Yeah I was AMAZED how much junk came out of the cowl. Especially since the rest of the car is so clean. I kinda figured it had been stored inside because of the condition of the paint and interior. Guess it wasn't inside the whole time!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My "new" '74 Duster- or why I need a project like a hole in the head

- Thread starter 72bluNblu

- Start date

-

Sully1190

Look. It's a Gold Duster.

Two questions!

#1, where can one find these rallye dash frames/ dashes. Is a junk yard the best place to look? Or does someone repop?

#2, would you mind taking a picture of /exactly/ where you had to go, what you had to remove/open/etc to get to your cowl to clean it out?

Thanks!

#1, where can one find these rallye dash frames/ dashes. Is a junk yard the best place to look? Or does someone repop?

#2, would you mind taking a picture of /exactly/ where you had to go, what you had to remove/open/etc to get to your cowl to clean it out?

Thanks!

Two questions!

#1, where can one find these rallye dash frames/ dashes. Is a junk yard the best place to look? Or does someone repop?

#2, would you mind taking a picture of /exactly/ where you had to go, what you had to remove/open/etc to get to your cowl to clean it out?

Thanks!

#1- You can get the dashes and frames from just about anywhere. The bezels are re-popped by B/E&A, but they cost like $500. Which is why I'm restoring mine. You can get woodgrain or carbon overlays to repair the stock woodgrain sections from Detroit Muscle Technologies, they're pretty slick. And I've been working with them to make lower overlays too, so it should make restoring the old bezels MUCH easier.

Anyway, the rallye dashes and frames came in all the A body Barracuda's from 67-69, and mostly from Dusters and Demons from '70-71. A few came in Darts and Valiants too, but they're hard to find. Most of mine came out of Barracuda's. I've bought a few on eBay, and found a few locally on C-list or the local swap meets, an just recently bought one here in the for sale section. If you don't mind doing some epoxying and refinishing, the bezels that have been cut/damaged are much cheaper. Kind of a buy a few and put them together kind of proposition.

The dash frames are the same way, I bought one on eBay, found one locally, that sort of thing. And I converted the one in my Duster, but as I said above that's not as simple as it looks. If you have some sheet metal skills and some welding ability you can try it, but its easier to just find a frame and install it.

#2-To clean out the cowl on my non-AC car, I first opened up the fresh air vent doors and scooped that stuff out. Then, I actually removed both of the fresh air vent boxes so I could get my arm up into the cowl. I had the front cover off my air box at the time as well. I'll get some pictures up in a bit.

Sully1190

Look. It's a Gold Duster.

#1- You can get the dashes and frames from just about anywhere. The bezels are re-popped by B/E&A, but they cost like $500. Which is why I'm restoring mine. You can get woodgrain or carbon overlays to repair the stock woodgrain sections from Detroit Muscle Technologies, they're pretty slick. And I've been working with them to make lower overlays too, so it should make restoring the old bezels MUCH easier.

Anyway, the rallye dashes and frames came in all the A body Barracuda's from 67-69, and mostly from Dusters and Demons from '70-71. A few came in Darts and Valiants too, but they're hard to find. Most of mine came out of Barracuda's. I've bought a few on eBay, and found a few locally on C-list or the local swap meets, an just recently bought one here in the for sale section. If you don't mind doing some epoxying and refinishing, the bezels that have been cut/damaged are much cheaper. Kind of a buy a few and put them together kind of proposition.

The dash frames are the same way, I bought one on eBay, found one locally, that sort of thing. And I converted the one in my Duster, but as I said above that's not as simple as it looks. If you have some sheet metal skills and some welding ability you can try it, but its easier to just find a frame and install it.

#2-To clean out the cowl on my non-AC car, I first opened up the fresh air vent doors and scooped that stuff out. Then, I actually removed both of the fresh air vent boxes so I could get my arm up into the cowl. I had the front cover off my air box at the time as well. I'll get some pictures up in a bit.

