A buddy of mine is rebuilding a 360 and had a question for me - when torquing head bolts do you do them dry or lubed with a little bit of light oil on the threads. I said with a little lube but began second guessing myself. The correct way is . . . . . .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head Bolts Torqued Dry or Oiled?

- Thread starter 65 Dartman

- Start date

-

68383GTS

Well-Known Member

I always put a little bit of lube on them. Jim

green1

Well-Known Member

light oil.

mopar340dave

Well-Known Member

My book says that torque values are based on clean dry threads and to reduce the torque value by 10% if threads are oiled prior to install.

It does not mention oiling them when installing...just says to torque them to 50 foot pounds in the right sequence, then retorque in same sequence to 75 foot pounds and then finally retorque to 95 foot pounds.

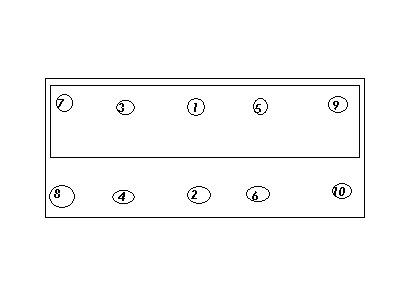

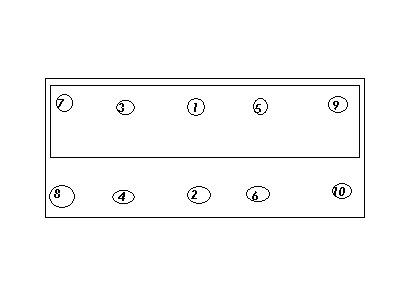

Torque sequence for small block mopar head:

It does not mention oiling them when installing...just says to torque them to 50 foot pounds in the right sequence, then retorque in same sequence to 75 foot pounds and then finally retorque to 95 foot pounds.

Torque sequence for small block mopar head:

moper

Well-Known Member

Mopar's factory specs were for a bolt lubed with straight 30wt dinosaur oil. The hole and the bolt should have the threads cleaned/chased. The bolt should have a few drops of oil on it (not enough to be forced out of the threads onto the gasket surface while torquing, and it should be torqued in 3 stages. I also add a drop of oil under the bolt head where it contacts the head. With oil, it takes more torque than ARP or moly lubes. Never install them dry.

mikedevore

Well-Known Member

Mopar's factory specs were for a bolt lubed with straight 30wt dinosaur oil. The hole and the bolt should have the threads cleaned/chased. The bolt should have a few drops of oil on it (not enough to be forced out of the threads onto the gasket surface while torquing, and it should be torqued in 3 stages. I also add a drop of oil under the bolt head where it contacts the head. With oil, it takes more torque than ARP or moly lubes. Never install them dry.

DITTO

Mopar's factory specs were for a bolt lubed with straight 30wt dinosaur oil. The hole and the bolt should have the threads cleaned/chased. The bolt should have a few drops of oil on it (not enough to be forced out of the threads onto the gasket surface while torquing, and it should be torqued in 3 stages. I also add a drop of oil under the bolt head where it contacts the head. With oil, it takes more torque than ARP or moly lubes. Never install them dry.

I second that.

Fred B

There are various grades of tap. A cheap tap is a no no. I put a small amount of grease in the flutes of a grade 5 tap and chase the threads in the holes. The grease helps bring out any debrie. Brakleen and regrease between holes. Then I wire brush used bolt threads also. New head bolts are best.

Light oil to lubricate the threads and not enough to drip off the end of the bolt into the bolt hole. Oil doesn't compress and too much could hydraulic the bolt before it seats.

toolmanmike

toolmanmike

340butterduster

no title

Light oil to lubricate the threads and not enough to drip off the end of the bolt into the bolt hole. Oil doesn't compress and too much could hydraulic the bolt before it seats.

toolmanmike

I second that, you don't want a false reading, due to hydraulics.

So the info I gave my friend was correct. Thanks for all the replies. Shouldn't have second guessed myself but doesn't hurt to check.

-

Similar threads

- Replies

- 129

- Views

- 3K

- Replies

- 63

- Views

- 4K

- Replies

- 17

- Views

- 2K