unless the engine is so loaded up it can't accelerate...

So what is a 340 cam?

You've been given the correct answer by now. Chrysler spec'd their cams differently so the shop manual number cant be used to comapre. Your cam is similar enough your engine should be in the same ballpark.

And wasted $800.00 on dyno.

Add my 2 cents that not entirely wasted. You got break in and some information.

On the other hand, I myself have had first hand experience with dyno operators who really didn't know what they were doing.

Got less HP, the distributor curve restarded from where it was when I brought in (in his atttempt to get it to run bettter?) and no data because he didn't know how to copy files. I don't know if its how he loaded the dyno or something else. I wasn't familiar with that particular above ground set up even though it was a Dynojet. (I've made over 30 runs with that car/engine combo on dynojets.)

For tuning, I find its often up to the customer to lay out the test plan, as well as goals.

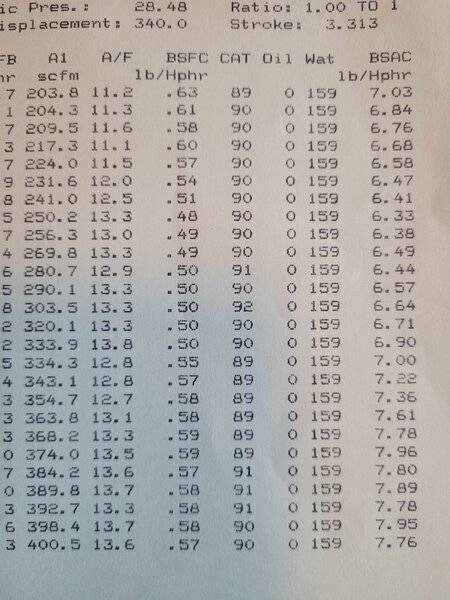

The things you can look at from engine dynos are fuel consumptions vs rpm which can indicate somehting different than what the WBO2 is showing.

My link above shows on a chassis dyno. On an engine it would be slightly more.

Does your guy really know how to run a dyno? What standards did he correct to? There are SO many variables here it's pathetic. I can run a dyno and make a stock 318 show 500HP. So there's THAT. lol

Unfortunately that's the truth.

it would be good to know the rate of acceleration allowed. IIRC 300 and 600 rpm/sec are two common standards.

Hi Rob. He can run a dyno. Was trying to correct for A/F ratio. He only had a bigger carb than mine. Test results were not much different.

Hi ch1ll. Regarding Carter AVS. Dyno operator only had a lager Holley which yielded similar results. He will receive 600cfm Holley for pull tomorrow if weather permits. Humidity is currently high. Operator does not have any replacement jets or metering rods. The Carter I had rebuilt was stock unit for 68 or 70 340 4 speed application. Can't remember which. Would only think jetting would be correct.

Cam is from Camcraft. I know, you never heard of them. Wish I hadn't. Only looking to make stock horsepower. That's all I can expect using stock engine components.

I think the cam is close to what you want, and running a known carb certainly wouldn't hurt to verify that it isn't (or is) carb related.

Definately throw some fresh spark plugs in and verify timing at a couple of rpms. I would check 600 rpm (or whatever the slow idle is) and 3000 rpm since 3000-6000 is what you will be really testing on the dyno. Also look at the plugs removed and verify they look rich. WBO2 can only interpret AFR accurately within a certain range of burn.

Agree!No … not really . Dyno time is so you can break in the engine , check for leaks and find performance issues before you spend days installing , tuning , diagnosing and then having to pull the engine againe and start all over .

although $800 seams spendy for a dyno shop that wont even rejet your carb muchless redegree your cam or set lash etc….

it could make it a little lazy but basically agree.Please someone with real world experience jump in here but if I move the timing +/- 6 degrees it will NOT devastate the curve like that in the simulation model. Your curve is totally crazy. All it really does is shift the peak around, it does not make it collapse like yours does.

I posted some timing curve vs power simulations along with some real life experiences.

Last edited:

For sure, verify TDC with the positive-stop method, then check the total timing revved-up w/o the vacuum advance hose on & plugged. Shoot for 34°, then see what You have at idle, trust real..accurate timing marks...not dial-back lights. They can be off by enough that I won't use them any longer.New balancer but timing mark not verified.

