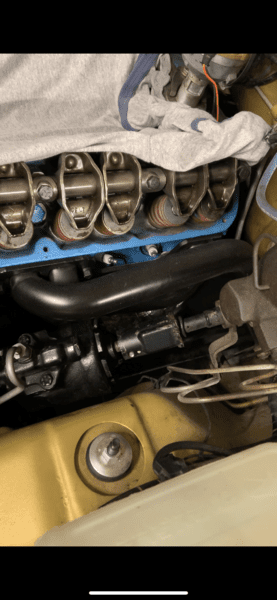

Having issue accessing my rear two spark plugs on the driver side to tighten them (5 and 7. I installed headers for the first time, slipped the plugs in and I can’t get a socket in there. It’s 13/16. I don’t think I could even get a wrench in there. Do I need to back the headers out and hope I can make it work, or is there a tool? Or do I need to basically fab up a tool? I don’t have a welder but can have someone come up with something if needed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reaching plugs with Hedman headers

- Thread starter jrc4y4

- Start date

-

That’s incredibly tight. I don’t even see you getting the plug boots on and off. I’d call hedman, thats just stupid.

I hadn't had that trouble, have they changed the bends?

Don't be afraid to modify tools. "Back in the day" I've changed plugs on several cars that for reasons or another had difficult plugs. Took an old box end wrench, cut it, and welded the stub box end back on the remaining wrench "at whatever" angle it took. Heated and bent them---with a propane torch and a vise. And I've STILL (from the 70's) got one 13/16 socket with a HEX rear so you can get a box/ open end onto the socket, and I SAWED the socket off so the thing, when on the plug, barely covers the hex. This allows "tipping" the wrench onto a socket in a tight place. And take the rubber pad out of the socket, although you must be "careful" not to break plug ceramics

Make sure you measure it with the extension inserted, otherwise the plug may extend into the drive square and make the socket too short!!!

You can also take a 13/16 socket, and cut it down, weld a handle on, and make a "deep" box end wrench. This is best done with a 12 point, and carefully position the handle. You can also take a "scrap" small socket, say 1/2", and weld to the side of a cut down socket to make a 'crow's foot' box

Or maybe certain types of "crow's foot"

Don't be afraid to modify tools. "Back in the day" I've changed plugs on several cars that for reasons or another had difficult plugs. Took an old box end wrench, cut it, and welded the stub box end back on the remaining wrench "at whatever" angle it took. Heated and bent them---with a propane torch and a vise. And I've STILL (from the 70's) got one 13/16 socket with a HEX rear so you can get a box/ open end onto the socket, and I SAWED the socket off so the thing, when on the plug, barely covers the hex. This allows "tipping" the wrench onto a socket in a tight place. And take the rubber pad out of the socket, although you must be "careful" not to break plug ceramics

Make sure you measure it with the extension inserted, otherwise the plug may extend into the drive square and make the socket too short!!!

You can also take a 13/16 socket, and cut it down, weld a handle on, and make a "deep" box end wrench. This is best done with a 12 point, and carefully position the handle. You can also take a "scrap" small socket, say 1/2", and weld to the side of a cut down socket to make a 'crow's foot' box

Or maybe certain types of "crow's foot"

Last edited:

Dustert73

Stripping bolts since ‘10

Normal cheap header stuff. You have to fish the socket under that horizontal tube and either use some wobble extensions in the attempt to space outwards to get a ratchet or try to get your ratchet under that tube along with the socket and maybe a real small extension. Most spark plug sockets have a hex on the end so you can use that to somewhat get a wrench on the socket.

Then you’re going to need to get two 90 degree plug wire boots and wrap those plug wires around and under that horizontal tube. If you run them down between the tube and valve cover you’ll burn plug wires every time even with a heat sleeve.

**** sucks to work around. you get what you pay for in the header department. I’m almost out of dealing with cheap ones myself.

Then you’re going to need to get two 90 degree plug wire boots and wrap those plug wires around and under that horizontal tube. If you run them down between the tube and valve cover you’ll burn plug wires every time even with a heat sleeve.

