Are our rockers on the shaft correct? There are lefts and rights.I think (I hope) we’ll find some answers when I pull the cam and lifters. Drained the oil today and it was very, very clean. I’m going to cut into the filter and see what it looks like, and check the rod and main bearings (at least a few) to ensure they’re in good shape.

When I pulled the valve cover, I saw the #1 intake pushrod shifted to the side. Here you can see the divot it made in the rocker. And yes, I have a new rocker to replace it!View attachment 1715614237

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do hydraulic flat tappet lifters fail?

- Thread starter Righty Tighty

- Start date

-

I’m glad you brought that up. When I disassembled the engine last year, I kept everything in the exact order it was as it came off the engine. I noticed most of the rockers were stamped with “LH” or “RH”, by which using common sense would mean left hand or right hand. Some were stamped with other codes like “94LT”. I assume the L still means “left.” This particular rocker pair is stamped “LH” and some symbol I can’t quite make out. So that one went to the right (where I found it).Are our rockers on the shaft correct? There are lefts and rights.

512Stroker

We are all here because we are not all there.

Interesting the old chicken or the egg deal, which failed first?I think (I hope) we’ll find some answers when I pull the cam and lifters. Drained the oil today and it was very, very clean. I’m going to cut into the filter and see what it looks like, and check the rod and main bearings (at least a few) to ensure they’re in good shape.

When I pulled the valve cover, I saw the #1 intake pushrod shifted to the side. Here you can see the divot it made in the rocker. And yes, I have a new rocker to replace it!View attachment 1715614237

My money is on the lifter, it failed first. Although those rocker arms are dam hard and normally can take alot of abuse before leaving a mark like that, you may have a valve guide issue causing all this.

I no longer use hydraulic flat tappet or roller lifters because of the problems with them.

Did you check each and every lifter for surface crown before you installed them?

pishta

I know I'm right....

Actually the lifter bottoms are convex, they bow out. you can rock to new lifters face to face and see light between the edges. The lifters rotate because the cam lobes are crowned on the lobe tip, higher on one side than the other so the cam actually only hits the lifter on one side causing it to rotate and that lobe angle should be close to the convex face angle of the lifter. You can see this pattern on a camshaft lobe as one side is worn more. Its been said that you should watch the lifters to see if they rotate on engine break in. put a dab of white on the edge. If they dont then you need to determine why ASAP.The lifters spin because the bottoms of them are not flat, they are slightly concave. That's what causes them to rotate slightly every up and down.

I hope not, but best believe I'll be inspecting all of the guides, bores, rockers.....EVERYTHING.you may have a valve guide issue causing all this.

Stupid question, but how do you watch the lifters during break in? I suppose I could leave the valve covers off, but at 2000-3000 RPM I would guess there'd be oil going everywhere. Or do you mean turning the engine over by hand and watching them before the initial start up? That technique was mentioned earlier and I like it, going to give that a shot.Its been said that you should watch the lifters to see if they rotate on engine break in.

There have been so many good tips in this thread, thanks everyone.

threewood

Well-Known Member

They should be free moving when you install them and almost go in without a fight. If you had to force them in, that is a sign the lifter bores are out of whack.

Yep. Gotta put them in with just a little oil on the sides. Mark the top with a sharpie and turn the cam. The lifters should all rotate. This is done before the timing gear is installed.

RustyRatRod

Caput villa stultus

I thought it was bad practice to fill lifter before installation. It becomes like a solid lifter and maybe valve hit piston creating damage.

It's terrible practice and has not been recommended in YEARS. The proper procedure is to install the lifters without pumping them up and then prime the engine. Whether this had anything to do with the failure, I don't know.

Righty, I sure do hate this, but remember, it's just a THING and things can be repaired. I cannot remember. Did you go through every single oil galley and passage with e cleaning brush? This motor failed before. It's almost as if there's "something" somewhere in an oil passage blocking oil flow since it's not just the "one" lobe and lifter, but seems to be many. I also agree about the valve guide clearance comment from dartfreak75. That's always something to pay attention to.