Next, Your cam is smaller than any 340HP cam, and the "closer to real NET" for the '72-'73 340 is 245hp. Even tho' they might have the smaller 1.88" intakes, You have a smaller cam, so that may make it a wash depending on the valve job quality.

Last, You keep saying "secondaries are opening", are You stating that the air-doors on top are opening? If so, are they opening fully? Next & last, but not least, Woodruff may have done a fine job of rebuilding the carb for You...but the float levels can get totally screwed by mis-handling during shipping. Just something else to consider.

sireland67

Well-Known Member

Did Hops send you a sheet with the distributor advance, when he done your distributor?

I know the one he built for me, he included it.

I know the one he built for me, he included it.

The shape of the curve in post 145 page 6 is not the shape I would expect to see for a correctly running engine.

Check and verify the basics as many have pointed out. Use known good parts to substitute parts that are on the engine now to eliminate some possibilities.

As a dyno operator some motors can be frustrating to sort out. Sometimes it takes more than one attempt to find the problem.

Check your uncorrected numbers and compare to your corrected numbers to make sure you don’t have a weather station sensor messing up your numbers. Your correction factor channel should be steady during the pull.

Good luck!

Check and verify the basics as many have pointed out. Use known good parts to substitute parts that are on the engine now to eliminate some possibilities.

As a dyno operator some motors can be frustrating to sort out. Sometimes it takes more than one attempt to find the problem.

Check your uncorrected numbers and compare to your corrected numbers to make sure you don’t have a weather station sensor messing up your numbers. Your correction factor channel should be steady during the pull.

Good luck!

Should have one all mine do. Just stumbled on this thread.Did Hops send you a sheet with the distributor advance, when he done your distributor?

I know the one he built for me, he included it.

BalancerMy machine shop buddy finds TDC and marks the balancer exactly where TDC is when he builds a motor... Good thought.

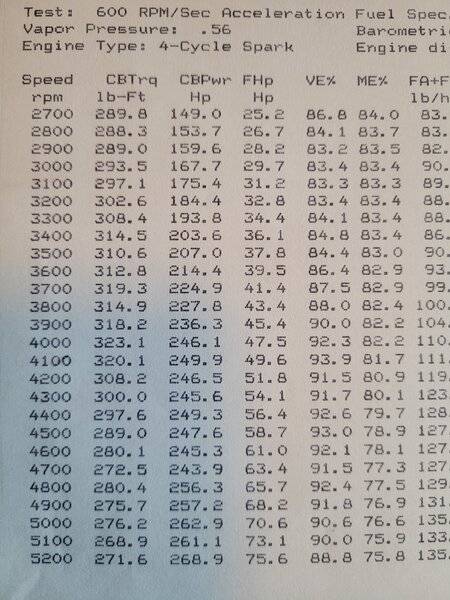

Well I'm back after another pull scheduled for Friday afternoon. Brought my heat gun with me. During engine warmup, discovered cylinder 7 only at about 387 *F. All others are in excess of 1000. Heat gun only goes to 1000. Turns out the spark plug wire was burned about in half by the headers. This was through heat sleave I have in place. Pull results are as follows.

Second pull A/F ratio not as good. Going back for another pull today at noon.

Forgot to post initial timing numbers. 600-680 rpm = 10* / 800-900 rpm= 15*-16* / 2500 rpm= 35*

MidnightSwinger

Well-Known Member

Running on 7 cylinders will do some weird **** on a Dyno for sure. Looks a lot better.

Stock 340 was .429, .444 w /.210 and .220 duration and produced about 275 hp and 340 lb. ft.

You are pretty close to stock but there is something not quite right...you should be up about another 45.

I don't think the problem is cam selection. Give us the dyno details and compression height?

...you have duplicated a lo compression 340 numbers?

Did you consider head gasket thickness. That makes a difference.Big valve "O" heads, flat top JE pistons with 2 valve reliefs. Calculated 9.687:1 compression, dynamic at 11.103. cc"d at 65.6 Compression check at 150 after 5 revs.

Gasket volume was advertised at 8.9cc which was used in calc.Did you consider head gasket thickness. That makes a difference.

Was second pull with a holley?

Tell him you want your avs and to tune it.

If that does not suit your horsepower goals, get a thermo quad and have him tune it on the dyno.

Tell him you want your avs and to tune it.

If that does not suit your horsepower goals, get a thermo quad and have him tune it on the dyno.

-

Similar threads

- Replies

- 48

- Views

- 3K