**** sucks to work around. you get what you pay for in the header department. I’m almost out of dealing with cheap ones myself.

skep419

5.9 Magnum 4 speed afficionado

on the head of this

rigger3006

Well-Known Member

i use a shorty wrench, it takes time but its doable

Inertia

Well-Known Member

Plug socket with hex head and a wrench .

Headers have been bent like that for DECADES. You just have to figure it out the best way for you. I always run the 5/8" hex plug for the same heat range to give a little more room to get at it.

abodyjoe

Well-Known Member

Normal cheap header stuff. You have to fish the socket under that horizontal tube and either use some wobble extensions in the attempt to space outwards to get a ratchet or try to get your ratchet under that tube along with the socket and maybe a real small extension. Most spark plug sockets have a hex on the end so you can use that to somewhat get a wrench on the socket.

Then you’re going to need to get two 90 degree plug wire boots and wrap those plug wires around and under that horizontal tube. If you run them down between the tube and valve cover you’ll burn plug wires every time even with a heat sleeve.

**** sucks to work around. you get what you pay for in the header department. I’m almost out of dealing with cheap ones myself.

this is how i used to do it with cheap headers. it was so nice once i changed to tti headers. those plugs sre wide open on tti's

Normal cheap header stuff. You have to fish the socket under that horizontal tube and either use some wobble extensions in the attempt to space outwards to get a ratchet or try to get your ratchet under that tube along with the socket and maybe a real small extension. Most spark plug sockets have a hex on the end so you can use that to somewhat get a wrench on the socket.

Then you’re going to need to get two 90 degree plug wire boots and wrap those plug wires around and under that horizontal tube. If you run them down between the tube and valve cover you’ll burn plug wires every time even with a heat sleeve.

**** sucks to work around. you get what you pay for in the header department. I’m almost out of dealing with cheap ones myself.

Yeah this is my first encounter with headers. I’ve ran manifolds the last 15 years but picked up new in box from the 90s Hedman for almost nothing. Now paying the price lol.

I'd like to see some dyno tests on the "cheap" headers versus the expensive ones. Same tube diameters. Same engine with no changes. I bet the differences, if any would barely show up. And that's using someone who is independent on the dyno and not someone who is all sponsored up. I just bet besides the fit, they are about 100% even. I don't argue the TTI and Dougs are both REAL nice. I've even run the Dougs. Best fittin headers I ever used. But as long as your front end is at stock ride height with stock height tires, you're not going to have a problem. The cheap headers get a bad rap because lots of people want their cars lower than stock and that's not what cheap headers are made for. We have lots of members running them with no problems. I've run several sets.

abodyjoe

Well-Known Member

I'd like to see some dyno tests on the "cheap" headers versus the expensive ones. Same tube diameters. Same engine with no changes. I bet the differences, if any would barely show up. And that's using someone who is independent on the dyno and not someone who is all sponsored up. I just bet besides the fit, they are about 100% even. I don't argue the TTI and Dougs are both REAL nice. I've even run the Dougs. Best fittin headers I ever used. But as long as your front end is at stock ride height with stock height tires, you're not going to have a problem. The cheap headers get a bad rap because lots of people want their cars lower than stock and that's not what cheap headers are made for. We have lots of members running them with no problems. I've run several sets.

whens the last time you drove in nj? i can tell you that 99.999% of the small block cars around her that are stock height (some higher) that are running the "cheap" headers all have smashed tubes. just a fact of life around here. power wise im sure they are close. hell the cheap ones may turn out yo make more power for all i know but id much rather spend the money for a tti or dougs and not have to cringe everytime i come to a dip in the road. the plug access is an added bonus.

Dustert73

Stripping bolts since ‘10

Yeah this is my first encounter with headers. I’ve ran manifolds the last 15 years but picked up new in box from the 90s Hedman for almost nothing. Now paying the price lol.

Classic run whatcha brung! The nicety of expensive headers is a cool upgrade for the future on your car. Not a necessity though.

How do they compare to the roads in Michigan? @Bad Sport has them on his car and doesn't scrub. So do a lot of other members. I do admit, I've always heard the roads in NJ SUCK.whens the last time you drove in nj? i can tell you that 99.999% of the small block cars around her that are stock height (some higher) that are running the "cheap" headers all have smashed tubes. just a fact of life around here. power wise im sure they are close. hell the cheap ones may turn out yo make more power for all i know but id much rather spend the money for a tti or dougs and not have to cringe everytime i come to a dip in the road. the plug access is an added bonus.

j par

Well-Known Member

Oregon's known for the worst roads...

