You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Overheating 360 new engine

- Thread starter Slappy

- Start date

-

Silent Run non flex 18" fan. It cuts the air, instead of flexing with centrifugal force. That's why it's a Silent Run.

Solved the problem of crammed serpentine space, the problem of overheating, did not break the bank, and did not have to chop up the original mopar wiring.

Car owner is Happy, Happy, Happy and is enjoying the freedom of driving his classic without worry of overheating.

View attachment 1715991960

1967 Coronet R/T 440 cu.in.

So, all that money for a serpentine set up and you don't even run a proper fan shroud? Again, you're just tossing hp down the toilet. What's the CFM rating at idle BTW? Or at 6,000 rpm?

"Cuts the air"? Wow. Somebody has been reading too many advertising gimmicks.

George J,

Agree with you. Some will just never get it....

What is the point of 'saving' hp with toy electric fans, but your engine overheats & you cannot enjoy driving it!

You're right, some people like yourself just will never understand thermal efficiency.

My engine has never overheated with my "toy fans", although I have had that pleasure with factory mechanical fans on other cars. Like I said, the fans I run are proven OE technology. They're just not 50+ year old, outdated technology. I've been running the same set up for almost 8 years, 35k+ miles, and it's been fine when stuck in traffic in 110°F weather. 99% of the time I don't even need the high speed setting on the fans at all, there's plenty of overkill built into the system. More than in the stock system.

But hey, if you don't understand how to properly set up a cooling system, maybe it's best you stick with stock.

Dave_J

Well-Known Member

The problem "most don't get" is you must use a "System" and not go so cheap. Using some small CFM electric fans will not work. Using 1 big fan also may not work.George J,

Agree with you. Some will just never get it....

What is the point of 'saving' hp with toy electric fans, but your engine overheats & you cannot enjoy driving it!

Don't expect to throw a bunch of crap parts together and have it out preform a stock fan.

Shrouds are a must.

If the radiator is 25 inches wide and 17 tall, two 12 inch HIGH CFM fans should keep any proper built engine cool. Six 8 inch ones will work best but costs too much.

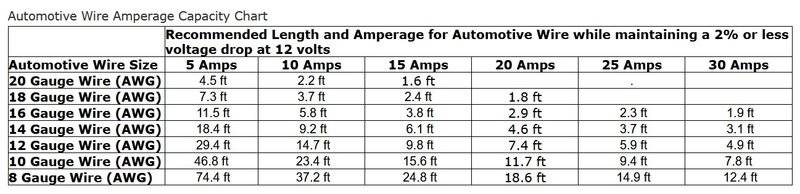

If it draws 30 Amps, don't try to use 18 - 12 gauge wire, use 10 - 8 gauge. Use 18 gauge only on the relay trigger sides.

Relays, Make a power source 40 Amp relay that is switched on with the ignition. Feed it from the battery with 8 gauge wire. Now you can hook up Fan relays, Headlight relays, Horn relays, Fog Light relays...... All fed with 30-40 Amp's

Use proper sensors and relays or controller boxes.

So many times I have helped guys figure out electric cooling fan issues. 90% of the time they are using 18 gauge wire, coming off the Ampmeter side and maybe a relay switched by a temp sensor.

I rewire it all using proper size wires, relays and controls. Piss poor design equals piss poor performance.

The problem "most don't get" is you must use a "System" and not go so cheap. Using some small CFM electric fans will not work. Using 1 big fan also may not work.

Don't expect to throw a bunch of crap parts together and have it out preform a stock fan.

Shrouds are a must.

If the radiator is 25 inches wide and 17 tall, two 12 inch HIGH CFM fans should keep any proper built engine cool. Six 8 inch ones will work best but costs too much.

If it draws 30 Amps, don't try to use 18 - 12 gauge wire, use 10 - 8 gauge. Use 18 gauge only on the relay trigger sides.

Relays, Make a power source 40 Amp relay that is switched on with the ignition. Feed it from the battery with 8 gauge wire. Now you can hook up Fan relays, Headlight relays, Horn relays, Fog Light relays...... All fed with 30-40 Amp's

Use proper sensors and relays or controller boxes.

