The MRE rockers have 900 miles on them, so I took the rocker shafts off and disassembled everything. Those miles included a 200 mile endurance test with a minimal speed of 80 mph, and top speeds of 110+ mph. Thus the minimum cruise engine speed was 3700 rpm for 200 miles. I did stop once for gas. FYI there are 6 states in the northern Rocky Mountains with 80 mph speed limits on open-road 4 lane highways.

Valve spring pressures are the low-end spring that TrickFlow offers for flat tappet cams. IE 120 lb seat and under 400 lb open load, which I was told is the max load for these MRE rocker arms.

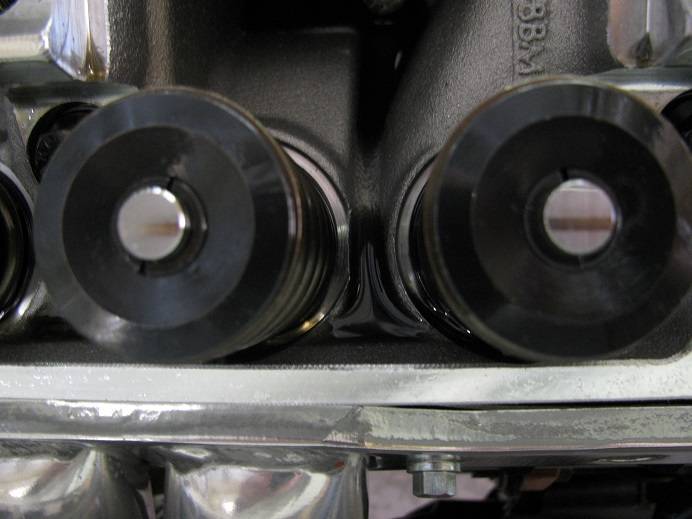

Inspection of the rocker assemblies showed no problems anywhere. Details include:

No issues with the MRE rocker arms #MRE-57001-16, 1.6 ratio with spacers.

No valve spring retainer pull-thru past the valve locks on the Trick Flow heads, all trick flow parts.

No scuffing of the 3/8 diameter pushrods in the Trick Flow heads pushrod slots.

No overheat of the pushrod cups at the rocker arm adjuster interface.

No problems with the Smith Brothers pushrods, 8.90 inch effective length, 5/32 radius ball & cup.

No issues with the rocker shaft studs, ARP part #AJ2750-1B.

No problems with Hughes rocker shaft hold down brackets or 12 point nuts. These were left over from the rocker shaft hold down kit for the old 906 heads. New Trick Flow part #HUG-7442TF.

No problems with the Crower Camsaver lifters, part #66031X3-16, they provide extra lube to cam lobes.

No problems with MRE rocker shafts #MRE-715. I had carefully tapped out the end plugs with a punch, and yes they did need some cleaning inside with a long lifter galley brush. Reused and staked the end plugs.

Rocker shaft shim kits: 440 source #113-1108 spacers, 105-1108 shims, and VSI 201 x .03 shims.

Dougs headers D452, with 2 inch diameter primary tubes fit the low deck block and Ebody no issues. First time I have not needed to add any clearance dents.

After reassembling the engine top end I prelubed the rocker assemblies again before engine start.

Averaged 14 mpg fuel economy at 70 mph during a separate 280 mile run. 3.23 axle ratio.

Concerning the rocker geometry, many engine builders like the mid-lift layout where the rocker arm roller is at the same position on the valve stem with valve closed and valve max lift. I noticed Jesel recommended their rockers be about 0.10 inch below mid-lift so there would be less roller movement across the valve stem as the valve approached full valve lift. Thus the TrickFlow as-is rocker shaft location with MRE rockers appears to be somewhat the Jesel method.

Jesel - Tech Tips & Faq

Not trying to start something. On another forum I was told there are as many opinions of rocker geometry as there are members on the forum.