:wack:new rebuilt compressor using r-12/ new drier . clutch cycles/ max 50lbs high side pressure, Low side pressure is 45+50lbs drops down to 20lbs when clutch is engauged and then as soon as it gets to 20 clutch dis=engauges.the high also drops down when compressor is engauged. when i jump the temperature sending switch inside the clutch stays engauged low side pressure is 15 but i only have 50lbs on high side . temperature inside is 25 degress. system is not low on freon '

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

no high pressure rv2 help!

- Thread starter lucahemi

- Start date

-

67Dart273

Well-Known Member

What year/ model we working on?

If it's a factory system, did you read the shop manual?

Is it a system you put together from parts, and did it ever work (previously)?

What is the ambient temperature, and where are you located?

What is "temerature inside?" (25*) Inside the shop? Inside the car? probe stuck in the evap fins? 25F or 25C?

Did you try blocking the condenser to raise head pressure?

What makes you think the system is not "low on Freon?"

Are you using a PROPER R-12 refrigerant or are you using one of these aftermarket "fake" R12 mixes with propane or lipstick or some other unknown chemical added?

If it's a factory system, did you read the shop manual?

Is it a system you put together from parts, and did it ever work (previously)?

What is the ambient temperature, and where are you located?

What is "temerature inside?" (25*) Inside the shop? Inside the car? probe stuck in the evap fins? 25F or 25C?

Did you try blocking the condenser to raise head pressure?

What makes you think the system is not "low on Freon?"

Are you using a PROPER R-12 refrigerant or are you using one of these aftermarket "fake" R12 mixes with propane or lipstick or some other unknown chemical added?

Everything '273 had to say above ^ plus this:

What is the static pressure of the system, engine off & ambient temperature at the time of the pressure measurement?

What kind of oil, and how much of it do you have in the sump on the RV2?

B.

What is the static pressure of the system, engine off & ambient temperature at the time of the pressure measurement?

What kind of oil, and how much of it do you have in the sump on the RV2?

B.

1972 dodge demon 340/ yes factory 100% stock a/c . yes on reading the manual . proper oil non parafin. 8-10oz of compressor oil. never ran the system prior resto on the car. In Chicago heated garage 70 degrees farenhiet. 25 degrees inside car with temo gauge probe in vents. No on blocking condensor to raise pressure. Per the mopar book on amount of r-12. The freon is from the 70s good stuff.Afer installing proper amount of freon . I added more to see if situation improve - no change. Original factory condensor cleaned out prior installing . The only thing I havent changed is the expansion valve, After shutting down the presures eqalize 70lbs on high 70lbs on low.?????????????????? Guys if I jump the temperature sending switch on the inside clutch remain on constant / low side drops to 15 temp inside vent 25 degrees almost snows inside / only 50lbs high side . Obviously cant leave that way freezing up

67Dart273

Well-Known Member

FIRST you need to block the condenser, and the shop manual mentions that. You need to get AT LEAST 125LB (the manual says more) head pressure. If the head does not come up much, and if the suction doesn't come up, it's either low on refrigerant or the TXV or if it uses the evap pressure reg is bad/ plugged.

WATER (freezing) in the system with do that. What did you do to evacuate the system? HEAT helps. That is, if you evacuate the system in very cold weather, even if you pulled a good vacuum, the water may not be out of the system.

Receiver dryer? New one?

Is the blower running up to speed? You sure it's getting air across the evap, that is, are the blower doors opening/ closing properly?

WATER (freezing) in the system with do that. What did you do to evacuate the system? HEAT helps. That is, if you evacuate the system in very cold weather, even if you pulled a good vacuum, the water may not be out of the system.

Receiver dryer? New one?