RustyRatRod

Caput villa stultus

Righty, @dartfreak75 asked you a question on page 2. Did you measure retainer to guide clearance? Did you cut the guides for clearance? His cam has almost the exact same lift as yours and he had guide to retainer clearance issues and had to cut the guides down. If you don't answer questions, we just go deeper down the abyss.

Dartfreak75

Restore it, Dont part it!

The best way to check for rotating lifters is by thr push rods mark them with a paint marker and with the valve cover off or one with a whole cut in it see if the mark spinsI hope not, but best believe I'll be inspecting all of the guides, bores, rockers.....EVERYTHING.

Stupid question, but how do you watch the lifters during break in? I suppose I could leave the valve covers off, but at 2000-3000 RPM I would guess there'd be oil going everywhere. Or do you mean turning the engine over by hand and watching them before the initial start up? That technique was mentioned earlier and I like it, going to give that a shot.

There have been so many good tips in this thread, thanks everyone.

512Stroker

We are all here because we are not all there.

Decades ago we would submerge the hyd lifters in a coffee can of 30wt oil facing up then take them to the drill press where we would pump up the lifters with a chucked up push rod. Never failed one lifter over dozens.It's terrible practice and has not been recommended in YEARS. The proper procedure is to install the lifters without pumping them up and then prime the engine. Whether this had anything to do with the failure, I don't know.

Righty, I sure do hate this, but remember, it's just a THING and things can be repaired. I cannot remember. Did you go through every single oil galley and passage with e cleaning brush? This motor failed before. It's almost as if there's "something" somewhere in an oil passage blocking oil flow since it's not just the "one" lobe and lifter, but seems to be many. I also agree about the valve guide clearance comment from dartfreak75. That's always something to pay attention to.

Simple and effective.The best way to check for rotating lifters is by thr push rods mark them with a paint marker and with the valve cover off or one with a whole cut in it see if the mark spins

pishta

I know I'm right....

Stupid question, but how do you watch the lifters during break in? I suppose I could leave the valve covers off, but at 2000-3000 RPM I would guess there'd be oil going everywhere. Or do you mean turning the engine over by hand and watching them before the initial start up? That technique was mentioned earlier and I like it, going to give that a shot.

There have been so many good tips in this thread, thanks everyone.

Yes, prime it turn motor by hand or even bump it (assembled) with no spark. You got so much assembly lube on it that a few revolutions wont hurt the cam or bearings. Remote starter switch is great for this. The lifters are very easy to see with no intake on it. Hand rotating will be enough to notice if the lifters are 'rolling' in their bores.

Dartfreak75

Restore it, Dont part it!

I did mine by hand I dropped the lifters in and cranked it with a ratchet a couple revolutions.Yes, prime it turn motor by hand or even bump it (assembled) with no spark. You got so much assembly lube on it that a few revolutions wont hurt the cam or bearings. Remote starter switch is great for this. The lifters are very easy to see with no intake on it. Hand rotating will be enough to notice if the lifters are 'rolling' in their bores.

This seems to be the consensus, and I had read about this prior to installation, but I decided to follow the manufacturer's instructions. I won't be soaking them from now on.It's terrible practice and has not been recommended in YEARS.

I answered in my reply:Righty, @dartfreak75 asked you a question on page 2. Did you measure retainer to guide clearance? Did you cut the guides for clearance? His cam has almost the exact same lift as yours and he had guide to retainer clearance issues and had to cut the guides down. If you don't answer questions, we just go deeper down the abyss.

