skep419

5.9 Magnum 4 speed afficionado

I have been stranded twice in the last month because of electricity. I have a mopar Alt (dual field ext V reg) mini starter, battery in the trunk. Today The alt was not charging while I was 10 miles from home. As I looked for the issue the car got up to 235 deg and I was forced to shut it off. I checked V at the battery and terminals 12.4. Checked at started solenoid 12.4. Turn key to start clickckckckckckckckck. :angry7: Cleaned all battery terminals.The battery relocation kit came with crappy non soldered eyelet ends with a stud and wing nut battery terminal. As I was cleaning the battery terminals the pos Eyelet fell off :angry7:. Took a screwdriver and a hammer to it for temporary fix. Finally I called a friend to bring a battery jump pack over. Hooked it up nothing. can't believe this day. Long story crappy ground was the culprit. Engine finally started tick tick tick tick for about five min. Still not charging. Checking fuses noticed alt field fuse blown. Field spade was loose. After replacing fuse and tightening spade terminal. It is now Charging at 14.

Where to mount the ground wire. Trunk floor is NOT cutting it... (car has sub frame connectors)

Anybody run a ground wire to there alt? Is there such thing as too many grounds :toothy10:

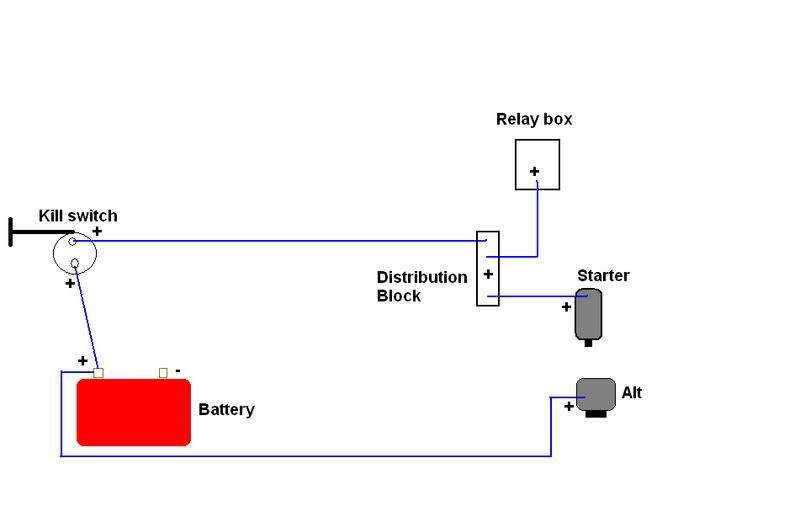

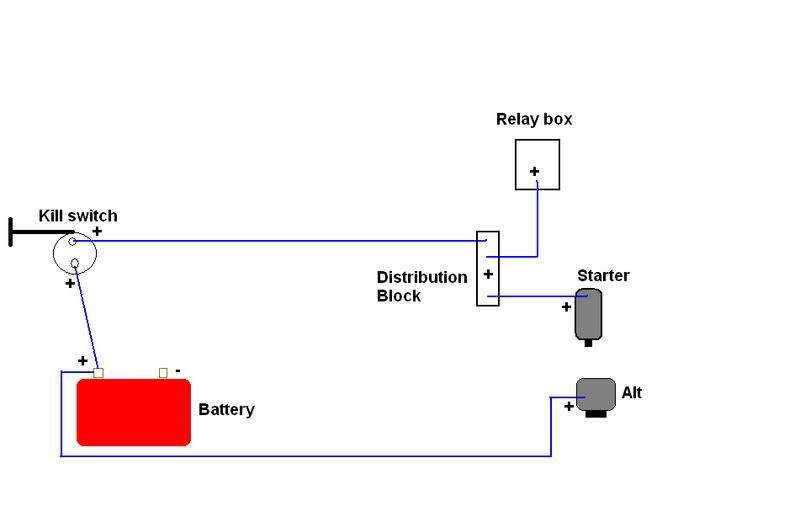

This diagram is what I will be going off of.

Where to mount the ground wire. Trunk floor is NOT cutting it... (car has sub frame connectors)

Anybody run a ground wire to there alt? Is there such thing as too many grounds :toothy10:

This diagram is what I will be going off of.