Is the blower running up to speed? You sure it's getting air across the evap, that is, are the blower doors opening/ closing properly?

new dryer. the service manual on the car says nothing about blocking the condensor in my book. it says the high side should be a minimum of 140-180 or 200.what do you mean by the txv. we pulled a vacumm in a heated garage. The car is in a heated garage at all times . I am trying to finish the resto.The compressor I purchased rebuilt has no valve in the low side port . The people I have talked to says its impossible to buy them today. Why does the clutch engage when you push the max a/c button and only run for 10 seconds. off for 10 sec the cycles on -off. I have almost 4 lbs of freon in the system . Initial calls for almost 3 . Thought it was low addes another 1 lb no difference yes on the doors and blower good to go

67Dart273

Well-Known Member

The thing is cycling on the low pressure switch. You can bypass it for testing, but I would not run it for more than a minute in that condition.

Here's the 72 manual download:

http://www.forabodiesonly.com/mopar/showthread.php?t=132309&highlight=manual,+download

It's the "72 Plymouth" shop manual

TXV is "thermostatic expansion valve"

I guess I was mistaken, the A series cars evidently don't use an evap pressure regulator.

In the download posted, page 24- on, and again, page 24-31 they say

Onwards through the pages, 24-28, in "charging" they mention RPM, and 24-30, performance tests, they refer you back to that RPM (refer to test 4)

Notice that they speak of watching the sight glass. I've never been big on depending on the sight glass, as on very hot days, it can show foam and still be properly charged, thus leading you to incorrectly add refrigerant. Many newer systems don't even HAVE a sight glass.

I prefer to use SUPERHEAT which is a method by which you insure that the compressor is not being "slugged" by liquid refrigerant. There will be some argument as to just what the proper superheat should be, but I'd say NOT LESS than 10*F and NOT MORE than 25*F

To do that, all you need is the temp. scale on your low pressure gauge, or a pressure-temp chart for R-12, and a good thermometer. Strap a thermometer near the compressor on the suction line and away from engine hot spots as best you can. Insulate the area of the temp. probe, and you usually want the probe to be on the lower 3/4 of the tube, IE about 3-4 oclock or so.

This of course will be after you get the system working enough to finalize the charge, and should be done on a warm day as in the book with doors and windows open. Run the system to get it stable, with a good big fan into the engine. Even better would be a road test, and of course I realize this is difficult if not impossible.

In any case after the system is stable, you read the temp at the suction line and compare it to the temp on the low pressure gauge. The temp difference, 10-20 degrees or so, is your "superheat."

Some of the main things that affect system pressure:

HEAT LOAD. More heat in the passenger compartment, hot day, humidity, sun load, raises evap temp and raises head and suction pressures. Too much refrigerant will raise at least head pressure, and probably suction as well. A TXV (as opposed to an orifice system) and a nice big receiver gives you a little leeway in that dept.

Not enough blower at the evap, plugged/ iced evap, or cold temps lowers it, along with low refrigerant.

Typically, a bad compressor (leaky valves) will give you reduced head but higher than normal suction

AND IS IT POSSIBLE that there is some foreign plug in the system? That is a dust plug over the compressor outlets or something else in the hoses, / fittings?

Here's the 72 manual download:

http://www.forabodiesonly.com/mopar/showthread.php?t=132309&highlight=manual,+download

It's the "72 Plymouth" shop manual

TXV is "thermostatic expansion valve"

I guess I was mistaken, the A series cars evidently don't use an evap pressure regulator.

In the download posted, page 24- on, and again, page 24-31 they say

Onwards through the pages, 24-28, in "charging" they mention RPM, and 24-30, performance tests, they refer you back to that RPM (refer to test 4)

Notice that they speak of watching the sight glass. I've never been big on depending on the sight glass, as on very hot days, it can show foam and still be properly charged, thus leading you to incorrectly add refrigerant. Many newer systems don't even HAVE a sight glass.

I prefer to use SUPERHEAT which is a method by which you insure that the compressor is not being "slugged" by liquid refrigerant. There will be some argument as to just what the proper superheat should be, but I'd say NOT LESS than 10*F and NOT MORE than 25*F

To do that, all you need is the temp. scale on your low pressure gauge, or a pressure-temp chart for R-12, and a good thermometer. Strap a thermometer near the compressor on the suction line and away from engine hot spots as best you can. Insulate the area of the temp. probe, and you usually want the probe to be on the lower 3/4 of the tube, IE about 3-4 oclock or so.