So many times I have helped guys figure out electric cooling fan issues. 90% of the time they are using 18 gauge wire, coming off the Ampmeter side and maybe a relay switched by a temp sensor.

I rewire it all using proper size wires, relays and controls. Piss poor design equals piss poor performance.

Exactly. If you slap a bunch of junk together you will get a bunch of junk.

Heck, even if you spend a TON of money without doing your homework and figuring out the requirements of the system you can end up with a bunch of really expensive junk! There are really expensive, aftermarket electric fans out there that do not move enough CFM for a lot of systems.

Which is how I ended up with Ford Contour fans. They fit the 26" radiator size for these cars (a stock size on the later A's!!!), they move plenty of CFM to keep the car cooled properly, and despite having better flow ratings than a lot of aftermarket fans they're available for half the price. You have the match the components to your needs.

Dave_J

Well-Known Member

Is Slappy still following this?

Is Slappy still following this?

He's in Florida, so he may have other things on his mind at the moment...

No shortage of people here trying to figure out how to keep their engines running cool.

The simple solution is the best. No Ford parts required on a mopar.

Water pump shaft drives the fan.

Keeps them running cool.

The simple solution is the best. No Ford parts required on a mopar.

Water pump shaft drives the fan.

Keeps them running cool.

I'm not an electric fan guy. But I'll be the first to stand in line and agree with you that those fans you run are some total badass fans. I've worked on a lot of those cars before and I'm here to tell you that those fans MOVE some air.So, all that money for a serpentine set up and you don't even run a proper fan shroud? Again, you're just tossing hp down the toilet. What's the CFM rating at idle BTW? Or at 6,000 rpm?

"Cuts the air"? Wow. Somebody has been reading too many advertising gimmicks.

You're right, some people like yourself just will never understand thermal efficiency.

My engine has never overheated with my "toy fans", although I have had that pleasure with factory mechanical fans on other cars. Like I said, the fans I run are proven OE technology. They're just not 50+ year old, outdated technology. I've been running the same set up for almost 8 years, 35k+ miles, and it's been fine when stuck in traffic in 110°F weather. 99% of the time I don't even need the high speed setting on the fans at all, there's plenty of overkill built into the system. More than in the stock system.

But hey, if you don't understand how to properly set up a cooling system, maybe it's best you stick with stock.

No shortage of people here trying to figure out how to keep their engines running cool.

Amazingly, there never is. lol

You are probably all aware that even 1500 series trucks today run electric fans. Most of those engines are 400+ hp and cool while towing through the desert or idling in Phoenix city traffic. Electric fans are like anything else: they must be engineered to meet the needs of the job.

No shortage of people here trying to figure out how to keep their engines running cool.

View attachment 1715992067

The simple solution is the best. No Ford parts required on a mopar.

Water pump shaft drives the fan.

Keeps them running cool.

View attachment 1715992072

The absolutely hilarious part about this? All the posts in that picture, except this one, are about guys with mechanical fans. Seems like mechanical fans aren't so foolproof either?

I'm not an electric fan guy. But I'll be the first to stand in line and agree with you that those fans you run are some total badass fans. I've worked on a lot of those cars before and I'm here to tell you that those fans MOVE some air.

They work great! Mechanical fans can work great too, but not for every application. Start making modifications and you run out of room really quick. And yeah, there's the free horsepower. Even with a clutch fan you're always spinning that fan, even if it's not at 100% it still takes power to drive it. And at WOT you shouldn't need the fan at all. So why run it? Why not just run it when you need it?

Plus, I can program the temperatures I want the fans to turn on and turn off at, setting the window for my engine operation at all times. And I can even run the fans after I shut the car down so it cools further instead of heat sinks.

The bottom line is you won't find mechanical fans on very many modern cars anymore, they're just not efficient.