Thanks for the tips!

And yeah, pics will help. people have told me about said boxes before, but by god I just can't seem to find the darn things!

Thanks for the tips!

And yeah, pics will help. people have told me about said boxes before, but by god I just can't seem to find the darn things!

Here are some pictures of the vents. On the drivers side, its just to the left of the parking brake. 3 nuts hold it onto the lower cowl, two I highlighted in the picture. That gives you access to the cowl space.

On the passenger side, you have to remove the front of the heater box. Once off, it gives you access to the cowl space which I highlighted. First picture is from below, second picture is through the glove box. You'll need to pull the glovebox liner to make it work on the passenger side.

Last edited:

Sully1190

Look. It's a Gold Duster.

You know, I know for a fact I have never noticed that driver's side box in my car. And I would have, cause I've looked there, and I've dug all through the wires hanging there... I'm starting to wonder if maybe it's been removed entirely, and that's why it leaks on that side of my car.

You know, I know for a fact I have never noticed that driver's side box in my car. And I would have, cause I've looked there, and I've dug all through the wires hanging there... I'm starting to wonder if maybe it's been removed entirely, and that's why it leaks on that side of my car.

It's pretty hard to miss.

Even the A/C cars had them, at least, my '71 Dart does. Just look up. If there's a big round hole with nothing over it, the vent box is missing.

The vent box shouldn't keep anything from leaking per se though, the lower cowl has a lip on it so water should go around it and into the drains, not into the vent box. Of course, if the lower cowl is full of crud you might get a significant amount of water in there.

Sully1190

Look. It's a Gold Duster.

It's pretty hard to miss.

Even the A/C cars had them, at least, my '71 Dart does. Just look up. If there's a big round hole with nothing over it, the vent box is missing.

The vent box shouldn't keep anything from leaking per se though, the lower cowl has a lip on it so water should go around it and into the drains, not into the vent box. Of course, if the lower cowl is full of crud you might get a significant amount of water in there.

it's definitely a cowl leak that I have. taped over it in the last rainstorm and didn't get a drop inside. Just need to clean it all out. First, gotta find the hole! (as per usual)

Ok, a little update!

I've been working on a few different things as I try to get this Duster back on the road, but I figured since I've pretty much finished my dash resto that I'd update the thread.

You've already seen the work I did to the "standard" dash to make it fit a rally cluster. But here's the work I did to restore the rally cluster I plan to install. So here goes with the rally dash restoration.

This is what I started with. Your basic cut up rally dash. It had been badly painted at least once as well.

After sanding it down and cleaning up where it had been cut for a radio, I ended up with this. I started with 220 grit for the rough stuff, then moved up to 400 grit for the finish sanding.

Now here's where the barracuda owners get to have a coronary. I bought a used dash trim piece, removed the barracuda script, and sanded things down. Then, I cut it to fit my dash. Notice here that I opted to change my dash from stock. The glove box trim piece NEVER seems to line up, and the corner of the dash piece always seems broken. So, instead of making the cluster continue all the way across the entire dash, I set it up to end evenly with the top part of the bezel.

Now, clamped in place and ready for the Plast-Aid I bought online. That stuff is great!!! Smells horrible, but the repairs seem much stronger than even the original material.

All finished with the repair stage. The lower piece is repaired and I sanded everything to blend it together.

Here we are painted with flexible plastic primer. No, I haven't the slightest idea why its that color.

Next I painted the dash with low gloss black paint. This is high heat engine paint, I kinda hope it holds up better to the sun.

Taped for semi-gloss. Notice that I'm not too worried about the infill areas. I have an overlay for the top to replace the original, and a trick up my sleeve for the lower infill area.

Painted with semi-gloss where it needs to be. The semi-gloss engine paint is actually pretty glossy...

I then used an "argent" silver paint pen to trim out the lettering and raised circles around the switches. I did the same with the lens cups, but I didn't take any pictures of that process. Same deal, sanded, primed, then low-gloss black.