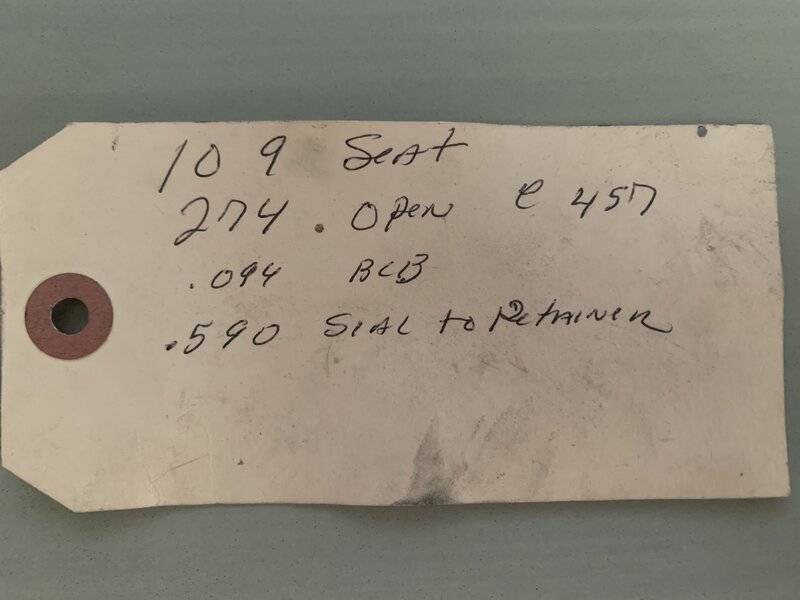

I dug up the specs I got from the machine shop, the seal to retainer clearance is .590. I don't know how much he had to cut to get that. He checked the lifter bores and guides, and actually corrected my first choice of springs.The machine shop did have to cut the guides down. By how much I don't remember.

I'm really not trying to be difficult Rusty, there's a lot I'm trying to learn and understand here. If I miss a question, it's certainly not deliberate.

This engine did fail before, but I attribute that to being run with no coolant in August in Arizona, on the interstate. The bearings melted and the oilers clogged, then it was allll downhill from there. Looking back on the break in after the rebuild, the engine didn't start with the first (or second or fourth) turn of the key. It's being suggested that excessive cranking prior to the initial startup could ruin a cam?

And I didn't go through the passages with a brush, I used compressed air. Do you think that's insufficient?

Cuda416

Well-Known Member

Actually the lifter bottoms are convex, they bow out. you can rock to new lifters face to face and see light between the edges. The lifters rotate because the cam lobes are crowned on the lobe tip, higher on one side than the other so the cam actually only hits the lifter on one side causing it to rotate and that lobe angle should be close to the convex face angle of the lifter. You can see this pattern on a camshaft lobe as one side is worn more. Its been said that you should watch the lifters to see if they rotate on engine break in. put a dab of white on the edge. If they dont then you need to determine why ASAP.

Ok, well that's what I meant. Feel better? lol, just kidding, it's kind of important.

RustyRatRod

Caput villa stultus

I'm really not trying to be difficult Rusty, there's a lot I'm trying to learn and understand here. If I miss a question, it's certainly not deliberate.

I know.....there's just so MUCH information to sort through it can be overwhelming. How did you prep the lifter bores?

Here are the specs I got from the machine shop. 302 heads, Lunati 73262 springs.

With a gloved hand, smeared some of the same oil that the lifters had been soaking in. I think I might've mentioned earlier that I used assembly lube on the lifters, but looking back, I don't think that was the case.I know.....there's just so MUCH information to sort through it can be overwhelming. How did you prep the lifter bores?

pishta

I know I'm right....

Sure. It's for the web search that finds this....I can show you a set of slant lifters that were concave, and the thing ran great!Ok, well that's what I meant. Feel better? lol, just kidding, it's kind of important.

Cuda416

Well-Known Member

Sure. It's for the web search that finds this....I can show you a set of slant lifters that were concave, and the thing ran great!

A slant size will run the the apocalypse... that's not a good example.. Ha, some good info here like always, until some chucklehead confuses right/left (me) and muddies the water. Doh!

RustyRatRod

Caput villa stultus

And I didn't go through the passages with a brush, I used compressed air. Do you think that's insufficient?

Very much insufficient.

Dammit.Very much insufficient.

Dartfreak75

Restore it, Dont part it!

Here is a pic of the gunk that came out of my passages and this is after the machine shop cleaned the block if you look close you can see the pile of gunk on the floorDammit.

Sheeeiiittttt, look close? I can see that from 2 counties over! Well it's official. I want a do over!

-

Similar threads

- Replies

- 13

- Views

- 734