This of course will be after you get the system working enough to finalize the charge, and should be done on a warm day as in the book with doors and windows open. Run the system to get it stable, with a good big fan into the engine. Even better would be a road test, and of course I realize this is difficult if not impossible.

In any case after the system is stable, you read the temp at the suction line and compare it to the temp on the low pressure gauge. The temp difference, 10-20 degrees or so, is your "superheat."

Some of the main things that affect system pressure:

HEAT LOAD. More heat in the passenger compartment, hot day, humidity, sun load, raises evap temp and raises head and suction pressures. Too much refrigerant will raise at least head pressure, and probably suction as well. A TXV (as opposed to an orifice system) and a nice big receiver gives you a little leeway in that dept.

Not enough blower at the evap, plugged/ iced evap, or cold temps lowers it, along with low refrigerant.

Typically, a bad compressor (leaky valves) will give you reduced head but higher than normal suction

AND IS IT POSSIBLE that there is some foreign plug in the system? That is a dust plug over the compressor outlets or something else in the hoses, / fittings?

Ok, the static pressure at 70f should be around 70 psi, and the system should equalize with the compressor shut down. 70 low & 70 high is fine.

Generally the system heating from underhood engine heat will hold the system temperature above ambient, and the static pressure will reflect this. For reference, with R12 @ 90f you should see 100 psi static.

You say you have 4 lbs in the system. You should see more on the highside with that charge.

do you have both valves closed on the manifold set while testing?

.

Generally the system heating from underhood engine heat will hold the system temperature above ambient, and the static pressure will reflect this. For reference, with R12 @ 90f you should see 100 psi static.

You say you have 4 lbs in the system. You should see more on the highside with that charge.

do you have both valves closed on the manifold set while testing?

.

yes I by-passed /jumped the low presure switch it still continued to cycle on /off. the manual refers to another switch that senses the temp on the condensor inside the car. It refers it to a temp sensing switch. That I jumped and the clutch continually stayed on which is what brought the low side down to 15 and very low temps inside the vehicle. I still cannot get the high side higher than 50. When i first installed the compressor I had 100 on the high side . Now only 50 . If it had a blockage why after the car is shut off it equalize to 70 on both sides . yes the valves are closed on the manifold. My partner is fairly versed on a/c on General Motors/ he 2 thought we were low on freon. I have a sight window on the drier . We addes more freon after the 2-3 lbs spec out by the manual due to a few air bubles just ptrior the clutch cycling back on.

I really appreciate all your help! . I have ordered a new one . That is the only piece that i havent changed,Please stay with me on this one its driving me crazy and broke at the same time. I am a fairly good wrench but the learning curve is way to long for my patience. I will post the results so we can all learn . Thanks Glen

cudamark

Well-Known Member

That was my first thought too......expansion valve stuck open.My first inclination is that the TXV is defective.

67Dart273

Well-Known Member

That was my first thought too......expansion valve stuck open.

no.......closed. Stuck open (rare) would be VERY high suction pressure, possible damage to compressor, and high head on a warm day.

nuttyprof

Well-Known Member

Are you checking pressure at the compressor? At the filter/dryer? At the condenser inlet? Outlet? If you are not checking at the compressor, you may have a restricted/plugged high side line, filter/dryer, condenser. I ask because with it overcharged you should be getting much higher pressures when equalized. If you are checking after the condenser there is plenty of room to fill with liquid refrigerant to hide all that, however the pressure will be dangerously high. Running it with the safety controls bypassed could lead to a catastrophic failure including damage to the car and to you! Be safe! If the high side drops when the compressor kicks on you have a restriction between the compressor and the high side service port!