I agree 100% with using a complete system whatever that is. Usually, for most street/strip stuff up to around 500 HP a good factory style cooling system will work. But you always see people leavin stuff off, substituting something they think is better when it's not, or just cobbling in general. Mechanical fans can be efficient enough in the right circumstances. Like stock or close to stock. But your reasoning is difficult to argue with given all of the modern choices available. On my rat truck for instance, I am at the point where I am figuring out exactly where and how to mount my radiator. I THOUGHT about an electric fan.....for about ten seconds. Know why I'm not going to use one? Probably the dumbest of reasons. Because a mechanical fan better fits the old rat truck. An electric fan would be too modern. Either way can work, it's when you start cobbling and cutting corners that gets you in trouble.The absolutely hilarious part about this? All the posts in that picture, except this one, are about guys with mechanical fans. Seems like mechanical fans aren't so foolproof either?

They work great! Mechanical fans can work great too, but not for every application. Start making modifications and you run out of room really quick. And yeah, there's the free horsepower. Even with a clutch fan you're always spinning that fan, even if it's not at 100% it still takes power to drive it. And at WOT you shouldn't need the fan at all. So why run it? Why not just run it when you need it?

Plus, I can program the temperatures I want the fans to turn on and turn off at, setting the window for my engine operation at all times. And I can even run the fans after I shut the car down so it cools further instead of heat sinks.

The bottom line is you won't find mechanical fans on very many modern cars anymore, they're just not efficient.

Inertia

Well-Known Member

Electric fans became necessary with transverse engines, no water pump fan at the front behind the rads .

Then morphed .

Then morphed .

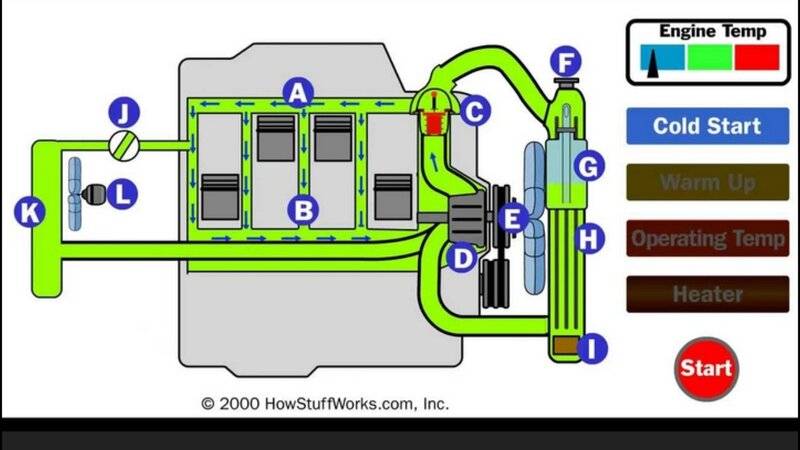

Just like the picture shows:

How Stuff Works

Simple is good, and it works well. No need to over think.

How Stuff Works

Simple is good, and it works well. No need to over think.

Just like the picture shows:

How Stuff Works

View attachment 1715992098

Simple is good, and it works well. No need to over think.

Again, what's your point?

With an electric fan everything in that picture works the same except your fan's cooling ability is no longer tied directly to the engine RPM, which is basically inversely tied to the air velocity available for cooling. Highest cooling requirements for the fan? Idle RPM at a stop. Lowest output for a mechanical fan? Idle RPM at a stop. See how that works? You're already running an alternator and a temp sending unit.

Just because it's simple, does not mean it's better.

I mean, this is way more simple than a car, so, by your logic this is a far better form of transportation...

And of course you're completely ignoring the fact that the original cooling system had a LOT of thought put into it. Radiator size and cooling ability, water pump output, pulley ratio's, the size and output of the fan, the fan shroud, the fan clutch were all engineered to be what they were. You just tossed half of that out the window, bought a cheap *** flex fan, and got lucky.

Last edited:

72Blu.

Post #77.

I understand thermal efficiency just fine, thanks. You do not. Waaaaaaay back in this thread that for reasons unknown, I noted the OPs engine runs hot. His engine is not the only engine that runs hot for unknown or non-obvious reasons. I offered some reasons for that, such as internal friction. Whatever! The OP has tried all the common fixes, still runs hot.

So now OP has two options: strip the engine to try & find the problem. Or, improve cooling so that it runs cooler. OP has chosen the latter.

