That's why its very small. Just big enough to. Pressure rise the shafts and not damage the main bearings from bleed off and always use a hv pumpYou have to be very careful if you do this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless, Bushed PRW Rocker Arms

- Thread starter Mopar69gts

- Start date

-

Thank you for your comments.May not have anything to do with it but when I got my PRW 1.6 rockers I stripped them down and ran them through the ultrasonic tank. Then I still had to clear every oil port hole with a wire. I’d say 30% of them were packed with chips or crud. I cleaned the shafts out as well as I could without removing the plugs but I may go back and do that again because I haven’t installed them yet. If yours weren’t cleaned out before they were put in you could have restricted oil flow on some. Either way with any of these parts it’s important to pull them down and clean them out because manufacturers are taking every shortcut that they can to save a buck.

I also don’t like the color of those bushings and the deposit on the shaft it almost looks like there’s too much copper or wasn’t blended well so it could be an issue with the material

And yes I did thoroughly clean each individual Rocker and each shaft.

Also I did as per Mike @b3 and PRW says

To soak the Rockers in oil before installing

To get oil into the rollers for initial start up.

Took my time with alignment and side clearance as well.

This is the second set to do this.

I'll be talking with PRW hopefully tomorrow and I'll keep you all updated...

Thanks, Mike

MOPAROFFICIAL

If it has tits, it's a liabilititty.

As I said a lot of cams have a full groove journals now like Rubens cams does.I built the Engine with X Heads and stock non adjustable rocker arms and shafts

2 years before swapping to Trick Flows with PRW Rockers.

And had driven it about 20k Miles.

No problems with valve train at all.

The oil hole in the Trick Flow head is much smaller then factory, but they say it's plenty.

If it were a magnum with Trick Flow heads

All they get is pushrod oiling

The PRW Rockers are made to work with both LA and Magnum Engines.

So adding pushrod oiling to this 340 it's getting double the oil.

The side clearance was set at .010

Rat Bastid

Dunamis Metron

Rat,

You have given no proof that grooves are reqd in rocker shafts, just your opinion. Do you have any test results, such as rockers tested with grooves...& without?

What do you want, pictures? How about you prove they don’t work.

Bakerlite

Well-Known Member

- Joined

- Nov 12, 2007

- Messages

- 6,431

- Reaction score

- 3,327

Mopar is not the only one to groove shafts or rockers for that matter.

Toyota for one.

Trend makes shafts for Duramax engines. They too have a groove.

Mopar TA shaft..

What does the groove do? It's mystery hahahaha!!!!

Toyota for one.

Trend makes shafts for Duramax engines. They too have a groove.

Mopar TA shaft..

What does the groove do? It's mystery hahahaha!!!!

Last edited:

Rat Bastid

Dunamis Metron

Pictures, a link, whatever you like. Some proof of this statement you made in post #52: The shaft MUST have grooves for hyd lifters [ capital letters in original ].

Let’s see. Decades of taking apart engines that had hydraulic lifters and scored shafts and rockers. Fixing all that and grooving the shafts and not one ever failed again.

IIRC in 68 when the 273 went to hydraulic lifters the shafts were grooved.

It’s amazing the **** you will argue about. Looks the OP’s pictures. It’s not that the Chinese bushings are soft because a 273 rocker will do the same thing without a groove in the shaft.

W2 rockers came in unbushed and bushed. For hit RPM you had to use the bused rocker because the unbushed rocker would grab the shaft no matter what you did. And all those shafts are grooved.

He's already got pictures of what happens without nanner grooves right in this thread. I don't need more proof.What do you want, pictures? How about you prove they don’t work.

It's easy to understand what the grooves do. They allow for a larger contact area of oil between the rockers and shafts. The old style stamped style paddle rockers don't need that because they have much less area of contact. The factory adjustable rockers or any other rocker that has full contact needs the grooves. What's not to understand? Just because "I tore one down that didn't have grooves" that doesn't mean it was right.

Rat Bastid

Dunamis Metron

He's already got pictures of what happens without nanner grooves right in this thread. I don't need more proof.

FE ford engines 390,428, 360 ect always needed rocker arms and shafts if you slid the arm over on the shaft and inspected it they used springs for spacers they are set up just like mopar 273 but not adjustable and no groves on shafts they were always wore out /with hydraulic lifters

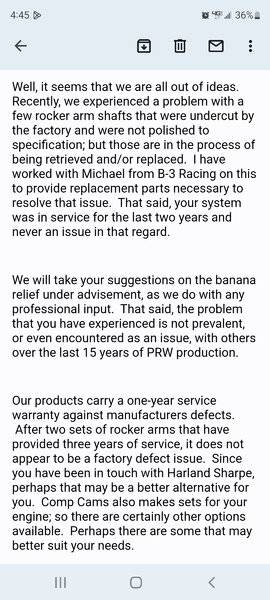

Just received this email from PRW

mopar head

DoD nuisance Alien/Squatch extermination team

Well aren`t they special...Just received this email from PRW

Rat Bastid

Dunamis Metron

It is what it is. There is some other issue. It’s not bad bushings or undersized shafts doing that. It’s lack of oil.

That's the nicest **** off I ever read.Just received this email from PRW

View attachment 1715983731

Rmoore

Well-Known Member

Fixing to buy rocker arms myself…… It will not be PRW’s !!

Exactly. Look at the small contact area just on the bottom and the area on the top where the oil can puddle. The non adjustables get over oiled it seems.It's easy to understand what the grooves do. They allow for a larger contact area of oil between the rockers and shafts. The old style stamped style paddle rockers don't need that because they have much less area of contact. The factory adjustable rockers or any other rocker that has full contact needs the grooves. What's not to understand? Just because "I tore one down that didn't have grooves" that doesn't mean it was right.

Not sure what that means?I get the sense some think they have recourse with everything and anything. Nope, you have been misled!

Please see post #49

Unless I am misunderstanding.

Rat Bastid

Dunamis Metron

Fixing to buy rocker arms myself…… It will not be PRW’s !!

I’d buy them again in a NY second. He’s got oiling issues.

Didn't you say they need banana grooves?I’d buy them again in a NY second. He’s got oiling issues.

BTW I drove my car for about 2 years with X Heads and factory rockers with no issues.

Before putting Trick Flows on with PRW Rockers.

Some also suggest the oil hole is a bit too small in the Tf's

But really shouldn't matter because I doubled the oiling when I added pushrod oiling.

It was getting plenty of oil.

I think banana grooves would certainly help if not eliminate the problem altogether.

I'm Sorry if I have you mixed up with someone else.

Also I drove my car several thousand miles with the Trickflows and 273 Rockers with Factory Banana grooved Shafts with zero wear, with just through the head oiling.

So there's that too.

My personal Opinion is what you and a lot of knowledgeable people have said all along,

They need Banana grooves and possibly better bushings and roller tips.

Lastly Mike @ b3 said he did not find any bluing or any discoloration to my PRW Rockers or Shafts that would indicate heat like from a lack of oil.

Last edited:

Johnny Dart

Well-Known Member

Face it .... Chinese Junk.

-

Similar threads

- Replies

- 7

- Views

- 484

- Replies

- 16

- Views

- 457

- Replies

- 0

- Views

- 308