Nuttyprof

Nuttyprof

67Dart273

Well-Known Member

OK, first, there are only so many service connections on these vehicles. Second, unless it is overcharged to such an extent that there is insufficient volume for vapor pressure, the static pressure will follow the pressure / temperature curve of "saturated refrigerant." The only time the pressure will be BELOW saturated press/ temp is if there is not enough liquid in the system, and likewise if the pressure is ABOVE saturated press/ temp, then there is so much liquid that the refrigerant can no longer expand.

The readings he's getting tell us neither of this is true. R12 press/ temp for a 70* F garage (static) is gonna be about 70 psi -- just what he has at rest.

This is typical of a failed TXV -- a leaky temp bulb/ diaphragm

http://www.central-air-conditioner-and-refrigeration.com/thermostatic_expansion_valve.html

The readings he's getting tell us neither of this is true. R12 press/ temp for a 70* F garage (static) is gonna be about 70 psi -- just what he has at rest.

This is typical of a failed TXV -- a leaky temp bulb/ diaphragm

http://www.central-air-conditioner-and-refrigeration.com/thermostatic_expansion_valve.html

cudamark

Well-Known Member

With the cooling he's getting, there must be plenty of flow. If the valve was stuck shut, you wouldn't get any cooling at all. I agree that usually when the valve sticks shut, you get those kinds of readings because there is no flow but how do you account for the 25 degrees at the evaporator? You would think that the low side reading would be higher though.....maybe some crud got into the dryer and is partially plugging it. It's always possible that the new compressor has damaged reed valves also.no.......closed. Stuck open (rare) would be VERY high suction pressure, possible damage to compressor, and high head on a warm day.

nuttyprof

Well-Known Member

However he said that when he runs the compressor the high side pressure drops, that indicates a restriction between the compressor and the service port. If the volume of that section line is less than the 4lb he said he put in and he runs the compressor long enough with no safetys then he risks the line rupturing.

67Dart273

Well-Known Member

However he said that when he runs the compressor the high side pressure drops, that indicates a restriction between the compressor and the service port. If the volume of that section line is less than the 4lb he said he put in and he runs the compressor long enough with no safetys then he risks the line rupturing.

I don't know where you are getting this "section of line." Again, there are only so many service ports on an automotive AC system. So far as I know, the only ones on the A bodies are on the compressor.

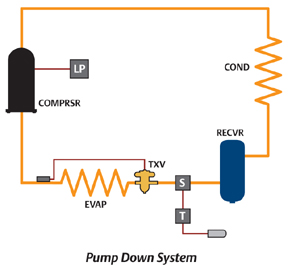

When the TXV is closed due to failure, this is essentially the same thing as "pumping down" a system. Some refrigeration systems use solenoids in the liquid line (the line between the receiver and the TXV)

When you close the liquid line, or in this case (assuming) the TXV is closed/ failed, you have NO HEAT LOAD in the system. That is, the evap is doing no work. The compressor attempts to "pull a vacuum" all the way from the "plug" IE solendoid valve or failed TXV, through the evap, through the suction line, and out the compressor, where the condenser, which again, HAS NO heat load, simply condenses the liquid in the condenser / receiver. Because the condenser is now "over" cooled, the liquid simply condenses and "sits there." (Known as "sub" cooled, IE below the saturation pressure/ temp.) Head pressure will start about normal on a "pump down" system, and as the pump down action continues, the head pressure, as well as suction, will fall to a fairly low value.

How a pump down system basically operates, and IF the TXV is bad, this is a direct comparison:

http://www.real-world-refrigeration.com/refrigeration-control-system-3.html

another:

http://www.achrnews.com/articles/quick-facts-migration-and-pump-down-systems

The diagram from the above page: Notice the solenoid valve between the receiver and TXV. What I'm trying to get across, here, is that essentially the same principles apply. A failed/ plugged TXV is essentially the same thing as a closed solenoid in a system with intentional pump down

Some systems use this as part of the control system. Typically, you have either a temperature control which senses box/ evap temp, or a pressure control on the evap. When the temp gets to the set point, or the evap pressure gets to the set point, the control shuts off the solenoid, shutting off liquid supply to the TXV. The compressor continues to run until it shuts off on a second low pressure switch.

cudamark

Well-Known Member

I would agree if it wasn't for the fact he's getting cooling.....in fact, mega cooling at the evaporator and the low side is not in vacuum which is what I would expect from an expansion valve being stuck shut. With the expansion valve stuck shut you should not get ANY cooling, correct?