And next, the final product...

I've been working on a few different things as I try to get this Duster back on the road, but I figured since I've pretty much finished my dash resto that I'd update the thread.

You've already seen the work I did to the "standard" dash to make it fit a rally cluster. But here's the work I did to restore the rally cluster I plan to install. So here goes with the rally dash restoration.

This is what I started with. Your basic cut up rally dash. It had been badly painted at least once as well.

After sanding it down and cleaning up where it had been cut for a radio, I ended up with this. I started with 220 grit for the rough stuff, then moved up to 400 grit for the finish sanding.

Now here's where the barracuda owners get to have a coronary. I bought a used dash trim piece, removed the barracuda script, and sanded things down. Then, I cut it to fit my dash. Notice here that I opted to change my dash from stock. The glove box trim piece NEVER seems to line up, and the corner of the dash piece always seems broken. So, instead of making the cluster continue all the way across the entire dash, I set it up to end evenly with the top part of the bezel.

Now, clamped in place and ready for the Plast-Aid I bought online. That stuff is great!!! Smells horrible, but the repairs seem much stronger than even the original material.

All finished with the repair stage. The lower piece is repaired and I sanded everything to blend it together.

Here we are painted with flexible plastic primer. No, I haven't the slightest idea why its that color.

Next I painted the dash with low gloss black paint. This is high heat engine paint, I kinda hope it holds up better to the sun.

Taped for semi-gloss. Notice that I'm not too worried about the infill areas. I have an overlay for the top to replace the original, and a trick up my sleeve for the lower infill area.

Painted with semi-gloss where it needs to be. The semi-gloss engine paint is actually pretty glossy...

I then used an "argent" silver paint pen to trim out the lettering and raised circles around the switches. I did the same with the lens cups, but I didn't take any pictures of that process. Same deal, sanded, primed, then low-gloss black.

And next, the final product...

Last edited:

Now, for the finished product and my "trick". Not really a trick, I originally purchased a carbon fiber overlay from Detroit Muscle Technologies on eBay. I was darned impressed with the product, so I contacted the owner, Jim Fillmore, about making lower overlay pieces as well. After mailing back and forth a few rally dashes, Jim sent me back a set of lower carbon fiber overlays.  rayer:

rayer:

Unfortunately, because the dash for my Duster isn't stock, I had to do a little trimming of my own. But it all worked out! I did a ton of buffing on the painted sections of the dash, which now are pretty much a gloss black. You can see the reflection of the gauges in the upper part of the dash. I also glued the lenses and everything back into the dash.

The lower overlays are just laid in. As you can see the holes for mounting the dash are covered, so final installation of the overlays has to be done in the car with the dash mounted already, unless you want to cut out the holes (a single hole paper punch would work great!). I opted for the clean look.

And before anyone asks, here's a link to the carbon fiber overlay and the DMT website. The overlays aren't listed on the site, just eBay.

Carbon fiber overlay

The ebay store

http://stores.ebay.com/Detroit-Muscle-Technologies-LLC?_trksid=p2047675.l2563

And the DMT home website.

http://www.detroitmuscletechnologies.com/

Keep in mind these overlays are also made in the original woodgrain. The lowers aren't listed for sale on eBay yet, but I'm guessing if you contacted Jim through his website he'd be able to help. The lowers should be available in a semi gloss black and a silver color, to match the original layouts.

Unfortunately, because the dash for my Duster isn't stock, I had to do a little trimming of my own. But it all worked out! I did a ton of buffing on the painted sections of the dash, which now are pretty much a gloss black. You can see the reflection of the gauges in the upper part of the dash. I also glued the lenses and everything back into the dash.

The lower overlays are just laid in. As you can see the holes for mounting the dash are covered, so final installation of the overlays has to be done in the car with the dash mounted already, unless you want to cut out the holes (a single hole paper punch would work great!). I opted for the clean look.