When I was young and I wanted the front end low my head is scraped all the time but now I'm older and the car runs at stock heights I've never scraped the header once...

The ticket for me on the five and seven was definitely elbows on those two spark plugs with heat shields but more important to route them so they don't touch running underneath the header..

Running 5/8 spark plugs and having a spark plug socket with the swivel belt onto the end of it... And of course I always change the park spark plugs when the engine's cool.. and if I have to pull a plug or two when it's hot to check things out just not those two....

For less than the price of dougs headers let alone tti's I got cheapies that are ceramic coated and look Chrome...

When I was young and I wanted the front end low my head is scraped all the time but now I'm older and the car runs at stock heights I've never scraped the header once...

The ticket for me on the five and seven was definitely elbows on those two spark plugs with heat shields but more important to route them so they don't touch running underneath the header..

Running 5/8 spark plugs and having a spark plug socket with the swivel belt onto the end of it... And of course I always change the park spark plugs when the engine's cool.. and if I have to pull a plug or two when it's hot to check things out just not those two....

For less than the price of dougs headers let alone tti's I got cheapies that are ceramic coated and look Chrome...

All I know is, people have been getting to #5 and #7 for decades with those type headers. It's not difficult, you just need to find what works best for you.

Summit sells a set of sockets made for this situation. I don't recall the brand, but I can check tomorrow if you'd like.

All I know is, people have been getting to #5 and #7 for decades with those type headers

They are a bit of a pain but nothing that can't be managed. I have yet to scrub my tubes on anything...................yet, lol.

So I feel stupid guys but I pulled out the rubber from the socket and it slipped right onto the plugs. Now all I need to do is get a 7/8 wrench I can cut down and I can come at the socket from under the pipe!

j par

Well-Known Member

No...So I feel stupid guys but I pulled out the rubber from the socket and it slipped right onto the plugs. Now all I need to do is get a 7/8 wrench I can cut down and I can come at the socket from under the pipe!

You need this 5/8 socket with the swivel built onto it and probably just a shorter extension than what I'm showing..

And of course make sure you're spark plugs are the smaller 5/8 plugs not the 13/16...

Inertia

Well-Known Member

Plug sockets come with a smaller hex, needing a smaller/shorter wrench.

Good job .

You're gonna be a hot-.rodder .

Good job .

You're gonna be a hot-.rodder .

MOPAROFFICIAL

If it has tits, it's a liabilititty.

Go buy a powerbuilt swivel 13/16 spark plug socket, use a 12" extension..put the socket onto the plug by itself..position the female 3/8 drive portion up between tube and valve cover.. insert 3/8 12" extension and using a 3/8 ratchet ...loosen it half way ...remove 3/8 12" extension..and by hand unscrew the socket/plug. Install in reverse.Having issue accessing my rear two spark plugs on the driver side to tighten them (5 and 7. I installed headers for the first time, slipped the plugs in and I can’t get a socket in there. It’s 13/16. I don’t think I could even get a wrench in there. Do I need to back the headers out and hope I can make it work, or is there a tool? Or do I need to basically fab up a tool? I don’t have a welder but can have someone come up with something if needed.

View attachment 1715925798

I can change all the plugs in 20 min or less.

That's how much room there is.

Here's quickly made video of mine on the subject. @jrc4y4

Last edited:

Pm sent

mopowers

Well-Known Member

Lots of ways to skin this cat. When I had those shitty headers on my Duster in high school, I used a 13/16" socket and made a short piece of 3/8" square stock (maybe 1" long?) out of a bolt with an angle grinder. The short 1" square stock slipped into the 3/8" drive of the socket and allowed me to use a 3/8" wrench to tighten/loosen the plugs. I was young, broke, and didn't know of any other ways. Hell, I didn't even know there were 5/8" socket plugs. haha!!

Nothing receivedPm sent

-

Similar threads

- Replies

- 5

- Views

- 762

- Replies

- 36

- Views

- 1K

- Replies

- 3

- Views

- 425