67Dart273

Well-Known Member

Suction pressure indicates he is NOT getting "mega" cooling. The thing is, the TXV or whatever is causing the problem is/ may not be completely shut off, it's just leaking a little. This explains the low suction, with not much heat load, and the low head, considering the shop is not all that warm.

But as I said earlier, don't discount that it could be water in the system, which TYPICALLY will work for a minute or so, then freeze up at the TXV, causing a restriction/ plug

I'm no expert on all the hardware used on cars over the years, but I spent a few years working on HVAC/R

Whenever you get a system that has been left open, and or not properly evacuated, filters replaced, in the case of vehicular AC a "sweep test charge" is a good idea, and don't discount that if you FOR SURE do not know the origin of the refrigerant you are using --off brand mixtures, or "recovered" or even a "used bottle" it might just be contaminated right out of the can.

It's really too bad that these compressors don't have proper service valves like the Ferds typically did, because it makes servicing/ testing these systems a lot easier.

Service valves have a "double seat." "Normal operation" the valve is "back seated" which closes the service (gauge) port. You hook up the gauge, "crack" the back seat open (CW) and now you have access. For certain tests, it's handy to be able to shut off the suction or discharge valve (front seated) which you cannot do on the Mopars.

"REAL" refrigeration systems typically have valves on the compressor, as well as the receiver outlet. This allows you to service a leaky evap, or change a compressor or TXV without pulling the refrigerant out of the system.

But as I said earlier, don't discount that it could be water in the system, which TYPICALLY will work for a minute or so, then freeze up at the TXV, causing a restriction/ plug

I'm no expert on all the hardware used on cars over the years, but I spent a few years working on HVAC/R

Whenever you get a system that has been left open, and or not properly evacuated, filters replaced, in the case of vehicular AC a "sweep test charge" is a good idea, and don't discount that if you FOR SURE do not know the origin of the refrigerant you are using --off brand mixtures, or "recovered" or even a "used bottle" it might just be contaminated right out of the can.

It's really too bad that these compressors don't have proper service valves like the Ferds typically did, because it makes servicing/ testing these systems a lot easier.

Service valves have a "double seat." "Normal operation" the valve is "back seated" which closes the service (gauge) port. You hook up the gauge, "crack" the back seat open (CW) and now you have access. For certain tests, it's handy to be able to shut off the suction or discharge valve (front seated) which you cannot do on the Mopars.

"REAL" refrigeration systems typically have valves on the compressor, as well as the receiver outlet. This allows you to service a leaky evap, or change a compressor or TXV without pulling the refrigerant out of the system.

nuttyprof

Well-Known Member

I apologize! I was thinking he might be using a service port on the filter/dryer, most of the ones I've seen had them. If he was the filter/dryer could be mostly plugged and then he would have high pressure in the cond. coil and part of the filter/dryer and some in the line to the orifice then very low press in the evap. and suction lines. I have seen this happen, and becausevery little heat is picked up in the high side line from the filter/dryer to the orifice the evap. will sub cool. If in that situation the compressor were to run continuously and moved refrigerant faster than it was passing out of the filter/dryer you could end up with nearly all of the 4lb he said he put in there in the cond. and filter/dryer. May be I have no idea what I'm talking about, (I got out of automotive service in 95) If so I repent in sack cloth and ashes. rayer:

rayer:

cudamark

Well-Known Member

25 degrees sounds pretty darn mega cold to me! I've had many systems where I was tickled just to get it down to 40!Suction pressure indicates he is NOT getting "mega" cooling. The thing is, the TXV or whatever is causing the problem is/ may not be completely shut off, it's just leaking a little. This explains the low suction, with not much heat load, and the low head, considering the shop is not all that warm.