And before anyone asks, here's a link to the carbon fiber overlay and the DMT website. The overlays aren't listed on the site, just eBay.

Carbon fiber overlay

The ebay store

http://stores.ebay.com/Detroit-Muscle-Technologies-LLC?_trksid=p2047675.l2563

And the DMT home website.

http://www.detroitmuscletechnologies.com/

Keep in mind these overlays are also made in the original woodgrain. The lowers aren't listed for sale on eBay yet, but I'm guessing if you contacted Jim through his website he'd be able to help. The lowers should be available in a semi gloss black and a silver color, to match the original layouts.

Took the dash outside this morning to get a better picture. The carbon really looks awesome in person! Hard to get the lighting right for a good picture, but this one comes pretty close.

Now to get it installed!

Now to get it installed!

Last edited:

TylerW

Well-Known Member

You do very, very good work. I really enjoy following a build where things are planned out and executed well. Keep up the good work!

You do very, very good work. I really enjoy following a build where things are planned out and executed well. Keep up the good work!

Thanks! :thumbup:

I might have to take issue with my "planning" ability though, since I'm working on installing my 3rd engine in a /6 auto car I was just going to putt around in. ;-)

But I am hoping for well executed, because I really only want to make this a 400+ hp 340/4 speed car once, and there's A LOT to do.

You know, like replace pretty much every single mechanical part that was on the car when I got it. Less than year ago. When I was just going to use it as a /6 driver.

Ok, another update. I took a break from the dash to work on the chassis, fabricating a set of frame connectors from 1.5" x 3" x.120" wall steel. I originally wanted to do 2x3x.120, but I decided I wanted to stay away from cutting the floor.

It's hard to tell in these pics, but I also boxed in the end that was cut to fit over the rear frame rails in addition to adding the extra plates to cover more surface area on the rear rails.

I also reinforced the torsion bar anchors when I was welding in the connectors, since I have 1.12" bars from Firm Feel to replace the 1" Just Suspension bars that are in there now.

I also added torque boxes to the car, front and rear.

What I didn't do was take pictures of the installation of my Dillinger Chassis J bars and radiator support brace. :banghead: Although, you'll get to see them shortly anyway...

It's hard to tell in these pics, but I also boxed in the end that was cut to fit over the rear frame rails in addition to adding the extra plates to cover more surface area on the rear rails.

I also reinforced the torsion bar anchors when I was welding in the connectors, since I have 1.12" bars from Firm Feel to replace the 1" Just Suspension bars that are in there now.

I also added torque boxes to the car, front and rear.

What I didn't do was take pictures of the installation of my Dillinger Chassis J bars and radiator support brace. :banghead: Although, you'll get to see them shortly anyway...

Last edited:

After adding the frame connectors, torque boxes, J bars, radiator support brace, and reinforcing the torsion bar anchors, I finally decided I was ready to drop the engine in.

I built this 340 originally to go into my Challenger, but since the Challenger is still a ways out from needing a new engine, and will need some body repair before that happens anyway, I decided the place for it to go was my Duster. Better engine for it anyway, the Challenger is probably better suited to a stroker anyway.

Some quick stats on the engine

'68 340

.060" over with KB 243 hyper pistons, .018" over the deck, ~9.8:1

Forged crank turned .20/.20

Stock 340 rods, resized with ARP bolts

308 heads, 2.02/1.60 valve, 65 cc's chambers, stage II ported and flowing 264 cfm at .500"

Harland Sharp 1.5 roller rockers, Smith pushrods

Lunati 60404 Hydraulic cam, .513/.533", 276/284 advertised duration

Milodon Road race pan, stock 340 windage tray

Since the '74 Duster has spool mounts, I already knew I had to drop the engine straight down without the transmission to clear the pan. What I DIDN'T know was that not even the flywheel can be attached. So, pay attention 4 speed guys...

Ok, here we go!

Yup, its tight...