You claim your fans pass 5000 cfm. Do you have any evidence of that? Your fans also have S blades which pull less air than straight blades.

This engine is going to need more air flow, more coolant volume, bigger radiator. These three factors are what will cool the engine. Either one on it's own or a combination.

Post #77.

I understand thermal efficiency just fine, thanks. You do not. Waaaaaaay back in this thread that for reasons unknown, I noted the OPs engine runs hot. His engine is not the only engine that runs hot for unknown or non-obvious reasons. I offered some reasons for that, such as internal friction. Whatever! The OP has tried all the common fixes, still runs hot.

So now OP has two options: strip the engine to try & find the problem. Or, improve cooling so that it runs cooler. OP has chosen the latter.

You claim your fans pass 5000 cfm. Do you have any evidence of that? Your fans also have S blades which pull less air than straight blades.

This engine is going to need more air flow, more coolant volume, bigger radiator. These three factors are what will cool the engine. Either one on it's own or a combination.

Here is a well explained video of how a proper cooling system works.

An opportunity to learn more things that a person may have overlooked from their first analysis of how a cooling system should work.

Notice how it shows the proper 180° operating temperature of the system, and how it is easily regulated.

☆☆☆☆☆

An opportunity to learn more things that a person may have overlooked from their first analysis of how a cooling system should work.

Notice how it shows the proper 180° operating temperature of the system, and how it is easily regulated.

☆☆☆☆☆

72Blu.

Post #77.

I understand thermal efficiency just fine, thanks. You do not. Waaaaaaay back in this thread that for reasons unknown, I noted the OPs engine runs hot. His engine is not the only engine that runs hot for unknown or non-obvious reasons. I offered some reasons for that, such as internal friction. Whatever! The OP has tried all the common fixes, still runs hot.

So now OP has two options: strip the engine to try & find the problem. Or, improve cooling so that it runs cooler. OP has chosen the latter.

You claim your fans pass 5000 cfm. Do you have any evidence of that? Your fans also have S blades which pull less air than straight blades.

This engine is going to need more air flow, more coolant volume, bigger radiator. These three factors are what will cool the engine. Either one on it's own or a combination.

No other engine that runs hot for non-obvious reasons is relevant here. Lots of engines using mechanical fans run hot for non-obvious reasons. Internal friction is probably the last relevant option that should be considered, once everything else has already been ruled out.

The OP has NOT tried ALL the common fixes. We have no idea what water pump he's running or how many vanes it has. We have no idea what CFM his electric fans are putting out either, and since his problem is one primarily at idle the fan CFM is extremely relevant. We do know the fans have no shroud, so, even if they had a decent CFM rating that can't pull air across the entire core.

There is absolutely no reason to "strip the engine" at this point. Heck, we don't even know what size his radiator is, Champion makes 22" and 26" radiators in 2, 3 and even 4 cores for these cars so it could be anything. We barely know anything about this engine or cooling set up.

Yes, at one point I had a chart for the Contour fans showing they pulled ~3,000 cfm on the low setting and 5,000 cfm on the high setting. Who knows where that went. How about a redneck on youtube showing they'll pull 4,400 cfm with a sketchy harness and undersized wiring? good enough?

Where's the data showing the factory 7 blade fan will pull 6,000 cfm like you claim? And since it's RPM specific, lets see the CFM vs RPM graph please, because I want to see the idle RPM numbers.

Honestly, although I made the decision to run these fans based on the old data I had, the simple fact of the matter is they outperform the mechanical fan that they replaced, which is more than proof enough for me. If I can sit in stop and go traffic with an iron-headed 340 at 9.8:1 compression making 400+ hp when it's 110°F out and not overheat, well, that's good enough for me.

Here is a well explained video of how a proper cooling system works.

An opportunity to learn more things that a person may have overlooked from their first analysis of how a cooling system should work.

View attachment 1715992113

Notice how it shows the proper 180° operating temperature of the system, and how it is easily regulated.

☆☆☆☆☆

Wow, that's horribly basic.