But as I said earlier, don't discount that it could be water in the system, which TYPICALLY will work for a minute or so, then freeze up at the TXV, causing a restriction/ plug

I'm no expert on all the hardware used on cars over the years, but I spent a few years working on HVAC/R

Whenever you get a system that has been left open, and or not properly evacuated, filters replaced, in the case of vehicular AC a "sweep test charge" is a good idea, and don't discount that if you FOR SURE do not know the origin of the refrigerant you are using --off brand mixtures, or "recovered" or even a "used bottle" it might just be contaminated right out of the can.

It's really too bad that these compressors don't have proper service valves like the Ferds typically did, because it makes servicing/ testing these systems a lot easier.

Service valves have a "double seat." "Normal operation" the valve is "back seated" which closes the service (gauge) port. You hook up the gauge, "crack" the back seat open (CW) and now you have access. For certain tests, it's handy to be able to shut off the suction or discharge valve (front seated) which you cannot do on the Mopars.

"REAL" refrigeration systems typically have valves on the compressor, as well as the receiver outlet. This allows you to service a leaky evap, or change a compressor or TXV without pulling the refrigerant out of the system.

guys" How important is the" evaporator pressure regulator"? Several people tell me that you cannot get that part anymore and any rebuilt compressors that you buy would would be without that component. Can a system operate without a EVR valve?????? This weekend I am changing the Expansion Valve per your advice . The book keeps referencing this EPR valve test that may be faulty that is not in my rebuilt compressor nor was it in the old original compressor on the car.I hate to keep opening the system up . Also loosing patience. Thanks Glen

67Dart273

Well-Known Member

IF you can eliminate it without compromising the internals of the compressor, the system would work without it. For example, the aftermarket "hang on" A/C in my old RR had no such component, and in fact, the only two controls on compressor operation was a low pressure switch in series with the off/on and temp control under the dash.

I believe the gauge port is on the evap side of the valve however, so if the valve was stuck closed, you should be getting higher than normal pressure rather than lower.

Look at the diagram in the shop manual

I believe the gauge port is on the evap side of the valve however, so if the valve was stuck closed, you should be getting higher than normal pressure rather than lower.

Look at the diagram in the shop manual

slantsixdan

=..=

There was no EPR (Evaporator Pressure Regulator) valve used on A-body A/C systems until 1974. Instead, the pre-'74 systems used a clutch cycling thermal switch with its temperature probe inserted between fins of the evaporator. On systems through '72, the setpoint of this switch is adjustable by operating the cool/hot slide lever on the dashboard. For '73, a nonadjustable switch is used in conjunction with a blend-air system (operating the cool/hot slide lever blends hot air from the heater core with cold air from the evaporator). The clutch cycling switch opens or completes the circuit to the compressor clutch so as to maintain the setpoint. The minimum setpoint is a degree or two or three above 32°F; the point is to maximise cooling but prevent the evaporator from freezing. If the evaporator drops to 32°F or below for more than a brief few moments, condensed water will freeze and block airflow through the evaporator.

The EPR valve accomplishes the same task (preventing the evaporator freezing) by selectively throttling the low side of the system. On a system with an EPR valve, the compressor clutch has power whenever an A/C mode is selected, unless the high- or low-pressure safety cutout switch opens the circuit.

So, to review, there should not be an EPR valve in the low side (rear) port of your compressor on your pre-1974 A-body. If there is one, it won't do any harm as long as it's working correctly, but if it is not, it'll bollix things up.

The EPR valve accomplishes the same task (preventing the evaporator freezing) by selectively throttling the low side of the system. On a system with an EPR valve, the compressor clutch has power whenever an A/C mode is selected, unless the high- or low-pressure safety cutout switch opens the circuit.

So, to review, there should not be an EPR valve in the low side (rear) port of your compressor on your pre-1974 A-body. If there is one, it won't do any harm as long as it's working correctly, but if it is not, it'll bollix things up.

-