But it doesn't clear. Hard to tell from this picture, but the pan is directly above the spool mount. Needs to go back another inch...

So, out it came and back off with the flywheel. Turns out that's exactly the right amount to clear the spool on the way down.

And viola. Told you you'd get the see the J bars soon!

I built this 340 originally to go into my Challenger, but since the Challenger is still a ways out from needing a new engine, and will need some body repair before that happens anyway, I decided the place for it to go was my Duster. Better engine for it anyway, the Challenger is probably better suited to a stroker anyway.

Some quick stats on the engine

'68 340

.060" over with KB 243 hyper pistons, .018" over the deck, ~9.8:1

Forged crank turned .20/.20

Stock 340 rods, resized with ARP bolts

308 heads, 2.02/1.60 valve, 65 cc's chambers, stage II ported and flowing 264 cfm at .500"

Harland Sharp 1.5 roller rockers, Smith pushrods

Lunati 60404 Hydraulic cam, .513/.533", 276/284 advertised duration

Milodon Road race pan, stock 340 windage tray

Since the '74 Duster has spool mounts, I already knew I had to drop the engine straight down without the transmission to clear the pan. What I DIDN'T know was that not even the flywheel can be attached. So, pay attention 4 speed guys...

Ok, here we go!

Yup, its tight...

But it doesn't clear. Hard to tell from this picture, but the pan is directly above the spool mount. Needs to go back another inch...

So, out it came and back off with the flywheel. Turns out that's exactly the right amount to clear the spool on the way down.

And viola. Told you you'd get the see the J bars soon!

Last edited:

nice ,coming along great

Yup, trying to get this thing DONE.

Been hung up waiting for parts to install the clutch so I can get the bellhousing on and the 4 speed installed. Would love to get that done so I can get the engine hooked up and ready to fire. Still a way to go, but actually getting it to run again would be pretty motivational.

Been hung up waiting for parts to install the clutch so I can get the bellhousing on and the 4 speed installed. Would love to get that done so I can get the engine hooked up and ready to fire. Still a way to go, but actually getting it to run again would be pretty motivational.

Alright, another little update.

Since the Duster was a /6 it came with a 7.25, so that has to change. Since its a Duster, a B body rear fits better than an A-body rear with modern rims. So, enter a '68-70 B body rear. This one actually measures just a smidge under 55", so its actually the 54 15/16" its supposed to be!

And since we're moving perches, might as well throw in an offset spring kit. Perches will be 42" c-c.

First, I added a drain plug to make 3rd member swaps easier

Then sectioned the original perch. This lets me use the rest of the old perch to match the angles. Probably not perfect from the standpoint of setting the pinion angle, but it beats installing, tacking, uninstalling, welding, etc, only to lower or raise the car again later.

New perch welded on, old one completely removed...

Repeated the same thing for the opposite side, and checked the angles to make sure they were the same. Housing is ready to install once I finish the transmission and engine stuff.

Since the Duster was a /6 it came with a 7.25, so that has to change. Since its a Duster, a B body rear fits better than an A-body rear with modern rims. So, enter a '68-70 B body rear. This one actually measures just a smidge under 55", so its actually the 54 15/16" its supposed to be!

And since we're moving perches, might as well throw in an offset spring kit. Perches will be 42" c-c.

First, I added a drain plug to make 3rd member swaps easier

Then sectioned the original perch. This lets me use the rest of the old perch to match the angles. Probably not perfect from the standpoint of setting the pinion angle, but it beats installing, tacking, uninstalling, welding, etc, only to lower or raise the car again later.

New perch welded on, old one completely removed...

Repeated the same thing for the opposite side, and checked the angles to make sure they were the same. Housing is ready to install once I finish the transmission and engine stuff.

Last edited:

Ok, here we go again.