And, oh, right, the thermostatic switch could trigger an electric fan just as easily and the whole thing would work exactly the same in the cute little animation. Well, except they'd have to add an alternator. And maybe consider that the whole thing was attached to a car moving at speed. Did I say horribly basic?

Woodys_Cuda

Ontario, Canada

I've read the whole thread and there is lots of good info and agree with the post above, #93. There are too many unknowns from the OP. Seems he has the timing right. He needs to find out the CFM rating of his fans. There is no temp change when the car is moving and he doesn't have room for a stock setup.

I'm thinking he also has a lean condition on some cylinders. I had an overheating issue on my 340 sixpack (six corner idle) when I first got it. I replaced the thermostat, clutch fan and added a shroud and checked the timing with no change. It ended up probably being a lean condition on the rear carb which is near impossible to adjust on the car. A mixture screw was jammed fully seated in it. I changed the baseplate to a Promaxx one to cure my issue.

Hopefully he is okay at his location in Florida.

I'm thinking he also has a lean condition on some cylinders. I had an overheating issue on my 340 sixpack (six corner idle) when I first got it. I replaced the thermostat, clutch fan and added a shroud and checked the timing with no change. It ended up probably being a lean condition on the rear carb which is near impossible to adjust on the car. A mixture screw was jammed fully seated in it. I changed the baseplate to a Promaxx one to cure my issue.

Hopefully he is okay at his location in Florida.

Last edited:

Inertia

Well-Known Member

Past years "overheating" usually go another 50 ish posts .

mopowers

Well-Known Member

If nothing else, this thread shows that there's obviously more than one way to skin a cat when it comes to cooling systems.

Past years "overheating" usually go another 50 ish posts .

At least!

Overheating threads are like threads on what oil to use and discussing 17"+ wheels on classics. Everyone has an opinion, and a lot of those opinions don't match the facts.

If nothing else, this thread shows that there's obviously more than one way to skin a cat when it comes to cooling systems.

Absolutely. All that's required is that you can dissipate heat at a rate faster than the engine makes it and there are a lot of ways to accomplish that. Hell there are air cooled engines that work just fine.

The issue that I have with it is that every time a thread comes up where someone is using an electric fan, a bunch of people always say "get a mechanical fan" no matter what the issue is, even if putting a stock mechanical fan into the system won't solve the problem at all.

A lot of engineering went into designing the factory cooling system, and it works well as long as the horsepower and driving requirements stay relatively close to the factory outputs. Start changing stuff- adding horsepower, changing pulley ratio's, adding accessories etc and there's no guarantee the factory system will still work as intended.

But by the same token, you can't just slap on any old electric fan and have it work. That's not a shortcoming of electric fans in general, they're no different than anything else. If you want to run electric fans and be successful you have to make sure they fit properly, flow enough CFM for your application, control them accurately, and supply them with enough amperage in a consistent way so they can perform as designed.

Pretty much every instance where I've seen someone with an electric fan that wouldn't do the job the problem has been the installation, not the fact that an electric fan was used.

Inertia

Well-Known Member

I get a kick outta how many folks forget about all the parasitic power loss thru friction, belts, bearings, brushes, magnetism, drag, etc, etc. that a water pump mounted fan doesn't have.

Clutch fans don't spin over 4k ish, and sorta freewheel when hot.

Each has it's advantages, mounting being a deciding factor .

Electric fans do take power, it's not free !

My racecars have significant rpm loss when the fans kick on !

jmo

Clutch fans don't spin over 4k ish, and sorta freewheel when hot.

Each has it's advantages, mounting being a deciding factor .

Electric fans do take power, it's not free !

My racecars have significant rpm loss when the fans kick on !

jmo

Dave_J

Well-Known Member

Running the stock 5/16" fuel line on a 1965 Barracuda feeds the 273 4bbl OK. But will it feed a 383 with a 780 double pumper OK?

Wire gauge of most older aftermarket fan controllers used too small of gauge.

Wire gauge of most older aftermarket fan controllers used too small of gauge.

-

Similar threads

- Replies

- 18

- Views

- 422

- Replies

- 129

- Views

- 9K