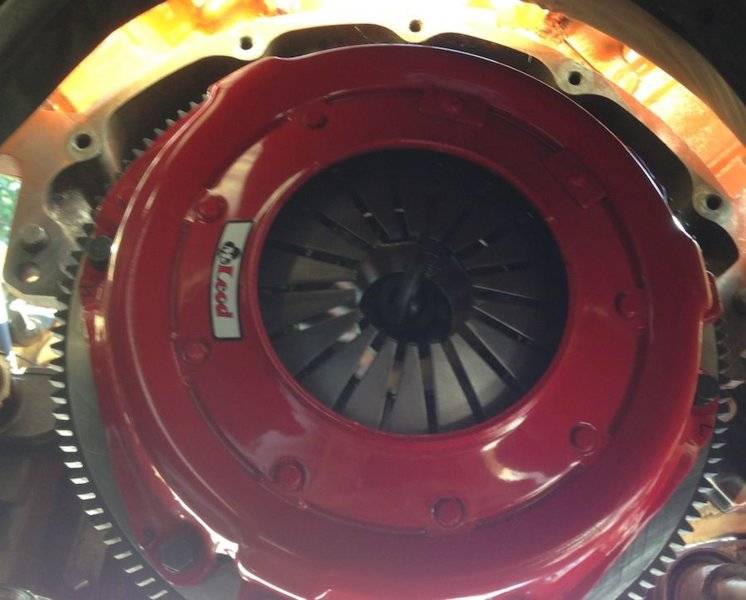

Last I left it the engine was in, but no flywheel or transmission yet. Installed my new flywheel and Mcleod Super Streetpro clutch...

And after many trials and tribulations getting everything lined up underneath the car, I got the transmission installed. It still needs a few things hooked up, the speedo gear installed and filled with oil, but we're getting there.

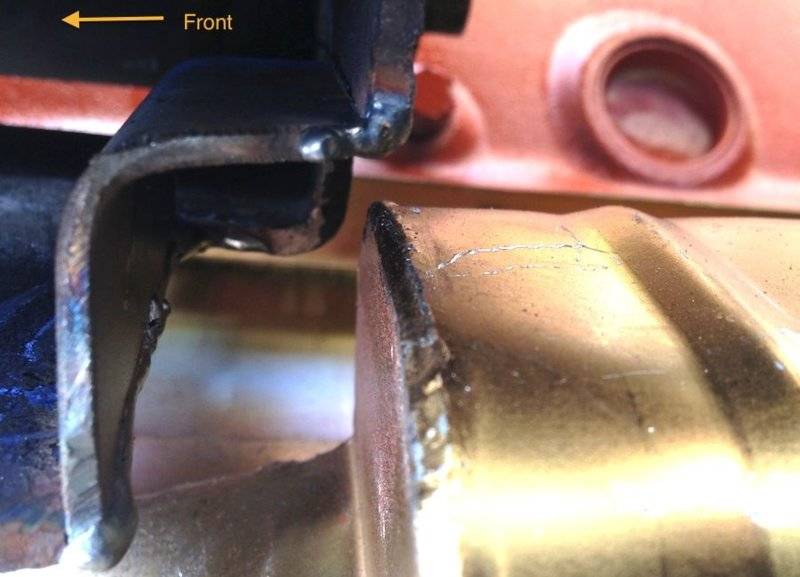

And then there was this...

:banghead: :banghead: :banghead: :banghead: :banghead: :banghead: :banghead:

My new Milodon road race pan hitting the lower part of the driver's side spool mount. I had noticed this area before, but the clearance (or lack thereof) was dependent on the angle of the engine. Since I didn't have the transmission on, I figured it was sagging and raised it up a bit, no biggie. And assumed that once the transmission was in place it would still clear fine. Well, we all know assumptions do... #-o

So, instead of pulling the transmission and lifting the engine back out, I supported the engine with a hoist and dropped the K frame out the bottom to notch the mount for clearance.

Once the notch was cut I reinforced the mount (probably unnecessary)

And reinstalled the K and dropped the engine back into the mounts. Plenty of clearance now!

Why this was an issue I'm not really sure. The Milodon road race pan fits pretty tight with the 73-76 A body spool mounts, but I haven't seen one that interfered yet. Granted, it really just touched the mount, there was no pressure or load on the pan, just contact there. I did replace the stock worn out rubber mounts with poly inserts for the spools, so I suppose that may have been part of it.

Still have to finish buttoning up the suspension, I needed to swap out the 1" JS torsion bars for the 1.12" Firm feel bars I bought so this seemed like a good time with the other bars already dropped to remove the K. That and the new Bilsteins. Then back on to getting the engine hooked up and ready to fire.

Last I left it the engine was in, but no flywheel or transmission yet. Installed my new flywheel and Mcleod Super Streetpro clutch...

And after many trials and tribulations getting everything lined up underneath the car, I got the transmission installed. It still needs a few things hooked up, the speedo gear installed and filled with oil, but we're getting there.

And then there was this...

:banghead: :banghead: :banghead: :banghead: :banghead: :banghead: :banghead:

My new Milodon road race pan hitting the lower part of the driver's side spool mount. I had noticed this area before, but the clearance (or lack thereof) was dependent on the angle of the engine. Since I didn't have the transmission on, I figured it was sagging and raised it up a bit, no biggie. And assumed that once the transmission was in place it would still clear fine. Well, we all know assumptions do... #-o

So, instead of pulling the transmission and lifting the engine back out, I supported the engine with a hoist and dropped the K frame out the bottom to notch the mount for clearance.

Once the notch was cut I reinforced the mount (probably unnecessary)

And reinstalled the K and dropped the engine back into the mounts. Plenty of clearance now!

Why this was an issue I'm not really sure. The Milodon road race pan fits pretty tight with the 73-76 A body spool mounts, but I haven't seen one that interfered yet. Granted, it really just touched the mount, there was no pressure or load on the pan, just contact there. I did replace the stock worn out rubber mounts with poly inserts for the spools, so I suppose that may have been part of it.

Still have to finish buttoning up the suspension, I needed to swap out the 1" JS torsion bars for the 1.12" Firm feel bars I bought so this seemed like a good time with the other bars already dropped to remove the K. That and the new Bilsteins. Then back on to getting the engine hooked up and ready to fire.

Last edited:

TylerW

Well-Known Member

Great build, I just love plain Jane cars with big engines

Ok, time for some updates on this one. While I haven't been posting on this build, I have actually been working on it.

Since I last posted, I

-finished the rally dash install, including installing an RTE ivr

-broke in the cam

-installed an oil filter relocation kit

-installed my Doug's headers and modified my 4 speed Z-bar to fit

-installed a 2.5" Summit dual exhaust

-recurved the dizzy to deal with 20* of initial advance

-relocated the battery to the trunk

-installed bucket seat floor reinforcments and aftermarked buckets

-converted the car from a standard to fold down rear seat (no really, I did!)

-lined the roof and floor with Fatmat

-installed a new headliner and did a complete color change on the interior

-changed the fuel sending unit (twice!) :banghead:

-cut down an E-body crush can and re-welded it to make an A body tuff wheel adaptor

-Put about 70 miles on it so far

There's more I've done that I've probably forgotten, but those are the highlights. I'm going to do a separate thread on my fold down conversion, as I know the topic has come up before. Still a long way from finished, but being back on the road is VERY nice. :glasses7:

Here are some pictures along the way. I'll get some more showing the current state of things, as I'm a bit further along than these suggest.

Since I last posted, I

-finished the rally dash install, including installing an RTE ivr

-broke in the cam

-installed an oil filter relocation kit

-installed my Doug's headers and modified my 4 speed Z-bar to fit

-installed a 2.5" Summit dual exhaust

-recurved the dizzy to deal with 20* of initial advance

-relocated the battery to the trunk

-installed bucket seat floor reinforcments and aftermarked buckets

-converted the car from a standard to fold down rear seat (no really, I did!)

-lined the roof and floor with Fatmat

-installed a new headliner and did a complete color change on the interior

-changed the fuel sending unit (twice!) :banghead:

-cut down an E-body crush can and re-welded it to make an A body tuff wheel adaptor

-Put about 70 miles on it so far

There's more I've done that I've probably forgotten, but those are the highlights. I'm going to do a separate thread on my fold down conversion, as I know the topic has come up before. Still a long way from finished, but being back on the road is VERY nice. :glasses7:

Here are some pictures along the way. I'll get some more showing the current state of things, as I'm a bit further along than these suggest.

Last edited:

Another update!

Nothing too exciting, been sorting out a lot of little things and doing some interior work. Engine is running strong, seems like its fairly well tuned considering I haven't done much other than recurve the dizzy. Over 300 miles on it now, gotta go back in and change out the 7 1/4 for my B body 8 3/4 before I break it.

Here's a little video with the engine running. That lunati 60404 cam is a brute! Exhaust doesn't sound too bad, especially for just having the Summit Turbo mufflers that came with the Summit 2.5" exhaust system.

Exhaust doesn't sound too bad, especially for just having the Summit Turbo mufflers that came with the Summit 2.5" exhaust system.

[ame]http://youtu.be/C_P8H2aLYPU[/ame]

Nothing too exciting, been sorting out a lot of little things and doing some interior work. Engine is running strong, seems like its fairly well tuned considering I haven't done much other than recurve the dizzy. Over 300 miles on it now, gotta go back in and change out the 7 1/4 for my B body 8 3/4 before I break it.

Here's a little video with the engine running. That lunati 60404 cam is a brute!

[ame]http://youtu.be/C_P8H2aLYPU[/ame]

DionR

Well-Known Member

Sweet! Don't know how I missed the earlier updates, I was looking for them but missed them somehow. Now I'm subscribed.

What wheels you going to run, 17's?

Why the conversion to a fold down seat? I can see the uses, I'd just worry about losing some stiffness in the back.

What wheels you going to run, 17's?

Why the conversion to a fold down seat? I can see the uses, I'd just worry about losing some stiffness in the back.

DionR

Well-Known Member

I'm sure I missed it somewhere, but what shocks are you running with those TB's? How's it ride?

Sweet! Don't know how I missed the earlier updates, I was looking for them but missed them somehow. Now I'm subscribed.

What wheels you going to run, 17's?

Why the conversion to a fold down seat? I can see the uses, I'd just worry about losing some stiffness in the back.

I'm sure I missed it somewhere, but what shocks are you running with those TB's? How's it ride?

I'm planning on running 18's. I want to run 275's on all 4 and 18's clear the outer tie rod up front so you can run tires that size without hitting the fender. I've got a set of 18x9.5's that will be going on once I get the 8 3/4 in the car.

I did the fold down conversion strictly for utility. This is going to be my daily while I work on my GT and my Challenger, and I tend to haul a lot of parts for my other cars that I find locally. As for chassis stiffness, I'm not worried about it. I'm pretty convinced that the fold down cars were just as stiff as the standard cars anyway, especially after removing that cross brace and seeing how little there really is to it. My car has frame connectors, torque boxes, and all of the original fold down bracing out of a donor car. I also added some additional bracing myself.

I'm running Bilsteins with the 1.12" torsion bars. The car rides very well, it's pretty close in quality to my g/f's 2013 mustang with the premium suspension package. Definitely firm, but not punishing at all.

I still need to get the 8 3/4 in the car, but the interior is pretty much done. I have a little carpet work to do in the fold down seat compartment still. Priority is the 8 3/4, once that's in I can get the car on a dyno and do the front brakes, rims and tires.

-

Similar threads

- Replies

- 77

- Views

- 5K

- Replies

- 9

- Views

- 363

- Replies

- 142

- Views

- 8K